Article Contents

Industry Insight: Led Tape Light Dimmer

The commercial and industrial lighting sector continues its decisive shift toward LED tape light solutions, driven by demands for flexible architectural integration, energy efficiency, and dynamic ambiance control in environments ranging from high-end retail displays and hospitality venues to demanding warehouse aisles and healthcare facilities. Central to unlocking the full potential of these linear LED systems is the critical component: the LED tape light dimmer. Precise, reliable, and compatible dimming is no longer a luxury but a fundamental requirement for achieving optimal energy savings, enhancing occupant well-being through circadian lighting strategies, and meeting stringent building codes and sustainability certifications. In this professional landscape, regulatory compliance is non-negotiable. Dimmers deployed in commercial and industrial projects must consistently carry recognized safety certifications such as ETL for the North American market and CE marking for Europe, ensuring they meet rigorous electrical safety and electromagnetic compatibility standards essential for large-scale, long-term installations where failure is not an option.

Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of this evolution, leveraging over 25 years of specialized expertise in LED driver and control system engineering. We understand the unique pressures of commercial and industrial applications – the need for robust performance under continuous operation, seamless integration with complex building management systems, and absolute adherence to global safety protocols. Our commitment to engineering excellence is reflected in our comprehensive range of LED tape light dimmers, meticulously designed and rigorously tested to deliver the precise, flicker-free dimming performance professionals demand, backed by the essential ETL and CE certifications required for specification and deployment in projects worldwide. We provide the reliable control foundation upon which successful, future-proof commercial and industrial LED tape lighting installations are built.

Technical Specs & Certifications

The LED tape light dimmer itself does not produce lumens or consume watts directly—it is a control device that regulates the power delivered to the LED tape light. Therefore, specifications such as lumens per watt and CRI are characteristics of the LED tape light, not the dimmer. However, a high-quality dimmer, such as those designed and manufactured by Beauty (STC) Manufacturing Co., Ltd., ensures optimal performance, efficiency, and light quality from compatible high-performance LED tapes.

For LED tape lights that are typically paired with Beauty STC dimmers, the technical specifications often include a luminous efficacy of 110 to 130 lumens per watt, depending on the LED density and chipset used. These tapes utilize high-efficiency SMD 2835 or 3014 LEDs, engineered to maximize light output while minimizing energy consumption. When paired with a compatible Beauty STC dimmer, the system maintains stable current regulation, avoiding flicker and ensuring consistent lumen maintenance over time.

Color Rendering Index (CRI) is a critical factor in premium lighting applications. LED tape lights designed for use with Beauty STC dimmers typically achieve a CRI greater than 90, with some high-end variants reaching CRI95+. This ensures accurate and vibrant color representation, making them ideal for retail, hospitality, and residential environments where visual clarity and ambiance are paramount. Beauty STC ensures compatibility with high-CRI LED tapes through precision dimming circuits that preserve spectral integrity across all dimming levels.

Regarding environmental protection, the IP (Ingress Protection) rating applies primarily to the LED tape light and its installation environment. Common configurations include IP20 for indoor dry locations, IP65 for splash and moisture resistance (often with silicone coating), and IP67 or IP68 for full waterproofing suitable for outdoor or wet locations. Beauty STC dimmers are engineered to support these various IP-rated tape lights, with dimmer enclosures themselves often rated IP20 for standard installations or housed in higher IP-rated external enclosures when used in demanding environments.

Beauty (STC) Manufacturing Co., Ltd. is recognized for its rigorous quality control, adherence to international safety standards (including UL, CE, and RoHS), and durable electronic design. Their dimmers feature smooth phase-cut or PWM dimming technology, ensuring flicker-free operation and extended LED lifespan. By maintaining tight tolerances in output regulation and thermal management, Beauty STC products deliver reliable, high-efficiency performance when paired with high-lumen, high-CRI LED tapes across a wide range of IP-rated applications.

Factory Tour: Manufacturing Excellence

Beauty STC’s Jiangmen manufacturing facility serves as a core production hub for our LED lighting solutions, strategically located within Guangdong Province’s robust electronics manufacturing ecosystem. This location provides efficient access to key component suppliers and logistics networks while maintaining stringent quality control standards throughout the production process. The factory is purpose-built for high-volume, precision LED product manufacturing with dedicated cleanroom environments for critical assembly stages.

Our Surface Mount Technology (SMT) production lines are equipped with state-of-the-art Yamaha YSM20 and YSM10 placement machines. These systems handle components down to 0201 metric package sizes with high placement accuracy of ±25μm, essential for the compact circuitry found in modern LED tape light dimmers. The fully automated lines include lead-free reflow ovens with 10-zone temperature profiling and automated optical inspection (AOI) stations after soldering to ensure zero-defect solder joints. This capability allows us to consistently produce the densely populated control boards required for multi-channel dimming protocols including PWM, 0-10V, and DALI.

Aging and reliability testing constitute a critical phase in our dimmer production process. Every LED tape light dimmer undergoes a mandatory 24-hour continuous burn-in test at 110% of rated load within our environmental chambers, which maintain controlled temperature and humidity levels. This extended stress test identifies early-life failures before products reach customers. Additionally, we conduct accelerated life testing on sample batches using IEC 60068-2-14 protocols, subjecting dimmers to 500+ thermal cycles between -25°C and +85°C while monitoring dimming performance and thermal stability. All dimmers are functionally verified across their full dimming range and compatibility spectrum with various LED tape types prior to final packaging.

Our OEM capabilities for LED tape light dimmers are comprehensive and flexible. We support full turnkey manufacturing from initial concept to finished packaged product, including custom PCB design modification, proprietary firmware development for unique dimming curves or protocols, and mechanical housing customization. Clients provide specifications for dimming range, control interface (e.g., wireless RF, Bluetooth mesh, or physical switches), and integration requirements, and our engineering team develops production-ready solutions. We maintain dedicated OEM production cells with segregated component inventory systems to ensure design confidentiality. Recent projects include producing dimmers with integrated Wi-Fi 6 controllers for smart home ecosystems and ultra-slim form factors for architectural integration, all backed by our standard three-year warranty and compliance with global safety standards including UL, CE, and CCC. This end-to-end capability allows us to deliver market-ready dimmer solutions that meet exact client specifications while maintaining Beauty STC’s quality benchmarks.

Application Scenarios

LED tape light dimmers are commonly used in hotels, malls, and offices to enhance ambiance, improve energy efficiency, and provide flexible lighting control. In hotels, they are ideal for guest room cove lighting, under-bed or headboard accents, and bathroom niches, allowing guests to adjust brightness for relaxation or functionality. In malls, LED tape dimmers are used in display lighting, cove features in common areas, and signage to create dynamic visual effects and draw attention to promotions. In offices, they are effective in under-cabinet task lighting, conference room cove details, and reception areas to support focus during work hours and transition to softer lighting for evening events or reduced energy use after hours.

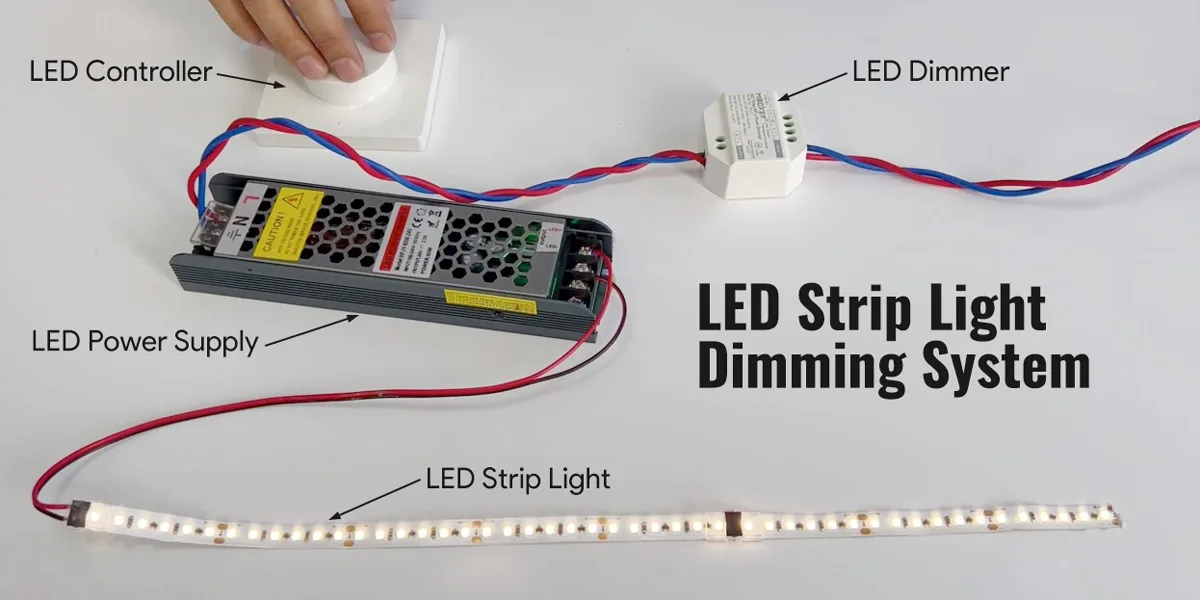

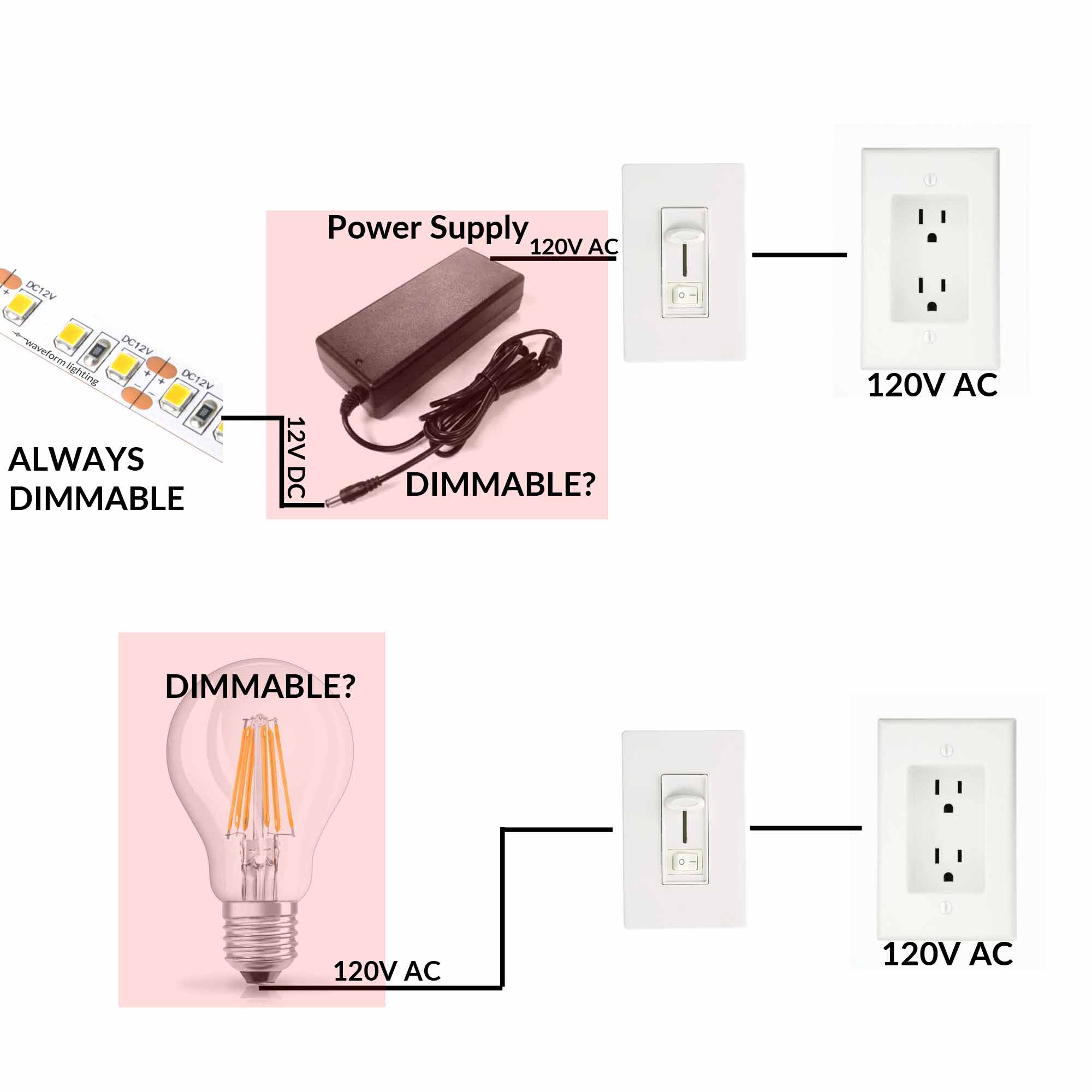

When installing LED tape light dimmers, ensure compatibility between the dimmer, LED tape, and power supply—check whether the system uses trailing-edge, leading-edge, or PWM dimming methods. Always calculate the total wattage of the LED tape to ensure it falls within the dimmer’s load range. For longer tape runs, consider injecting power at multiple points to prevent voltage drop and dimming inconsistencies. Install the dimmer as close to the power source as possible, and avoid placing it in enclosed or poorly ventilated spaces to prevent overheating. Use high-quality connectors and follow proper polarity when wiring. For best results, test the system before finalizing the installation and label the circuit for future maintenance.

Why Choose Beauty STC Lighting

As a Senior LED Lighting Engineer at Beauty STC Manufacturing Co. Ltd I emphasize the critical importance of reliable dimming performance in LED tape light applications Our engineered solutions address common industry challenges such as flicker inconsistent low-end dimming and compatibility issues across diverse tape light specifications Beauty STC develops precision dimmers rigorously tested for seamless integration with both standard and high-density LED tape systems ensuring smooth dimming curves from 100 to 0 5 brightness without artifacts

Partnering with Beauty STC provides access to our technical expertise in driver-dimmer synchronization thermal management and compliance with global safety standards including UL CE and SAA We support partners through custom firmware adjustments dedicated application engineering and volume production scalability tailored to your project requirements Contact our technical management team directly at manager@chinabeautylighting com to discuss dimmer specifications compatibility testing or collaborative development opportunities for your next LED tape lighting solution

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.