Article Contents

Industry Insight: Led Driver Signsls

The commercial and industrial lighting sector continues to evolve with a growing emphasis on energy efficiency, reliability, and regulatory compliance. At the heart of this transformation are LED drivers—critical components that ensure optimal performance, longevity, and safety of LED lighting systems. In demanding environments such as warehouses, manufacturing facilities, office complexes, and outdoor installations, the importance of stable, high-quality power delivery cannot be overstated. LED driver solutions designed for these applications must meet rigorous standards, with certifications such as ETL and CE serving as key indicators of safety, performance, and global market readiness. These certifications confirm that products adhere to North American and European safety requirements, giving engineers, contractors, and facility managers confidence in their lighting infrastructure.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of LED driver innovation for over two decades. Specializing in commercial and industrial lighting solutions, Beauty STC combines advanced engineering with stringent quality control to deliver drivers that meet the exacting demands of modern applications. With a commitment to performance, durability, and compliance, the company has built a trusted reputation across global markets, providing reliable power solutions that support sustainable and future-ready lighting systems.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. produces high-performance LED drivers specifically engineered for illuminated signage applications, where reliability, efficiency, and color fidelity are critical. It is important to clarify that lumens per watt (lm/W) is a metric for the complete LED luminaire or sign module, not the driver itself. The driver’s primary contribution to lm/W is its electrical efficiency in converting input power to stable DC output for the LEDs, minimizing energy loss as heat. Beauty STC drivers typically achieve 92-94% efficiency (e.g., models using premium components like Mean Well or custom-engineered solutions), directly supporting sign fixtures that reach 120-140+ lm/W system efficacy when paired with high-efficiency LEDs. This high driver efficiency ensures maximum usable light output from the electrical input, reducing operational costs and thermal stress on the sign assembly.

Regarding Color Rendering Index (CRI), drivers do not directly generate light or influence CRI values. CRI is a property of the LED light source itself. However, Beauty STC drivers are meticulously designed to provide exceptionally stable, ripple-free constant current output. This stability is crucial for maintaining the consistent color point and high CRI performance of the LEDs over their lifespan. Beauty STC signage systems consistently utilize LEDs with CRI >90 (typically Ra 92-95), and the precision of our drivers prevents flicker or color shift that could degrade perceived color quality, ensuring vibrant, true-to-life colors essential for brand-critical signage. Our drivers incorporate advanced filtering and regulation to meet stringent flicker-free standards (IEEE PAR1789), further safeguarding color integrity.

IP (Ingress Protection) ratings are critical for sign drivers exposed to outdoor or harsh environments. Beauty STC drivers for signage are predominantly sealed within the sign housing or mounted in protected enclosures. Common driver IP ratings integrated into our sign solutions include IP65 for standard outdoor use (protected against dust and low-pressure water jets) and IP67 for demanding applications requiring temporary submersion resistance (e.g., street-level signs exposed to flooding or heavy washdowns). Drivers are potted with high-thermal-conductivity, UV-resistant silicone within robust aluminum or polycarbonate housings, ensuring long-term protection against moisture, dust, and corrosion even in coastal or industrial settings. Internal thermal management design prevents overheating, a common failure point in lower-quality sign drivers.

Beauty STC’s commitment to quality is embedded in every driver. We adhere strictly to ISO 9001 quality management systems throughout design and manufacturing. Components are sourced from Tier-1 suppliers with rigorous incoming inspection. Each driver undergoes 100% automated functional testing and a minimum 4-hour burn-in at full load to screen for early failures. We exceed IEC 61347-1 and IEC 61347-2-13 safety standards, incorporating robust over-voltage, over-temperature, and short-circuit protection. Our drivers are designed for a minimum 50,000-hour lifespan at 40°C ambient, significantly outperforming generic alternatives. This focus on reliability, efficiency, and compatibility with high-CRI LEDs ensures Beauty STC signage delivers exceptional visual performance, reduced lifetime costs, and minimal maintenance for our global clients.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern manufacturing facility in Jiangmen, Guangdong Province, which is strategically located to support efficient production and logistics for both domestic and international markets. The factory is equipped with advanced Surface Mount Technology (SMT) production lines, featuring high-precision automated SMT machines that ensure consistent quality and reliability in the assembly of electronic components, particularly for LED lighting products and control systems such as LED drivers.

The SMT lines are integrated with automated optical inspection (AOI) systems to detect placement errors and soldering defects in real time, minimizing defects and enhancing product consistency. These capabilities are especially critical for manufacturing compact and high-performance LED driver circuits used in signage and architectural lighting applications.

To ensure long-term reliability, the Jiangmen factory implements comprehensive aging and burn-in testing procedures. Completed LED drivers and signage units undergo extended operational testing under elevated temperatures and electrical loads, simulating real-world conditions over prolonged periods. This aging process helps identify early-life failures and ensures that only robust, high-quality products are shipped to customers.

Beauty STC has strong OEM capabilities and actively supports custom development for LED driver signage solutions. The company works closely with clients to design, engineer, and manufacture tailored LED drivers that meet specific voltage, current, dimming, and form factor requirements for use in illuminated signs and digital displays. With in-house R&D, tooling, and full supply chain control, the factory can deliver low-volume custom projects as well as high-volume production runs, all compliant with international standards including CE, RoHS, and UL.

Overall, the Jiangmen facility reflects Beauty STC’s commitment to technological advancement, quality assurance, and flexible manufacturing to serve a global customer base in the LED lighting and signage industries.

Application Scenarios

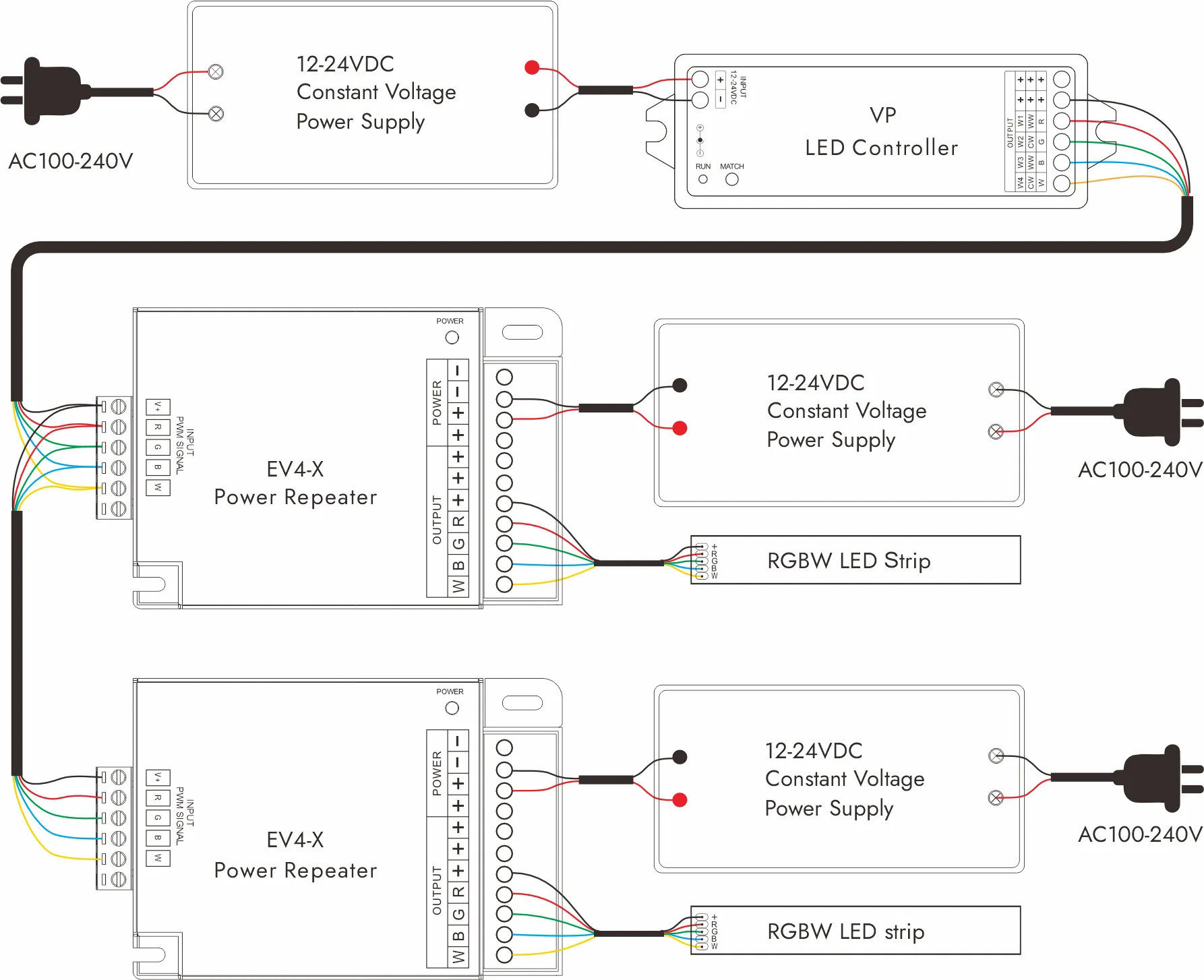

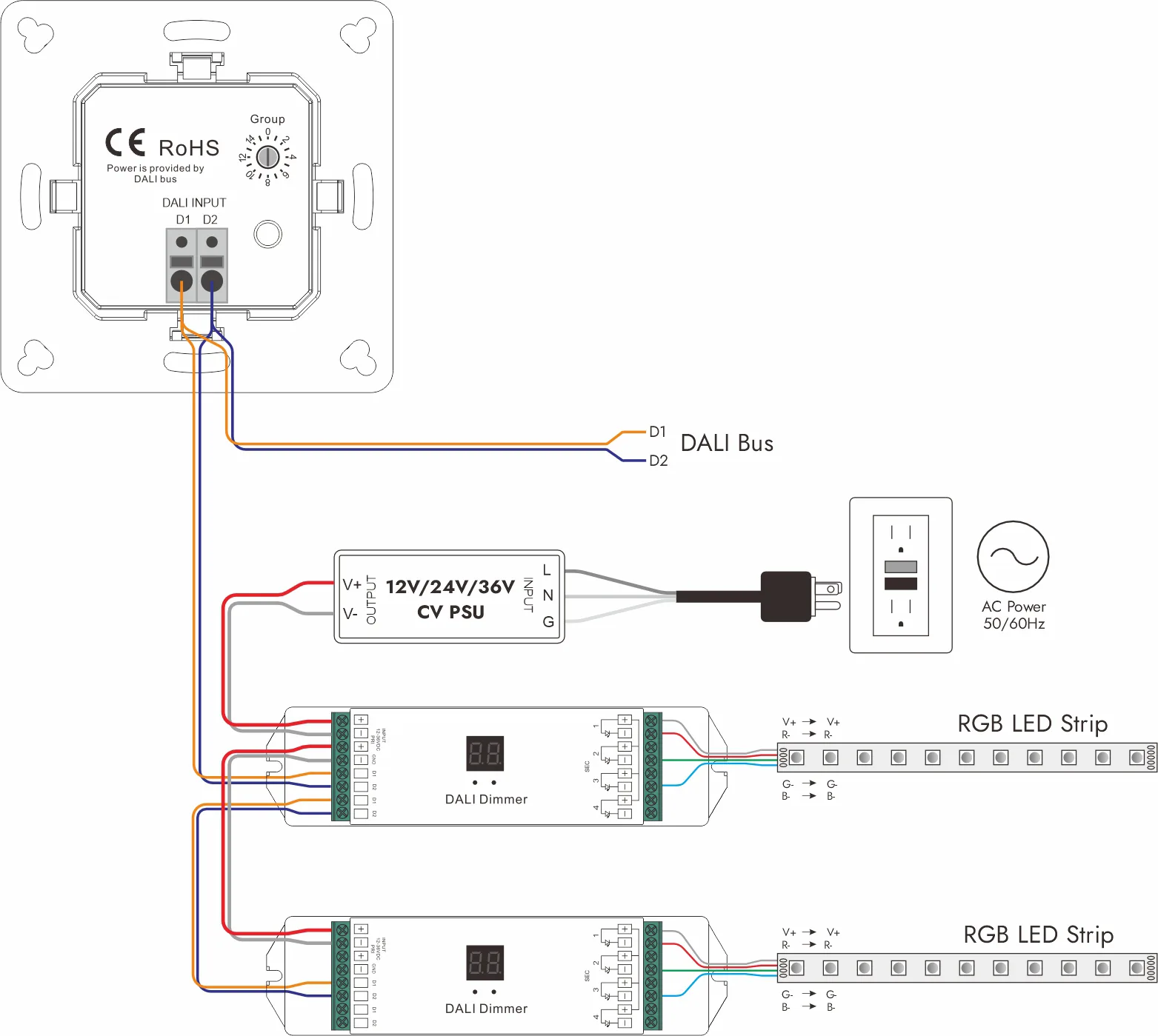

The term “LED driver signsls” appears to be a typographical error. Based on the context of Hotels, Malls, and Offices, it is highly likely the intended query refers to LED signage (such as channel letters, lightboxes, or digital displays) which inherently require LED drivers as critical internal components. LED drivers themselves are not standalone “signs” but rather the power supplies that convert AC line voltage to the low-voltage DC required by LED modules within signage systems. Therefore, the appropriate focus is on where LED signage is deployed in these environments and installation considerations for the complete sign system, including proper driver integration.

LED signage is extensively used across Hotels, Malls, and Offices for branding, navigation, information, and ambiance. In Hotels, it is critical for exterior building identification, lobby directories, wayfinding to amenities like pools or spas, restaurant signage, and room number indicators. Malls rely heavily on LED signage for anchor store identifiers, directory kiosks, promotional displays, restroom labels, and emergency exit markings throughout large concourses. Offices utilize it for suite numbers, department identifiers, conference room labels, reception area branding, and safety signage within corporate campuses or high-rises. The common thread is the need for high visibility, energy efficiency, long life, and design flexibility that LED technology provides in high-traffic commercial settings.

Installation of LED signage systems requires careful attention to the integrated LED driver. Always mount the driver in a well-ventilated area within the sign cabinet or a nearby accessible enclosure to prevent overheating, which is the primary cause of premature driver failure. Ensure the driver is rated for the specific environmental conditions of the installation location; for instance, use drivers with appropriate IP ratings for outdoor hotel facades exposed to weather or near mall entrances with high humidity. Secure all wiring connections according to local electrical codes using wire nuts or terminal blocks rated for the current, and maintain separation between high-voltage input wiring and low-voltage LED output wiring to avoid interference. Crucially, verify that the driver’s output current and voltage precisely match the requirements of the LED modules within the sign – mismatched drivers will cause flickering, reduced lifespan, or immediate failure. For large installations like mall directories or multi-story hotel signs, group LEDs logically on drivers to allow for staged power-up and simplify future diagnostics.

Accessibility for maintenance is non-negotiable in commercial settings. Install drivers in locations reachable without dismantling the entire sign structure – a service panel within the sign cabinet or a nearby electrical room is ideal. This is especially important in Hotels where guest areas require minimal disruption and Offices where facilities teams need efficient access. Always use drivers certified to relevant safety standards (UL, CE, etc.) for the installation region and ensure the entire sign assembly complies with building and fire codes, particularly regarding materials used inside plenums for ceiling-mounted office signs. Finally, engage qualified electricians for the mains power connection to the driver, as improper line-voltage wiring poses significant safety hazards. Proper driver selection and installation directly impact the reliability and longevity of the signage investment across all these demanding commercial applications.

Why Choose Beauty STC Lighting

Looking for reliable LED driver solutions for your signage projects? Partner with Beauty STC, a trusted manufacturer with years of expertise in high-quality LED lighting components. Our advanced LED drivers ensure optimal performance, durability, and energy efficiency for all types of signage applications.

Contact us today to discuss your requirements and discover how we can support your business growth. Reach out to our sales manager at [email protected] and take the first step toward a successful partnership.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.