Article Contents

Industry Insight: Sheet Lights Led

The commercial and industrial lighting sector faces relentless pressure to deliver exceptional performance, energy efficiency, and seamless integration within demanding architectural and operational environments. In this context, LED flat panel lighting—often referred to colloquially as ‘sheet lights’—has emerged as a dominant solution, fundamentally transforming how spaces like offices, retail stores, hospitals, schools, and warehouses are illuminated. These ultra-slim, surface-mounted fixtures provide unparalleled uniformity, eliminate glare, and offer significant operational cost savings through reduced energy consumption and extended lifespans compared to legacy fluorescent systems. Crucially, for any specification in these high-stakes environments, compliance with rigorous safety and performance standards is non-negotiable. Products must consistently meet and bear the marks of recognized certification bodies, specifically ETL for the North American market and CE marking for Europe, ensuring electrical safety, electromagnetic compatibility, and adherence to regional regulatory frameworks. These certifications are not mere formalities; they are the bedrock of trust and liability protection for facility managers and specifying engineers.

Beauty STC Manufacturing Co., Ltd., established in 1998, stands at the forefront of this evolution. For over 25 years, we have dedicated ourselves to engineering and manufacturing high-performance LED lighting solutions precisely tailored to the exacting demands of commercial and industrial applications. Our deep expertise in thermal management, optical design, and robust construction ensures our LED flat panel systems not only achieve the highest efficiency and light quality metrics but also consistently pass the stringent testing required for ETL and CE certification. We understand that in professional settings, lighting is infrastructure—it must be reliable, compliant, and deliver a rapid return on investment. Beauty STC leverages decades of manufacturing excellence to provide the certified, high-value LED flat panel solutions that modern commercial and industrial spaces require.

Technical Specs & Certifications

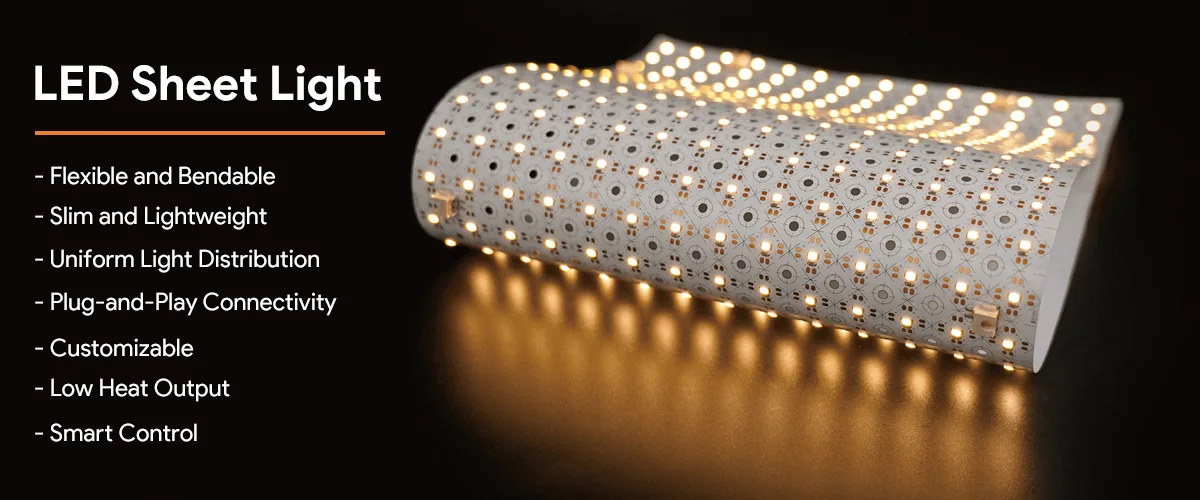

Sheet lights LED, commonly referred to as LED panel lights or flat panel luminaires, are designed for architectural and commercial lighting applications where uniform illumination, slim profile, and energy efficiency are critical. At Beauty (STC) Manufacturing Co., Ltd., our sheet lights LED are engineered to deliver superior performance, combining high efficiency, excellent color rendering, and robust environmental protection.

In terms of luminous efficacy, Beauty STC’s sheet lights LED achieve a typical range of 120 to 150 lumens per watt (lm/W), with select high-efficiency models exceeding 150 lm/W under optimal operating conditions. This high lumens-per-watt ratio ensures significant energy savings compared to conventional lighting solutions, making them ideal for long-duration use in offices, hospitals, schools, and retail environments.

Color Rendering Index (CRI) is a key performance metric for applications where accurate color representation is essential. All our premium sheet lights LED are designed with CRI values greater than 90, and many models offer CRI >95, ensuring natural and vibrant color reproduction. This high CRI performance is achieved through the use of high-quality phosphor-coated LEDs and advanced optical diffusers that minimize color variance across the light surface.

Regarding environmental protection, Beauty STC’s sheet lights LED are available in multiple IP (Ingress Protection) ratings to suit varying installation conditions. Standard recessed and surface-mounted models typically carry an IP40 rating, providing protection against solid objects larger than 1 mm and no protection against water—suitable for indoor dry locations. For more demanding environments such as restrooms, kitchens, or semi-outdoor covered areas, we offer models with IP54 rating, which ensures protection against dust ingress and water splashes from any direction. These higher-rated units are ideal for commercial installations requiring enhanced durability and reliability.

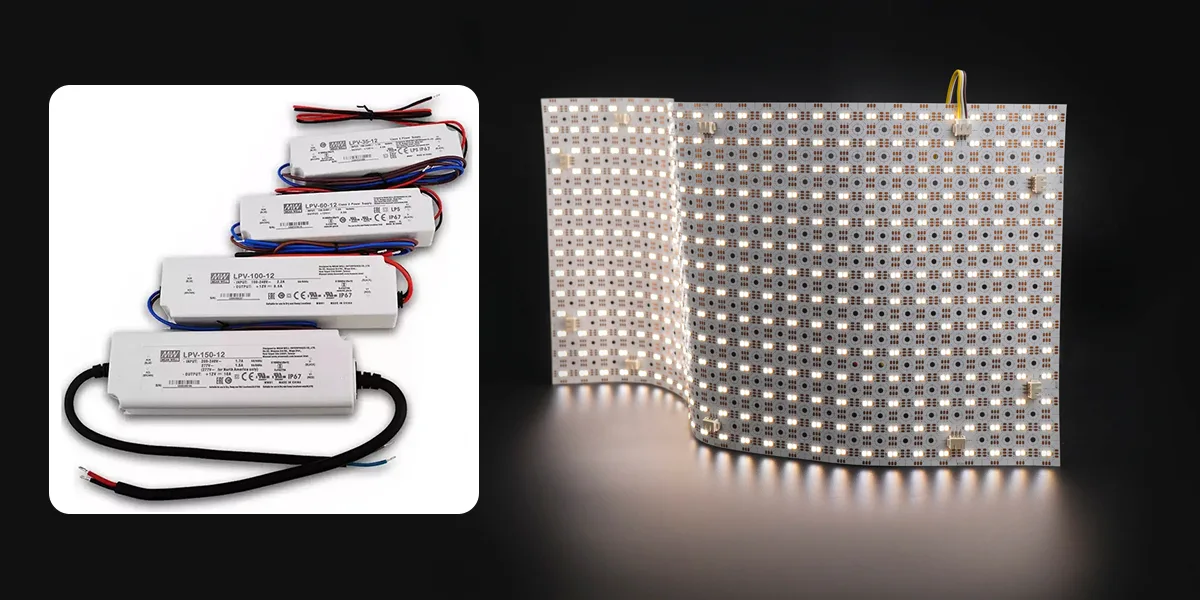

Beauty STC is committed to quality and consistency in every product. Our sheet lights LED undergo rigorous testing for photometric performance, thermal management, and long-term lumen maintenance. We utilize high-grade materials including aircraft-grade aluminum heat sinks, polycarbonate diffusers, and driver components with surge and short-circuit protection. Our manufacturing processes adhere to ISO 9001 standards, and our products are CE, RoHS, and UL certified where applicable, ensuring global compliance and safety.

In summary, Beauty STC’s LED sheet lights deliver exceptional lumens per watt, CRI >90 for superior color fidelity, and flexible IP ratings from IP40 to IP54, all backed by our reputation for engineering excellence and durable, reliable lighting solutions.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, serves as our primary production hub for advanced LED lighting solutions, with a significant focus on flat panel and sheet light products. The factory occupies a modern, climate-controlled space designed specifically for precision electronics assembly, featuring strict electrostatic discharge (ESD) protocols and cleanroom standards in critical production zones to ensure component integrity. Central to our manufacturing capability are multiple high-speed Yamaha YS24 SMT (Surface Mount Technology) production lines. These state-of-the-art machines handle components as small as 0201 metric package sizes with exceptional placement accuracy down to ±25 microns, essential for the dense PCB layouts required in slim-profile sheet lights. Each line integrates automated optical inspection (AOI) systems immediately post-reflow to verify solder joint quality and component placement, minimizing defects before further assembly. Our SMT capacity supports multi-layer PCBs up to 10 layers, accommodating complex driver circuits and thermal management designs necessary for high-lumen, low-profile sheet light applications, with a combined monthly output capacity exceeding 1.5 million units for sheet light products alone.

Rigorous aging and reliability testing form a non-negotiable part of our quality control process for all sheet light LED products. Every production batch undergoes mandatory 24-hour continuous burn-in testing at elevated temperatures of 50°C, simulating accelerated operational stress to identify early-life failures. This process occurs in dedicated environmental chambers with real-time monitoring of electrical parameters and luminous output. For premium OEM orders or specific client requirements, we offer extended 72-hour aging cycles. Crucially, our aging protocol includes automated optical inspection during and after the burn-in phase to detect any lumen depreciation inconsistencies, color shift, or visible defects like pixelation in the diffuser – common failure points in thin-sheet LED designs. All sheet lights also undergo comprehensive photometric testing per IESNA LM-79 standards post-aging, verifying lumen maintenance, CCT stability, and CRI values before shipment. This multi-stage validation ensures our products consistently achieve L70 lifetimes exceeding 50,000 hours under standard operating conditions.

Our OEM capabilities for sheet lights LED are highly developed and flexible, leveraging the full vertical integration of the Jiangmen facility. We support complete customization from initial concept through to packaged product, including tailored optical designs with multiple diffuser options (prismatic, opal, micro-lens), custom color temperatures down to ±50K tolerance, and bespoke driver configurations for dimming protocols like 0-10V, DALI, or phase-cut. Clients can specify mechanical dimensions, frame finishes, mounting systems, and even integrated emergency backup solutions. The factory houses in-house tooling and molding departments capable of producing custom acrylic diffusers and extruded aluminum frames, eliminating reliance on external vendors for key components. Engineering teams collaborate directly with clients during the design phase to optimize thermal pathways and optical homogeneity – critical factors for ultra-slim sheet lights. With standardized lead times of 25-30 days for new OEM projects after final approval and the capacity to handle annual volumes from 50,000 to over 2 million units, we provide scalable manufacturing without compromising on the stringent thermal management and uniformity standards that define high-end architectural sheet lighting. All OEM productions adhere to IEC 60598 safety standards with optional regional certifications managed through our dedicated compliance laboratory.

Application Scenarios

Sheet lights LED, commonly known as LED panel lights or flat panel lights, are widely used across various commercial and institutional environments due to their sleek design, high energy efficiency, uniform illumination, and low glare. These fixtures are ideal in spaces where clean, bright, and evenly distributed light is required.

In hotels, LED sheet lights are frequently installed in lobbies, guest corridors, conference rooms, and back-of-house areas such as staff rooms and utility corridors. Their modern aesthetic complements contemporary interior designs, while their consistent light output enhances guest comfort and safety. In guest room ceilings, recessed panel lights provide ambient lighting without creating harsh shadows, contributing to a relaxing atmosphere.

Malls benefit significantly from LED sheet lights in common areas, food courts, restrooms, and administrative offices. Their ability to deliver high lumen output with minimal energy consumption makes them cost-effective for large, continuously operated spaces. The uniform light distribution reduces dark spots in walkways and enhances the visual appeal of retail environments, indirectly supporting branding and customer experience.

Offices are one of the most common applications for LED sheet lights. They are typically mounted in drop ceilings in open-plan workspaces, private offices, meeting rooms, and reception areas. The diffuse, glare-free lighting helps reduce eye strain and supports productivity and employee well-being. Their slim profile allows for a clean ceiling appearance, contributing to a professional and modern office environment.

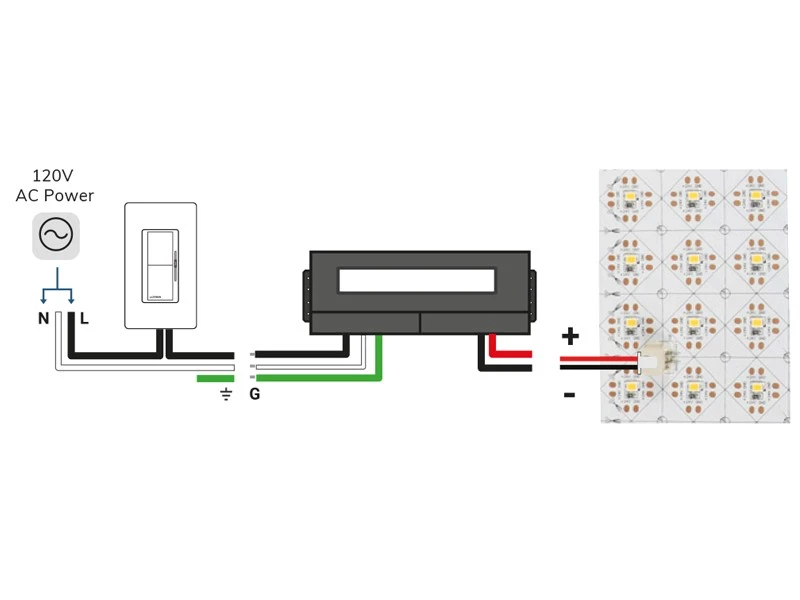

When installing LED sheet lights, several tips should be followed to ensure optimal performance and longevity. First, verify the ceiling type and grid compatibility—especially for drop ceilings—ensuring that the panel fits securely within the T-bar layout. For surface-mounted or recessed installations, confirm structural support and proper clearance. Always turn off power at the circuit breaker before beginning installation to ensure safety.

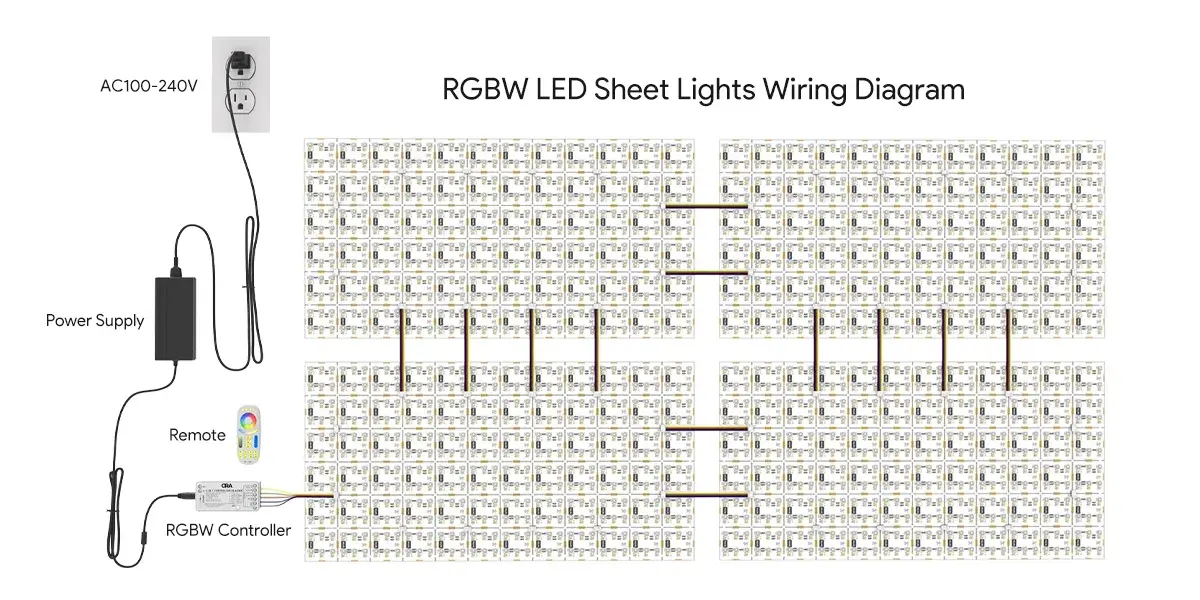

Proper wiring is essential; connect the panel to the mains using certified electricians and follow local electrical codes. Avoid daisy-chaining too many panels on a single circuit to prevent overloading. Ensure adequate spacing between fixtures to maintain uniform illumination—typically 1.5 to 2 times the ceiling height apart, depending on required lux levels.

Additionally, consider using dimmable drivers if adjustable lighting is desired, especially in hotels and conference rooms where ambiance control is important. Regular cleaning of the diffuser panel and surrounding ceiling grid helps maintain light output and efficiency over time. Finally, choose the appropriate color temperature—3000K to 4000K is typical for hospitality and offices—balancing warmth and clarity based on the space’s function and design intent.

Why Choose Beauty STC Lighting

Elevate your lighting projects with Beauty STC’s premium LED sheet lights, engineered for seamless illumination and architectural elegance. Our advanced solutions deliver uniform brightness, exceptional energy efficiency, and customizable integration for commercial, retail, and high-end residential applications. Partner with Beauty STC Manufacturing Co., Ltd. to access cutting-edge technology, rigorous quality control, and dedicated engineering support tailored to your specifications. Transform your vision into reality with reliable, high-performance sheet lighting that exceeds industry standards. Contact our lighting solutions manager today at [email protected] to discuss collaboration opportunities and technical requirements. Let Beauty STC illuminate your next project with precision and innovation.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.