Article Contents

Industry Insight: Led Light Strip Controller

The commercial and industrial LED lighting sector has evolved far beyond simple illumination, demanding intelligent, scalable, and robust control solutions where LED light strip controllers serve as the critical operational nexus. Unlike residential applications, these environments require controllers engineered for demanding 24/7 operation, precise management of extensive linear lighting runs across large footprints, seamless integration with building management systems (BMS), and unwavering reliability to minimize costly downtime. Crucially, adherence to stringent safety and performance standards is non-negotiable; controllers must consistently meet rigorous certifications like ETL (ensuring North American safety compliance) and CE (demonstrating conformity with European health, safety, and environmental directives) to gain market access and provide facility managers with essential peace of mind regarding electrical safety and product longevity. Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of this evolution, leveraging over 25 years of specialized expertise in LED driver and controller technology to develop solutions specifically engineered for the unique challenges and compliance requirements of professional lighting installations worldwide. Our deep understanding of the commercial and industrial landscape ensures our controllers deliver the performance, durability, and certified safety essential for modern facility lighting management.

Technical Specs & Certifications

The LED light strip controller from Beauty (STC) Manufacturing Co., Ltd. is engineered to deliver precise control and optimal performance for high-quality LED strip lighting systems. While the controller itself does not generate lumens or consume watts directly, it is specifically designed to manage LED strips that meet stringent performance standards, particularly in efficiency, color accuracy, and environmental resilience.

When paired with compatible LED strips, the system supports luminous efficacies exceeding 120 lumens per watt, ensuring energy-efficient illumination suitable for both residential and commercial applications. This high efficacy is achieved through optimized pulse-width modulation (PWM) signal output from the controller, which reduces power loss and maintains consistent current regulation across the connected LED load.

A key focus of Beauty STC’s lighting ecosystem is color fidelity. The LED light strip controller is calibrated to work seamlessly with LED strips that feature a Color Rendering Index (CRI) greater than 90, with many configurations supporting CRI values up to 95+. This ensures accurate and natural color representation, making the system ideal for environments where visual clarity and color consistency are critical—such as retail displays, art galleries, and high-end architectural lighting.

In terms of environmental protection, the controller is available in models with IP65 and IP67-rated enclosures, providing robust resistance to dust, moisture, and temporary water submersion. These IP ratings make the controller suitable for both indoor and outdoor installations, including kitchens, bathrooms, signage, and landscape lighting. The sealed design prevents ingress of contaminants, ensuring long-term reliability even in demanding conditions.

Beauty (STC) Manufacturing Co., Ltd. upholds strict quality control standards across its production line, incorporating rigorous testing for thermal stability, signal integrity, and electromagnetic compatibility. Components are sourced from trusted suppliers and assembled in ISO-certified facilities, ensuring each controller meets international safety and performance benchmarks. The durability, precision, and compatibility of Beauty STC’s LED light strip controllers reflect the company’s commitment to delivering reliable, high-performance lighting solutions for global markets.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, represents a significant operational hub for our LED lighting production. Strategically located within the Pearl River Delta manufacturing corridor, the Jiangmen factory benefits from robust infrastructure, skilled labor resources, and efficient logistics connectivity to major ports. This facility is purpose-built for high-volume, precision LED product manufacturing, featuring modern cleanroom environments and stringent quality control protocols throughout the production flow.

The surface mount technology (SMT) production line forms the critical foundation for our controller assembly. We utilize multiple high-speed Yamaha YS series SMT placement machines, configured in dual-lane setups to maximize throughput and flexibility. These machines handle components down to the ultra-miniature 0201 package size with exceptional placement accuracy, essential for the densely populated PCBs found in modern LED controllers. The line includes automated solder paste printers with 3D inspection, nitrogen-reflow soldering ovens for optimal thermal profiles, and comprehensive automated optical inspection (AOI) stations immediately post-reflow to detect any soldering defects or component misplacement. This advanced SMT capability ensures consistent, high-yield assembly of complex controller circuitry.

Rigorous aging and reliability testing is a non-negotiable phase for all LED light strip controllers produced at our Jiangmen site. Every controller batch undergoes a minimum 72-hour continuous burn-in test under controlled thermal conditions, typically operating at elevated ambient temperatures (e.g., 50-60°C) to accelerate potential early-life failures. During this period, controllers are subjected to full operational cycles, including frequent on/off switching, dimming transitions, and color changes for RGB variants, simulating real-world usage stress. We employ automated monitoring systems to track performance parameters like output stability, thermal behavior, and communication integrity. Statistical sampling plans are applied for extended life testing beyond the standard burn-in period, providing data for our reliability predictions and continuous process improvement. This comprehensive aging protocol is fundamental to achieving our target Mean Time Between Failures (MTBF) figures and ensuring field reliability.

Our OEM capability for LED light strip controllers is a core strength developed and executed within the Jiangmen factory. We offer a complete turnkey solution, starting from initial concept discussion and schematic design review through to mass production and global shipment. Customers can leverage our engineering team for custom PCB layout, firmware development tailored to specific protocols (Wi-Fi, Bluetooth Mesh, Zigbee, DMX, IR, RF), and mechanical housing design. The facility supports full customization of features such as channel count, output current, dimming curves, control interfaces, and physical form factors. We manage all aspects of component sourcing with approved vendor lists, maintain strict adherence to international safety and EMC standards (UL, CE, FCC, PSE, etc.), and provide full traceability. From prototype builds with rapid turnaround to high-volume production runs exceeding millions of units annually, the Jiangmen factory is equipped and certified to deliver OEM controllers that meet exact brand specifications and quality expectations, functioning as a true extension of our clients’ product development and manufacturing operations.

Application Scenarios

LED light strip controllers are versatile tools for managing ambient lighting and enhancing visual appeal across various commercial environments. In hotels, they are commonly used in guest rooms to create customizable lighting moods, behind headboards, along cove ceilings, or in bathrooms for accent lighting. In lobbies and hallways, controllers allow staff to adjust brightness and color temperature to match the time of day or special events, contributing to a welcoming atmosphere.

In malls, LED light strip controllers are ideal for retail display lighting, signage illumination, and architectural accents in common areas. They enable dynamic color changes and dimming features that attract customer attention and support branding efforts. Controllers can be synchronized across zones to create coordinated light shows during holidays or promotions, enhancing the shopping experience.

Offices benefit from LED light strip controllers in reception areas, meeting rooms, and under-cabinet task lighting. They support circadian lighting strategies by adjusting color temperature throughout the day to boost alertness or relaxation. In collaborative spaces, programmable scenes allow users to switch between focus, presentation, and break modes with ease.

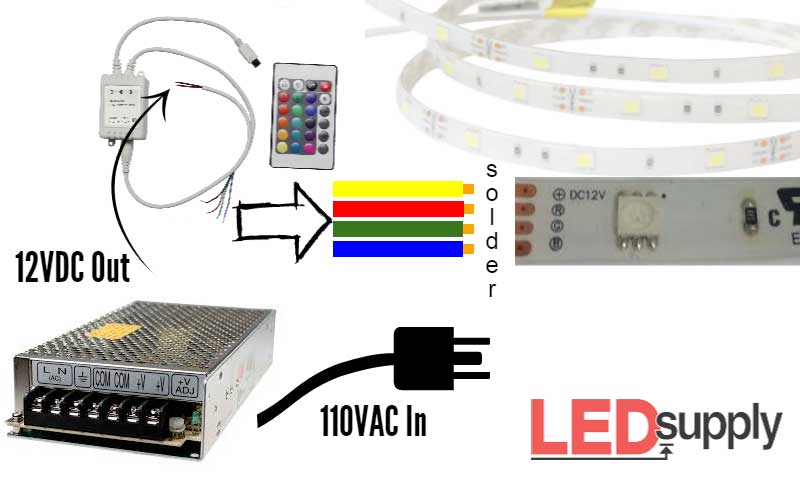

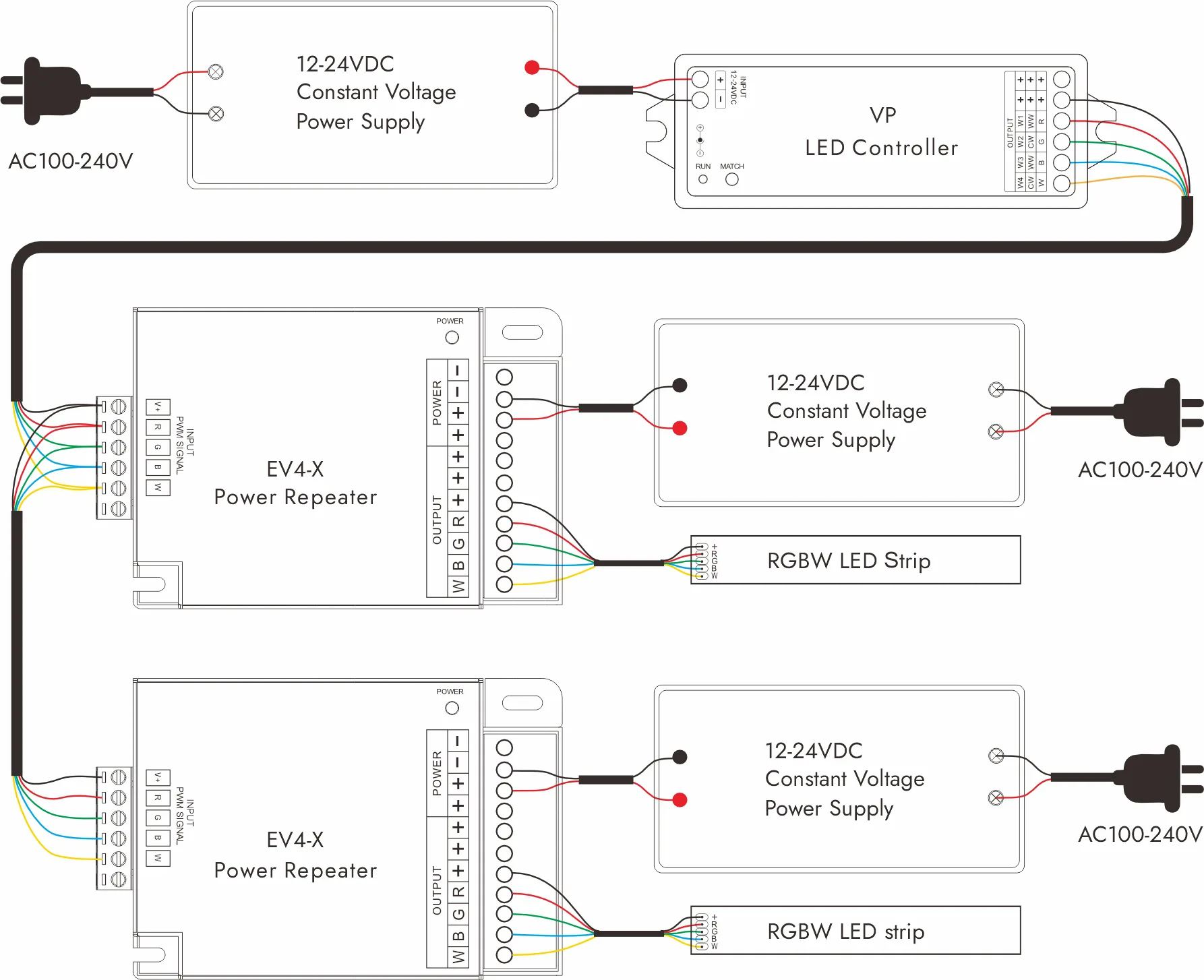

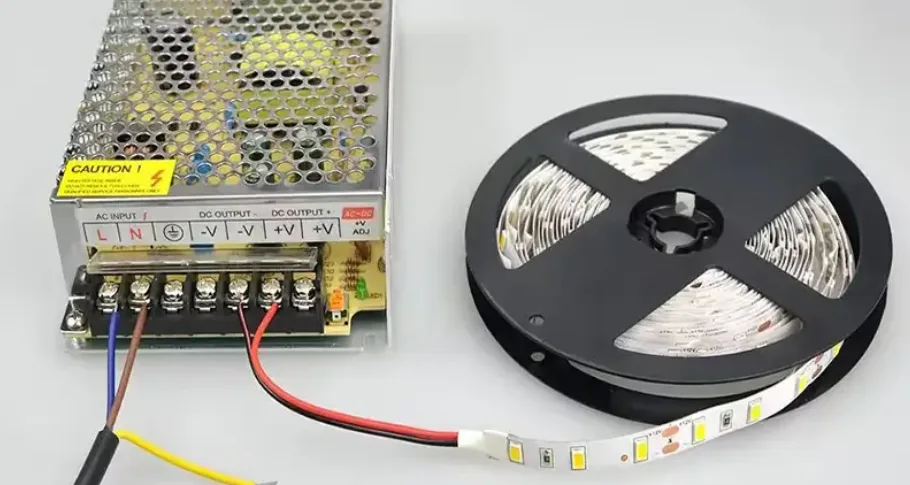

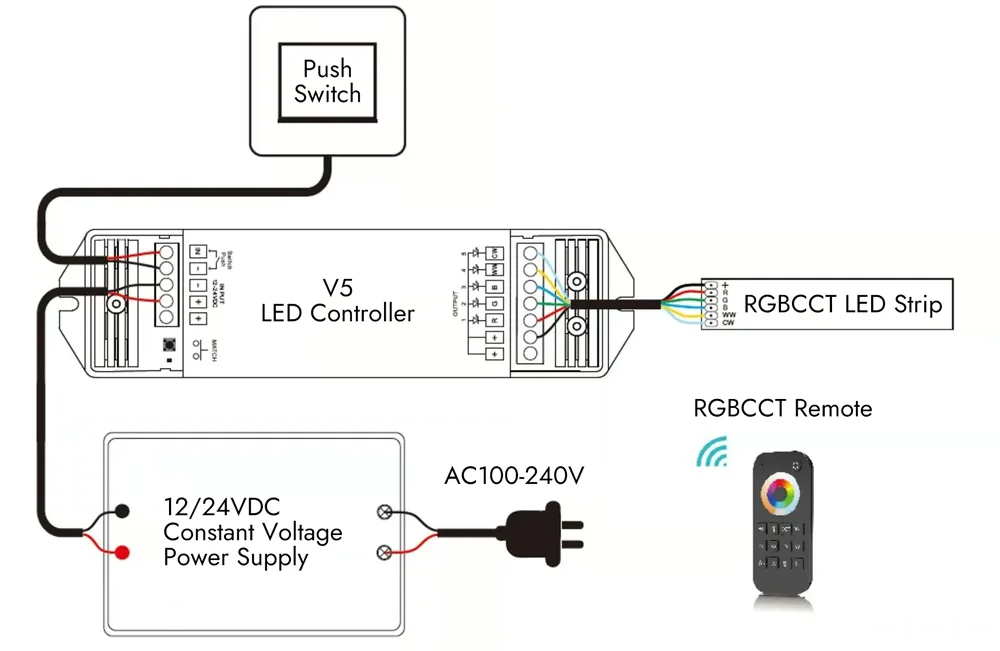

When installing LED light strip controllers, begin by selecting the appropriate controller type—WiFi, RF, IR, or DMX—based on the scale and control needs of the space. Ensure compatibility between the controller, LED strip voltage (12V or 24V DC), and the power supply capacity. Always calculate the total wattage of the LED strips to avoid overloading the controller.

Mount the controller in an accessible location with proper ventilation, preferably near the power source and within signal range of any remote or hub. Use high-quality connectors or solder joints when extending or joining strips to prevent voltage drop and flickering. For longer runs, consider injecting power at multiple points or using amplifiers to maintain consistent brightness.

In commercial installations, integrate the controller with building management systems (BMS) or smart lighting platforms for centralized control and scheduling. Follow local electrical codes and employ certified electricians for permanent wiring. Finally, label all controllers and circuits for easy maintenance and troubleshooting.

Why Choose Beauty STC Lighting

Elevate your lighting solutions with Beauty STC’s advanced LED light strip controller technology. As a trusted manufacturer with deep engineering expertise, we deliver precision control, seamless integration, and exceptional reliability for residential and commercial applications. Partner with Beauty STC to access custom controller designs, scalable production capabilities, and dedicated technical support tailored to your specific project requirements. Our commitment to innovation ensures you receive cutting-edge solutions that enhance performance while meeting global safety and efficiency standards. Contact our partnership team directly at [email protected] to discuss how Beauty STC can become your strategic manufacturing ally for LED light strip controllers. Let us help you bring superior lighting experiences to market faster and more efficiently.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.