Article Contents

Industry Insight: Led Wire To Wire Connector

In the rapidly evolving landscape of commercial and industrial lighting, reliable electrical connectivity is paramount to ensuring performance, safety, and longevity of LED lighting systems. Among the critical components enabling seamless integration and maintenance-free operation, LED wire-to-wire connectors stand out as essential elements in modern lighting installations. These connectors provide secure, efficient connections between LED strips, drivers, and power sources, minimizing voltage drop and reducing the risk of system failure—especially in high-demand environments such as warehouses, retail spaces, and manufacturing facilities.

As building codes and energy efficiency standards become more stringent, compliance with recognized safety certifications such as ETL and CE has become non-negotiable. These certifications ensure that wire-to-wire connectors meet rigorous electrical and environmental performance benchmarks, offering peace of mind to engineers, contractors, and facility managers responsible for large-scale lighting deployments.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has emerged as a trusted leader in the design and production of high-quality LED connectivity solutions. With over two decades of expertise, Beauty STC delivers robust, code-compliant wire-to-wire connectors engineered specifically for the demands of commercial and industrial applications. Backed by a commitment to innovation, precision manufacturing, and global regulatory standards, Beauty STC continues to support the lighting industry’s transition toward smarter, safer, and more sustainable infrastructure.

Technical Specs & Certifications

LED wire-to-wire connectors themselves do not possess lumens per watt (lm/W) output or Color Rendering Index (CRI) values, as these are photometric and colorimetric properties inherent to the light source – the LED chip and associated phosphor system within the luminaire. Wire-to-wire connectors are passive electrical components responsible solely for establishing reliable, low-resistance electrical connections between cable segments or between cables and LED modules/drivers. Lumens per watt and CRI >90 are critical specifications for the LED light engine assembly that the connector helps power, not the connector itself. Confusing these metrics with connector specifications is a common point of misunderstanding; the connector’s role is to deliver power efficiently and safely to the component that generates light with those specific performance characteristics.

The technical specifications for Beauty STC’s high-reliability LED wire-to-wire connectors focus on electrical, mechanical, and environmental performance to ensure they support the demanding requirements of quality LED lighting systems, including those achieving high lm/W and CRI >90. Key specifications include low contact resistance, typically less than 10 milliohms per contact point, to minimize voltage drop and power loss, thereby contributing indirectly to overall system efficiency. High insulation resistance exceeding 1000 MΩ at 500 VDC ensures safety and prevents leakage currents. Voltage ratings are commonly 300 VAC, suitable for standard low-voltage LED applications, with current ratings per contact ranging from 2A to 8A depending on wire gauge and specific series. Operating temperature ranges span -40°C to +105°C, accommodating diverse installation environments from freezers to enclosed luminaires. Crucially, IP ratings define the connector’s ingress protection level; Beauty STC offers connectors rated IP65 for dust-tight and water-jet resistance suitable for outdoor protected areas, IP67 for temporary immersion protection (up to 1 meter for 30 minutes), and IP68 for continuous submersion, essential for harsh environments like landscape lighting, pool areas, or industrial settings where maintaining the integrity of the high-CRI, high-efficiency light source is paramount.

Beauty STC’s commitment to quality is embedded in every stage of our wire-to-wire connector manufacturing. We utilize premium materials, including phosphor bronze or beryllium copper contacts with precise gold or tin plating for superior conductivity and corrosion resistance, and high-grade thermoplastic housings with excellent flame retardancy (UL 94 V-0 rated) and thermal stability. Our connectors undergo rigorous in-house testing far exceeding IEC 60309 and UL 486 standards, including 500+ mating cycles, 1000+ hours of salt spray testing, thermal cycling from -40°C to +125°C, and stringent pull tests to ensure wire retention. This meticulous attention to detail guarantees minimal contact resistance degradation over time, preventing voltage drops that could compromise the stable power delivery required for LEDs to consistently achieve their rated lm/W efficiency and maintain CRI >90 throughout their lifespan. Beauty STC’s ISO 9001-certified processes ensure traceability and consistency, meaning our connectors provide the robust, maintenance-free electrical integrity that professional lighting systems demand, directly supporting the long-term performance and reliability of the high-efficiency, high-CRI luminaires they serve.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, Guangdong Province, is a modern, vertically integrated facility specializing in the production of high-quality LED lighting components and solutions. Strategically located in the Jiangmen Jianghai District, the factory benefits from proximity to key supply chains and logistics networks in the Pearl River Delta region, enabling efficient operations and timely delivery.

The facility is equipped with advanced Surface Mount Technology (SMT) production lines that ensure precision and consistency in assembling LED lighting modules and related electronic components. These SMT machines are fully automated, supporting high-speed placement of components on printed circuit boards (PCBs) with tight tolerances, which is essential for maintaining the reliability and performance of LED products. The SMT process is complemented by automated optical inspection (AOI) systems to detect defects and ensure quality control throughout production.

To guarantee product longevity and performance under real-world conditions, Beauty STC conducts rigorous aging tests at its Jiangmen factory. Completed LED assemblies undergo extended burn-in periods under elevated temperatures and continuous operation. This aging process helps identify early-life failures and ensures that only stable, durable products reach customers. Environmental testing, including thermal cycling and humidity exposure, further validates product robustness.

Beauty STC also offers comprehensive OEM services, including customized manufacturing of LED wire-to-wire connectors. The company supports clients in designing, prototyping, and mass-producing connectors tailored to specific voltage, current, connector type, cable length, and insulation requirements. With in-house tooling, molding, and assembly capabilities, the factory can accommodate low to high-volume OEM orders while maintaining strict quality standards and competitive lead times. This flexibility makes Beauty STC a trusted partner for brands seeking reliable, custom-engineered LED connectivity solutions.

Application Scenarios

LED wire-to-wire connectors serve a critical function in commercial lighting installations across hotels, malls, and offices by enabling reliable, solderless connections between LED strips, power supplies, and control systems. Their primary use cases in these environments stem from the need for modularity, ease of maintenance, and adherence to safety standards during both new construction and retrofit projects. In hotels, these connectors are essential for linking flexible LED strips within guest room cove lighting, under-bed illumination, and bathroom mirror surrounds where discreet, vibration-resistant connections are necessary near moving fixtures or in humid zones like spa areas. They allow for quick replacement of damaged sections without rewiring entire runs, minimizing guest disruption. Malls heavily utilize them for connecting linear LED fixtures in high-ceiling atriums, escalator handrail lighting, and display window accents where long cable runs require segmented power distribution; their secure locking mechanisms prevent disconnection due to foot traffic vibrations or thermal expansion in large open spaces. Offices deploy them extensively in suspended ceiling grids for troffer replacements, under-cabinet task lighting in workstations, and architectural feature walls where reconfigurable layouts demand tool-free disconnection during office renovations or furniture adjustments. Crucially, in all these settings, connectors must be rated for the specific environmental conditions—such as IP65 for mall exterior entrances exposed to weather or damp-rated types for hotel poolside corridors—to comply with electrical codes like NEC Article 410.130 for permanent installations.

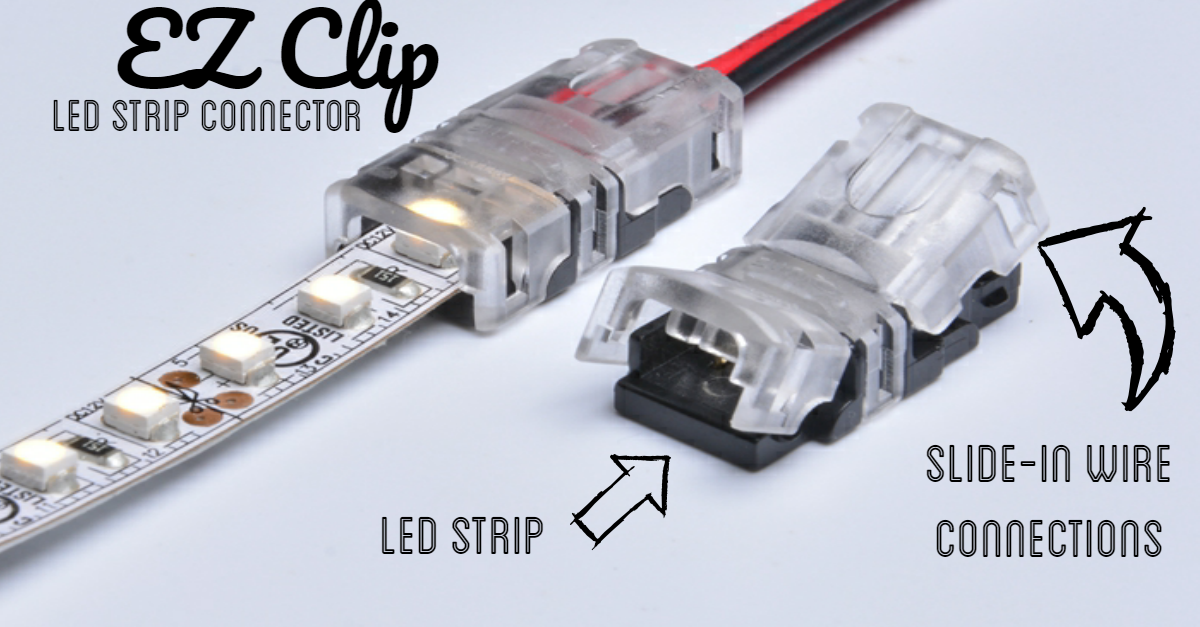

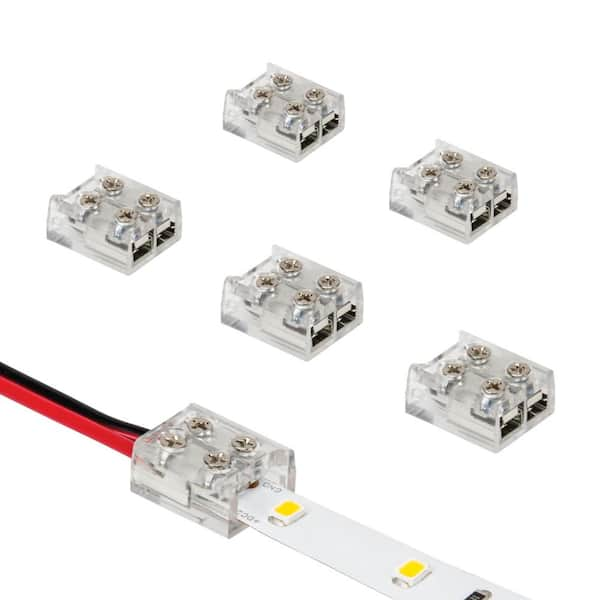

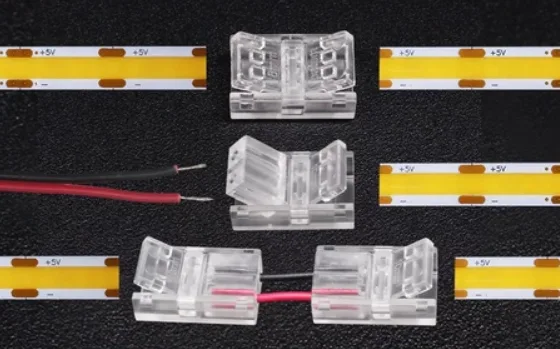

Proper installation begins with meticulous wire preparation: strip exactly 4–5mm of insulation using a dedicated LED wire stripper to avoid nicking conductors, which causes hotspots. Always match wire gauge to the connector’s specification—typically 18–22AWG for standard 24VDC LED strips—and verify polarity markings (usually red for +V, black for GND) on both the strip and connector to prevent reverse-polarity damage. When inserting wires, push firmly until you hear an audible click for push-in types or tighten screw terminals to the manufacturer’s torque spec (usually 0.2–0.3 Nm) to ensure gas-tight contact without crushing the wire. Never rely solely on the connector for strain relief; secure the cable 10–15mm before the connector with cable ties to fixtures or mounting surfaces to prevent tension on the joint. In high-moisture areas like hotel pool decks, apply dielectric grease inside the connector before mating and seal the assembly with heat-shrink tubing rated for 105°C. Always test connectivity with a multimeter for continuity and voltage drop before final concealment, as even a 0.5V drop per connector can cascade into visible dimming across multiple joints. For large-scale deployments in offices or malls, implement color-coding—such as blue for data lines in DMX-controlled systems and red/black for power—to streamline troubleshooting during maintenance. Finally, retain a 10% surplus of connectors on-site matching the exact model used, as mixing brands or generations often leads to compatibility failures under sustained load.

Why Choose Beauty STC Lighting

Looking for reliable LED wire to wire connectors? Partner with Beauty STC, a trusted manufacturer of high-quality LED lighting components. Our precision-engineered connectors ensure secure, durable connections for a wide range of lighting applications. With consistent performance and rigorous quality control, Beauty STC is the preferred choice for businesses seeking dependable solutions.

Take the next step in enhancing your product reliability and efficiency. Contact us today at [email protected] to discuss your requirements and discover how Beauty STC can support your success.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.