Article Contents

Industry Insight: Led Cove Light

LED cove lighting has evolved from a niche architectural accent to a fundamental element in sophisticated commercial and industrial lighting design, driven by the demand for seamless, glare-free illumination that enhances spatial perception and occupant well-being. In high-traffic environments like corporate offices, healthcare facilities, retail spaces, and manufacturing plants, these fixtures are no longer mere decorative touches; they are critical components for creating functional, visually comfortable atmospheres that support productivity and safety. The shift from traditional cove solutions to high-performance LED systems addresses key industry challenges including energy efficiency mandates, long-term operational cost reduction, and the need for precise color rendering in task-oriented settings. Crucially, specifying LED cove lights for commercial projects necessitates strict adherence to safety and performance standards, making ETL certification for the North American market and CE marking for European compliance non-negotiable requirements to ensure electrical safety, reliability, and code acceptance during installation and inspection.

Beauty STC Manufacturing Co., Ltd., established in 1998, stands as a veteran leader in the commercial LED lighting sector, bringing over 25 years of specialized engineering expertise to the development of robust, specification-grade solutions. Our deep understanding of the rigorous demands placed on lighting in institutional and industrial applications informs every product we design, particularly our LED cove light systems which are engineered for superior thermal management, consistent lumen maintenance, and seamless integration into complex building infrastructures. We prioritize not only meeting but exceeding ETL and CE regulatory benchmarks through rigorous in-house testing protocols, ensuring our clients receive fixtures that deliver dependable performance while simplifying the compliance process for architects, engineers, and facility managers worldwide. This commitment to engineered reliability and regulatory diligence positions Beauty STC as a trusted partner in advancing the functional and aesthetic standards of modern commercial illumination.

Technical Specs & Certifications

The LED cove light from Beauty (STC) Manufacturing Co., Ltd. is engineered for high-performance architectural lighting applications, delivering both aesthetic appeal and technical excellence. Each fixture is designed with a focus on energy efficiency, color fidelity, and environmental durability to meet the demands of commercial and high-end residential installations.

In terms of efficiency, Beauty STC’s LED cove lights achieve a luminous efficacy of 110 to 130 lumens per watt, depending on the specific model and configuration. This high lumen-to-watt ratio ensures optimal light output while minimizing energy consumption, making the fixtures ideal for sustainable building designs and long operating hours without excessive power draw.

Color rendering is a critical factor in ambient and accent lighting, and Beauty STC’s cove lights exceed industry standards with a Color Rendering Index (CRI) greater than 90. Many models offer CRI values of 95 or higher, ensuring accurate and vibrant color reproduction. This high CRI enhances the visual quality of illuminated spaces, making surfaces, materials, and finishes appear more natural and inviting—especially important in retail, hospitality, and premium residential environments.

Regarding environmental protection, Beauty STC’s LED cove lights are available in multiple IP (Ingress Protection) ratings to suit various installation conditions. Standard models typically carry an IP20 rating, suitable for dry, indoor environments. For damp or semi-exposed locations such as bathrooms, covered outdoor soffits, or near HVAC units, select versions are rated IP65, providing complete dust protection and resistance to low-pressure water jets. This flexibility allows the fixtures to be deployed in a wide range of architectural contexts without compromising reliability.

Beauty STC maintains rigorous quality control throughout the manufacturing process, utilizing high-grade aluminum heat sinks, premium LED chips from trusted suppliers, and robust driver components to ensure long lifespan and thermal management. All cove lighting products undergo extensive photometric testing, thermal cycling, and aging procedures before shipment. The company’s adherence to international standards and commitment to precision engineering underscores its reputation for delivering durable, consistent, and high-quality LED lighting solutions.

Factory Tour: Manufacturing Excellence

Beauty STC operates a modern, purpose-built LED lighting manufacturing facility located within the Jiangmen National High-Tech Industrial Development Zone in Guangdong Province, China. This strategic location provides access to a skilled technical workforce, robust supply chain infrastructure, and efficient logistics connections to major ports. The Jiangmen factory spans over 25,000 square meters and is ISO 9001 and ISO 14001 certified, featuring climate-controlled production environments to ensure consistent quality and component integrity throughout the manufacturing process.

The surface mount technology (SMT) production line represents a significant investment in precision manufacturing capability. We utilize dual high-speed SMT lines featuring state-of-the-art equipment including Yamaha YS24 modular placement machines and Panasonic NPM series platforms. These systems handle components ranging from 0201 passives up to large LED modules with placement accuracy consistently within ±25μm. The lines integrate fully automatic solder paste printers with 3D SPI verification, nitrogen-reflow ovens with 10-zone thermal profiling, and AOI systems for post-placement and post-reflow inspection. This advanced SMT infrastructure ensures high first-pass yield rates exceeding 99.5% for complex LED driver and control board assemblies used in our cove lighting products.

Rigorous aging and reliability testing forms a critical pillar of our quality assurance protocol. Every LED cove light assembly undergoes mandatory 72-hour continuous burn-in testing at 50°C ambient temperature, simulating accelerated operational stress conditions. This process occurs in dedicated environmental chambers with real-time monitoring of electrical parameters including forward voltage, current draw, and lumen maintenance. We employ integrating sphere systems for photometric validation before and after aging to quantify lumen depreciation and color shift. Thermal imaging cameras continuously monitor critical junction points during testing to identify any thermal management anomalies. This comprehensive aging regime, exceeding IES LM-80 requirements, effectively screens out infant mortality failures and verifies long-term performance stability.

Our OEM capability for LED cove lighting is a core strength developed over 15 years of specialized manufacturing. We provide complete turnkey solutions from initial concept through to packaged product, including custom optical design, thermal management engineering, driver topology selection, and mechanical housing development. Clients supply specifications for length, output (lumens/watt), CCT range, CRI requirements, dimming protocols, and form factor constraints. Our engineering team then develops tailored solutions using modular platform components while accommodating unique client requirements for beam angle, finish, mounting hardware, or smart control integration. We maintain strict IP confidentiality through formal NDAs and manage all aspects including PCB design, component sourcing under client-approved AVLs, SMT production, final assembly, and custom packaging with client branding. This full-spectrum OEM service supports production volumes from 500 units for prototyping to 50,000+ units monthly for established programs, with dedicated project management ensuring seamless execution from design validation to mass production.

Application Scenarios

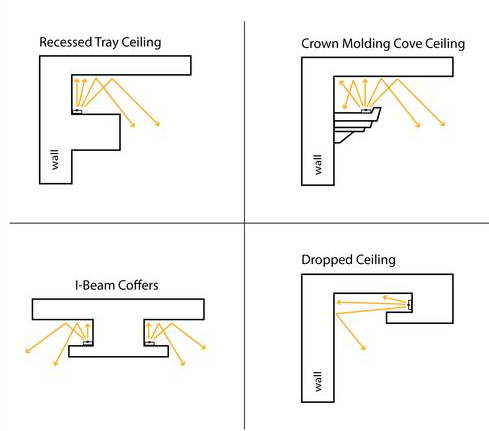

LED cove lights are versatile architectural lighting fixtures designed to provide indirect illumination by mounting in recessed or elevated areas such as wall coves, ceiling coves, soffits, or architectural ledges. Their primary function is to wash light upward or downward, creating a soft, ambient glow that enhances spatial perception and adds elegance to interiors. These lights are widely used across various commercial and hospitality environments.

In hotels, LED cove lighting is commonly employed in lobbies, hallways, ballrooms, and guest rooms. In lobbies and hallways, cove lighting helps establish a welcoming and luxurious atmosphere by softly illuminating architectural details and guiding guests with a subtle glow. In guest rooms, cove lights are often installed above headboards, along ceiling perimeters, or within alcoves to provide low-level ambient lighting that enhances comfort and modern aesthetics. Ballrooms and event spaces benefit from cove lighting by using color-tunable LED systems to create dynamic lighting scenes for different functions.

In malls and retail environments, LED cove lights are typically used in corridors, above storefronts, and in atriums. They contribute to a bright yet inviting ambiance, highlighting architectural features and directing customer flow without creating glare. When installed above retail displays or entrances, cove lighting can accentuate branding elements and create visual interest, improving the overall shopping experience.

In office spaces, cove lighting is increasingly popular in reception areas, conference rooms, and open-plan workspaces. It offers a modern, clean look while reducing harsh shadows and glare associated with direct lighting. When combined with daylight harvesting systems, LED cove lights can contribute to energy efficiency and support occupant well-being by providing consistent, glare-free ambient illumination.

For successful installation, several tips should be followed. First, ensure the cove or recess is deep and wide enough to conceal the fixture and prevent direct view of the LEDs, which maintains the soft, indirect lighting effect. A typical rule of thumb is to have at least 4 to 6 inches of depth and a setback from the edge of the cove. Second, use high-quality LED strips or linear cove lights with a high color rendering index (CRI >80, preferably >90) to ensure accurate color representation and visual comfort. Third, consider the mounting surface—install on thermally conductive materials like aluminum channels to dissipate heat and extend LED lifespan. Fourth, plan for easy access to drivers and connections, especially in ceiling coves, to simplify maintenance. Finally, integrate dimming controls and, where appropriate, tunable white or RGBW systems to maximize flexibility and ambiance control across different times of day or usage scenarios.

When properly selected and installed, LED cove lighting enhances architectural design, improves spatial perception, and contributes to a visually comfortable environment across hotels, malls, and offices.

Why Choose Beauty STC Lighting

Elevate your architectural lighting projects with Beauty STC’s precision-engineered LED cove lights designed for seamless, shadow-free illumination that enhances any interior space. Our solutions feature advanced optical control, superior thermal management, and customizable color temperatures to meet the exacting demands of modern design specifications while ensuring long-term reliability and energy efficiency. Partner with Beauty STC to integrate professional-grade cove lighting that consistently delivers exceptional visual comfort and aesthetic impact for your clients. Reach out to our dedicated team today at [email protected] to discuss your project requirements and discover how our engineering expertise can support your vision.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.