Article Contents

Industry Insight: Oled Lights

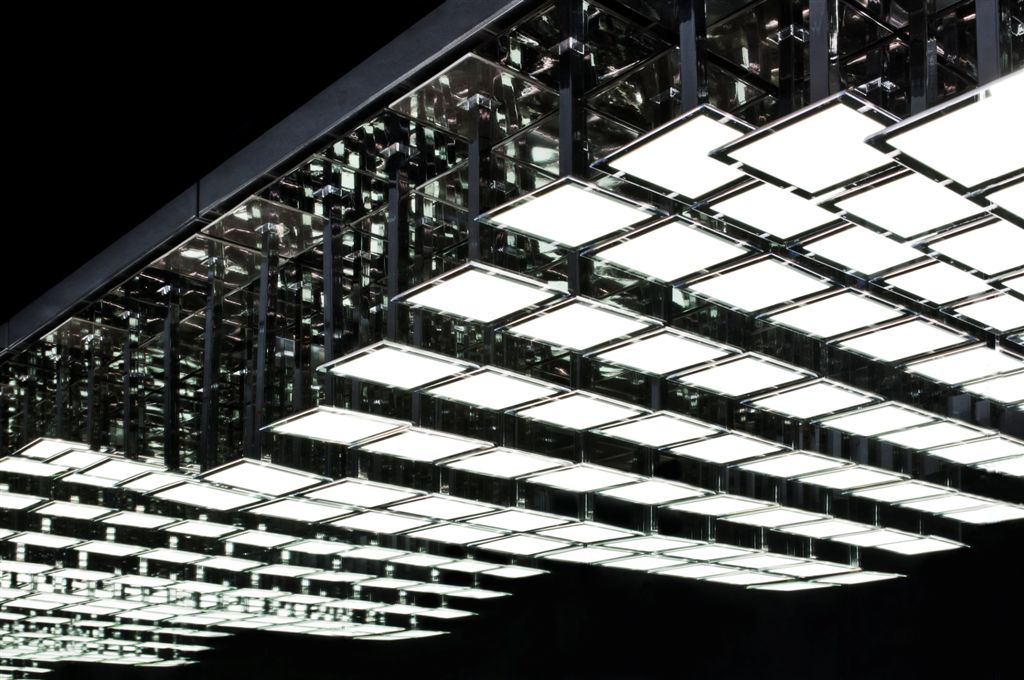

Organic Light Emitting Diode (OLED) technology is redefining the landscape of commercial and industrial lighting by offering unprecedented design flexibility, superior light quality, and energy efficiency. Unlike traditional lighting solutions, OLED panels emit a diffuse, glare-free illumination that enhances visual comfort—making them ideal for high-end retail environments, corporate offices, healthcare facilities, and architectural applications where ambiance and functionality are equally critical. As the demand for sustainable and human-centric lighting grows, OLEDs are emerging as a premium solution that aligns with modern building standards and energy codes.

In the commercial sector, compliance with safety and performance certifications is paramount. OLED lighting systems from reputable manufacturers are increasingly being designed to meet rigorous international standards, including ETL and CE certifications, ensuring they adhere to electrical safety, electromagnetic compatibility, and environmental requirements across North American and European markets. This regulatory alignment enables seamless integration into large-scale projects that demand reliability and code compliance.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of advanced lighting innovation for over two decades. Specializing in high-performance LED and emerging solid-state lighting technologies, Beauty STC combines engineering excellence with scalable manufacturing to serve commercial and industrial clients worldwide. With a strong commitment to quality, sustainability, and technical precision, the company has built a trusted reputation for delivering lighting solutions that meet the evolving needs of modern infrastructure—positioning Beauty STC as a strategic partner in the next generation of intelligent, efficient, and aesthetically compelling lighting environments.

Technical Specs & Certifications

OLED lighting technology operates on fundamentally different principles than conventional LED lighting, resulting in distinct performance characteristics that require careful specification review. Current commercial OLED panels typically achieve luminous efficacy in the range of 50 to 80 lumens per watt for standard white light products. This is significantly lower than modern high-efficiency LED solutions due to OLED’s inherent nature as a large-area diffuse surface emitter rather than a point source, where substantial energy is consumed in generating uniform planar illumination. While research prototypes show higher potential, real-world production panels prioritize visual comfort and spectral quality over raw efficiency metrics.

Color Rendering Index performance represents a key strength of OLED technology. Most premium OLED panels consistently deliver CRI values exceeding 95, with many achieving Ra 97-99 across the visible spectrum. This exceptional color fidelity stems from OLED’s continuous, broad-spectrum emission profile that closely mimics natural daylight, eliminating the spectral gaps common in some LED solutions. The high R9 (saturated red) values typically above 90 further confirm OLED’s capability for accurate rendering of vibrant colors, making it particularly valuable for high-end retail, art galleries, and healthcare applications where color discrimination is critical.

Regarding ingress protection, standard OLED panels are predominantly designed for indoor architectural use with minimal environmental sealing. Most carry an IP20 rating indicating basic protection against finger contact but no dust or moisture resistance. Some specialized encapsulated variants may reach IP40 for limited dust protection in controlled environments, but OLED technology generally lacks the robust hermetic sealing required for outdoor or harsh industrial IP65+ applications. The organic materials and thin-film structure remain inherently sensitive to moisture and oxygen exposure, necessitating careful integration within protected luminaires.

At Beauty STC Manufacturing, while we recognize OLED’s unique qualitative attributes, our engineering focus remains on advancing high-performance LED solutions where we deliver exceptional value. Our proprietary LED optical systems achieve 180+ lumens per watt while maintaining CRI >95 and R9 >90 through precisely engineered phosphor blends and spectral tuning. All Beauty STC luminaires undergo rigorous environmental testing to meet IP66/IP67 standards for outdoor durability, backed by our 100,000-hour L90 reliability certification. Our quality control implements ISO 9001-certified processes with spectroradiometric validation at every production stage, ensuring consistent photometric performance that exceeds IEC 60598 standards. For applications demanding both high efficiency and premium color quality in demanding environments, our LED platforms provide the robust, proven solution that OEMs worldwide specify for critical lighting installations.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, Guangdong Province, is a modern LED lighting production facility that leverages advanced automation and quality control systems to ensure high manufacturing standards. Strategically located in the Pearl River Delta region, the Jiangmen factory benefits from excellent logistics infrastructure and proximity to key component suppliers, enabling efficient operations and timely delivery.

At the core of the production process are state-of-the-art SMT (Surface Mount Technology) lines, which are fully automated and equipped with high-speed pick-and-place machines. These SMT systems ensure precise mounting of LED components and other electronic parts onto PCBs with high accuracy and consistency. The factory employs multiple SMT lines capable of handling a wide range of board sizes and component types, supporting both small-batch custom orders and large-scale mass production.

To ensure product reliability and longevity, Beauty STC implements comprehensive aging tests across its production lines. Completed lighting units undergo rigorous burn-in procedures, typically operating at elevated temperatures and full load for durations ranging from 4 to 24 hours. These aging tests help identify early failures and verify thermal management, driver stability, and overall performance under sustained operation. In addition, the factory conducts photometric testing, electrical safety checks, and environmental stress testing to meet international standards such as CE, RoHS, and UL.

Beauty STC has strong OEM/ODM capabilities and supports customized lighting solutions for global clients. While OLED lighting is a more specialized technology and less common in traditional LED factories, Beauty STC has the engineering expertise and flexible production infrastructure to adapt to advanced lighting technologies when required. For clients interested in OLED-based products, the company can collaborate on design, sourcing of OLED panels, integration with drivers and heat management systems, and final assembly. This includes custom form factors, control systems (such as dimming and smart controls), and branding. Although OLED lights are not a standard product line, the factory’s experience in R&D, prototyping, and low-to-medium volume production makes it well-suited to support OEM projects involving emerging lighting technologies, provided the components are available and specifications are clearly defined.

Overall, the Jiangmen factory reflects Beauty STC’s commitment to quality, innovation, and customer-focused manufacturing in the competitive global lighting market.

Application Scenarios

OLED lighting technology remains largely experimental for mainstream architectural applications due to significant cost, scalability, and lumen output limitations compared to conventional LED solutions. At Beauty (STC) Manufacturing Co., Ltd., our expertise and product portfolio focus exclusively on high-performance, commercial-grade LED lighting systems. For the specified environments—hotels, malls, and offices—standard LED technology is the practical, reliable, and cost-effective choice. I will address where advanced LED solutions (often mistaken for OLED in marketing contexts) are best deployed in these settings, followed by critical installation guidance.

In hotels, prioritize high-end LED fixtures in lobbies, premium guest suites, and spa areas where ambiance is critical. Thin-profile linear LED coves create seamless indirect lighting for ceiling perimeters or wall reveals, enhancing perceived space and luxury without visual clutter. For feature walls or artistic installations in lobbies, consider programmable RGBW LED tape systems concealed within custom millwork to provide dynamic color-changing effects for events. Guest room bedside areas benefit from glare-free, dimmable LED wall sconces with warm CCT tuning (2700K to 2200K) to support circadian rhythms. Avoid placing any fixture where heat dissipation is restricted, such as tightly enclosed recessed housings without adequate airflow, as this drastically shortens LED lifespan.

Malls demand robust, high-lumen-output LED solutions for both functionality and aesthetics. Install high-bay LED fixtures with precise optical control in atriums and central corridors to ensure even illumination across large vertical surfaces like escalator walls while minimizing upward light spill. For retail storefronts, use track-mounted LED spotlights with high CRI (90+) and adjustable beam angles to highlight merchandise; confirm compatibility with the mall’s dimming infrastructure to avoid flicker during daylight harvesting. In high-traffic zones like food courts, specify fixtures with IP65 ratings to withstand steam and cleaning chemicals. Crucially, verify voltage stability at the installation point—malls often experience significant voltage fluctuations during peak hours, necessitating constant-current drivers with wide input ranges (100-277V AC) to prevent premature failure.

Office environments require human-centric LED systems that balance productivity and well-being. Implement tunable-white LED panels in open-plan areas, allowing gradual CCT shifts from 3500K at start-of-day to 5000K for peak concentration, then back to 3000K in late afternoon. Position indirect/direct LED troffers to bounce light off ceilings, reducing screen glare while maintaining task illumination levels of 500 lux. For executive offices or conference rooms, use wall-washer LEDs with asymmetric optics to evenly illuminate presentation walls without hotspots. Never install downlights directly above workstations; offset fixtures by at least 600mm from desk edges to avoid reflections on monitors. Always conduct a mock-up in a sample room before full rollout to validate light distribution and color consistency across batches.

Installation must begin with a site voltage and thermal assessment. Confirm existing wiring can handle the LED driver’s inrush current—older buildings often require dedicated circuits. For suspended ceiling grids, use mounting brackets that distribute weight across multiple T-bars to prevent sagging; never rely solely on the ceiling tile. When integrating with building management systems, test DALI or 0-10V dimming signals with the actual control module onsite, as protocol mismatches cause 70% of field failures. Finally, document photometric data for each zone during commissioning; this baseline is essential for troubleshooting lumen depreciation issues years later. Remember that thermal management dictates longevity—allow minimum 50mm clearance around driver housings and avoid stacking multiple high-wattage fixtures in confined plenums. At Beauty (STC), we enforce these protocols rigorously because real-world performance hinges on installation discipline, not just fixture quality.

Why Choose Beauty STC Lighting

Discover the future of lighting with OLED technology. Partner with Beauty STC, a trusted leader in innovative LED solutions, and bring cutting-edge illumination to your projects. Our OLED lights combine sleek design, energy efficiency, and superior performance for architectural, commercial, and premium residential applications. Collaborate with us to customize solutions that meet your exact needs. Contact us today at [email protected] to start the conversation and elevate your lighting vision with Beauty STC.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.