Article Contents

Industry Insight: Neon Flex

The commercial and industrial lighting landscape continues to evolve rapidly, driven by demands for energy efficiency, design flexibility, and durable solutions that deliver long-term value. Within this dynamic market, LED neon flex has emerged as a transformative technology, moving decisively beyond its decorative origins to become a serious contender for mainstream architectural, signage, and task lighting applications in demanding environments. Its unique combination of soft, uniform illumination, exceptional bendability for complex installations, low voltage operation, and robust performance characteristics addresses critical pain points for facility managers, architects, and contractors seeking versatile yet reliable lighting. However, the transition from novelty to trusted commercial solution hinges significantly on rigorous adherence to safety and performance standards.

For any lighting product deployed in commercial or industrial settings, compliance with recognized safety certifications is non-negotiable. ETL listing to UL standards in North America and CE marking for the European market are fundamental requirements, assuring end-users, specifiers, and authorities having jurisdiction that the neon flex product has undergone independent testing and meets stringent criteria for electrical safety, fire resistance, and operational reliability. Failure to provide properly certified neon flex solutions introduces significant liability risks and project delays, making certification a primary filter for professional buyers evaluating suppliers. The commercial sector demands products engineered from the outset for real-world installation demands and longevity, not just aesthetic appeal.

Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of this evolution in flexible LED lighting. With over 25 years of dedicated expertise in LED technology and manufacturing, we understand the exacting requirements of commercial and industrial projects. Beauty STC specializes in developing and producing high-performance, rigorously tested neon flex solutions designed specifically for professional applications. Our commitment to engineering excellence ensures that every meter of neon flex we manufacture not only meets but consistently exceeds ETL and CE certification requirements, providing specifiers and installers with the confidence that the product will perform safely and reliably throughout its extended service life in demanding environments. We bridge the gap between innovative lighting design and the uncompromising standards demanded by the commercial and industrial sectors.

Technical Specs & Certifications

Neon Flex by Beauty (STC) Manufacturing Co., Ltd. is engineered to deliver high-performance, flexible LED lighting solutions ideal for architectural, commercial, and decorative applications. Our Neon Flex products are designed with precision to ensure optimal efficiency, color fidelity, and durability.

In terms of energy efficiency, Beauty STC’s Neon Flex achieves a luminous efficacy ranging from 90 to 110 lumens per watt, depending on the color temperature and configuration. This high lumens-per-watt ratio ensures reduced power consumption while maintaining bright, consistent illumination, making it an energy-efficient alternative to traditional neon and other linear lighting systems.

Color Rendering Index (CRI) is a critical performance metric for applications requiring accurate color representation. Beauty STC’s Neon Flex exceeds industry standards with a CRI greater than 90, and select high-CRI variants reach up to 95. This ensures vibrant, true-to-life color rendering, which is particularly important in retail environments, hospitality spaces, and art installations where visual quality is paramount.

Regarding environmental protection and durability, Beauty STC offers Neon Flex in multiple IP (Ingress Protection) ratings to suit diverse installation conditions. Standard models are available in IP65 for protection against dust and low-pressure water jets, suitable for covered outdoor or damp indoor environments. For fully outdoor or washdown applications, we provide IP67-rated Neon Flex, which is dust-tight and capable of withstanding temporary immersion in water up to 1 meter for 30 minutes. These robust ratings ensure long-term reliability in challenging environments.

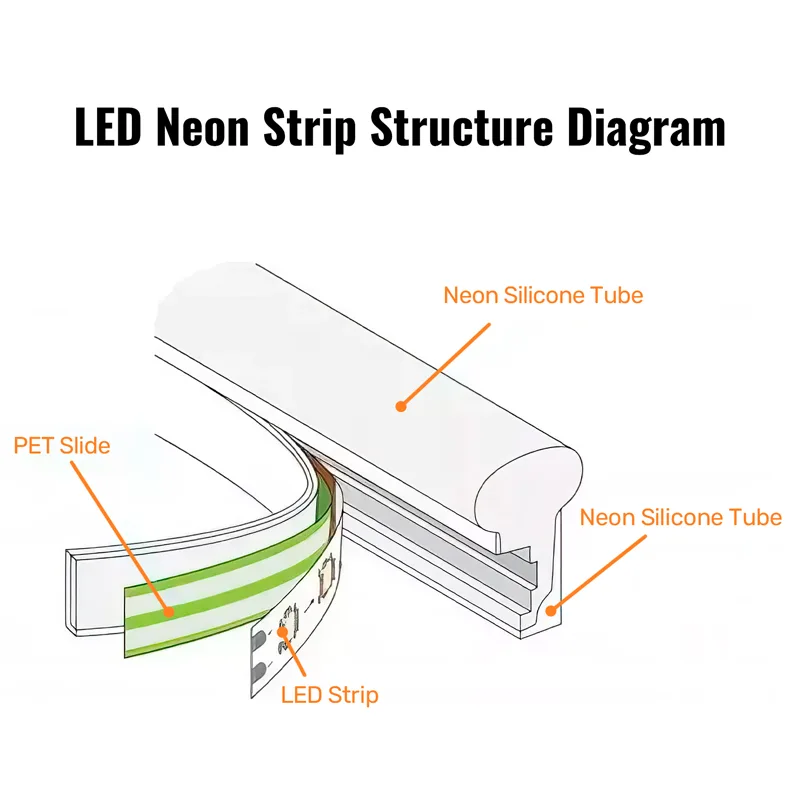

Beauty STC maintains rigorous quality control throughout the manufacturing process, utilizing high-grade silicone jackets, precision-mounted LED chips on flexible PCBs, and advanced diffusers to eliminate pixelation and ensure uniform glow. Our Neon Flex products undergo extensive testing for thermal management, UV resistance, and mechanical flexibility, confirming compliance with international safety and performance standards. With consistent color consistency, long lifespan (L70 >50,000 hours), and superior build quality, Beauty STC’s Neon Flex stands out as a premium choice for demanding lighting projects worldwide.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a dedicated LED lighting production facility in Jiangmen, Guangdong Province, specifically engineered for high-volume, precision manufacturing of flexible LED products including our core ‘neon flex’ lines. The factory spans over 15,000 square meters and integrates advanced surface mount technology with rigorous quality control systems under an ISO 9001-certified framework.

Our SMT production lines are centered around multiple high-speed Yamaha YS series machines configured in dual-lane setups, capable of placing components as small as 0201 metric package sizes with ±25μm placement accuracy. These lines handle the precise assembly of LED chips, resistors, and ICs onto flexible printed circuits for neon flex strips, operating at peak speeds of 85,000 components per hour per line. Each machine integrates automated optical inspection (AOI) systems that perform real-time solder joint and component alignment verification, ensuring minimal defects before the curing stage. The SMT车间 maintains strict environmental controls with temperature stabilized at 23±2°C and humidity at 45±5% RH to prevent moisture-related issues during assembly.

Aging tests are conducted in dedicated environmental chambers where every neon flex batch undergoes mandatory 24-hour continuous operation at 50°C and 80% rated voltage. This accelerated life testing identifies early failures through automated monitoring of current draw and luminance stability. Units exhibiting >5% lumen depreciation or electrical variance are automatically quarantined for root-cause analysis. For premium OEM projects, we implement extended 48-hour aging cycles with step-stress testing up to 60°C, followed by manual visual inspection for color consistency and silicone integrity under controlled lighting conditions.

Our OEM capability for ‘neon flex’ encompasses full turnkey solutions from prototype to mass production. We support customizations including but not limited to bespoke color temperatures (1800K-6500K), specialized silicone diffuser profiles (round, square, or asymmetric optics), and custom PCB lengths up to 100 meters per reel. The factory maintains in-house tooling for rapid mold creation of silicone extrusions and injection-molded end caps, allowing clients to develop proprietary form factors with typical lead times of 15 days for new tooling. Minimum order quantities start at 5,000 meters for standard configurations, with flexible options down to 1,000 meters for engineered solutions. All OEM projects include IP protection agreements and co-engineering support through our Jiangmen-based R&D team for thermal management and optical optimization specific to neon flex applications.

Application Scenarios

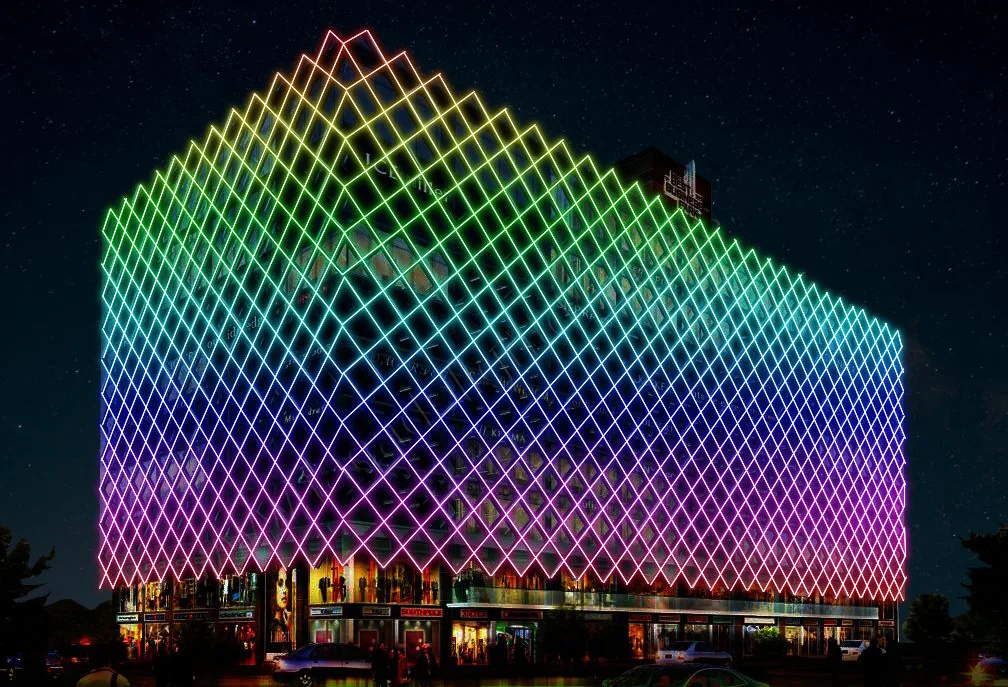

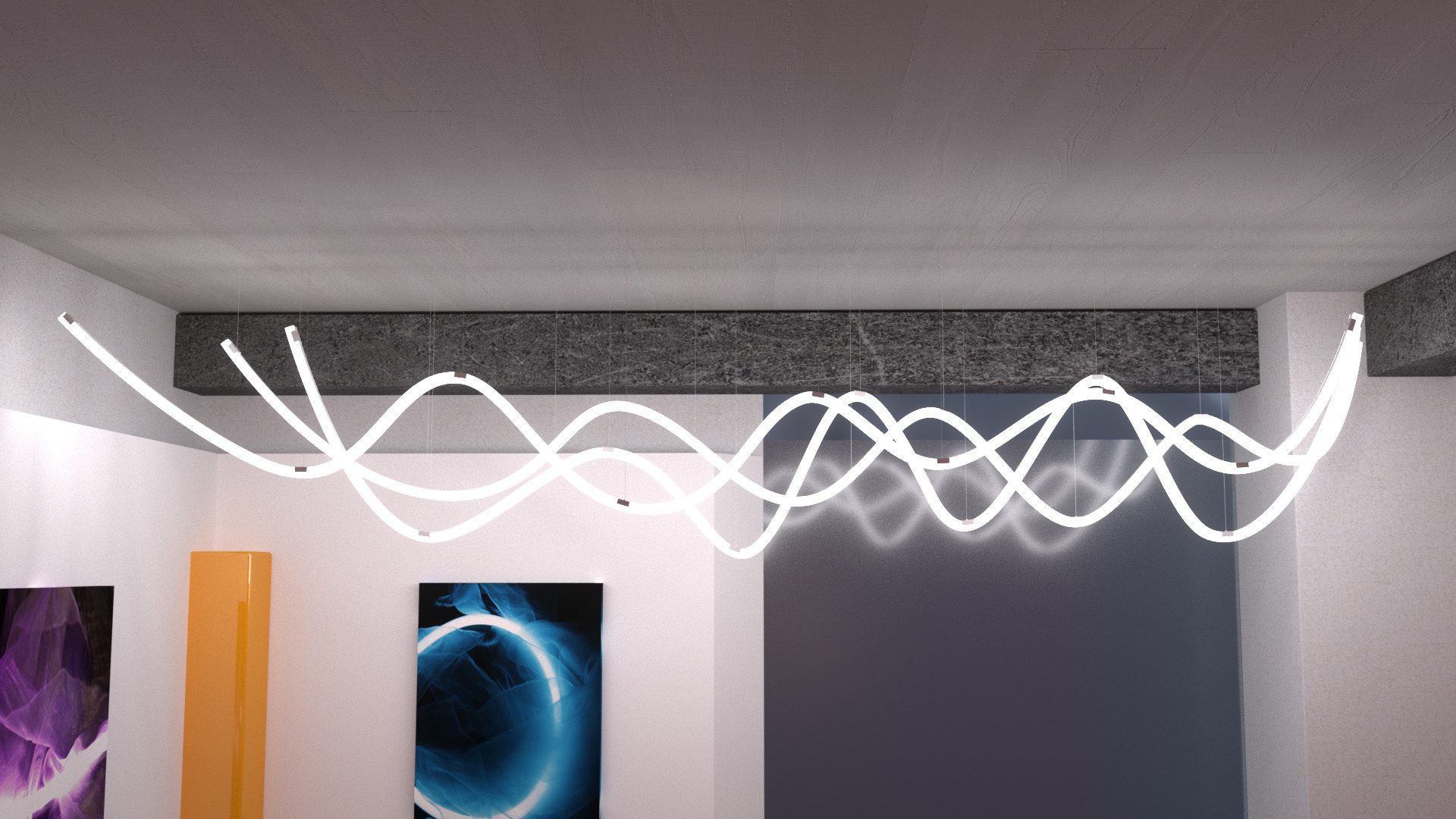

Neon flex is a versatile and energy-efficient lighting solution that can enhance the aesthetics of various commercial and hospitality environments. In hotels, neon flex is commonly used to accentuate architectural features such as reception desks, ceiling coves, stairway edges, and lounge areas. Its soft, diffused glow creates a warm and inviting ambiance, ideal for lobbies, bars, and guest corridors. The ability to customize colors and shapes allows designers to incorporate brand elements or thematic lighting that aligns with the hotel’s interior design.

In malls and shopping centers, neon flex is frequently installed in signage, display windows, and wayfinding systems. It adds visual interest to storefronts and promotional areas, drawing attention with vibrant, even illumination. Its flexibility enables creative designs such as curved logos, dynamic outlines, and artistic installations in common areas or food courts. The low heat output and durability make it suitable for high-traffic environments where safety and longevity are important.

In office spaces, neon flex is typically used for indirect lighting in reception areas, meeting rooms, or along ceiling perimeters to provide a modern and professional look. It can highlight branding elements or create a subtle, glare-free ambient light that supports a productive work environment. While less common in traditional office settings, it is increasingly used in creative agencies or tech startups seeking a contemporary design aesthetic.

For installation, ensure the surface is clean, dry, and smooth to promote proper adhesion of mounting clips or adhesive backing. Always follow the manufacturer’s bending radius specifications to avoid damaging the neon flex during shaping. Use compatible power supplies and drivers rated for the length and wattage of the strip, and avoid overloading circuits. For outdoor or high-moisture areas, select IP65 or higher rated neon flex and ensure all connections are properly sealed. It is advisable to install neon flex with end caps and secure connections to prevent moisture ingress and electrical faults. Finally, consider using dimmable drivers for greater control over light output and energy efficiency, especially in hospitality and retail applications where mood lighting is desired.

Why Choose Beauty STC Lighting

Transform your lighting projects with Beauty STC’s premium neon flex solutions, engineered for superior performance and design versatility. As a trusted manufacturer with deep expertise in LED innovation, we deliver consistent color accuracy, exceptional durability, and seamless integration for commercial, architectural, and creative applications. Our commitment to rigorous quality control ensures every meter of neon flex meets global safety standards while offering customizable lengths, colors, and dimming capabilities to match your exact specifications.

Partner with Beauty STC to leverage our end-to-end engineering support, scalable production capacity, and responsive collaboration from concept to installation. We prioritize long-term partnerships by providing technical guidance, timely delivery, and solutions tailored to your market’s evolving demands. Elevate your offerings with reliable, high-impact lighting that stands out in a competitive landscape.

Reach out directly to our technical team to discuss how our neon flex technology can enhance your product portfolio. Contact [email protected] to initiate a conversation and discover why industry leaders choose Beauty STC as their strategic manufacturing ally.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.