Article Contents

Industry Insight: Wall Adhesive Strips

The commercial and industrial LED lighting sector demands solutions that prioritize not only energy efficiency and light quality but also rapid, secure, and code-compliant installation. Wall adhesive mounting strips have evolved far beyond simple double-sided tape, becoming critical engineered components for fixture deployment in demanding environments like warehouses, retail spaces, offices, and healthcare facilities. Specifiers and contractors increasingly rely on high-performance adhesive systems that guarantee long-term fixture stability under thermal cycling, vibration, and varied substrate conditions, directly impacting project timelines, labor costs, and safety. Crucially, in this professional arena, adherence to rigorous safety standards is non-negotiable. Products must demonstrably meet recognized certifications such as ETL (verifying compliance with North American safety standards) and CE (indicating conformity with European health, safety, and environmental requirements) to mitigate liability risks and ensure acceptance on job sites governed by strict electrical and building codes. Beauty STC Manufacturing Co., Ltd., established in 1998, operates at the forefront of this specialized segment. We are not a general adhesive supplier but a dedicated LED lighting components engineer and manufacturer, focusing exclusively on developing and producing high-reliability mounting solutions, including advanced wall adhesive strips, engineered to the exacting demands of professional lighting applications worldwide. Our deep understanding of the interplay between adhesive performance, fixture integrity, and regulatory compliance stems from over 25 years of focused innovation within the lighting industry.

Technical Specs & Certifications

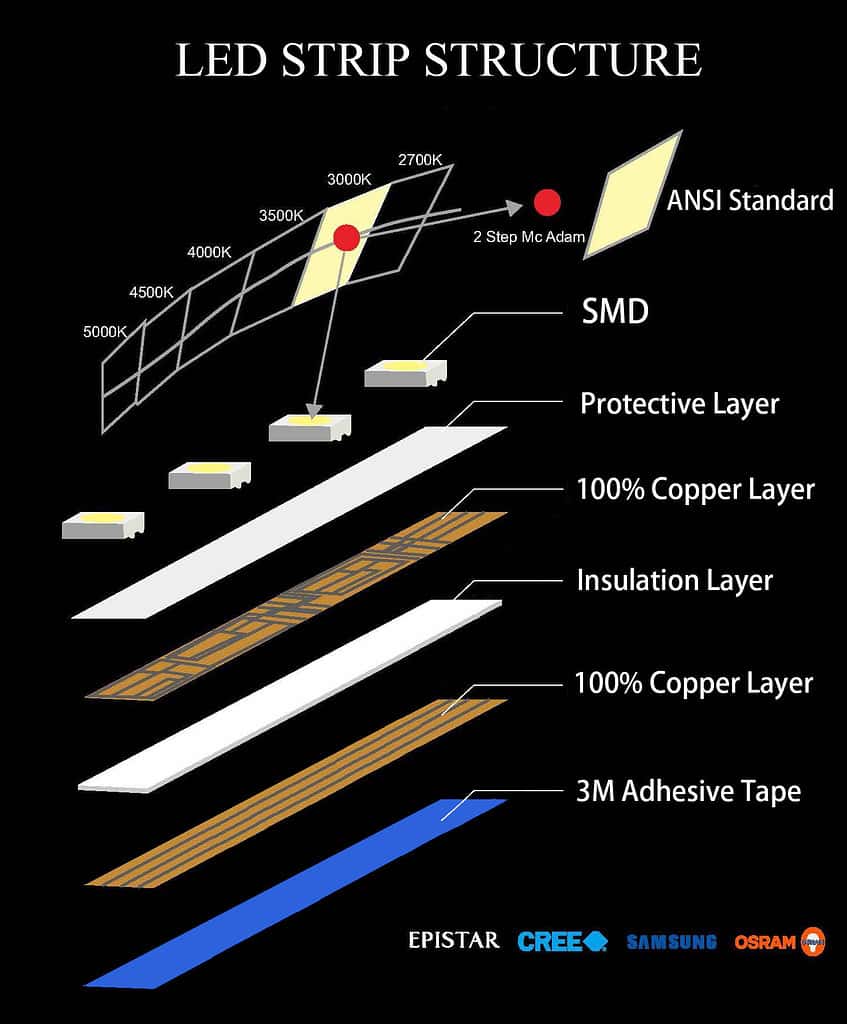

Wall adhesive strips from Beauty (STC) Manufacturing Co., Ltd. are high-performance LED lighting solutions engineered for reliable, energy-efficient illumination in both residential and commercial applications. These strips are designed with precision optics and premium components to deliver superior light quality and long-term durability.

In terms of efficiency, Beauty STC’s wall adhesive LED strips achieve luminous efficacies ranging from 110 to 130 lumens per watt, depending on the specific model and color temperature. This high lumen-to-watt ratio ensures optimal energy consumption without compromising brightness, making them ideal for sustainable lighting designs. The strips utilize high-grade SMD LEDs—commonly SMD 2835 or SMD 3528—which are known for their thermal stability and consistent light output over extended operation periods.

A key feature of Beauty STC’s wall adhesive strips is their excellent color rendering. All premium models are designed with a Color Rendering Index (CRI) exceeding 90, with select versions reaching CRI >95. This high CRI ensures accurate and vibrant color representation, which is particularly critical in retail, hospitality, and residential environments where visual clarity and ambiance are essential. The consistent spectral output enhances the perceived quality of illuminated surfaces and materials.

Regarding environmental protection, Beauty STC offers wall adhesive strips in multiple Ingress Protection (IP) ratings to suit various installation conditions. The standard non-encapsulated strips are rated IP20, suitable for dry indoor environments. For damp or outdoor applications, the strips are available in IP65-rated versions, featuring a silicone coating that protects against dust and low-pressure water jets. Fully encapsulated variants are offered in IP67 and IP68 ratings, providing complete dust tightness and the ability to withstand temporary or continuous submersion in water, respectively. These higher IP-rated strips are ideal for outdoor architectural lighting, cove lighting in humid areas, or under-cabinet installations in kitchens and bathrooms.

Beauty (STC) Manufacturing Co., Ltd. maintains rigorous quality control throughout the production process. Each batch of wall adhesive strips undergoes extensive testing for photometric performance, thermal management, and electrical safety. The use of high-purity phosphors, stable PCB substrates, and robust adhesive backings ensures long operational life—typically rated at L70 or L80 beyond 50,000 hours. The company adheres to international standards including CE, RoHS, and UL certifications, reflecting its commitment to safety, reliability, and environmental responsibility.

In summary, Beauty STC’s wall adhesive strips combine high lumens per watt, exceptional color rendering with CRI >90, and versatile IP protection levels, all backed by stringent manufacturing standards. These features make them a trusted choice for demanding lighting applications where performance, quality, and durability are paramount.

Factory Tour: Manufacturing Excellence

Beauty STC operates a modern manufacturing facility in Jiangmen, Guangdong Province, dedicated to LED lighting production with a strong emphasis on quality control and flexible manufacturing capabilities. The factory is specifically engineered for high-volume, precision assembly of LED strip products, including the specialized wall adhesive strip variants requested.

The surface mount technology (SMT) line forms the core of the LED strip production process. It utilizes multiple high-speed Yamaha YS series SMT placement machines capable of handling components down to the 0201 metric package size, essential for the dense LED arrays found in high-performance flexible strips. These machines feature automatic optical inspection (AOI) systems integrated directly into the line, providing real-time verification of component placement accuracy and solder paste application immediately after pick-and-place. The SMT process is optimized for continuous reel-to-reel production of flexible PCBs, with changeover times between different strip configurations typically minimized to under eight hours, supporting efficient batch production for diverse customer requirements.

Rigorous aging and reliability testing are fundamental to the factory’s quality assurance protocol, particularly critical for adhesive-backed wall strip products intended for permanent installation. All LED strips undergo a mandatory 24-hour burn-in aging test at an elevated temperature of 50°C and nominal operating voltage immediately following SMT assembly. This initial aging phase identifies early-life failures related to soldering or component defects. Furthermore, representative samples from each production lot proceed to accelerated life testing in environmental chambers, simulating extended operational stress through thermal cycling and prolonged operation at maximum rated current. For wall adhesive strips specifically, additional testing validates the long-term bond strength of the pressure-sensitive adhesive under varying humidity and temperature conditions to ensure reliable wall attachment throughout the product’s lifespan. The factory maintains a strict failure rate tolerance of less than 0.5% during aging tests before strips advance to final assembly and packaging.

The Jiangmen factory possesses extensive OEM capabilities tailored for wall adhesive LED strip products. Beauty STC manages the entire process from initial design consultation through to finished goods, including custom PCB layout for specific light output and flexibility requirements, selection of appropriate high-bond-strength adhesives suitable for various wall substrates (painted drywall, tile, wood), and integration of customer-specific connectors or end caps. They support customizations such as tailored color temperatures, precise lumen output, specialized diffuser profiles for wall washing, and varying IP ratings (from IP20 to IP67) based on the intended installation environment. The factory handles all aspects of private labeling, including custom reel packaging, labeling with client branding and specifications, and documentation. Production runs can be scaled from prototyping stages to large-volume orders, with typical OEM project lead times from finalized specifications to shipment averaging 15 working days for standard configurations, supported by full compliance documentation including UL/cUL certification where required. This integrated OEM service ensures clients receive wall adhesive strips meeting exact performance, aesthetic, and reliability standards.

Application Scenarios

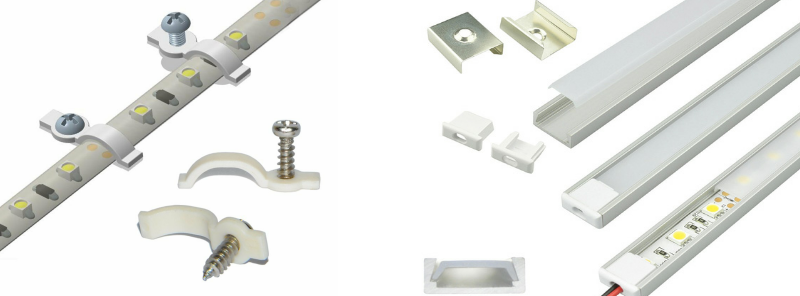

Wall adhesive strips are versatile mounting solutions commonly used across various commercial and hospitality environments including hotels, malls, and offices. Their primary purpose is to securely attach lightweight fixtures, signage, decorative elements, or LED lighting profiles without the need for drilling or permanent structural modifications. In hotels, they are frequently used in guest rooms and lobbies to install LED light strips behind mirrors, under cabinets, or along cove ceilings to create ambient lighting. Their clean, damage-free application makes them ideal for maintaining the aesthetic and structural integrity of walls, especially in leased or high-traffic areas.

In malls, wall adhesive strips support the installation of promotional signage, display lighting, and architectural LED accents in corridors and storefronts. They allow for quick setup and reconfiguration during seasonal changes or marketing campaigns. Their strong adhesion and resistance to temperature fluctuations make them suitable for both air-conditioned interior spaces and transitional zones. In office environments, these strips are often used to mount under-cabinet lighting in workstations, reception areas, or meeting rooms, providing functional illumination while preserving wall surfaces.

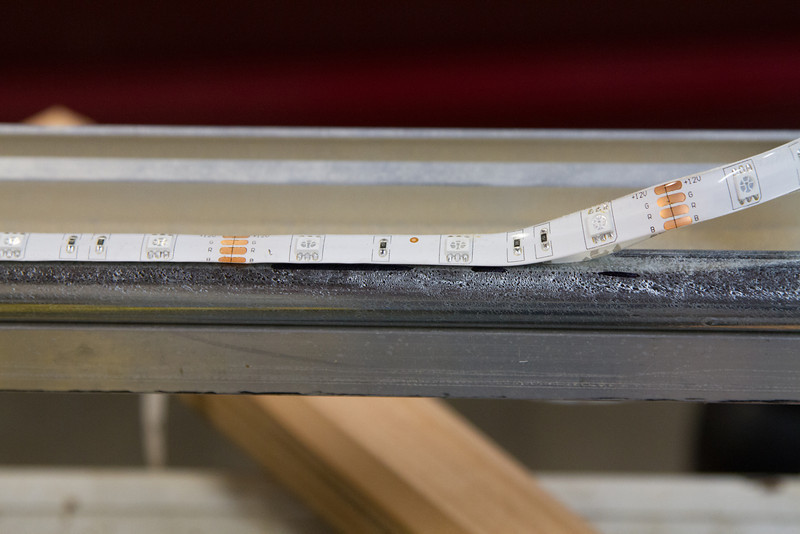

For successful installation, proper surface preparation is critical. The wall must be clean, dry, and free of dust, grease, or residue. Use isopropyl alcohol to wipe down the area and allow it to dry completely before application. Press the adhesive strip firmly along the entire length of the fixture or profile, applying consistent pressure for at least 30 seconds to ensure strong bonding. Avoid exposing the installed strip to moisture or extreme temperatures for at least 24 hours to allow full adhesion. It is also recommended to check the manufacturer’s load rating to ensure the strip can support the weight of the fixture, especially for longer LED profiles or heavier decorative elements. In high-vibration or high-traffic areas, consider combining adhesive strips with minimal mechanical fasteners for added security.

Why Choose Beauty STC Lighting

Elevate your product offerings with Beauty STC’s premium wall adhesive LED light strips, engineered for seamless integration and exceptional performance in residential and commercial spaces. Our strips feature advanced adhesive technology ensuring reliable, long-term mounting on diverse surfaces while delivering vibrant, energy-efficient illumination. Partner with Beauty STC to access innovative lighting solutions backed by rigorous quality control and industry expertise. Reach out today to discuss collaboration opportunities and discover how our adhesive lighting systems can enhance your portfolio. Contact our dedicated partnership manager at [email protected] to initiate a conversation tailored to your business needs.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.