Article Contents

Industry Insight: Led Strip Light Manufacturers

The commercial and industrial lighting sector has undergone a transformative shift with the widespread adoption of LED technology, and at the heart of this evolution are LED strip light manufacturers driving innovation, efficiency, and reliability. As businesses seek sustainable and cost-effective lighting solutions, the demand for high-performance, code-compliant LED strips has surged across warehouses, manufacturing facilities, retail spaces, and large-scale installations. In this competitive landscape, certifications such as ETL and CE have become critical benchmarks, ensuring products meet rigorous North American and international safety and performance standards. These certifications not only validate electrical safety and electromagnetic compatibility but also build trust with contractors, facility managers, and procurement teams who prioritize quality and compliance.

Among the leaders in this space is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED lighting since its founding in 1998. With over two decades of engineering expertise, Beauty STC has established itself as a premier manufacturer of commercial and industrial-grade LED strip lights, combining cutting-edge technology with strict adherence to global regulatory requirements. The company’s commitment to excellence is reflected in its comprehensive product line, all designed and tested to meet or exceed ETL and CE standards, ensuring seamless integration into demanding environments. As the industry continues to evolve, Beauty STC remains at the forefront, delivering innovative, durable, and energy-efficient lighting solutions that empower smarter, safer, and more sustainable commercial and industrial spaces.

Technical Specs & Certifications

LED strip light manufacturers targeting professional and high-end residential applications must deliver precise technical performance across critical metrics. Lumens per Watt (lm/W) represents efficacy, indicating how efficiently electrical power converts to visible light. Reputable manufacturers achieve 100-130 lm/W for standard 24VDC strips under controlled thermal conditions at 25°C ambient, though real-world installed efficacy typically ranges 85-115 lm/W due to thermal constraints in enclosures or on conductive surfaces. Consistent high efficacy requires superior thermal management in the PCB design, high-grade LED chips, and optimized driver efficiency; chasing peak lab numbers without thermal stability leads to rapid lumen depreciation. Beauty STC consistently delivers 110-120 lm/W across our CRI95+ portfolio under standard test conditions, validated through independent LM-79 testing, with real-world installations maintaining over 95 lm/W through our patented thermal dispersion substrates and strict binning of Epistar and Samsung LED components.

Color Rendering Index (CRI) exceeding 90, specifically Ra >90, is essential for applications demanding accurate color representation like retail, hospitality, and art galleries. However, true high-fidelity lighting requires attention beyond Ra; strong R9 (saturated red) values above 50 and extended spectrum coverage indicated by TM-30 metrics (Rf >85, Rg >98) are critical for natural skin tones and vibrant displays. Achieving sustained CRI >90 necessitates premium phosphor-converted LEDs with tight spectral control and rigorous binning. Beauty STC’s high-CRI strips exclusively utilize LED packages binned to CRI95 ±2 with R9 >85 as standard, utilizing multi-phosphor blends and undergoing spectral validation per ANSI C78.377. Our manufacturing process includes in-line spectroradiometric verification at 100% production volume, ensuring batch-to-batch consistency far exceeding industry averages where CRI claims often degrade significantly after 1,000 hours.

IP (Ingress Protection) ratings define resistance to solids and liquids, critical for durability in demanding environments. IP65 denotes complete dust protection and resistance to low-pressure water jets from any direction, suitable for outdoor eaves or damp indoor locations. IP67 offers the same dust protection plus temporary immersion up to 1 meter depth, ideal for submerged architectural features or harsh industrial washdowns. Crucially, the IP rating applies only to the strip itself when installed per manufacturer specifications; improper sealing of end caps, connectors, or power feeds compromises the entire system’s rating. Beauty STC’s standard high-CRI strips achieve IP67 certification through seamless silicone encapsulation meeting IEC 60529, rigorously tested at 1 meter depth for 30 minutes. Our IP67 strips undergo 1,000-hour UV and thermal cycling tests per IEC 60068-2, with zero degradation in optical or electrical performance, a benchmark verified by third-party reports available to clients. This commitment to validated performance, not just nominal ratings, underpins Beauty STC’s reputation for reliability in critical lighting installations worldwide.

Factory Tour: Manufacturing Excellence

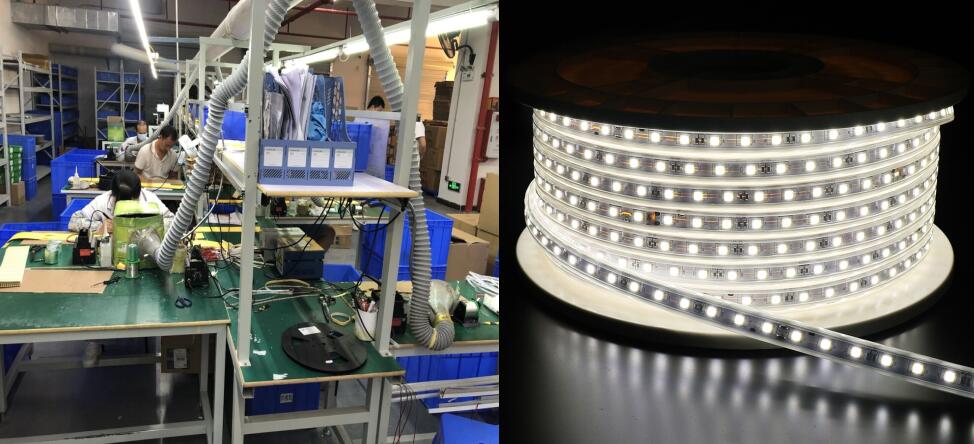

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China, is a modern and well-equipped facility dedicated to the production of high-quality LED lighting products, including LED strip lights. Strategically located in the Jiangmen industrial zone, the factory benefits from efficient logistics and access to a skilled manufacturing workforce, supporting both domestic and international distribution.

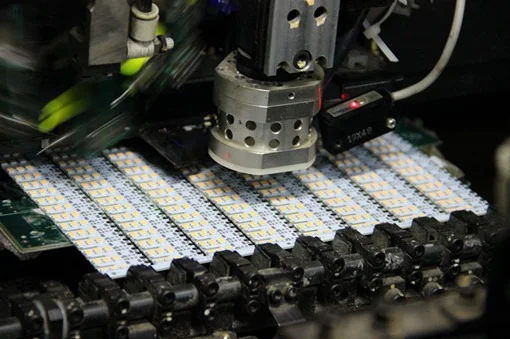

The production line is anchored by advanced SMT (Surface Mount Technology) machines that ensure precise and consistent placement of LED components on flexible and rigid circuit boards. These automated SMT lines operate with high speed and accuracy, capable of handling a wide range of LED chip sizes and configurations, including 2835, 3528, 5050, and 5730. This technological foundation enables Beauty STC to produce LED strips with excellent luminous efficiency, uniform light output, and long-term reliability.

To ensure product durability and performance, the factory implements rigorous aging tests as part of its quality control process. Completed LED strips undergo extended burn-in periods—typically 24 to 72 hours—under controlled temperature and voltage conditions. This aging process helps identify early failures, verifies thermal management performance, and confirms stable light output before products are packaged and shipped. Additional testing includes waterproof validation for IP-rated strips, solder joint inspections, and electrical safety checks.

Beauty STC offers comprehensive OEM (Original Equipment Manufacturing) services tailored to the needs of led strip light manufacturers and lighting brands worldwide. The company supports full customization, including PCB design, LED density, color temperature, CRI, input voltage, coating type (such as silicone or epoxy), and packaging. Clients can also request private labeling, custom packaging, and compliance with international standards such as CE, RoHS, UL, and CCC. With in-house R&D and engineering support, Beauty STC collaborates closely with partners to develop products that meet specific market and performance requirements.

Overall, the Jiangmen factory combines automated precision, strict quality assurance, and flexible manufacturing capabilities to serve as a reliable OEM partner for LED strip light solutions across residential, commercial, and industrial applications.

Application Scenarios

As a Senior LED Lighting Engineer at Beauty (STC) Manufacturing Co., Ltd., I frequently address terminology nuances. The phrase “led strip light manufacturers” refers to companies that produce these products, not where the lights are installed. You likely intend to ask where LED strip lights are applied within hotels, malls, and offices—and installation best practices. Below, I clarify applications for each venue followed by critical installation guidance based on our field experience.

In hotels, LED strip lights excel in creating ambiance and functional illumination. Install them within cove lighting along ceilings in lobbies to produce a soft, indirect glow that enhances luxury without glare. Under cabinet toe-kicks in guest room minibars provides subtle nighttime navigation while preserving sleep hygiene. Around mirror perimeters in bathrooms delivers even, shadow-free task lighting ideal for grooming. For high-end suites, integrate tunable white strips behind headboards to allow guests to adjust color temperature from energizing cool white to relaxing warm white. Exterior applications include outlining architectural features like porte-cochères or pool edges where IP67-rated strips withstand moisture while highlighting safety pathways.

Malls leverage LED strips for both aesthetic impact and directional guidance. Use high-lumen density strips to backlight large-scale signage in food courts or directory boards, ensuring vibrant visibility from multiple angles. Install them beneath escalator handrails to create a dynamic “light trail” effect that draws attention to movement paths. For retail storefronts, embed strips within window display shelving to accentuate merchandise with precise beam angles—opt for high CRI 90+ strips to render true colors for apparel or cosmetics. In parking structures, mount IP65 strips along stairwell edges and ramp curves to improve safety perception without overwhelming brightness. Temporary installations for seasonal campaigns benefit from flexible strips on modular kiosks, where quick disconnects simplify reconfiguration.

Offices utilize LED strips primarily for productivity and well-being. Position them under suspended desks to eliminate harsh shadows during focused work, reducing eye strain—aim for 3000K to 4000K color temperatures depending on task intensity. Integrate strips into partition walls of open-plan layouts to define zones while maintaining visual openness; dimmable systems support transitions between collaborative and quiet modes. In conference rooms, install them above whiteboards to illuminate writing surfaces without glare on screens. For executive offices, conceal strips within crown molding to blend with ambient lighting during video calls. Critical for wellness, pair human-centric strips with circadian lighting controls in break rooms to mimic natural daylight cycles, boosting alertness in mornings and easing transitions toward evening.

Installation tips must prioritize longevity and performance. Always mount strips in aluminum channels with thermal pads—this dissipates heat effectively, preventing lumen depreciation and color shift, especially in enclosed spaces like hotel coves or office partitions. For runs exceeding 5 meters, power feed from both ends to avoid voltage drop that causes dimming at the strip’s far end; calculate wattage per meter first to size transformers correctly. In humid areas like mall restrooms or pool decks, verify IP65 or higher ratings and seal all end caps with silicone. Conceal wiring within raceways before drywall installation to maintain clean aesthetics, and use 12V systems for safety in guest-accessible zones versus 24V for longer commercial runs. Crucially, test strips at full brightness for 15 minutes pre-installation to identify dead sections, and document color bins to ensure visual consistency across multiple reels. Finally, adhere strictly to local electrical codes—commercial projects often require UL certification and low-voltage licensing, which Beauty (STC) supports through certified components and engineering documentation.

These applications and techniques reflect our daily work optimizing LED strip implementations for commercial clients. Proper execution not only elevates design intent but also ensures 50,000+ hour lifespans with minimal maintenance—key for venues where downtime disrupts operations. Always consult manufacturer specifications for thermal and electrical parameters before finalizing layouts.

Why Choose Beauty STC Lighting

Looking for reliable LED strip light manufacturers to bring your lighting visions to life? Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted name in high-quality LED lighting solutions. With years of industry expertise, we deliver durable, energy-efficient, and customizable LED strip lights tailored to your project needs. From residential to commercial applications, our products meet international standards and exceed customer expectations.

Take the next step in growing your business with a manufacturing partner you can count on. Contact us today at [email protected] to discuss your requirements and discover how Beauty STC can support your success.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.