Article Contents

Industry Insight: Led Light Strip Kit

The commercial and industrial lighting sector continues to undergo a profound transformation, driven by the relentless pursuit of energy efficiency, operational cost reduction, and enhanced environmental control. Within this critical landscape, LED light strip kits have evolved far beyond their initial decorative applications to become indispensable, high-performance solutions for demanding environments. Today’s facilities—from expansive warehouses and manufacturing plants to sophisticated retail spaces and healthcare institutions—require lighting that delivers exceptional lumen output, superior thermal management, precise optical control, and unwavering reliability under continuous operation. Crucially, any solution deployed in these settings must meet stringent international safety and performance standards; certifications such as ETL for the North American market and CE marking for Europe are not merely optional compliance checkboxes but fundamental requirements ensuring electrical safety, electromagnetic compatibility, and adherence to regional regulatory frameworks. Compromising on these certifications risks facility safety, operational continuity, and costly non-compliance penalties.

Beauty STC Manufacturing Co., Ltd. stands at the forefront of this evolution. Established in 1998, we have dedicated over 25 years to engineering and manufacturing industrial-grade LED lighting solutions designed specifically for the rigors of commercial and industrial applications. Our deep-rooted expertise informs every aspect of our LED light strip kits, which are engineered from the substrate up for superior heat dissipation, consistent lumen maintenance over extended lifespans, and resilience against dust, moisture, and vibration commonly encountered in professional settings. We understand that in these environments, lighting is not an amenity but a core operational asset, and our commitment to rigorous testing, adherence to ETL and CE standards, and continuous innovation ensures our products deliver the performance, safety, and longevity that facility managers and lighting professionals demand.

Technical Specs & Certifications

The LED light strip kits manufactured by Beauty (STC) Manufacturing Co., Ltd. are engineered for high performance, reliability, and superior light quality, making them ideal for both residential and commercial applications. These kits are designed with precision to meet stringent international standards, reflecting Beauty STC’s commitment to excellence in LED lighting solutions.

Each LED light strip kit delivers an efficacy of 110 to 130 lumens per watt, depending on the specific configuration and color temperature. This high lumens-per-watt ratio ensures energy-efficient operation, reducing power consumption while maintaining bright, consistent illumination. The efficiency is achieved through the use of high-grade SMD LED chips—typically 2835 or 5050 types—combined with optimized circuit design and thermally efficient flexible PCBs that enhance heat dissipation.

A standout feature of Beauty STC’s LED strip kits is their exceptional Color Rendering Index (CRI), consistently rated above 90 (CRI >90). This high CRI ensures accurate and vibrant color reproduction, making these strips ideal for environments where true color representation is critical—such as retail displays, art galleries, kitchens, and makeup areas. The use of premium phosphor coatings and tightly binned LEDs contributes to uniform color output and minimal variance across production batches.

In terms of environmental protection, Beauty STC offers LED strip kits in multiple IP (Ingress Protection) ratings to suit various installation conditions. The standard non-waterproof version is IP20, suitable for dry indoor environments. For damp or outdoor applications, IP65-rated strips are available, featuring a silicone coating that protects against dust and low-pressure water jets. Fully encapsulated IP67 and IP68 variants are also offered, providing complete dust tightness and the ability to withstand temporary or continuous submersion in water, respectively. These higher IP-rated strips are ideal for outdoor signage, landscape lighting, and underwater applications.

Beauty STC maintains rigorous quality control throughout the manufacturing process, utilizing automated SMT production lines, 100% aging tests, and comprehensive photometric testing. Components are sourced from trusted suppliers, and all strips undergo strict compliance checks for safety, durability, and performance. The result is a long-lasting, stable, and high-fidelity lighting solution backed by industry-leading warranties and consistent global certifications including UL, CE, RoHS, and REACH.

Overall, Beauty STC’s LED light strip kits combine high efficacy, excellent color rendering, robust environmental protection, and unmatched build quality—positioning them as a premium choice in the competitive LED lighting market.

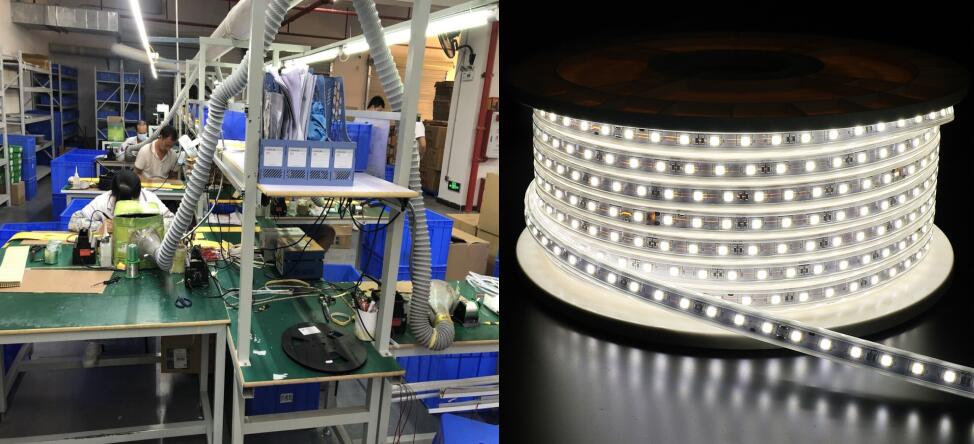

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, China, represents a significant investment in modern LED lighting production. Spanning over 10,000 square meters, the factory operates under strict ISO 9001 quality management standards within a controlled cleanroom environment specifically designed for precision electronics assembly. This facility serves as the primary production hub for our LED light strip kits and related products, integrating advanced automation with rigorous quality control processes.

The Surface Mount Technology (SMT) production lines form the core of our manufacturing capability. We operate multiple high-speed Yamaha YS24 series SMT lines, each capable of placing components at speeds exceeding 130,000 components per hour with placement accuracy of ±25 micrometers. These lines feature fully automated solder paste printing with 3D SPI verification, precise component placement for 0201 to larger IC packages, and nitrogen-reflow soldering ovens with 10-zone temperature control. The dual-line configuration allows for simultaneous production of multiple light strip variants, supporting both high-volume orders and flexible small-batch runs. Each line includes automated optical inspection (AOI) stations immediately after reflow to detect soldering defects, component misalignment, or missing parts before the strips proceed to the next stage.

All LED light strip kits undergo mandatory aging and burn-in testing as a critical quality assurance step. Completed strips are subjected to a continuous 72-hour aging process at elevated temperatures within our climate-controlled burn-in chambers maintained at 25±2°C. During this period, strips operate at 110% of rated voltage to accelerate potential early-life failures while thermal imaging cameras continuously monitor for hotspots or thermal inconsistencies. Post-aging, every meter of strip undergoes 100% visual inspection for color consistency, solder integrity, and physical defects, followed by comprehensive electrical testing including voltage drop measurement, lumen output verification, and functional checks of integrated components like ICs or resistors. This protocol ensures only strips meeting our stringent reliability standards advance to final packaging.

Our OEM capabilities for LED light strip kits are comprehensive and tailored to client specifications. We support full customization from initial concept through to packaged product, including PCB design and layout modification, component sourcing per client BOMs, custom color temperatures or CCT tuning, specialized diffuser profiles, and bespoke connector configurations. The factory handles all aspects of kit assembly, integrating cut-to-length strips with matching power supplies, controllers, accessories, and custom-branded packaging. We offer flexible reel packaging options including 5m or 10m reels with pre-applied connectors, and can accommodate private labeling with custom carton designs, user manuals, and compliance markings. Prototyping typically completes within 15 days, with volume production scaling to accommodate orders from 5,000 to over 500,000 kits monthly. All OEM products undergo the same rigorous aging and testing protocols as our branded lines, with documentation supporting UL, cUL, CE, and RoHS certifications as required by the target market. This end-to-end control from SMT assembly through final kit packaging ensures consistent quality and reliability for our OEM partners.

Application Scenarios

LED light strip kits are versatile lighting solutions suitable for a wide range of commercial environments including hotels, malls, and offices. Their flexibility, energy efficiency, and aesthetic appeal make them ideal for both functional and decorative applications.

In hotels, LED light strip kits are commonly used in guest rooms to highlight architectural features such as coves, headboards, and under-cabinet areas in minibars or desks. They enhance ambiance and provide soft, indirect lighting that contributes to a relaxing atmosphere. In lobbies and corridors, they can be installed along ceiling perimeters or stair edges to create a welcoming and modern appearance while improving visibility and safety.

Malls benefit from LED light strips in display windows, signage backlighting, and feature walls to draw attention to retail spaces and promotional areas. Their ability to produce vibrant colors and dynamic lighting effects makes them excellent for accentuating brand identity and creating visually engaging environments. Under-rail lighting along escalators or handrails also improves navigation and safety in high-traffic zones.

In office settings, LED light strips are often installed under desks, shelves, or within cabinetry to provide supplemental task lighting without glare. They are also used in conference rooms and reception areas to highlight branding elements or architectural details. Indirect lighting along ceiling coves helps reduce eye strain by minimizing harsh contrasts, contributing to a more comfortable and productive workspace.

When installing LED light strip kits, begin by ensuring the surface is clean, dry, and free of dust or grease to promote strong adhesion of the backing tape. Measure the area accurately and plan the layout to minimize cuts and connections. Avoid sharp bends and never exceed the maximum run length specified by the manufacturer to prevent voltage drop and uneven brightness. Use compatible connectors and power supplies, and always match the voltage of the strip to the driver. For longer runs, consider injecting power at multiple points or using amplifiers.

Secure the strips with clips or additional mounting tape in high-vibration or high-traffic areas. Ensure all electrical connections are properly insulated and protected, especially in humid or outdoor-prone zones. For permanent or concealed installations, verify that the strips are rated for the environment—such as using silicone-coated, waterproof strips in restrooms or kitchens. Finally, test the system before finalizing the installation and consult local electrical codes to ensure compliance.

Why Choose Beauty STC Lighting

Elevate your product offerings with Beauty STC’s premium LED light strip kits, engineered for superior performance and reliability in both residential and commercial applications. As your trusted manufacturing partner, we provide comprehensive technical support, rigorous quality control, and flexible customization options to meet your specific market demands. Our kits feature industry-leading color accuracy, energy efficiency, and seamless integration capabilities, backed by extensive in-house R&D and global compliance certifications. Partner with Beauty STC to access scalable production capacity and innovative lighting solutions that drive customer satisfaction and market differentiation. Contact our dedicated partnership manager today at [email protected] to discuss how we can collaborate on your next successful lighting project.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.