Article Contents

Industry Insight: Double Sided Tape For Led Strips

In the rapidly evolving landscape of commercial and industrial lighting, the demand for efficient, durable, and seamlessly integrated LED solutions continues to grow. As LED strip lighting becomes a preferred choice for architectural accents, task lighting, and large-scale installations, the importance of reliable mounting systems cannot be overstated. Double-sided tape for LED strips has emerged as a critical component in ensuring secure, clean, and professional installations across a wide range of environments—from retail spaces and office buildings to manufacturing facilities and cold storage units. Performance requirements go beyond mere adhesion; tapes must withstand temperature fluctuations, resist UV exposure, and maintain bond integrity over extended service life. In such high-stakes applications, compliance with international safety and performance standards is non-negotiable. Reputable solutions are rigorously tested and certified to meet ETL and CE standards, providing assurance of electrical safety, material quality, and environmental resilience.

At the forefront of innovation in this space is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED lighting accessories since 1998. With over two decades of engineering expertise, Beauty STC has consistently delivered high-performance mounting solutions tailored to the demanding needs of commercial and industrial projects. Their double-sided tapes are developed using advanced adhesive technologies and backed by stringent quality control processes, ensuring compatibility with a broad range of substrates and LED profiles. As the industry moves toward smarter, more sustainable lighting infrastructures, Beauty STC remains committed to supporting seamless integration, reliability, and long-term performance—solidifying its role as a strategic partner for professionals in the built environment.

Technical Specs & Certifications

Double-sided tape for LED strip mounting serves a purely mechanical function as an adhesive mounting solution and possesses no optical or electrical properties such as lumens per watt, Color Rendering Index (CRI), or inherent IP ratings. These specifications are exclusively characteristics of the LED strip itself, not its mounting hardware. Lumens per watt measures the efficacy of the light source, CRI quantifies the accuracy of color rendition under that light source, and IP ratings define the level of protection an electronic assembly has against solid objects and moisture ingress. The adhesive tape contributes zero lumens and cannot influence the light output quality or the electrical protection rating of the LED product.

The critical technical specifications for double-sided tape used with LED strips focus on adhesion performance and environmental resilience. Key parameters include initial tack strength, holding power (typically measured in ounces per square inch or Newtons per square millimeter), temperature resistance range (commonly -20°C to +80°C or higher for premium tapes), UV resistance to prevent degradation under light exposure, solvent resistance, and compatibility with common substrates like aluminum profiles, painted walls, plastics, and the LED strip’s own backing material. Peel adhesion force, often tested per ASTM D3330 standards, is a vital metric, with high-performance tapes for LED applications typically delivering 30-50+ oz/in (1.1-1.8 N/mm) peel strength. Long-term durability under thermal cycling, crucial for LED applications generating heat, is equally important.

While the tape itself does not carry an IP rating, its correct selection and application methodology significantly impact the final assembly’s ability to achieve a desired IP rating for the complete LED strip fixture. For instance, achieving IP65 or IP67 for an outdoor LED strip installation requires not only an appropriately rated silicone-sealed LED strip but also the use of a high-cohesion tape that maintains its bond integrity when exposed to moisture and thermal stress, preventing water ingress paths along the mounting surface. Tapes with excellent moisture resistance and stable adhesion across wide temperature swings are essential enablers for reliable IP-rated installations, though the rating itself applies to the fully assembled and sealed luminaire.

Beauty STC Manufacturing Co., Ltd. distinguishes its double-sided mounting tapes through rigorous material science and stringent quality control processes. We utilize high-purity acrylic adhesives formulated specifically for thermal stability under LED operating conditions, ensuring consistent bond strength from initial application through years of service. Our tapes undergo extensive validation testing, including 1000+ hour thermal aging cycles at 85°C and 85% relative humidity, accelerated UV exposure testing per ISO 4892, and peel adhesion verification across diverse substrates after environmental stress. This commitment to material integrity ensures our tapes prevent common field failures like strip delamination or yellowing, directly supporting the longevity and reliability of the LED lighting systems our customers build. Beauty STC tapes provide the dependable mechanical foundation required for high-performance, durable LED installations.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern manufacturing facility located in Jiangmen, Guangdong Province, a strategic location known for its robust industrial infrastructure and proximity to key supply chain networks in the Pearl River Delta. The Jiangmen factory is fully equipped to support high-volume, precision manufacturing of LED lighting products, with a strong emphasis on quality control, efficiency, and flexibility to serve both domestic and international markets.

The facility features state-of-the-art Surface Mount Technology (SMT) production lines, which are critical for the accurate and reliable assembly of LED strip components. These SMT machines are automated and utilize advanced pick-and-place technology to mount LEDs, resistors, capacitors, and other surface-mount devices onto flexible printed circuit (FPC) boards with high precision and repeatability. The integration of automated optical inspection (AOI) systems ensures that each board is thoroughly checked for soldering quality and component alignment immediately after the SMT process, minimizing defects and maintaining consistent product performance.

To guarantee long-term reliability, the factory conducts comprehensive aging tests on all LED strip products, including those with double-sided tape. Finished LED strips are subjected to extended operational testing under elevated temperatures and continuous power conditions—typically 24 to 72 hours—simulating real-world usage over extended periods. This aging process helps identify early-life failures, validates thermal management, and confirms the durability of materials such as adhesives and encapsulants used in the product.

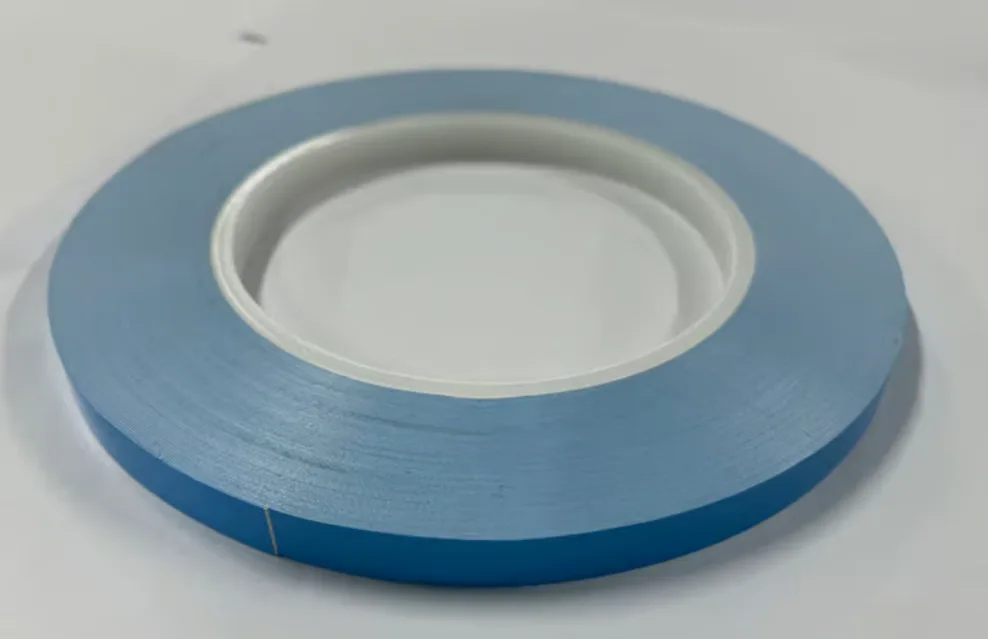

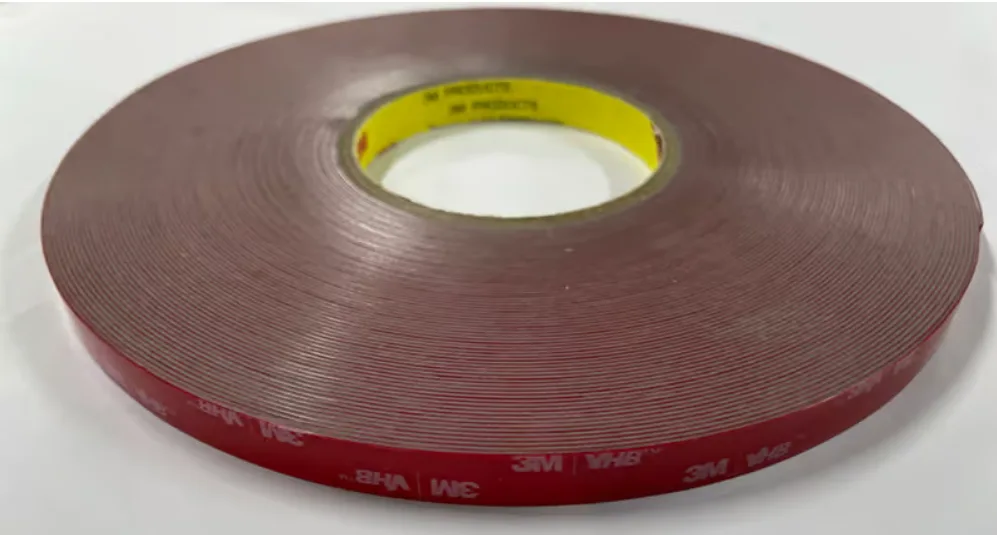

Beauty STC has well-established OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) capabilities, allowing the company to customize LED strip solutions according to client specifications. This includes the production of double-sided tape for LED strips, where the company can tailor adhesive type (e.g., 3M, Tesa, or high-bonding acrylic), tape thickness, peel strength, and temperature resistance to meet various application requirements—whether for indoor residential use, commercial displays, or outdoor installations exposed to harsh environments. The factory supports custom labeling, packaging, reel lengths, and even private branding, making it a preferred partner for global distributors and lighting brands seeking reliable and scalable manufacturing solutions.

Overall, the Jiangmen factory reflects Beauty STC’s commitment to advanced manufacturing practices, product innovation, and customer-centric service, positioning the company as a trusted supplier in the global LED lighting industry.

Application Scenarios

Double-sided tape is a critical installation component for LED strips in commercial environments like hotels, malls, and offices, but its application requires precision to ensure longevity and performance. In hotels, it is most effectively used for discreet cove lighting in lobbies, under vanity mirrors in guest bathrooms, along corridor handrails for safety lighting, and beneath floating shelves in executive suites. These locations demand clean aesthetics without visible fasteners, and the tape provides a secure bond where mechanical fixtures would compromise design. However, avoid using tape alone on vertical surfaces exceeding 3 meters in height or in high-moisture zones like shower enclosures without supplemental clips, as humidity and thermal cycling can degrade adhesion over time.

For malls, double-sided tape excels in mounting LED strips under curved display shelves, along the edges of escalator side panels, and within recessed ceiling coves in food courts. These applications benefit from the tape’s ability to conform to gentle curves where rigid brackets fail. Crucially, never rely solely on tape for installations on glass facades or high-traffic flooring edges; structural movement and footfall vibrations will cause detachment. Always pair tape with aluminum channels in high-traffic zones to dissipate heat and prevent strip warping.

In offices, tape is ideal for under-desk task lighting, within suspended ceiling perimeters for indirect glare-free illumination, and along partition wall bases for wayfinding. These uses leverage the tape’s quick installation during fit-outs. However, avoid applying tape directly to painted drywall in open-plan offices—low-sheen paints often lack sufficient adhesion strength. Instead, mount strips to pre-installed aluminum profiles bonded to the wall, ensuring the tape contacts only the profile’s anodized surface.

Installation must begin with rigorous surface preparation. Clean all substrates with isopropyl alcohol to remove dust, oils, or construction residues; even invisible contaminants cause 70% of tape failures. Apply tape only when ambient temperatures exceed 15°C, as cold surfaces inhibit adhesive activation. Press the LED strip firmly along its entire length using a roller—not your fingers—to eliminate air pockets and maximize contact. Allow a minimum 72-hour cure time before powering the LEDs, as thermal expansion during initial operation can shift poorly bonded strips. Always select high-bond acrylic foam tapes like 3M VHB, rated for continuous temperatures above 70°C, and never use silicone-based tapes which degrade under LED heat. For metal surfaces, add thermal pads between the strip and substrate to prevent heat trapping, which accelerates lumen depreciation. Finally, in all commercial settings, supplement tape with mechanical anchors every 300mm on vertical runs or in seismic zones to comply with building codes and prevent costly drop hazards.

Why Choose Beauty STC Lighting

Looking for reliable double sided tape for LED strips? Partner with Beauty STC, a trusted manufacturer of high-quality LED lighting solutions. Our advanced adhesive tapes ensure secure, long-lasting installation for all your LED strip projects. Engineered for durability and performance, they are the ideal choice for both residential and commercial applications.

Elevate your lighting installations with products you can trust. Contact us today to learn more and place your order. Reach out to our sales manager at [email protected] and discover the Beauty STC difference.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.