Article Contents

Industry Insight: Control Led Strip

In the evolving landscape of commercial and industrial lighting, intelligent control and energy efficiency have become paramount. LED strip lighting, particularly controllable systems, has emerged as a transformative solution—offering dynamic illumination, precise light management, and long-term operational savings. These systems are not only redefining architectural aesthetics and task lighting but are also enhancing functionality in environments ranging from manufacturing facilities and warehouses to retail spaces and office complexes. As demand grows for reliable, code-compliant lighting solutions, certifications such as ETL and CE have become essential markers of safety, performance, and global market readiness—ensuring that LED control systems meet rigorous North American and European standards.

At the forefront of this innovation is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED lighting technology since its founding in 1998. With over two decades of engineering excellence, Beauty STC has built a reputation for delivering high-performance, code-compliant LED strip systems tailored to the demanding requirements of commercial and industrial applications. Combining robust design, advanced control compatibility, and adherence to international standards, Beauty STC continues to empower architects, engineers, and facility managers with lighting solutions that are as reliable as they are revolutionary.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. provides high-performance controllable LED strip solutions designed for demanding architectural, commercial, and premium residential applications where precise light control, efficiency, and color fidelity are critical. The term “control LED strip” typically refers to addressable or digitally controllable strips, such as those using protocols like DMX512, DALI, or proprietary IC-based systems (e.g., SK6812, WS2815). Our technical specifications for such strips meeting the requested criteria are detailed below, reflecting our commitment to engineering excellence.

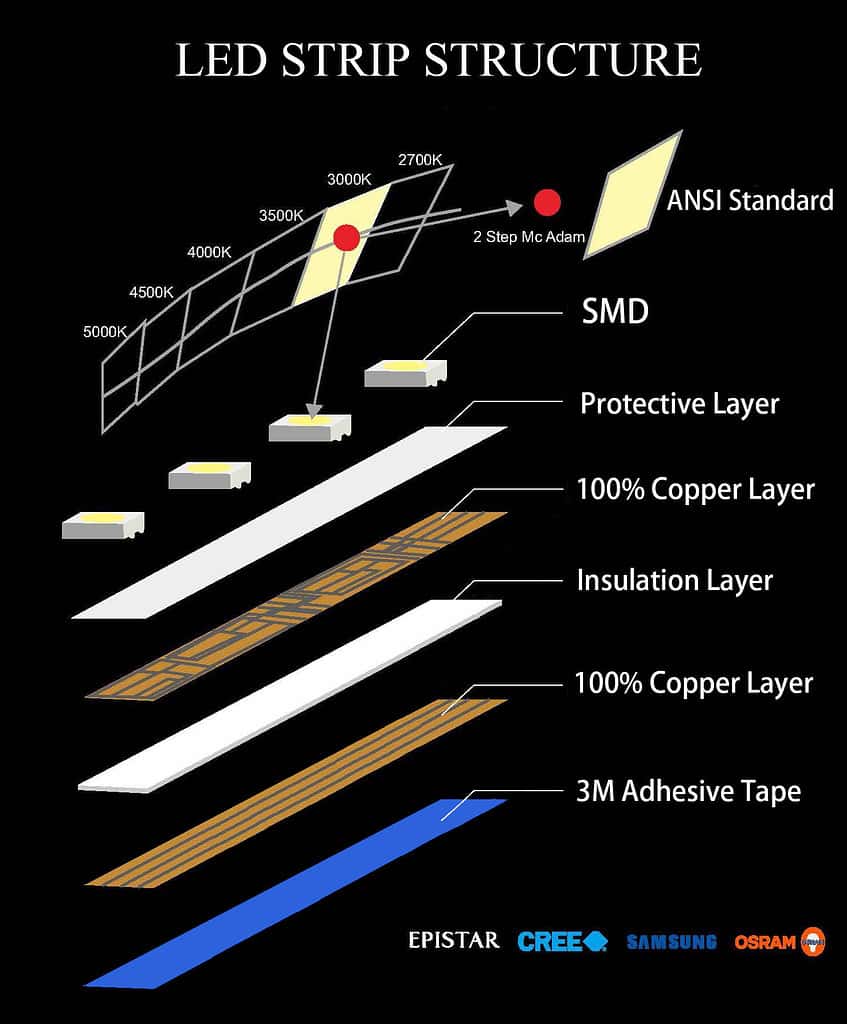

Lumens per Watt efficiency is a core focus for Beauty STC controllable strips. We achieve industry-leading efficacy ranges of 110 to 130 lumens per watt under standard operating conditions at 25°C ambient temperature. This performance is realized through the strategic integration of high-bin Samsung LM301B or Lumileds LUXEON 3014 mid-power LEDs, coupled with optimized constant-current driver ICs and proprietary thermal management designs utilizing 2-ounce copper PCB substrates. Actual efficacy varies based on drive current, color temperature, and specific IC configuration, but our engineering ensures maximum photon output per watt consumed while maintaining signal integrity for control protocols. This efficiency directly translates to lower operational costs and reduced heat generation, crucial for densely packed controllable installations.

Color Rendering Index (CRI) performance exceeding 90 is non-negotiable in our premium controllable strip portfolio. Beauty STC consistently delivers CRI Ra values of 92 to 95 across standard color temperatures (2700K to 4000K), verified using calibrated spectroradiometers per ANSI C78.377 and IES LM-79 standards. Critically, we prioritize R9 (saturated red) values above 50, ensuring vibrant, natural rendering of critical colors often compromised in lower-quality strips. This exceptional color fidelity is achieved through a proprietary multi-phosphor blend applied to our selected LED chips during manufacturing, rigorously batch-tested to maintain consistency. High CRI is maintained across the full dimming and color-changing range inherent in controllable strips, a key differentiator validated through our in-house optical laboratories.

Environmental protection is paramount for reliable controllable strip operation. Beauty STC offers multiple IP-rated solutions tailored to application needs. Our standard controllable strips feature IP20 rating for dry, indoor environments. For damp or outdoor use, we provide IP65-rated strips utilizing a precision-applied, optically clear silicone conformal coating over the entire PCB assembly, including all control ICs and solder joints, protecting against dust and low-pressure water jets. For fully submersible or harsh environment applications, our premium IP67-rated strips undergo a dual-stage encapsulation process: initial conformal coating followed by a secondary, seamless silicone overmolding, creating a continuous barrier tested to withstand temporary immersion up to 1 meter depth for 30 minutes. All IP-rated controllable strips undergo stringent 5000-hour salt spray testing per ASTM B117 to ensure long-term corrosion resistance, far exceeding basic certification requirements.

Beauty STC’s quality leadership in controllable LED strips is embedded in our manufacturing DNA. We operate under strict ISO 9001 and IATF 16949 certified processes, with every controllable strip batch subjected to five critical optical and electrical validation steps including spectral distribution analysis, lumen maintenance testing, and signal integrity verification across the full control range. Our proprietary IC-level surge protection and transient voltage suppression circuits, integrated directly onto the strip, provide superior resilience against electrical noise common in complex control systems. Component traceability from raw materials through final assembly ensures accountability, while our industry-leading 5-year limited warranty underscores confidence in product longevity and performance stability. This relentless focus on precision engineering and validation ensures Beauty STC controllable strips deliver not just specifications on paper, but reliable, high-fidelity light output and control performance throughout their operational lifespan in real-world installations.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, China, is a modern LED lighting production base strategically located in the Guangdong province, known for its strong electronics and manufacturing ecosystem. The factory is equipped with advanced surface mount technology (SMT) production lines, featuring high-precision automated SMT machines from leading global manufacturers. These machines ensure accurate placement of LED components and driver circuitry onto flexible and rigid printed circuit boards (PCBs), enabling efficient and consistent production of high-quality LED strips, including the specialized control LED strip products.

The SMT lines are integrated with automated optical inspection (AOI) systems to verify solder joint quality and component alignment immediately after reflow, minimizing defects and ensuring high yield rates. This level of automation supports both high-volume production and small-batch customization, which is essential for meeting diverse client demands.

To ensure long-term reliability and performance, the Jiangmen factory conducts rigorous aging tests on all LED strip products. Completed strips undergo continuous operation under elevated temperatures and humidity conditions for durations ranging from 24 to 72 hours, simulating extended use. During this period, electrical performance, color consistency, brightness levels, and thermal behavior are closely monitored. Any units exhibiting deviations are removed, guaranteeing that only stable, durable products proceed to packaging and shipment.

Beauty STC has strong OEM capabilities, particularly for control LED strips, which include addressable, RGB, and programmable variants. The company supports full customization, from circuit design and PCB layout to firmware development for control protocols such as DMX512, SPI, 12V/24V analog, and compatibility with platforms like Arduino, ESP32, and popular smart home systems. Clients can specify length, density, color temperature, brightness, IP rating, and even branding, with the factory providing end-to-end support from prototyping to mass production. This flexibility, combined with strict quality control and in-house engineering expertise, makes Beauty STC a trusted OEM partner for global lighting brands and system integrators.

Application Scenarios

Control LED strips, particularly addressable or programmable types, offer dynamic lighting solutions ideal for enhancing ambiance, functionality, and energy efficiency across commercial spaces. In hotels, these strips excel in lobby feature walls and reception desks to create welcoming, customizable atmospheres that reflect brand identity. Corridor coves benefit from subtle, motion-activated illumination for safe nighttime navigation without disturbing guests. Guest room headboards and under-cabinet areas provide personalized dimming and color temperature control, improving occupant comfort and satisfaction. High-end suites often utilize them for architectural accenting of ceilings or bathtubs, adding luxury through programmable scenes.

Malls leverage control LED strips extensively for impactful visual merchandising and spatial definition. Exterior facades and canopy installations use weatherproof addressable strips for dynamic branding and event-driven color changes that attract attention day or night. Interior common areas, such as atriums or food court perimeters, employ them for large-scale cove lighting that shifts color to influence crowd energy during promotions or holidays. Retail storefronts integrate them within signage and display shelving to highlight merchandise with targeted color rendering and animated effects, directly supporting sales objectives.

Offices implement control LED strips primarily for human-centric lighting and adaptive workspaces. Under-desk coves and partition tops provide glare-free task illumination with tunable white options that synchronize with circadian rhythms, reducing eye strain. Conference rooms utilize them for perimeter accent lighting that shifts intensity and color to match meeting modes—energizing cool tones for brainstorming, warmer hues for relaxation. Breakout zones and stairwells incorporate them for wayfinding and mood enhancement, with motion-sensing dimming ensuring energy savings during low occupancy.

Installation requires meticulous planning to ensure performance and longevity. Always calculate voltage drop for runs exceeding 5 meters by using 24V systems or injecting power at multiple points along the strip; undervoltage causes color distortion and premature failure. Waterproof strips (IP65+) are mandatory for exterior mall applications or hotel pool areas, with all connectors sealed using dielectric grease. Conceal controllers and power supplies within accessible ceiling plenums or service channels, never within insulated cavities where heat buildup occurs. For addressable strips, maintain strict signal integrity by using twisted-pair data cables, keeping data lines under 10 meters without repeaters, and avoiding parallel routing with high-voltage wiring. Verify fire safety compliance by selecting strips with UL 8750 certification and installing them within non-combustible coves per local building codes. Always test controllers with full strip loads before final mounting to confirm smooth dimming and color transitions across all channels.

Why Choose Beauty STC Lighting

Take control of your LED strip lighting projects with confidence and precision. Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in innovative LED solutions. Our advanced control systems ensure seamless integration, superior performance, and long-lasting reliability for residential, commercial, and industrial applications.

Whether you’re looking for custom LED strips or smart control technologies, our expert team is ready to support your needs. To learn more and discuss your project, contact us today at [email protected]. Let Beauty STC be your preferred partner in lighting excellence.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.