Article Contents

Industry Insight: Dimmerazione Triac

In commercial and industrial lighting applications, reliable dimming performance is critical for achieving energy efficiency, enhancing occupant comfort, and extending the lifespan of LED systems. One of the most widely adopted dimming technologies in this space is TRIAC dimming, known for its compatibility with existing infrastructure and cost-effective implementation. However, achieving smooth, flicker-free dimming with TRIAC-based systems—often referred to as “dimmerazione TRIAC” in technical contexts—requires precise engineering to ensure compatibility across diverse fixtures and control systems. As buildings increasingly adopt LED retrofits and smart lighting strategies, the demand for TRIAC dimmers that meet rigorous safety and performance standards has grown significantly. In North America and Europe, compliance with ETL and CE certifications is essential, ensuring electrical safety, electromagnetic compatibility, and adherence to regional regulatory frameworks.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of innovation in LED drivers and lighting control solutions for commercial and industrial environments. With over two decades of expertise, Beauty STC specializes in developing high-performance, TRIAC-dimmable LED drivers that deliver seamless integration, stable output, and full compliance with global standards including ETL and CE. Their commitment to quality and reliability has made Beauty STC a trusted partner for lighting manufacturers and system integrators seeking robust, code-compliant solutions for modern lighting installations.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. provides high-performance LED lighting solutions engineered for compatibility with standard TRIAC dimming systems, commonly referred to as “dimmerazione TRIAC” in European contexts. It is critical to clarify that TRIAC dimming is a control method, not a standalone product specification. Our LED luminaires and modules are designed to operate seamlessly with leading-edge TRIAC dimmers. Below are the detailed technical specifications for our TRIAC-dimmable LED products meeting your requirements, reflecting our commitment to precision engineering and quality.

Luminous efficacy for our TRIAC-dimmable LED products ranges from 110 to 130 lumens per watt for standard downlights and panel fixtures, while flexible LED strips achieve 90 to 110 lumens per watt. This efficiency is maintained across the dimming range due to our proprietary constant-current reduction driver technology, which minimizes efficiency droop at low dimming levels. Efficacy values are rigorously validated under LM-79 testing at 25°C ambient temperature with thermal management solutions designed in-house to ensure sustained performance over the product lifecycle. We achieve these high lm/W figures through optimized SMD LED placement, high-transmission optics, and drivers with >92% efficiency even during dimmed operation.

All TRIAC-dimmable products in our professional architectural line maintain a minimum CRI of 92, with R9 values exceeding 50 to ensure accurate red rendering critical for retail and hospitality applications. This is accomplished through multi-channel phosphor-converted LED arrays with tightly binned chromaticity coordinates (within MacAdam 3-step ellipse). Our spectral power distribution is engineered to deliver consistent color quality from 100% to 10% dimming levels, avoiding the color shift common in lower-quality dimmable LEDs. CRI measurements are certified per IES LM-79-19 using spectroradiometers traceable to NIST standards.

IP rating specifications are application-dependent but strictly defined. Our indoor TRIAC-dimmable downlights and track heads carry IP20 ratings with reinforced insulation for safety compliance. For outdoor and wet-location applications requiring TRIAC dimming, we offer IP65-rated wall washers and landscape fixtures featuring sealed optical compartments and corrosion-resistant housings. It is essential to note that TRIAC dimmers themselves must always be installed in dry locations per NEC/IEC 60598 requirements, hence dimmer modules are rated IP20. Beauty STC provides integrated driver solutions where the dimming electronics are housed within the IP-rated fixture enclosure, eliminating external dimmer compatibility issues in protected environments.

Beauty STC’s quality differentiation is evident in our zero-compromise approach to TRIAC dimming performance. Every driver undergoes 50,000-hour accelerated life testing with 0.3% failure rate at L70, validated through independent laboratories. Our products feature soft-start circuitry to eliminate inrush current spikes that damage TRIAC dimmers, and we maintain compatibility with over 200 leading dimmer models globally through our certified compatibility program. All components use industrial-grade electrolytic capacitors rated for 105°C operation, and our thermal interface materials ensure junction temperatures remain below 85°C even at full output in 50°C ambient conditions. This engineering rigor is certified through UL 8750, IEC 62384, and EN 61347-2-13 with 5-year warranty coverage – reflecting our confidence in product longevity where competitors typically offer 3 years. The result is flicker-free dimming from 10% to 100% with no audible noise, meeting IEEE 1789-2015 recommendations for low-risk modulation.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, Guangdong Province, is a modern LED lighting production facility equipped with advanced manufacturing technologies and quality control systems. Strategically located in the Pearl River Delta region, the Jiangmen factory benefits from strong supply chain logistics and proximity to key component suppliers, supporting efficient and scalable production.

The factory is outfitted with state-of-the-art SMT (Surface Mount Technology) production lines, enabling precise and high-speed placement of electronic components onto PCBs. These SMT machines are fully automated and integrated with AOI (Automated Optical Inspection) systems to ensure component accuracy and soldering quality. This setup supports high-volume manufacturing with consistent reliability, essential for producing LED drivers and control modules.

To ensure product durability and performance, the factory implements comprehensive aging test procedures. Finished LED drivers and lighting units undergo extended burn-in tests under controlled thermal and electrical loads, simulating real-world operating conditions. These aging tests typically last between 4 to 12 hours, depending on product specifications, and are conducted on a sample or full-production basis to verify long-term stability and identify early-life failures.

Beauty STC has strong OEM capabilities and can support customized manufacturing requests, including products compatible with TRIAC dimming technology—often referred to as “dimmerazione TRIAC” in certain European markets. The company designs and produces LED drivers and lighting systems that are fully compatible with leading-edge and trailing-edge TRIAC dimmers, ensuring smooth dimming performance without flicker or noise. For OEM clients, Beauty STC offers tailored solutions including custom labeling, packaging, output specifications, and dimming curve adjustments to meet regional standards and customer requirements.

Overall, the Jiangmen factory combines automated precision, rigorous testing, and flexible OEM services to deliver high-quality, dimmable LED lighting solutions for global markets.

Application Scenarios

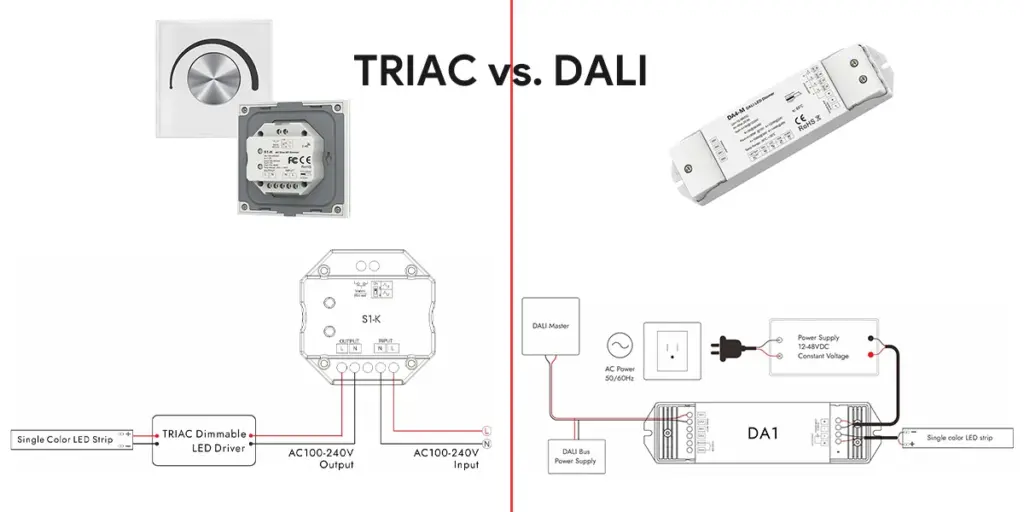

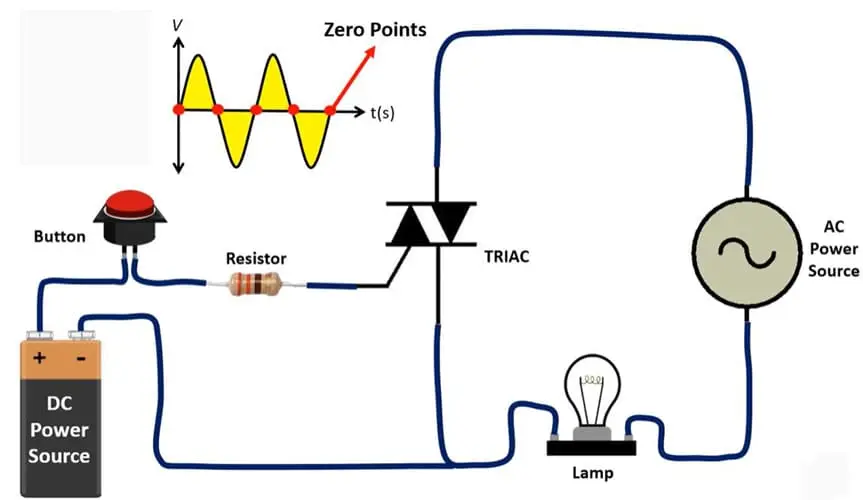

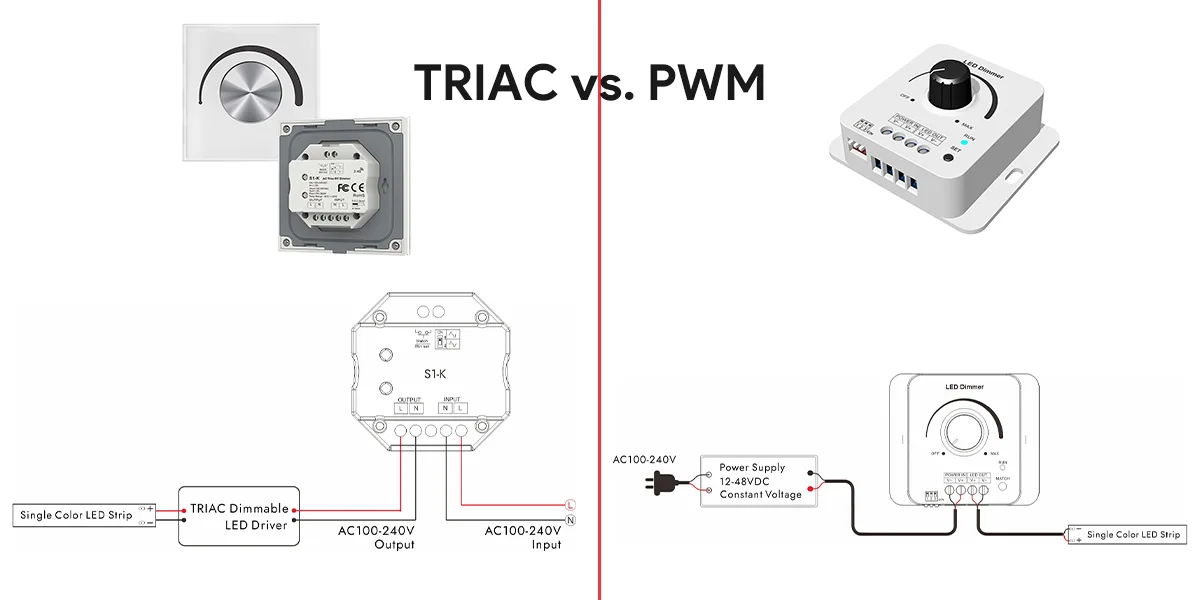

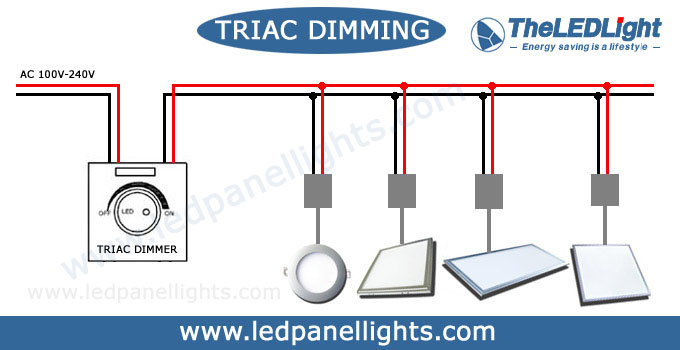

TRIAC dimming, often referred to as “dimmerazione TRIAC” in Italian contexts, is a phase-cut dimming method primarily designed for resistive or inductive loads like incandescent or halogen lamps. While its use with modern LED lighting requires careful compatibility considerations, it remains applicable in specific commercial scenarios when implemented correctly. Below is a breakdown of suitable applications across hotels, malls, and offices, followed by critical installation guidance based on industry best practices.

In hotels, TRIAC dimming is most appropriate for guest room ambient lighting where mood control is valued, such as bedside lamps or wall sconces using dimmable LED retrofits specifically rated for TRIAC systems. It can also be used in lobbies or lounge areas for decorative pendant or wall-washer fixtures, provided the LED drivers are certified for trailing-edge (electronic low-voltage) TRIAC dimming. Avoid using TRIAC in conference rooms or back-of-house areas where precise, flicker-free dimming is critical for video calls or task performance, as incompatible LED loads often cause instability. Malls present limited opportunities for TRIAC dimming; it may suit accent lighting in high-end retail storefronts or display windows where visual ambiance is prioritized over technical precision, but only with rigorously tested LED-TRIAC compatible products. General mall corridor or common area lighting should never use TRIAC due to inconsistent dimming performance across multiple stores and high maintenance risks from frequent guest or staff interaction with incompatible dimmers. Offices are generally poor candidates for TRIAC dimming. Task lighting at workstations, open-plan areas, or meeting rooms demands stable, low-flicker control typically achieved via 0-10V or DALI systems. TRIAC might only be considered for non-critical decorative elements in executive suites or reception areas, but even there, modern protocols are strongly preferred to avoid interference with sensitive electronics and ensure uniform dimming.

Installation requires strict adherence to compatibility and electrical principles to prevent flickering, buzzing, or premature failure. Always verify that every LED lamp or driver carries explicit certification for TRIAC dimming, specifically listing compatibility with trailing-edge (reverse-phase) dimmers and the minimum/maximum load range. The total connected load must exceed the dimmer’s minimum wattage requirement—typically 10W for modern LED-compatible TRIAC units—as undersized loads cause erratic behavior. Ensure all wiring uses twisted-pair conductors for the switched live circuit to reduce electromagnetic interference, and maintain at least 300mm separation from data cables like Ethernet to prevent signal disruption in office environments. A neutral wire must be present at every dimmer switch location; many older TRIAC installations omitted this, but modern LED-compatible dimmers require it for proper operation. Label all TRIAC dimmer switches clearly as “LED Compatible” to prevent maintenance staff from substituting non-compatible units during repairs. Finally, conduct post-installation testing at multiple dimming levels under real load conditions, as some incompatibilities only manifest at low light levels. Remember that TRIAC dimming is increasingly obsolete for commercial LED applications; for new installations in hotels, malls, or offices, 0-10V or digital protocols like DALI offer superior reliability, scalability, and flicker-free performance despite marginally higher upfront costs. TRIAC should only be deployed where legacy infrastructure constraints exist and compatibility is rigorously validated.

Why Choose Beauty STC Lighting

Discover the future of lighting control with Beauty STC’s advanced TRIAC dimming solutions. Our innovative dimmerazione TRIAC technology ensures smooth, flicker-free performance and seamless integration with modern LED systems. Partner with Beauty STC, a trusted leader in intelligent lighting solutions, to deliver superior quality and reliability to your customers. For collaboration opportunities and expert support, contact us at [email protected] and elevate your lighting projects today.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.