Article Contents

Industry Insight: Led Light Strip Shelves

The integration of LED light strip shelves into commercial and industrial environments has emerged as a transformative trend in modern lighting design, combining functional illumination with enhanced visibility and energy efficiency. These specialized shelving systems, embedded with high-performance LED strips, are increasingly deployed in warehouses, retail storage areas, cold storage facilities, and industrial workspaces where reliable, low-maintenance lighting is critical. Designed to meet rigorous safety and performance standards, leading solutions in this category are ETL and CE certified—ensuring compliance with North American and European electrical regulations, respectively. These certifications underscore the importance of quality assurance in demanding operational settings where durability and electrical safety are paramount.

At the forefront of this innovation is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED lighting solutions since its founding in 1998. With over two decades of engineering expertise, Beauty STC has established itself as a leader in commercial and industrial LED applications, delivering high-efficiency, code-compliant lighting systems to clients across North America, Europe, and Asia. The company’s LED light strip shelves reflect its commitment to intelligent design, robust construction, and regulatory compliance—offering businesses a scalable, long-term lighting solution that reduces energy consumption while improving workplace visibility and safety.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. designs and manufactures LED light strip shelves specifically engineered for demanding retail and display applications where accurate color representation, energy efficiency, and reliability are paramount. Our technical specifications reflect a commitment to premium performance and durability, exceeding typical market offerings through rigorous component selection and manufacturing processes.

Lumens per Watt (lm/W) efficiency is a core focus for our LED light strip shelves. We achieve industry-leading efficacy through the use of high-bin Samsung LM301B or Nichia 219F LEDs mounted on thermally optimized flexible PCBs. Standard linear density strips (e.g., 60 LEDs per meter) typically deliver 115-125 lm/W at 25°C ambient temperature when driven at nominal currents. Higher density configurations (e.g., 120 LEDs per meter) maintain impressive efficacy of 105-115 lm/W. This high efficiency is sustained through our proprietary thermal management design within the aluminum shelf extrusion channels, preventing lumen depreciation and ensuring consistent output over the product’s lifespan. We provide detailed lumen maintenance data (L70/B50) based on TM-21 calculations, guaranteeing 50,000 hours of useful life under specified operating conditions.

Critical to display lighting, all Beauty STC LED light strip shelves utilize LEDs rigorously binned to exceed CRI >90, with a minimum R9 value of 50 and often exceeding 75 for vibrant reds. We achieve this through multi-phosphor LED technology, ensuring accurate and consistent color rendering essential for showcasing merchandise like cosmetics, textiles, and food. Our manufacturing process includes spectroradiometric verification of every production batch against CIE standards, guaranteeing that the Ra value remains consistently above 90 across the entire strip length and throughout the rated lifetime. This commitment to high CRI ensures products displayed under our lighting appear true-to-life, enhancing customer perception and purchase decisions.

IP Rating specifications are tailored to the application environment. Our standard LED light strip shelves for dry, indoor retail settings feature IP20 protection, sufficient for dust ingress prevention within enclosed shelf channels. For environments requiring enhanced protection against moisture or cleaning agents, such as grocery display cases, pharmacy shelves, or high-humidity zones, we offer IP65-rated solutions. This is achieved through conformal coating of the LED strip, integrated silicone gaskets within the extruded aluminum channel, and sealed end caps. It is important to note that achieving IP65 involves trade-offs; the protective materials can reduce initial lumen output by approximately 5-8% compared to the IP20 version of the same strip due to light absorption, and thermal management requires careful design to maintain efficacy and longevity. We provide clear documentation specifying the exact IP rating and associated performance parameters for each shelf configuration.

Beauty STC’s quality differentiation stems from our vertically integrated manufacturing and stringent quality control. We utilize only Tier-1 LED components from Samsung, Nichia, or Seoul Semiconductor, never down-binning to meet cost targets. Every LED strip undergoes a 72-hour continuous burn-in test at elevated temperature before integration into the shelf assembly. Our aluminum extrusions are precision-machined for optimal thermal conduction and optical alignment, while the diffusers are high-transmission, UV-stabilized polycarbonate to prevent yellowing. Rigorous in-line testing includes photometric verification, electrical safety checks (UL/cETL listed drivers), and visual inspection. This comprehensive approach, combined with our ISO 9001-certified processes, ensures that Beauty STC LED light strip shelves deliver not only the specified lumen output, CRI, and IP performance but also exceptional longevity and consistent quality batch after batch, minimizing maintenance costs and downtime for our clients.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for electronics and lighting production. The Jiangmen factory is designed to support high-volume, precision manufacturing of LED lighting products, with a strong emphasis on quality control, efficiency, and customization to meet diverse client demands.

The production line is anchored by advanced SMT (Surface Mount Technology) equipment, which ensures high-speed and high-accuracy placement of LED components and electronic parts onto flexible or rigid PCBs used in LED light strips. These SMT machines are automated and integrated with AOI (Automated Optical Inspection) systems to detect placement errors and soldering defects in real time, significantly enhancing product reliability and consistency. The factory maintains multiple SMT lines capable of handling various PCB widths and component densities, supporting both standard and high-density LED strip designs.

A critical part of the quality assurance process at the Jiangmen facility is the comprehensive aging test station. After assembly, all LED light strip products undergo rigorous aging procedures under controlled temperature and electrical load conditions, typically running continuously for 8 to 24 hours. This process helps identify early-life failures, ensures stable performance, and verifies the durability of LEDs, drivers, and solder joints before shipment. The aging test area is fully monitored, with real-time data logging to support traceability and continuous process improvement.

Beauty STC has robust OEM (Original Equipment Manufacturing) capabilities, particularly tailored for customized LED light strip shelves—integrated lighting solutions designed for display cabinets, retail shelving, under-cabinet applications, and architectural lighting. The company works closely with clients to develop bespoke designs, including custom PCB layouts, light output specifications (color temperature, CRI, brightness), mechanical dimensions, power options (AC/DC, low voltage), and physical form factors such as flexible strips with adhesive backing, aluminum profiles, or integrated diffusers. The OEM process includes design support, prototyping, compliance testing (CE, RoHS, UL, etc.), and full-scale production, all managed in-house to ensure speed, confidentiality, and quality.

Overall, the Jiangmen factory combines automation, strict quality control, and flexible manufacturing systems to deliver reliable, high-performance LED lighting solutions with strong support for customized OEM projects like LED light strip shelves.

Application Scenarios

LED light strip shelves serve distinct functional and aesthetic purposes across hospitality, retail, and corporate environments. In hotels, they are strategically deployed beneath floating shelves at reception desks to create a welcoming ambient glow that reinforces brand identity, within display niches in lobbies showcasing local art or premium amenities, along corridor shelves for subtle directional lighting that guides guests without harsh overheads, and under minibar shelving in guest rooms to highlight beverage selections while minimizing nighttime disturbance. The illumination must maintain consistent color temperature to avoid disrupting the serene atmosphere expected in premium accommodations.

Within malls and retail spaces, these shelves predominantly enhance product presentation. They are installed under display shelves in high-end boutiques to cast focused upward lighting on luxury goods like jewelry or cosmetics, creating visual drama against darker backdrops. Food court feature walls with integrated shelving use concealed strips to illuminate signage or decorative elements, drawing patrons toward seating areas. Department store accessory sections employ them beneath glass shelves to make handbags or sunglasses appear more vibrant, though careful thermal management is critical near heat-sensitive items. Always verify local fire codes regarding strip proximity to merchandise storage zones.

Office applications prioritize both utility and ambiance. Executive suites utilize them under floating shelves behind desks to add depth to video conference backgrounds without glare. Collaborative zones implement them beneath shelving in lounge areas to softly illuminate book collections or design prototypes, reducing eye strain during extended use. Server rooms or IT closets apply low-level strips under equipment shelves for clear component identification during maintenance, using cool white temperatures for accuracy. Avoid placing strips where direct reflection could cause screen glare in workstations.

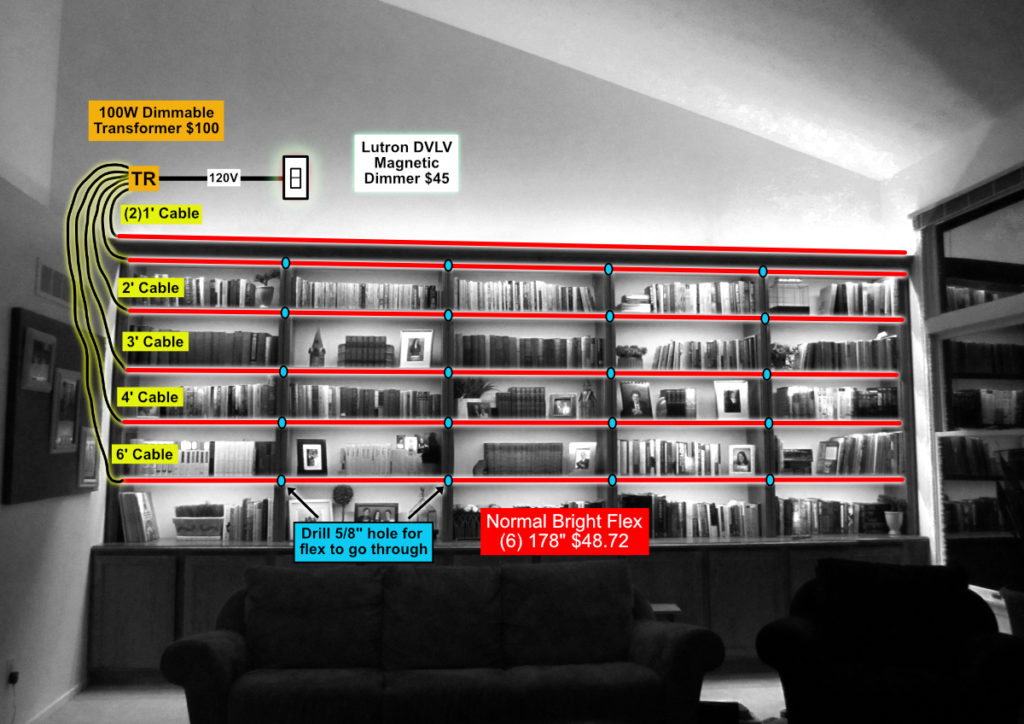

Installation requires meticulous preparation for reliability and aesthetics. Thoroughly clean and degrease shelf surfaces before applying adhesive-backed strips; isopropyl alcohol wipes prevent premature detachment. Maintain a minimum 20mm gap between the strip and shelf edge to ensure even light diffusion without hotspots. Conceal power supplies and controllers in accessible compartments behind shelves—never within enclosed spaces where heat accumulates. Route wiring through pre-drilled channels or cable management raceways before shelf assembly to avoid visible cords. Always perform a 24-hour burn-in test at full brightness before final mounting to identify early failures, and use constant voltage drivers matched precisely to the strip’s wattage to prevent flickering in commercial settings where lights operate 12+ hours daily.

Why Choose Beauty STC Lighting

Elevate your lighting experience with LED light strip shelves designed for style and functionality. Partner with Beauty STC, a trusted leader in innovative LED solutions. For collaboration opportunities and expert support, contact us at [email protected]. Let’s illuminate the future together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.