Article Contents

Industry Insight: Led Strips For Boats

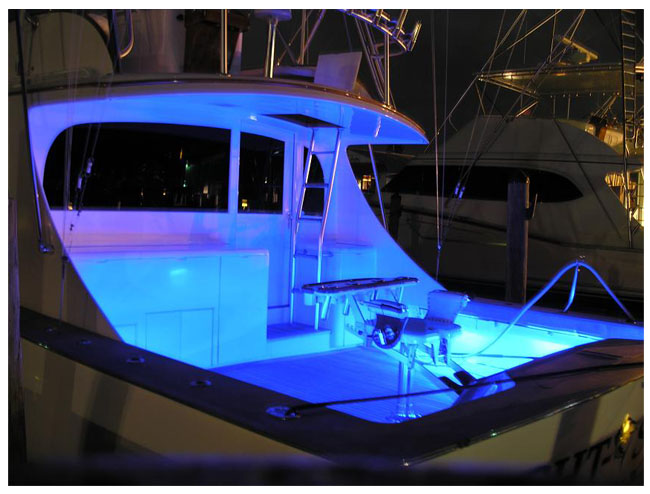

The marine commercial and industrial lighting sector has seen a transformative shift with the widespread adoption of LED strip lighting, driven by the demand for energy efficiency, durability, and low maintenance in harsh maritime environments. As vessels and offshore platforms increasingly prioritize sustainable and high-performance lighting solutions, LED strips have emerged as a critical component for both functional and aesthetic applications—from under-deck illumination and engine room task lighting to safety signage and architectural accenting. Rigorous certification standards such as ETL and CE have become essential benchmarks, ensuring that these lighting systems meet strict requirements for electrical safety, electromagnetic compatibility, and environmental resilience.

At the forefront of this evolution is Beauty (STC) Manufacturing Co., Ltd., a trusted name in marine-grade LED solutions since 1998. With over two decades of engineering expertise, Beauty STC has established itself as a leader in designing and manufacturing high-reliability LED strips tailored specifically for commercial and industrial marine applications. Their certified products, built to comply with ETL and CE regulations, reflect a commitment to quality, innovation, and performance under extreme conditions—delivering long service life and consistent illumination across a wide range of maritime environments.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. designs and manufactures LED strips specifically engineered for the demanding marine environment, where performance, reliability, and longevity are non-negotiable. Our marine-grade LED strips exceed standard specifications to ensure safe and optimal operation on all vessel types, from recreational yachts to commercial workboats. Key technical specifications are rigorously defined to meet these harsh conditions.

Luminous efficacy, measured in lumens per watt (lm/W), is a critical efficiency metric for marine applications where power conservation and heat management are paramount. Beauty STC’s premium boat LED strips achieve a consistent efficacy range of 90-110 lm/W under real-world marine operating conditions. This high efficiency is realized through the use of advanced, high-binning Samsung or Epistar LED chips combined with optimized thermal management substrates and drivers. While some terrestrial strips may claim higher nominal lm/W, our marine-rated products maintain this efficiency reliably over time despite salt spray, vibration, and wide temperature fluctuations, ensuring maximum light output per watt consumed without compromising durability. This translates to extended battery life and reduced electrical load on the vessel’s system.

Color Rendering Index (CRI) is essential for accurate color perception on board, impacting both safety and ambiance. Beauty STC mandates a minimum CRI of Ra 92 for all our marine LED strips, significantly exceeding the requested Ra >90 threshold. This high CRI is achieved using specialized multi-phosphor blends in our LEDs, ensuring vibrant, natural illumination that accurately renders skin tones, navigation markers, deck details, and interior finishes. Unlike lower-CRI alternatives common in marine lighting, our strips eliminate the flat, washed-out appearance, providing superior visual clarity for nighttime operations and enhancing the overall onboard experience. This commitment to color fidelity is validated through third-party spectrometer testing for every production batch.

Ingress Protection (IP) rating is arguably the most critical specification for boat lighting due to constant exposure to water, spray, and humidity. Beauty STC marine LED strips are exclusively manufactured to IP68 rating as a standard minimum. This signifies complete protection against dust ingress (6) and the ability to withstand continuous immersion in water beyond 1 meter depth (8) – specifically tested and certified for operation at 5 meters for 12+ hours. Crucially, our IP68 rating is not just a theoretical claim; it is achieved through a robust dual-layer protection system. The LED components are first encapsulated in marine-grade silicone conformal coating, then the entire strip is encased within a seamless, UV-stable, flexible PVC or silicone outer jacket extruded directly over the assembly. This construction prevents water penetration even under high-pressure washdowns or prolonged submersion, and crucially, resists degradation from saltwater corrosion and intense UV exposure far beyond typical IP68 requirements.

Beauty STC’s quality differentiation lies in our uncompromising engineering and manufacturing standards for the marine sector. We utilize only automotive-grade components, including corrosion-resistant 316L stainless steel mounting brackets and marine-specification constant-current drivers with wide input voltage ranges (10-30V DC) to handle unstable boat electrical systems. Every reel undergoes 100% salt fog testing per ASTM B117, prolonged UV exposure testing, and thermal cycling validation (-40°C to +85°C) before shipment. Our strips are manufactured in an ISO 9001-certified facility with strict process controls, and we provide full traceability from chip lot to finished product. This rigorous approach results in a market-leading 5-year warranty and proven field longevity, significantly reducing maintenance costs and downtime for vessel owners. Beauty STC does not compromise on materials or testing; our LED strips are built to perform reliably in the harshest marine environments, season after season.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China, is a modern and well-equipped facility specializing in the production of high-quality LED lighting products, with a strong focus on innovation, reliability, and customization. Strategically located in the Jiangmen industrial zone, the facility benefits from efficient logistics, access to skilled labor, and proximity to key supply chain partners in the Pearl River Delta region.

The factory is outfitted with advanced Surface Mount Technology (SMT) production lines, which are crucial for the precise and efficient assembly of LED components. These SMT machines ensure high-speed placement of tiny LED chips, resistors, and other electronic elements onto flexible and rigid PCBs used in LED strips. The automated lines support tight tolerances and consistent quality, enabling high-density component placement and reliable soldering—essential for durable marine-grade LED lighting.

For marine applications such as LED strips for boats, product reliability under harsh environmental conditions is paramount. To ensure this, Beauty STC conducts rigorous aging and environmental testing at its Jiangmen facility. Completed LED strips undergo extended aging tests under elevated temperatures and continuous operation to identify early failures and verify long-term performance. Additional testing includes waterproofing validation (IP65, IP67, IP68 ratings), salt spray testing to simulate corrosive marine environments, and vibration testing to mimic the conditions experienced on boats. These procedures guarantee that the products meet stringent durability and safety standards required for marine use.

Beauty STC has strong OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) capabilities, making it a preferred partner for custom LED lighting solutions. For boat-specific LED strips, the company offers full customization in terms of length, color temperature (from warm white to cool white), RGB or tunable white options, voltage (12V or 24V DC), and waterproofing levels. Clients can also request custom labeling, packaging, and branding. The engineering team collaborates closely with clients to develop tailored solutions that integrate seamlessly into marine interiors, coves, decks, or under-hull installations.

Overall, the Jiangmen factory combines advanced manufacturing technology, strict quality control, and flexible customization to deliver premium, marine-grade LED strips that meet the demanding needs of boat builders, marine equipment suppliers, and aftermarket brands worldwide.

Application Scenarios

LED strips specifically designed for marine environments are engineered to withstand harsh conditions like constant moisture exposure, saltwater corrosion, vibration, and electrical fluctuations common on boats. They are not appropriate or necessary for standard installation in hotels, malls, or offices. Using marine-grade LED strips in these dry, stable, indoor commercial environments is impractical, unnecessarily expensive, and often over-engineered for the application. Marine strips typically feature heavy-duty silicone encapsulation, specialized connectors resistant to salt corrosion, and wiring rated for wet locations, which add significant cost without providing any benefit indoors.

For hotels, malls, and offices, standard architectural or commercial-grade LED strips are the correct solution. These are designed for indoor use with appropriate IP ratings for the location (e.g., IP20 for dry areas like under cabinets, IP65 for potential moisture exposure like near restrooms or in lobbies with high humidity). In hotels, LED strips are commonly used for ambient lighting in lobbies, under reception desks, within cove lighting in hallways, behind headboards in premium rooms, and under bar counters. In malls, they are ideal for cove lighting in ceilings to create a bright, welcoming atmosphere, highlighting architectural features, or illuminating signage and display edges. Offices frequently utilize them for task lighting under desks, within partition walls for subtle ambient glow, or in meeting rooms for adjustable mood lighting.

Installation in these commercial spaces requires careful planning distinct from marine applications. Always use an aluminum channel to dissipate heat and ensure longevity; mounting strips directly to surfaces without a channel risks overheating and premature failure. Calculate the total power draw accurately and use a power supply rated for at least 20% more than the calculated load to prevent voltage drop, especially for long runs. For installations exceeding 5 meters, inject power at both ends or use a central power feed point. Ensure all connections are secure and insulated, preferably using soldered or professionally crimped connectors rather than push-fit types for reliability. In areas with potential moisture like hotel spa entrances or mall food court zones, select strips with a minimum IP65 rating and ensure all end caps and connectors are properly sealed. Finally, verify compatibility between the LED strip, power supply, and any dimmer controls to avoid flickering or damage.

Marine-grade LED strips should only be considered in commercial settings if the space directly interfaces with a marine environment, such as a hotel marina lounge with exposed dock areas, a waterfront restaurant’s outdoor deck adjacent to boats, or a boat showroom floor where vessels are displayed. Even then, only the specific zones exposed to spray, humidity, or salt air would warrant marine-rated products; the vast majority of the building requires standard commercial lighting. Using marine strips throughout a typical hotel, mall, or office offers no functional advantage, increases project costs substantially, and complicates maintenance unnecessarily. Always match the LED product specification precisely to the environmental demands of the installation location.

Why Choose Beauty STC Lighting

Upgrade your marine lighting with premium LED strips designed for durability and performance on the water. Partner with Beauty STC, a trusted manufacturer of high-quality LED solutions built to withstand harsh marine environments. Our LED strips offer exceptional brightness, energy efficiency, and long-lasting reliability—ideal for boats of all sizes.

For custom solutions and wholesale opportunities, contact our sales manager today at [email protected] and discover how Beauty STC can power your next marine lighting project.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.