Article Contents

Industry Insight: T8 Vs T12 Lights

In the evolving landscape of commercial and industrial lighting, the transition from T12 to T8 fluorescent lamps has become a pivotal consideration for facility managers, electrical contractors, and building owners focused on efficiency, compliance, and long-term cost savings. As energy codes tighten and sustainability initiatives gain momentum, T8 lighting has emerged as the preferred solution, offering superior energy efficiency, longer lifespan, and better light quality compared to the older T12 technology. This shift is not merely a trend but a strategic upgrade supported by global safety and performance standards, including ETL and CE certifications, which ensure reliability and regulatory compliance across diverse applications.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of this transformation, delivering high-performance LED and fluorescent lighting solutions tailored for demanding commercial and industrial environments. With decades of engineering expertise and a commitment to innovation, Beauty STC provides T8 and T12 lighting systems designed to meet rigorous international standards, helping customers achieve optimal illumination while reducing energy consumption and maintenance costs. As industries continue to modernize, Beauty STC remains a trusted partner in advancing smarter, safer, and more sustainable lighting infrastructure worldwide.

Technical Specs & Certifications

Traditional T12 fluorescent lamps represent obsolete technology that has been largely phased out globally due to energy efficiency regulations, while modern T8 LED tubes are the current standard for fluorescent retrofit and new construction. It is critical to clarify that direct comparisons between legacy T12 fluorescent systems and contemporary T8 LED solutions are not equivalent, as T12 production for general lighting ceased in most major markets including the US (fully banned for new installations after July 2012 under DOE rules, with limited exceptions ending in 2023) and the EU (RoHS restrictions). Beauty STC exclusively designs and manufactures high-performance LED lighting solutions, including T8 LED tubes that retrofit existing T12 and T8 fluorescent fixtures, but we do not produce or endorse legacy T12 fluorescent technology due to its inefficiency and environmental impact.

Regarding lumens per watt (LPW), legacy T12 fluorescent systems with magnetic ballasts typically delivered only 45-60 LPW at the lamp level, and system efficiency including ballast losses often fell below 40 LPW. In contrast, Beauty STC’s premium T8 LED tubes achieve 130-140+ LPW in standard 4-foot configurations. This represents a 150-200% efficiency gain over obsolete T12 systems, translating to substantial energy savings and reduced operational costs. Our LED tubes incorporate advanced driver circuitry and high-efficiency chips to maximize lumen output per watt without compromising longevity.

For Color Rendering Index (CRI), legacy T12 fluorescent lamps rarely exceeded CRI 75-82 even with premium tri-phosphor coatings, and achieving CRI >90 was physically impossible with standard T12 technology due to spectral limitations. Modern T8 fluorescent lamps could occasionally reach CRI 85-89 under optimal conditions but consistently achieving CRI >90 was uncommon and came with significant lumen depreciation. Beauty STC T8 LED tubes standardly deliver CRI >92 (Ra) with R9 >50, utilizing precisely engineered phosphor blends and binning processes to ensure exceptional color fidelity across the visible spectrum. This high CRI performance is maintained throughout the product lifetime due to our rigorous thermal management design, which protects LED junction temperatures.

IP ratings apply to the complete luminaire, not the lamp or tube alone. Legacy T12 fluorescent fixtures were almost universally rated IP20 (dust-protected, no water resistance) as they were designed for dry indoor use only. T8 LED retrofit tubes themselves carry no IP rating; the rating depends entirely on the fixture housing. Beauty STC T8 LED tubes are engineered to perform reliably within IP20 fixtures for standard indoor applications. For demanding environments, our tubes are compatible with IP65-rated enclosed fixtures designed for damp or wet locations when installed per manufacturer specifications. Beauty STC emphasizes system compatibility by providing detailed installation guidelines to ensure the final fixture assembly meets required environmental ratings.

Beauty STC distinguishes itself through uncompromising quality control in T8 LED manufacturing. Our tubes undergo 100% photometric testing with LPW verified to exceed 135 in standard 18W 4-foot models. We utilize high-CRI Nichia or Samsung LED chips with tight binning tolerances, ensuring consistent color quality across batches. Rigorous 3-hour burn-in testing, aluminum heat sinks for superior thermal dissipation, and UL/cUL/EAC certified drivers contribute to our industry-leading 50,000-hour L70 lifetime rating. Every tube is backed by a 5-year warranty reflecting our confidence in performance stability, including maintained lumen output and CRI throughout the rated life. This commitment to engineering excellence ensures Beauty STC products deliver superior energy savings, visual comfort, and reliability compared to both obsolete T12 systems and lower-tier LED alternatives.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial regions. The factory is designed to support high-volume, precision production of LED lighting products, with a strong emphasis on quality control, efficiency, and flexibility to meet diverse customer demands.

The production floor is anchored by advanced Surface Mount Technology (SMT) lines that ensure precise and reliable mounting of electronic components onto LED light circuit boards. These SMT machines are fully automated, enabling high-speed placement with tight tolerances, which is critical for maintaining consistent performance and longevity in LED products. The integration of automated optical inspection (AOI) systems further enhances quality assurance by detecting soldering and component placement defects in real time.

A comprehensive aging test process is implemented across all finished goods. Completed LED tubes, including both T8 and T12 models, undergo rigorous burn-in procedures that typically last 24 to 48 hours under controlled thermal and electrical conditions. This aging process helps identify early-life failures, ensuring that only reliable and stable products reach customers. Environmental testing chambers are also used to simulate long-term performance under varying temperatures and humidity levels.

Beauty STC has strong OEM capabilities, particularly for T8 and T12 LED tube lights. The company supports full customization, including length, lumen output, color temperature, housing material, and driver configuration. Clients can provide their own specifications or work with Beauty STC’s engineering team to develop tailored solutions. The factory can produce both single-ended and double-ended powered tubes, compatible with existing fluorescent ballast bypass or ballast-compatible installations. With flexible production lines and experienced R&D support, Beauty STC efficiently handles small prototype runs as well as large-scale OEM orders, ensuring compliance with international standards such as CE, RoHS, and UL.

Overall, the Jiangmen factory combines advanced automation, strict quality control, and responsive customization to serve global lighting brands seeking reliable, high-performance LED tube solutions.

Application Scenarios

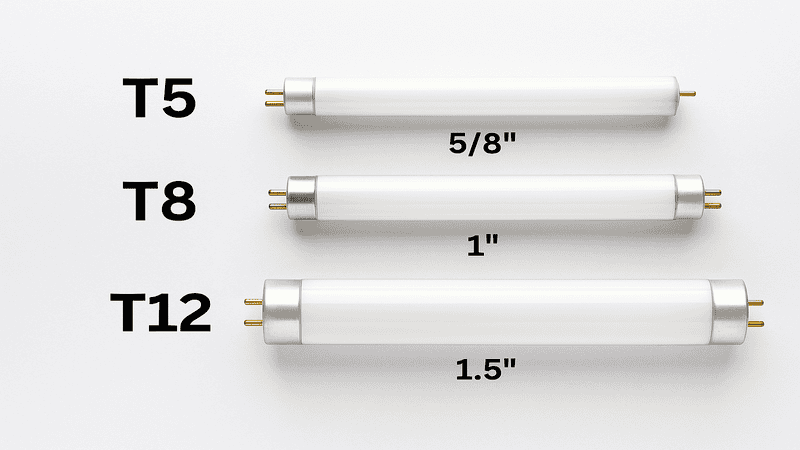

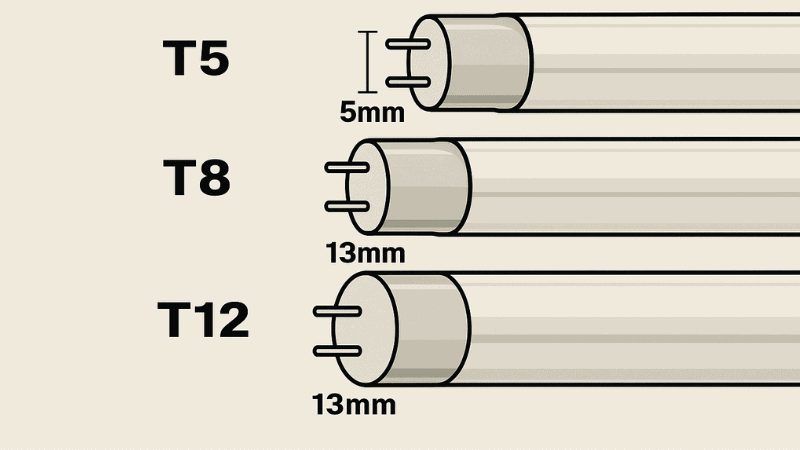

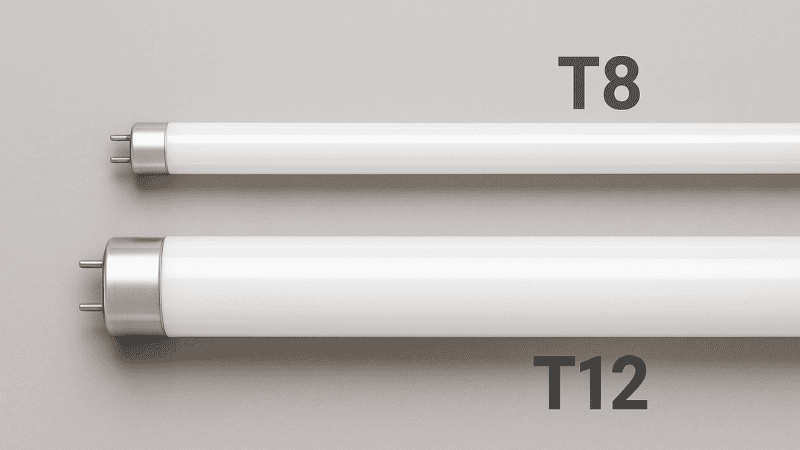

The question of T8 versus T12 lighting is largely historical in modern commercial applications like hotels, malls, and offices, as T12 fluorescent technology is obsolete and no longer manufactured or recommended for new installations or retrofits. T12 systems (1.5-inch diameter tubes) are significantly less energy-efficient, have shorter lifespans, poorer light quality, and higher operating costs compared to modern alternatives. The relevant comparison today is between traditional T8 fluorescent systems (1-inch diameter) and LED retrofit solutions, which often use the same T8 form factor but operate on fundamentally different technology. T12 fixtures should only be encountered in very old, un-upgraded buildings and should be prioritized for immediate replacement with LED systems.

For hotels, focus LED T8 retrofits or new LED troffers in high-traffic, long-operating-hour areas like lobbies, hallways, back-of-house corridors, staff rooms, and parking garages. These spaces benefit from the energy savings, durability, and cooler operation of LEDs. Avoid using outdated T12 systems anywhere; if encountered during renovations, replace the entire fixture or retrofit with ballast-bypass or direct-wire LED tubes. Guest rooms typically use decorative or recessed lighting rather than linear tubes, but if linear fixtures exist, LED retrofits are essential for guest comfort and energy management. Always select LEDs with a Color Rendering Index (CRI) of 80+ and a color temperature of 2700K-3000K for warm, inviting ambiance in guest-facing areas.

In malls and retail environments, prioritize high-CRI (90+) LED tubes or panels in sales floors, fitting rooms, and display areas to accurately render merchandise colors—critical for customer satisfaction. T12 systems are wholly unsuitable here due to poor color quality and inconsistent output. Use LED T8 form-factor solutions in service corridors, stock rooms, and food court support areas where 4000K light enhances alertness. Never install T12s; if replacing old T8 fluorescents, choose LEDs with precise lumen maintenance to avoid dark spots over time. Ensure fixtures have robust thermal management since mall lighting often operates 16+ hours daily, and verify dimming compatibility with the building management system for energy savings during off-peak hours.

For offices, LED T8 retrofits or new LED flat panels are ideal for open-plan workspaces, conference rooms, and private offices, providing flicker-free, uniform illumination that reduces eye strain. Target 3500K-4000K color temperature for balanced productivity. T12 fluorescents should not exist in modern offices; their replacement is non-negotiable for energy codes and occupant well-being. When installing, maintain a 1.2-1.5 meter spacing between fixtures to prevent shadows on work surfaces. In server rooms or technical areas, use LEDs rated for higher ambient temperatures. Avoid legacy T12 ballasts entirely—they fail often and increase maintenance costs.

Critical installation tips apply universally when upgrading from fluorescent to LED: Always verify whether the LED tube requires ballast bypass (direct-wire) or is ballast-compatible; ballast-compatible options add failure points and reduce efficiency, so direct-wire is strongly preferred. Confirm local electrical codes—many jurisdictions now mandate ballast removal for LED retrofits. Use only UL-listed LED tubes with appropriate safety certifications. When direct-wiring, disconnect and cap the old ballast wires securely; never leave energized ballast components. Match the LED tube’s voltage rating to the facility’s supply (e.g., 120-277V). Ensure proper grounding of fixture housings, especially in damp locations like mall restrooms or hotel laundry rooms. Finally, dispose of old fluorescent tubes as hazardous waste due to mercury content—never in regular trash. Modern LED systems deliver 30-50% energy savings over even T8 fluorescents, with near-zero maintenance for 50,000+ hours, making T12 replacement not just advisable but economically imperative.

Why Choose Beauty STC Lighting

Upgrade your lighting system with the right choice—T8 vs T12 lights. Discover the energy-efficient, long-lasting advantages of modern T8 technology compared to the older, less efficient T12 fluorescent lamps. Whether you’re retrofitting an existing space or designing a new installation, making the switch can significantly reduce energy costs and maintenance needs.

Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in LED lighting solutions. We specialize in high-performance T8 LED tubes and lighting systems designed for reliability, brightness, and sustainability. Our expert team ensures tailored lighting solutions that meet your project’s specific requirements.

Contact us today to make the smart switch. Email our sales manager at [email protected] and let Beauty STC illuminate your success.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.