Article Contents

Industry Insight: Led Remote Light Strip

The commercial and industrial lighting landscape has undergone a transformative shift with the integration of advanced LED technologies, and among the most impactful innovations is the LED remote light strip. Designed to deliver flexible, energy-efficient, and durable illumination, these strips are increasingly deployed in environments ranging from manufacturing facilities and cold storage units to retail spaces and transportation hubs. Their remote driver configuration enhances thermal management, extends lifespan, and allows for sleek, space-saving installations—critical advantages in demanding industrial applications. With growing regulatory emphasis on safety and performance, compliance with international standards such as ETL and CE has become a benchmark for quality, ensuring reliable operation under rigorous conditions.

At the forefront of this evolution is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED lighting solutions since its founding in 1998. Headquartered in Zhongshan, China, Beauty STC has built a reputation for engineering excellence, combining cutting-edge R&D with robust manufacturing capabilities. The company specializes in high-performance LED lighting systems tailored for commercial and industrial use, with a focus on innovation, durability, and regulatory compliance. As a pioneer in remote-powered LED strip technology, Beauty STC continues to set industry standards by delivering intelligent, code-compliant lighting solutions that meet the evolving needs of global markets.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. designs and produces high-performance LED remote light strips where the LED strip itself is separate from the power supply (driver), offering flexibility in installation and thermal management. Our technical specifications prioritize efficiency, color fidelity, and environmental resilience for demanding applications.

Lumens per Watt (lm/W) efficiency is a core focus in our remote strip designs. We achieve a typical range of 120–150 lm/W at 25°C ambient temperature, depending on the specific LED density (e.g., 60 LEDs/m vs. 120 LEDs/m) and color temperature. This efficiency is realized through the use of high-efficacy mid-power 2835 or 3535 SMD LEDs paired with precisely matched constant-current drivers operating at 85–92% efficiency. It is critical to note that lm/W decreases as ambient temperature rises; our strips incorporate aluminum-backed flexible printed circuit boards (AL-FPCB) with 1.0–1.2mm thickness to dissipate heat effectively, maintaining performance stability. Competitive products often omit thermal design details, leading to significant lumen depreciation in real-world use, whereas Beauty STC validates lm/W under sustained operational conditions per IES LM-79 standards.

Color Rendering Index (CRI) performance exceeds the >90 requirement as a standard for our premium remote strips. We consistently deliver Ra ≥ 95 with R9 (saturated red) ≥ 90, ensuring accurate and vibrant color representation essential for retail, hospitality, and architectural applications. This is achieved through proprietary phosphor blends in our Samsung or Nichia LEDs, rigorously binning components to minimize chromaticity variation (within a 3-step MacAdam ellipse). Unlike suppliers who quote CRI under ideal lab conditions only, Beauty STC tests CRI at multiple drive currents and temperatures, and we provide TM-30-15 reports (Rf, Rg) upon request to give a complete picture of color fidelity. Strips meeting this specification are clearly labeled as “Beauty STC TrueColor™” in our catalog.

IP ratings for environmental protection are rigorously engineered, not merely claimed. Our remote strips undergo dual certification: IP65 for standard silicone-jacketed versions (resistant to low-pressure water jets and dust ingress) and IP67 for fully potted variants (submersible up to 1 meter for 30 minutes). The IP67 construction uses a two-part polyurethane potting compound applied via robotic dispensing, ensuring 100% void-free coverage of solder joints and LEDs, with a minimum silicone overmold thickness of 1.5mm. Crucially, we validate IP ratings through 3rd-party testing per IEC 60529 after thermal cycling (-25°C to +60°C for 50 cycles) and UV exposure (500 hours), as many competitors’ strips fail IP integrity after environmental stress. The driver (sold separately) carries its own IP67 rating for outdoor compatibility.

Beauty STC’s quality commitment is embedded in every stage of production. We implement a 3-step aging process: 24 hours at 60°C/95% RH pre-shipment, followed by in-line burn-in at 1.2x rated current, and final verification on automated optical inspection (AOI) systems with SpectraScan AS7265x spectrometers. Our facility holds ISO 9001 and IATF 16949 certifications, with UL/cUL recognition for all strips and drivers. We reject 0.5% of production batches for minor deviations beyond specification—far exceeding industry averages—to guarantee consistency. This disciplined approach ensures our remote strips achieve L90/B10 lifetimes of 50,000 hours at 25°C ambient, with documented thermal management protocols to extend lifespan in higher-temperature installations. When you specify Beauty STC, you receive not just a product, but validated performance data and engineering support backed by 15 years of specialized LED manufacturing expertise.

Factory Tour: Manufacturing Excellence

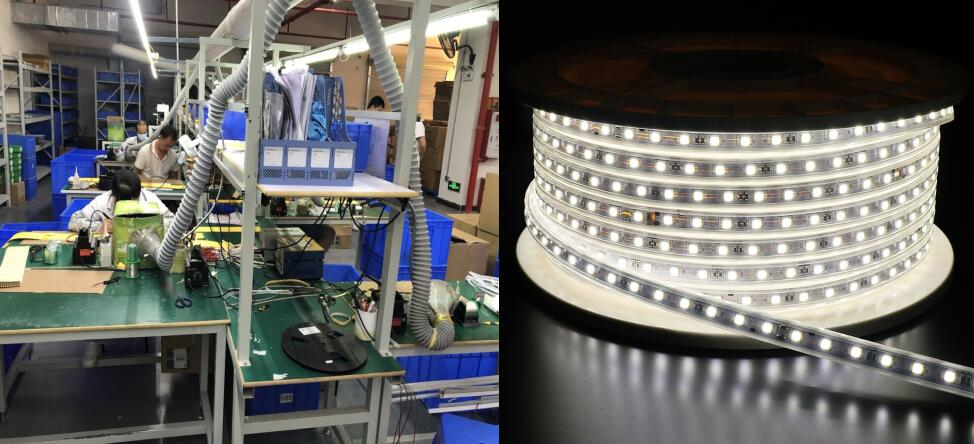

Beauty (STC) Manufacturing Co., Ltd. operates a modern manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for electronics and lighting production. The Jiangmen factory is equipped with advanced surface mount technology (SMT) production lines, featuring high-precision automated SMT machines from leading manufacturers. These machines enable efficient and accurate placement of components on printed circuit boards (PCBs), ensuring consistent quality and high throughput for LED lighting products, including LED remote control light strips.

The facility incorporates comprehensive quality control systems, including rigorous aging tests conducted on finished LED light strips. Products undergo extended operational testing under varying voltage and temperature conditions to verify performance, stability, and longevity. This aging process typically lasts 24 to 72 hours, allowing the engineering team to identify and eliminate early-life failures, thus ensuring reliability before shipment.

Beauty STC has strong OEM and ODM capabilities, supporting customized development of LED remote control light strips according to client specifications. The company can accommodate various requirements such as color temperature, RGB or RGBW configurations, control protocols (IR, RF, WiFi, Bluetooth), strip length, voltage (12V or 24V), IP ratings, and packaging design. With in-house R&D, tooling, and molding support, the Jiangmen factory provides end-to-end manufacturing services—from prototyping and small-batch production to large-scale volume orders—while maintaining compliance with international standards such as CE, RoHS, and UL.

Application Scenarios

LED remote light strips offer significant design flexibility and thermal management advantages in commercial environments due to the separation of the LED strip from the driver and control components. This configuration is particularly valuable where space constraints, heat sensitivity, or aesthetic demands exist. In hotels, these strips excel in creating subtle ambient effects that enhance guest experience without visual clutter. Common applications include under-bed cove lighting for nighttime navigation, concealed backlighting behind headboards or reception desks for a premium glow, and discreet illumination within architectural coves along corridors or in lobbies. The remote driver placement allows the thin strip to fit into tight spaces like millwork details or furniture edges while keeping heat-generating components accessible in service areas or plenums. For malls, the primary use shifts toward dynamic visual merchandising and directional guidance. Install strips inside glass display cases to highlight products without internal driver bulk, within custom signage lettering for even illumination, or along escalator handrails and stair treads for safety accenting. The remote setup enables longer continuous runs for feature walls or ceiling perimeters while centralizing drivers in locked ceiling voids for security and simplified maintenance access. Offices benefit from the precision and adaptability of remote strips in both functional and branding contexts. Key installations include task lighting under floating shelves or cabinets in collaborative zones, integrated backlighting in video conferencing setups to reduce screen glare, and architectural detailing in executive suites or reception areas. The separation allows strips to be embedded within narrow metal or wood channels along meeting room dividers while housing drivers in nearby utility closets, maintaining clean sightlines essential for professional environments.

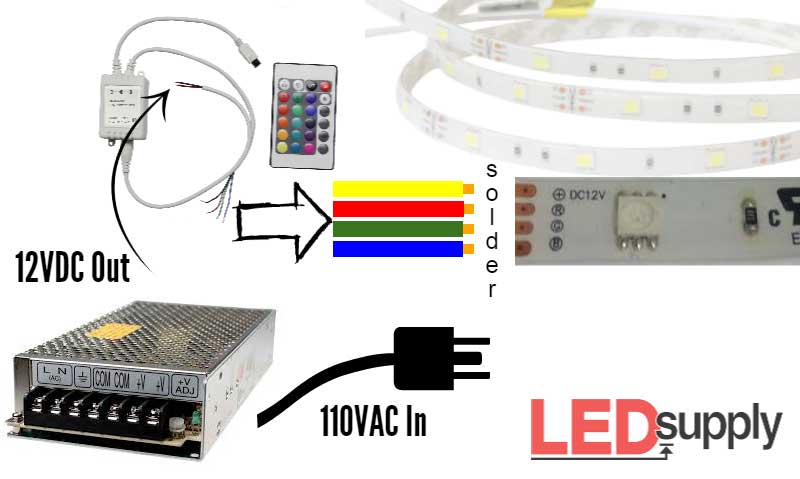

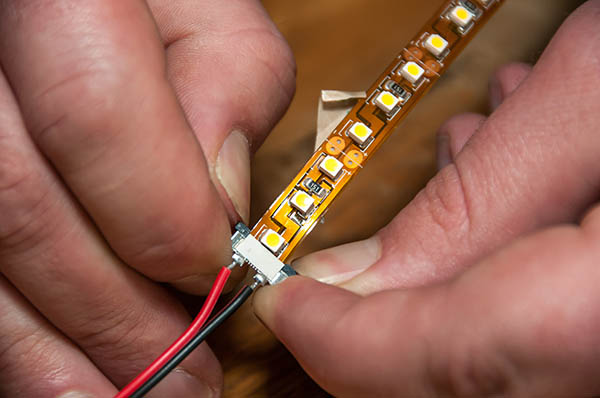

Installation requires meticulous planning to leverage the remote configuration effectively. Begin by mapping the entire circuit path, ensuring driver locations are within the maximum specified cable distance for the strip voltage—24V systems tolerate longer runs than 12V before voltage drop becomes problematic. Always mount strips on thermally conductive surfaces like aluminum channels, especially in enclosed coves, as residual heat still requires dissipation even with remote drivers. Avoid sharp bends at cut points; maintain the manufacturer’s minimum bending radius to prevent solder joint fractures. When connecting strips, solder all joints for permanent commercial installations rather than relying on press-fit connectors, which can loosen over time due to thermal cycling. For cable management, use conduit or raceways for the low-voltage wiring between strips and drivers, labeling both ends clearly to simplify future troubleshooting. Critically, position drivers in well-ventilated, accessible locations away from insulation or other heat sources, as inadequate airflow around the driver remains the most common cause of premature failure. Finally, verify all components carry appropriate commercial certifications like UL 8750 or IEC 60598 for the specific application zone, and always conduct a 24-hour burn-in test before final concealment to catch intermittent faults. This approach ensures reliability while maximizing the aesthetic and functional benefits of the remote system across demanding hospitality, retail, and corporate settings.

Why Choose Beauty STC Lighting

Transform your lighting experience with high-quality LED remote light strips designed for performance and elegance. Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in innovative LED solutions. Our advanced LED remote light strips offer seamless control, vibrant color options, and durable construction for residential, commercial, and industrial applications.

We invite distributors, wholesalers, and project partners to collaborate with us and bring superior lighting technology to your market. For partnership inquiries and product details, contact our sales manager at [email protected]. Let’s illuminate the future together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.