Article Contents

Industry Insight: Lighting Built In Shelves

Integrated lighting within shelving systems has evolved from a decorative afterthought to a critical strategic element in commercial and industrial environments. Far beyond simple illumination, purpose-built shelf lighting directly impacts operational efficiency, safety compliance, merchandise presentation, and energy consumption across retail stores, warehouses, distribution centers, laboratories, and manufacturing facilities. The demand for seamless, low-profile solutions that enhance visibility of stored items while minimizing glare and shadows is intensifying, driven by stringent workplace safety standards and the need for optimized space utilization. Crucially, any lighting solution deployed in these professional settings must adhere to rigorous safety and performance certifications; ETL listing for North American markets and CE marking for Europe are not optional extras but fundamental requirements ensuring electrical safety, reliability, and adherence to regional regulatory frameworks, mitigating liability risks and guaranteeing compatibility with facility infrastructure. Beauty STC Manufacturing Co., Ltd., established in 1998, brings over 25 years of specialized engineering expertise to this demanding sector. We focus exclusively on developing high-performance, code-compliant LED lighting systems tailored for the unique challenges of commercial and industrial shelving applications, where durability, precise optical control, and seamless integration are non-negotiable.

Technical Specs & Certifications

Lighting integrated into shelving units requires careful technical consideration to ensure optimal performance, visual comfort, and durability. At Beauty (STC) Manufacturing Co., Ltd., our built-in shelf lighting solutions are engineered to meet the highest standards in energy efficiency, color accuracy, and environmental resilience.

Our LED lighting systems for shelving are designed with a focus on high lumens per watt (lm/W) efficiency, consistently achieving outputs between 100 and 130 lumens per watt depending on the model and configuration. This ensures bright, uniform illumination while minimizing energy consumption—ideal for retail displays, residential cabinetry, and commercial interiors where continuous operation is common. High efficiency is maintained through the use of advanced SMD (Surface-Mounted Device) LED chips and optimized thermal management systems.

Color Rendering Index (CRI) is a critical factor in shelf lighting, especially where accurate color representation is essential, such as in retail or art displays. All Beauty STC built-in shelf lights feature a CRI greater than 90, with select models reaching CRI 95+. This high color fidelity ensures that fabrics, food, merchandise, and materials appear vibrant and true to life under illumination. We achieve this through the use of premium phosphor-coated LEDs and tight binning controls during manufacturing.

Ingress Protection (IP) ratings are tailored to the installation environment. For indoor dry locations such as bookshelves or display cabinets, our standard IP20-rated lighting strips provide reliable performance with protection against solid objects. For more demanding environments—such as kitchen shelving exposed to steam or outdoor shelving units—we offer IP54, IP65, and even IP67-rated solutions. These higher-rated fixtures are sealed against dust and moisture ingress, ensuring long-term reliability in humid or washdown-prone areas. Our silicone-jacketed, double-insulated LED strips and aluminum-channel systems are built to withstand challenging conditions without compromising light quality.

Beauty STC is committed to excellence in design and manufacturing. Our shelf lighting systems undergo rigorous quality control, including thermal cycling, electrical stress testing, and photometric validation. We use only RoHS-compliant materials and partner with trusted semiconductor suppliers to ensure consistency and longevity. With over two decades of experience in precision LED engineering, Beauty STC delivers lighting solutions that combine superior optical performance, robust construction, and elegant integration into modern shelving systems.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, represents a significant investment in modern LED lighting production. Strategically located within the Pearl River Delta manufacturing hub, the Jiangmen factory benefits from excellent logistics infrastructure and access to a skilled technical workforce. The facility is designed to support high-volume, precision manufacturing with a strong emphasis on quality control and process efficiency throughout the production lifecycle.

The surface mount technology (SMT) assembly lines form the backbone of our electronics production capability. We operate multiple high-speed, dual-lane SMT lines featuring advanced equipment from leading manufacturers such as Yamaha and Panasonic. These lines are configured for handling the full spectrum of components required for LED lighting products, from ultra-fine pitch ICs used in sophisticated drivers to larger passive components. The placement machines achieve micron-level accuracy, essential for reliable thermal management and electrical performance in densely packed LED modules. Each SMT line integrates fully automated optical inspection (AOI) systems immediately post-reflow, enabling real-time defect detection and correction. This comprehensive SMT capability ensures consistent, high-yield assembly of complex PCBs, forming the critical electronic foundation for all our lighting products including integrated solutions.

Rigorous aging and reliability testing constitute a non-negotiable phase in our quality assurance protocol. Every production batch undergoes structured aging procedures within our dedicated environmental test chambers. Standard aging tests involve continuous operation of finished luminaires at elevated temperatures, typically 50-60°C, for durations of 24 to 72 hours depending on the product specification and customer requirements. During this period, we monitor critical parameters including lumen output stability, color consistency, driver performance, and thermal behavior. Any unit exhibiting deviation beyond our stringent internal thresholds is immediately flagged for failure analysis. This systematic aging process, combined with our adherence to industry reliability standards like LM-80 and TM-21 for lumen maintenance projection, provides our customers with confidence in the long-term field performance and durability of Beauty STC products.

Our OEM capability for integrated lighting solutions, specifically “lighting built in shelves” applications, is a core strength developed through extensive experience. We provide end-to-end engineering and manufacturing services for custom shelf-integrated LED systems, working closely with furniture designers and manufacturers. This encompasses collaborative design support for optimal light distribution within constrained shelf profiles, thermal management solutions for enclosed environments, and customization of key parameters including length, color temperature, dimming protocols, and power delivery methods. We excel at producing low-profile linear modules, flexible strips, or bespoke rigid PCB assemblies that seamlessly integrate into shelving structures, whether for retail displays, cabinetry, or architectural millwork. Our Jiangmen factory supports this through flexible production scheduling, rapid prototyping capabilities using our in-house SMT and assembly resources, and strict adherence to international safety and performance certifications relevant to built-in lighting applications. This OEM service extends beyond manufacturing to include packaging tailored to furniture assembly workflows and scalable production volumes to meet both prototype and mass-market demands.

Application Scenarios

Lighting built into shelves is a functional and aesthetic design solution that enhances visibility, creates ambiance, and highlights displayed items. Its application varies across different environments such as hotels, malls, and offices, each with unique requirements.

In hotels, built-in shelf lighting is commonly used in guest room wardrobes, bathroom vanities, minibars, and reception display areas. It adds a touch of luxury and improves usability by illuminating personal items or amenities without requiring overhead lighting. For example, under-cabinet lighting in minibars helps guests easily identify beverages and snacks, while backlit shelving at the reception area can showcase decorative objects or branding elements. Warm white lighting (2700K–3000K) is typically preferred to maintain a welcoming and relaxing atmosphere.

In malls and retail environments, shelf-integrated lighting plays a critical role in product presentation. It is widely used in display cabinets, fashion boutiques, jewelry counters, and electronic kiosks. The primary goal is to draw attention to merchandise and enhance visual appeal. Cool white or neutral white LEDs (3500K–4000K) are often selected for their clarity and color rendering, ensuring products appear vibrant and true to color. Directional spotlights or linear LED strips behind or beneath shelves create depth and shadow control, emphasizing product features.

In offices, built-in shelf lighting is used in executive cabins, meeting rooms, and reception areas to highlight awards, corporate gifts, or literature. It contributes to a professional and modern look. Task lighting on open shelving units can also assist in locating files or office supplies. Lighting here should be subtle and glare-free, with a color temperature around 3500K to 4000K to support concentration and a clean environment.

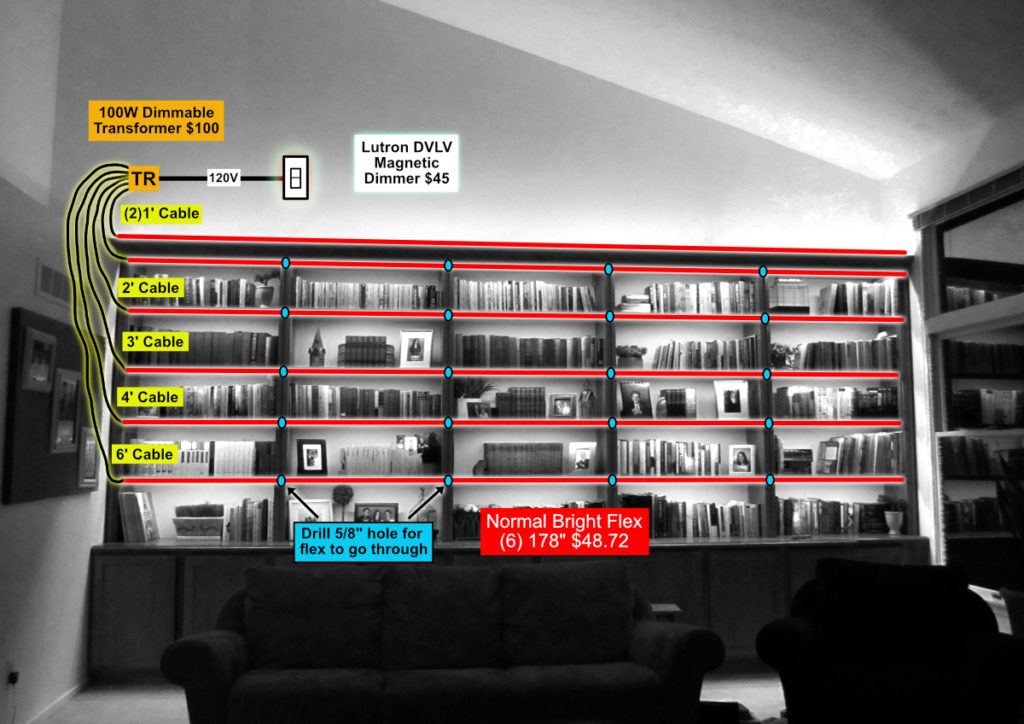

When installing lighting in shelves, several practical tips should be followed. First, choose low-heat LED solutions to prevent damage to shelf materials or stored items. Ensure the lighting is easily accessible for maintenance—consider using plug-in strips or connectors with quick-release joints. For adjustable shelves, install wiring in channels or raceways along the cabinet sides to allow height changes without disconnecting lights. Use dimmable drivers where ambiance control is desired, especially in hospitality settings. Always check the IP rating for humid areas like bathrooms—IP44 or higher is recommended. Finally, align lighting to avoid shadows and glare, positioning strips toward the front edge of shelves for optimal downlighting or using backlit panels to create a floating effect.

Proper planning during the interior design phase ensures power supply points are correctly located and concealed, maintaining a clean and professional appearance. Working with certified electricians and adhering to local electrical codes is essential for safety and long-term performance.

Why Choose Beauty STC Lighting

Elevate your shelf displays with precision-engineered lighting solutions designed specifically for built-in cabinetry and shelving systems. As a Senior LED Lighting Engineer at Beauty STC Manufacturing Co., Ltd., I can confirm that generic lighting often creates harsh glare, uneven illumination, or inaccurate color rendering in shelf applications—compromising both aesthetics and functionality. Our proprietary optical technologies ensure seamless integration, uniform light distribution, and exceptional color fidelity that enhances product visibility while protecting sensitive materials from UV exposure.

Partner with Beauty STC to access custom-engineered LED systems that solve real-world shelf lighting challenges through advanced thermal management, dimming compatibility, and architectural-grade components. We collaborate directly with designers and manufacturers to develop solutions that meet exact spatial constraints, voltage requirements, and ambient design goals without compromising on performance or longevity.

Take the next step toward flawless shelf illumination by contacting our dedicated partnership team at [email protected]. Share your project specifications, and we will provide a tailored technical proposal with photometric validation within 48 hours. Let Beauty STC’s engineering expertise become your competitive advantage in creating illuminated spaces that captivate and convert.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.