Article Contents

Industry Insight: Rgbww Strip

The commercial and industrial lighting sector is undergoing a significant transformation, driven by the demand for intelligent, adaptable, and human-centric illumination solutions. Traditional static lighting is increasingly giving way to dynamic systems capable of enhancing productivity, safety, ambiance, and energy efficiency across diverse environments – from retail displays and hospitality venues to warehouses, manufacturing floors, and healthcare facilities. At the forefront of this evolution is the RGBWW LED strip, a sophisticated technology merging full-color RGB capabilities with independently controllable warm white (2700K-3000K) and cool white (4000K-6500K) channels. This unique configuration transcends basic color changing, enabling precise tuning of both hue and white light temperature to match specific tasks, time of day, or desired atmospheric effects, a critical requirement for modern commercial applications where lighting directly impacts occupant well-being and operational outcomes. Crucially, for any product deployed in professional settings, adherence to stringent safety and performance standards is non-negotiable. Commercial-grade RGBWW strips must reliably carry recognized certifications such as ETL (verifying compliance with North American safety standards through Electrical Testing Laboratories) and CE (indicating conformity with European health, safety, and environmental regulations), ensuring they meet the rigorous safety benchmarks demanded by building codes, insurance requirements, and responsible facility management. Beauty STC Manufacturing Co., Ltd., established in 1998, has been a dedicated force within this demanding landscape. For over two decades, we have focused exclusively on engineering and manufacturing high-performance, specification-grade LED lighting solutions, including advanced RGBWW strip systems, built to the exacting standards required by commercial and industrial clients worldwide who prioritize reliability, performance, and certified safety in their lighting infrastructure.

Technical Specs & Certifications

The RGBWW LED strip from Beauty (STC) Manufacturing Co., Ltd. is engineered for high-performance color tuning and superior white light quality, combining red, green, blue, warm white (3000K), and cool white (6000K) diodes in a single flexible strip. This configuration enables precise color mixing and smooth transitions across the full spectrum while delivering exceptional quality white light with excellent color rendering.

In terms of efficiency, the RGBWW strip achieves a luminous efficacy of up to 95 lumens per watt, depending on the color mode and drive current. When operating in white light modes—particularly in blended warm or cool white—the efficacy remains high, typically ranging from 85 to 95 lumens per watt, making it suitable for both ambient and functional lighting applications where energy efficiency is critical.

A defining feature of Beauty STC’s RGBWW strip is its high Color Rendering Index (CRI), consistently exceeding 90 (Ra >90), with extended spectral coverage (R9 >50) to ensure vibrant reds and natural color reproduction. This is achieved through the inclusion of high-CRI warm and cool white LEDs, carefully selected and binned to maintain color consistency across production batches. The dual white channels allow for tunable white temperatures from 3000K to 6000K, enabling dynamic lighting scenes with accurate color fidelity.

Regarding environmental protection, Beauty STC offers the RGBWW strip in multiple IP-rated configurations to suit diverse installation environments. The standard non-encapsulated version is rated IP20, suitable for dry indoor use. For damp or outdoor applications, the strip is available with silicone coating (IP65), providing protection against dust and low-pressure water jets. Fully encapsulated versions are rated IP67 or IP68, offering submersion resistance (up to 1 meter for 30 minutes for IP67, and longer durations for IP68), making them ideal for outdoor signage, architectural cove lighting, or marine environments.

Beauty (STC) Manufacturing Co., Ltd. is recognized for its stringent quality control and adherence to international standards. All RGBWW strips are manufactured using high-grade Epitex and Samsung LEDs, with 5-layer PCBs for improved thermal management and longevity. Each batch undergoes rigorous testing for color consistency, lumen output, and electrical performance, ensuring reliability and long service life exceeding 50,000 hours at L70. With UL, CE, and RoHS certifications, Beauty STC’s RGBWW strips reflect a commitment to safety, sustainability, and premium performance in professional lighting applications.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, China represents a significant and modern production hub for the company, specifically engineered for high-volume, precision LED lighting manufacturing. The Jiangmen factory is a purpose-built facility designed to stringent international quality and environmental standards, featuring optimized production flow, clean room environments for critical processes, and comprehensive in-house capabilities spanning from component procurement through to final assembly and testing. This strategic location provides efficient logistics access within the Pearl River Delta region, supporting both domestic and global export demands.

The Surface Mount Technology (SMT) production line within the Jiangmen factory is a cornerstone of our manufacturing capability. We operate multiple high-speed, high-precision Yamaha YS series SMT lines, including models such as the YSM20 and YSM10. These machines are capable of placing components down to the 0201 metric package size with exceptional accuracy, essential for densely populated LED strip PCBs. The lines are fully integrated, incorporating automatic solder paste screen printers, nitrogen-reflow soldering ovens for superior joint reliability, and multiple automated optical inspection (AOI) stations. This setup ensures consistent, high-yield placement of LEDs, resistors, capacitors, and integrated circuits onto flexible and rigid PCBs, forming the foundation for all our strip products, including complex multi-channel types.

Rigorous aging and reliability testing are non-negotiable elements of our quality control system at the Jiangmen site. We maintain extensive dedicated aging chambers capable of simultaneously testing large volumes of finished LED strips under controlled thermal and electrical stress. Standard aging protocols involve continuous operation at elevated temperatures, typically 45°C, for durations of 48 to 72 hours, significantly exceeding basic industry norms. Every single RGBWW strip produced undergoes this 100% burn-in test. Parameters meticulously monitored during aging include forward voltage stability, lumen maintenance, chromaticity shift across all white and color channels, and overall circuit integrity. This exhaustive process identifies early-life failures and ensures only units meeting our stringent performance and longevity criteria are shipped to customers.

Our OEM capability for RGBWW LED strips is a core strength developed and executed at the Jiangmen factory. We offer comprehensive turnkey solutions where clients can define virtually every aspect of the product. This encompasses custom PCB design and layout for specific densities, lengths, and cut points, selection of premium LED packages from trusted suppliers like Epistar or Samsung, integration of specific driver ICs such as the popular WS2812B or equivalent alternatives supporting the RGBWW configuration, and tailored optical solutions like varying silicone encapsulation profiles for beam control. We handle custom programming of control protocols, unique labeling, specific reel packaging, and even bespoke carton design. The Jiangmen facility supports seamless transition from prototype development through to high-volume mass production, backed by our robust SMT lines and quality systems, ensuring consistent delivery of client-branded RGBWW strips that meet exact performance, aesthetic, and reliability specifications. This full OEM service is underpinned by our ISO 9001 certified quality management system implemented throughout the Jiangmen operation.

Application Scenarios

RGBWW LED strips are versatile lighting solutions that combine red, green, blue, warm white, and cool white diodes in a single strip. This configuration allows for precise color tuning and dynamic white light adjustment, making them ideal for environments where ambiance, functionality, and aesthetics are critical. Below is a breakdown of where they are best used and important installation tips.

In hotels, RGBWW strips are excellent for creating mood lighting in guest rooms, lobbies, hallways, and premium suites. They allow hotel operators to adjust lighting from warm, relaxing tones in the evening to cooler, energizing tones in the morning. Accent lighting behind headboards, under cabinets, or along cove ceilings enhances the sense of luxury. In hospitality areas like bars or lounges, dynamic color transitions can support branding or special events.

Malls benefit from RGBWW strips in signage, display windows, and architectural coving. The ability to shift from warm to cool white light helps highlight different products—warm for textiles and lifestyle goods, cool for electronics or cosmetics. Color-changing capabilities can be used during seasonal promotions or holidays to create visual interest and attract foot traffic. Corridor and staircase lighting with soft, tunable white light improves wayfinding while maintaining a modern aesthetic.

In offices, especially modern or creative workspaces, RGBWW strips can be used for indirect lighting in drop ceilings, under desks, or in breakout areas. While full color use should be limited in focused work zones to avoid distraction, the tunable white feature is valuable—cooler white (5000K–6500K) can boost alertness during work hours, while warmer tones (2700K–3000K) can be used in relaxation areas or at the end of the day. This supports circadian lighting principles and enhances occupant well-being.

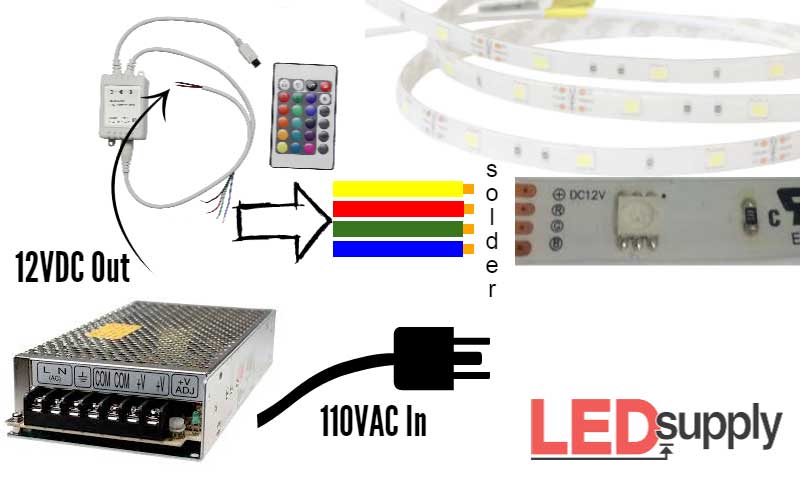

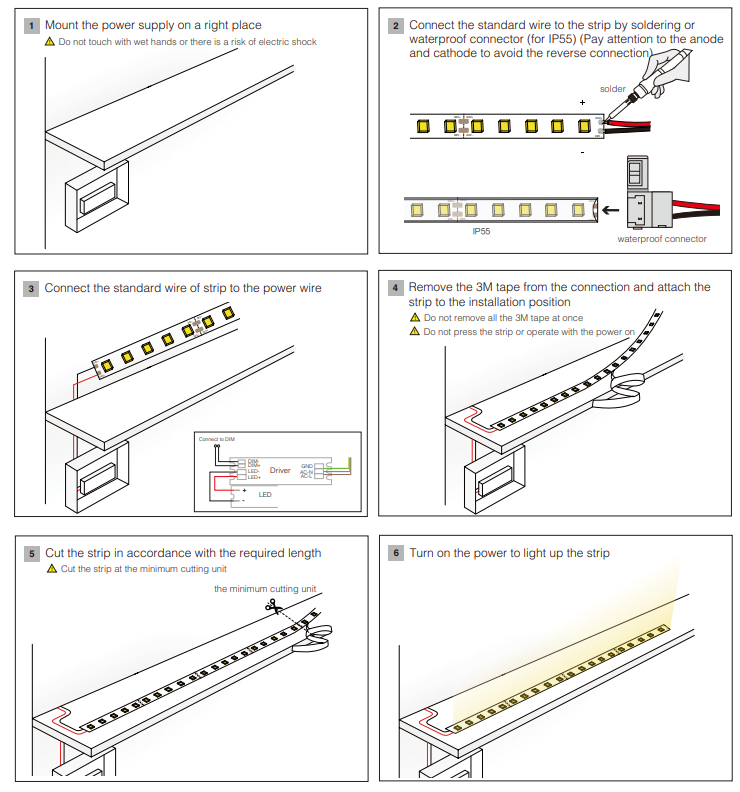

For installation, ensure the strip is mounted on a clean, dry, and flat surface. Use aluminum channels whenever possible to improve heat dissipation, extend LED life, and provide a clean, professional finish. Always follow the manufacturer’s recommended maximum run length to avoid voltage drop, especially with longer installations. Use a constant voltage power supply matched to the strip’s voltage (typically 12V or 24V) and ensure adequate power headroom—typically 20% more than the calculated load.

Connect the strip using proper connectors or soldered joints, and avoid sharp bends—maintain the minimum bending radius specified by the manufacturer. Waterproof versions should be used in high-humidity areas or outdoor sections. Use a compatible RGBWW controller (either DMX, DALI, or a dedicated app-based system) to fully utilize the color and white tuning features. Ensure proper grounding and use low-voltage wiring practices to maintain safety and compliance.

Finally, label control zones clearly, especially in large installations, to simplify maintenance and operation. Test the system thoroughly before final concealment or commissioning. With proper planning and installation, RGBWW strips offer a flexible, energy-efficient lighting solution that enhances both function and atmosphere across diverse commercial environments.

Why Choose Beauty STC Lighting

Elevate your lighting projects with Beauty STC’s premium RGBWW LED strip solutions engineered for precision color tuning and seamless integration. Partner with Beauty STC to access industry-leading quality, customizable technical support, and scalable manufacturing capabilities tailored to your specific application needs. Reach out today to discuss how our advanced RGBWW technology can enhance your product offerings and drive your business forward. Contact our dedicated partnership manager at [email protected] to initiate a collaboration that delivers exceptional performance and reliability.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.