Article Contents

Industry Insight: Led Diffuser Tape

The relentless pursuit of optimal visual environments in commercial and industrial settings has placed immense focus on the quality of LED illumination. While LEDs offer significant energy savings and longevity, their inherent point-source nature often creates harsh glare and uneven light distribution, detrimental to productivity, safety, and occupant well-being in spaces like warehouses, retail floors, offices, and manufacturing facilities. This challenge has propelled LED diffuser tape from a niche component to a critical enabler of high-performance lighting design. Effectively transforming intense point sources into smooth, uniform, and shadow-free illumination, modern diffuser tapes are essential for achieving the professional aesthetics and functional light quality demanded by architects, engineers, and facility managers. Crucially, specification in these demanding environments mandates strict adherence to safety and performance standards, making ETL certification for North American markets and CE marking for Europe non-negotiable requirements to ensure electrical safety, reliability, and regulatory compliance. Beauty STC Manufacturing Co., Ltd., established in 1998, leverages over two decades of specialized optical engineering expertise to develop and manufacture precision LED diffuser solutions precisely calibrated for the rigorous demands of commercial and industrial applications, where performance, consistency, and certified safety are paramount. Our commitment lies in providing the foundational optical components that empower lighting professionals to deliver superior, code-compliant illuminated environments.

Technical Specs & Certifications

LED diffuser tape from Beauty (STC) Manufacturing Co., Ltd. is engineered to deliver high-performance illumination with exceptional optical clarity and uniform light distribution. These tapes are designed for seamless integration into architectural, commercial, and high-end residential lighting applications where both aesthetic appeal and technical reliability are critical.

In terms of efficiency, Beauty STC’s LED diffuser tapes achieve a luminous efficacy ranging from 100 to 130 lumens per watt, depending on the specific configuration and LED density. This high efficiency ensures optimal energy consumption without compromising brightness, making the tapes ideal for sustainable lighting solutions. The light output is consistently uniform along the length of the tape, thanks to precision placement of high-quality SMD LEDs—typically 2835 or 5050 types—combined with advanced diffuser materials that minimize hotspots and provide a smooth, continuous glow.

Color rendering is a key strength of Beauty STC’s diffuser tapes. All premium-grade variants are rated with a Color Rendering Index (CRI) greater than 90, with some models reaching CRI Ra >95. This ensures accurate and natural color representation, which is essential in retail, hospitality, and display environments where visual fidelity is paramount. The high CRI is achieved through the use of phosphor-converted white LEDs and tight binning controls during manufacturing, ensuring minimal variance in color temperature across production batches.

Regarding environmental protection, Beauty STC offers LED diffuser tapes in multiple IP rating configurations to suit diverse installation conditions. IP20-rated tapes are suitable for dry, indoor environments, while IP65 and IP67-rated versions provide robust protection against dust and moisture, making them appropriate for damp locations, outdoor coves, or even semi-exposed architectural features. The higher IP-rated tapes feature silicone encapsulation or extruded polycarbonate diffusers that maintain optical performance while safeguarding the internal circuitry from ingress.

Beauty STC’s commitment to quality is evident in every stage of production. The company adheres to strict ISO 9001 quality management standards and conducts rigorous in-house testing for thermal performance, lumen maintenance (L70 >50,000 hours), and electrical safety. Components are sourced from trusted global suppliers, and each batch undergoes aging and photometric testing to ensure long-term reliability and consistent performance. With superior materials, precision engineering, and comprehensive quality control, Beauty STC’s LED diffuser tapes stand out as a trusted solution for demanding lighting applications worldwide.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, serves as a key production hub for our LED lighting solutions, strategically positioned within the Pearl River Delta for efficient logistics and access to skilled labor. The factory is modern, ISO 9001 certified, and designed specifically for high-volume, precision LED assembly with stringent quality control protocols integrated throughout the production flow.

Our surface mount technology (SMT) line forms the core of PCB assembly for LED products. It features multiple high-speed Yamaha YS series placement machines, including models like the YSM20 and YSM10, capable of handling ultra-fine pitch components down to 0201 metric size and complex LED packages. These machines operate at speeds exceeding 100,000 components per hour while maintaining exceptional placement accuracy, critical for dense LED arrays and miniature drivers. The line is supported by advanced automated optical inspection (AOI) systems after placement and solder paste printing, alongside nitrogen-reflow soldering using Heller ovens to ensure void-free, high-reliability solder joints essential for thermal management in LED applications. This SMT capability allows us to efficiently produce the complex driver and LED module PCBs required for various lighting products, including flexible strips.

Rigorous aging and reliability testing are non-negotiable at our Jiangmen facility. We operate a dedicated aging test area equipped with multiple large-scale environmental chambers capable of continuous operation. Finished LED products, particularly strips and modules, undergo mandatory burn-in tests at elevated temperatures, typically 60-70°C, for a minimum of 24 hours, though 48-72 hour cycles are standard for premium lines and customer-specific requirements. These chambers incorporate real-time monitoring systems that track and log critical parameters like forward voltage, current draw, and luminous output throughout the aging period. Any units exhibiting parameter drift beyond our tight tolerances or failure during this extended stress test are automatically rejected, ensuring only units with proven early-life reliability reach customers. This process significantly reduces infant mortality rates in the field.

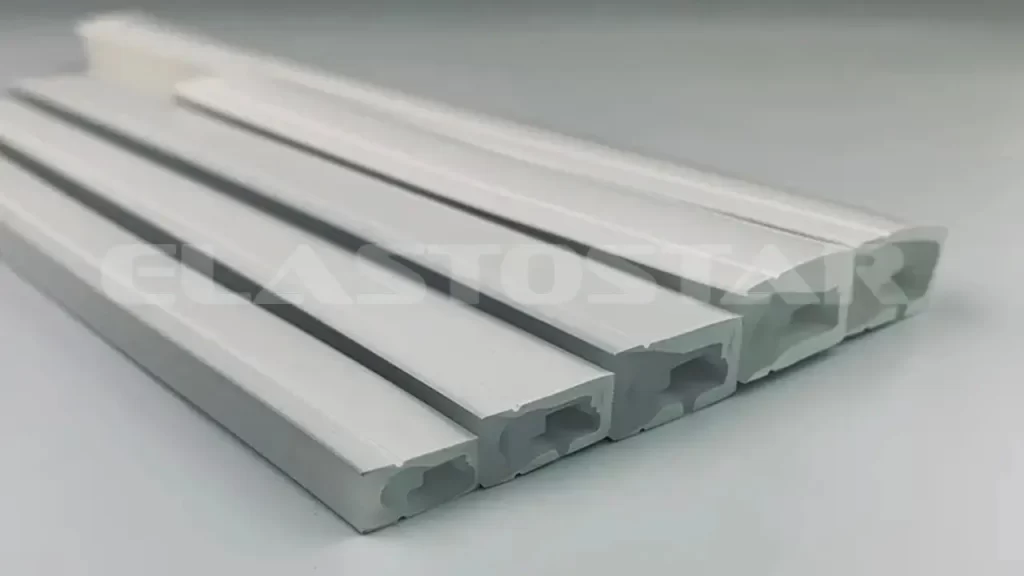

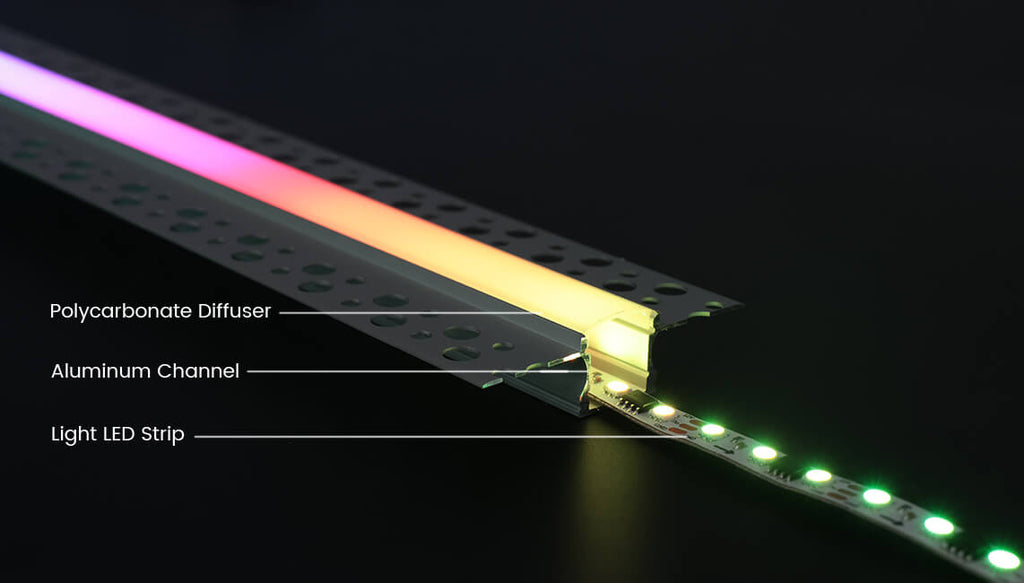

Regarding OEM capability for ‘LED diffuser tape’, it’s important to clarify terminology. The industry standard term is typically ‘LED strip lights’ or ‘flexible LED tape’, often incorporating a diffuser lens or cover. Beauty STC possesses extensive, proven OEM/ODM capability specifically for flexible LED strip lights, including comprehensive diffuser integration. We manufacture a wide range of customizable strips where the diffuser element is a critical component. Our Jiangmen factory can produce strips with various diffuser types including polycarbonate (PC) milky white or clear lenses, silicone jackets, and frosted PVC sleeves, tailored to specific beam angle and homogeneity requirements. We handle full OEM customization: clients can specify LED density (e.g., 30, 60, 120 LEDs/meter), LED type (2835, 3528, 5050, COB), color temperature, CRI, input voltage (DC12V, DC24V, AC120V/230V), cuttable lengths, connector types, adhesive backing, and IP rating (from IP20 to IP68). Our SMT lines and assembly processes are fully adaptable for low to high-volume OEM runs, supported by our in-house engineering for prototyping, final validation including the mandatory aging tests described, and full private labeling. We routinely produce these flexible LED strip products with integrated diffusers to exact client specifications for global lighting brands.

Application Scenarios

LED diffuser tape is widely used in commercial and hospitality environments such as hotels, malls, and offices due to its ability to create smooth, uniform lighting without visible hotspots or individual LED dots. It is ideal for applications where aesthetics and ambient lighting quality are critical.

In hotels, LED diffuser tape is commonly installed in cove lighting along ceilings, under cabinets in lobbies or bars, within recessed architectural features, and in guest room headboards or wardrobes. It enhances the ambiance with a soft, even glow that contributes to a luxurious and welcoming environment. In hallways and staircases, it provides subtle yet effective illumination for both safety and design.

In malls and retail spaces, diffuser tape is frequently used in coves, display niches, signage backlighting, and shelving. It helps highlight merchandise while maintaining a clean and modern visual appeal. The even light distribution ensures products are displayed attractively without harsh shadows or glare.

In offices, LED diffuser tape is often integrated into suspended ceiling coves, partition lighting, under desks or shelves, and in reception areas. It supports a professional and comfortable atmosphere, reducing eye strain and contributing to a well-lit workspace without the harshness of direct lighting.

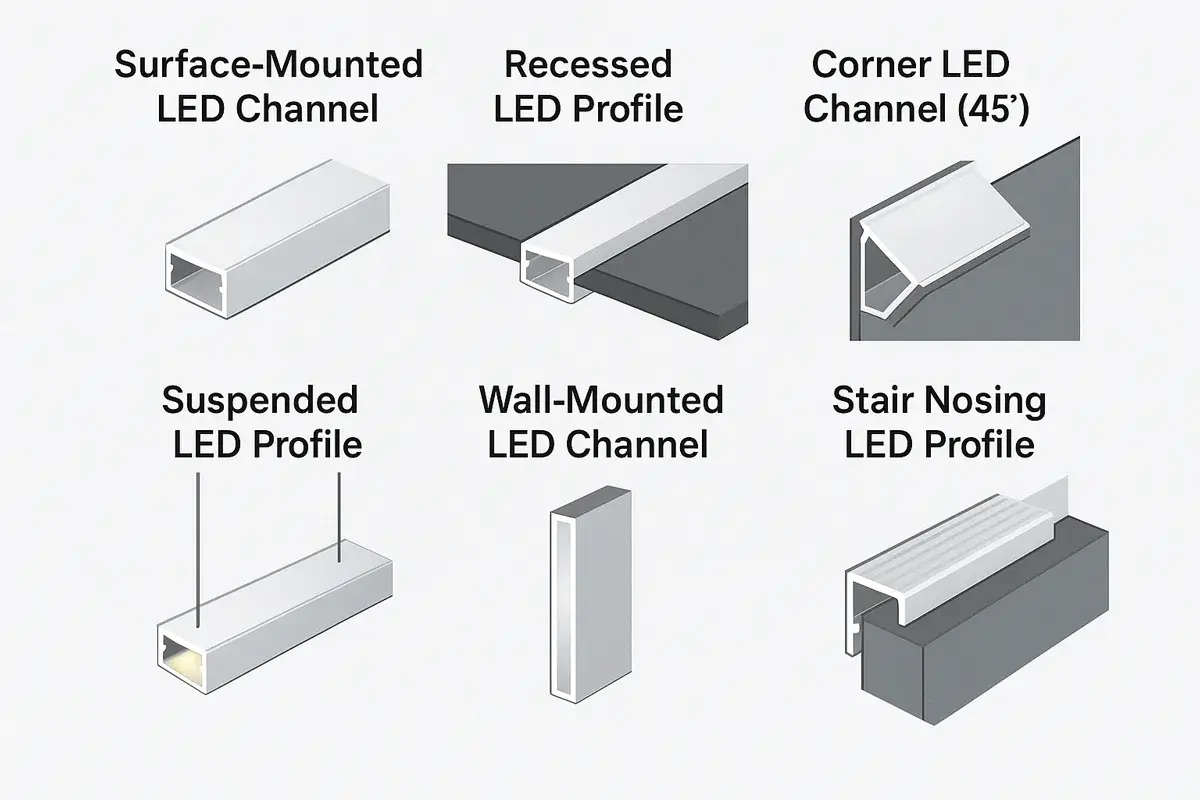

For successful installation, ensure the mounting surface is clean, dry, and free of dust or grease to promote strong adhesion. Always install the diffuser tape over compatible LED strips—typically 5050 SMD or similar high-density strips—and make sure the tape is cut only at designated cut points to avoid damaging the circuitry. Use aluminum channels whenever possible, as they not only protect the strip and diffuser but also improve heat dissipation and enhance light diffusion. Secure connections with proper waterproof or insulated connectors if required, and avoid sharp bends or tight curves that could crack the LEDs or diffuser. Finally, test the lighting before finalizing the installation to confirm uniformity and brightness across the entire run.

Why Choose Beauty STC Lighting

Elevate your lighting projects with Beauty STC’s premium LED diffuser tape, engineered to deliver seamless, uniform illumination without visible hotspots or banding. Our advanced optical materials ensure optimal light diffusion for architectural cove lighting, display cases, and high-end retail environments where precision matters. Partner with Beauty STC to integrate this critical component into your next design—leveraging our 15+ years of expertise in optical engineering and rigorous quality control. Contact our technical team directly at [email protected] to discuss custom solutions, volume pricing, and how our diffuser tape can solve your specific installation challenges. Let us help you achieve flawless light quality while reducing assembly time and material waste. Reach out today to start a collaboration built on engineering excellence.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.