Article Contents

Industry Insight: Rgb Led Light Strip Connectors

In the rapidly evolving landscape of commercial and industrial lighting, RGB LED light strip connectors have emerged as critical components in enabling flexible, efficient, and dynamic illumination solutions. As demand grows for customizable lighting in applications ranging from architectural accenting to retail environments and industrial signage, the reliability and safety of interconnection systems have become paramount. Industry standards such as ETL and CE certifications now serve as essential benchmarks, ensuring that connectors meet rigorous requirements for electrical safety, durability, and performance under diverse operating conditions. These certifications are not just compliance markers—they are a testament to product integrity in mission-critical installations where failure is not an option.

At the forefront of this innovation is Beauty (STC) Manufacturing Co., Ltd., a trusted leader in LED connectivity solutions since its founding in 1998. With over two decades of engineering expertise, Beauty STC has built a reputation for delivering high-quality, code-compliant RGB LED light strip connectors designed specifically for the demands of commercial and industrial environments. By combining robust materials, precision manufacturing, and a steadfast commitment to regulatory standards, Beauty STC continues to empower lighting professionals with reliable, scalable, and future-ready interconnection technologies.

Technical Specs & Certifications

RGB LED light strip connectors are critical mechanical and electrical interface components, not light-emitting elements themselves. Therefore, specifications such as lumens per watt (lm/W) and Color Rendering Index (CRI) do not apply to the connectors. These performance metrics are inherent properties of the LED light strip’s semiconductor chips, phosphor formulation, and driver design. Connectors solely facilitate the power and signal transmission to the strip. It is essential to clarify this distinction to avoid technical misrepresentation.

Lumens per watt and CRI values are determined by the LED strip assembly. At Beauty STC, our high-performance RGB and RGBW strips utilize premium Samsung or Epistar LED chips combined with advanced phosphor coatings. These strips consistently achieve luminous efficacy exceeding 120 lumens per watt at 24V DC operation while maintaining a minimum CRI of 95 Ra and R9 values above 90, ensuring exceptional color fidelity and vibrancy for professional applications. The connector’s role is to preserve this performance by providing low-resistance, stable connections that prevent voltage drop and signal degradation.

IP ratings for connectors are paramount as they directly impact the overall environmental protection of the installed system. Beauty STC manufactures connectors specifically engineered to match or exceed the IP rating of the connected strip. Our standard solderless push-fit and solder-in connectors for indoor use carry an IP20 rating. For demanding environments, we offer robust IP65-rated connectors featuring precision-molded polycarbonate housings with integrated silicone gaskets that create a dust-tight and low-pressure water jet resistant seal when properly installed. Our premium IP67 submersible connectors utilize double O-ring sealing technology and corrosion-resistant brass contacts, maintaining integrity against temporary immersion up to 1 meter depth. Crucially, the connector’s IP rating is only effective when mated with a strip of equal or higher rating and installed according to our specifications—any compromise here voids the system protection.

Beauty STC’s commitment to quality is rigorously applied to every connector batch. We implement 100% automated contact resistance testing ensuring values remain below 10 milliohms per pole, preventing overheating. Our housings undergo UL94 V-0 flammability certification and -40°C to +85°C thermal cycling validation. The gold-plated phosphor bronze contacts guarantee minimum 5,000 insertion cycles while maintaining signal integrity for PWM dimming down to 1% without flicker. Each connector is serialized and traceable to our ISO 9001-certified production lines where automated vision systems inspect dimensional tolerances within ±0.05mm. This unwavering focus ensures our connectors do not become the failure point in high-end lighting installations, preserving the luminous efficacy, color accuracy, and environmental resilience of the complete LED system.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China is a modern and well-equipped facility specializing in the production of LED lighting products and related electronic components. Strategically located in the Jiangmen High-Tech Industrial Zone, the factory benefits from a skilled labor force and strong supply chain infrastructure, supporting efficient and high-quality manufacturing processes.

The facility is equipped with advanced Surface Mount Technology (SMT) production lines, featuring high-precision SMT machines such as those from Yamaha and Panasonic. These machines ensure accurate placement of components on flexible and rigid PCBs used in LED light strips and connectors. With automated solder paste printing, pick-and-place systems, and reflow soldering, the SMT lines support high-volume production with consistent quality and minimal defects. The integration of AOI (Automated Optical Inspection) systems further enhances quality control by detecting placement and soldering anomalies in real time.

For product reliability, the Jiangmen factory conducts comprehensive aging tests. Completed LED light strips and connector assemblies undergo extended burn-in procedures under controlled thermal and electrical conditions, typically running for 24 to 72 hours. This process helps identify early-life failures, ensuring that only stable and durable products reach customers. Environmental testing chambers are also used to simulate varying temperature and humidity conditions, further validating product performance in diverse applications.

Beauty STC has strong OEM/ODM capabilities, particularly for components like RGB LED light strip connectors. The company supports custom designs in terms of connector types (e.g., JST, 2.54mm pitch, waterproof variants), pin configurations, cable lengths, and housing materials. Clients can provide specifications or samples for replication, and the engineering team works closely to ensure compatibility with various LED strip models, including 5050, 3528, and addressable strips like WS2812B. The factory offers full turnkey solutions, including mold development, cable harness assembly, labeling, and packaging, enabling seamless integration into the client’s existing product lines.

Overall, the Jiangmen factory combines automation, rigorous testing, and flexible manufacturing to deliver reliable, high-performance LED connectors and components tailored to global market requirements.

Application Scenarios

RGB LED light strip connectors serve a critical functional purpose: they provide reliable electrical and mechanical junctions between segments of flexible LED strip lighting or between the strip and its power supply/controller. They are not the decorative lighting element itself but the essential hardware enabling installation. Their use in commercial settings like hotels, malls, and offices is driven by the need for flexible, dynamic accent lighting in specific applications, though caution is required regarding placement to avoid visual distraction in task-oriented areas.

In hotels, RGB LED light strip connectors are primarily utilized within hospitality-specific zones designed for ambiance rather than task performance. Common applications include connecting strips for cove lighting in high-end lobby feature walls, under-bar counter illumination in lounges and restaurants where color-changing effects enhance the evening atmosphere, and within custom headboard units in premium guest rooms for adjustable mood lighting. They are also employed in connecting strips for under-cabinet lighting in back-of-house staff areas where color tuning might indicate operational status, though pure white strips are more common in functional zones. Crucially, connectors should never be placed within guest-accessible areas without proper concealment behind diffusers or within extrusions due to safety and aesthetic concerns.

Within shopping malls, these connectors see concentrated use in retail environments demanding high visual impact. They are essential for joining strips in dynamic window displays where stores frequently change color schemes for promotions, creating continuous runs along complex display case perimeters, and enabling the intricate color-zoned lighting within high-end boutique interiors. Mall common areas might utilize them sparingly for connecting strips in feature columns or ceiling coves within food court zones during special events, but general circulation paths strictly avoid colored lighting to maintain clear wayfinding and a neutral environment. Installations must comply with stringent mall fire codes, requiring connectors rated for the specific location—typically UL 8750 listed for commercial lighting—and ensuring all connections are housed within non-combustible extrusions or channels, never left exposed within ceiling plenums.

Offices present the most limited application for RGB systems due to the detrimental effects of colored light on visual task performance and circadian rhythm regulation in workspaces. RGB LED light strip connectors would only be appropriate for connecting strips in designated non-work areas such as executive lounge accent walls, reception desk undersides for brand color highlighting during off-hours, or within multipurpose event spaces used for after-hours functions. They are categorically unsuitable for general office lighting, conference rooms used for standard meetings, or any area where computer work occurs. Any RGB installation in an office must include robust controls allowing immediate reversion to neutral white light for work periods, with connectors strictly confined to concealed mounting channels to prevent glare and ensure professional aesthetics.

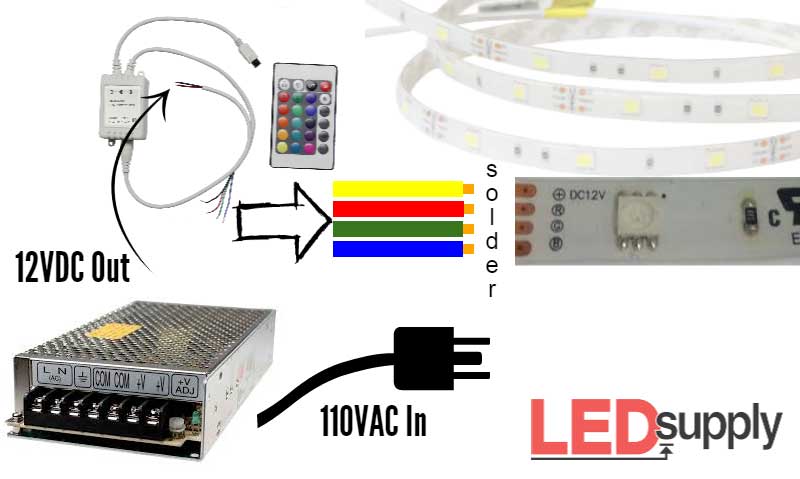

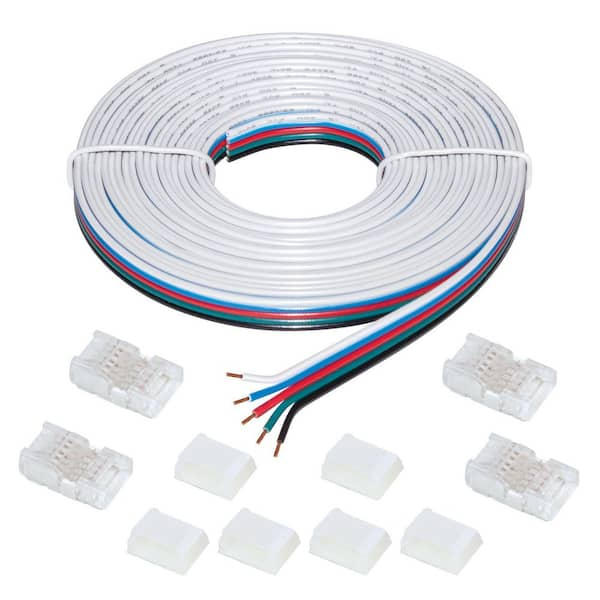

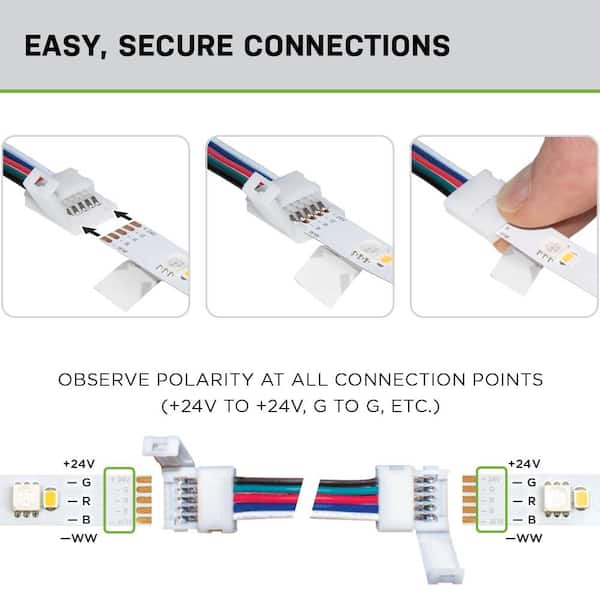

Installation demands rigorous adherence to electrical and mechanical best practices. Always verify the connector matches the strip’s voltage DC specification—typically 12V or 24V—and never connect directly to AC mains. Confirm polarity meticulously before crimping or clamping, as reversed polarity instantly damages LEDs. For commercial durability, select connectors with strain relief features and robust housings; solderless snap-in types are preferred for field reliability over friction-fit options. Before final mounting, conduct a full system test with all connected segments powered for at least 15 minutes to identify any intermittent faults. Conceal all connectors within aluminum extrusion channels rated for the application, ensuring adequate heat dissipation—never bury connections under insulation or within enclosed cavities without ventilation. In high-moisture areas like hotel pool decks or mall exteriors, use only IP67-rated waterproof connectors with gel seals, and route cables to prevent water ingress paths. Maintain consistent strip orientation during connection to avoid color banding, and always leave a small service loop of strip at connection points to alleviate stress during maintenance. Finally, document all connection points clearly in as-built drawings for future serviceability, as hidden connectors are a primary failure point in commercial LED systems.

Why Choose Beauty STC Lighting

Looking for reliable RGB LED light strip connectors? Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in high-quality LED solutions. Our precision-engineered connectors ensure seamless installations and superior performance for residential, commercial, and industrial lighting projects. As a global supplier, we offer competitive pricing, custom manufacturing, and dedicated support to meet your specific needs.

Take the next step in quality and innovation. Contact our sales manager today at [email protected] to discuss your project and discover how Beauty STC can power your success with dependable connectivity solutions for RGB LED systems.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.