Article Contents

Industry Insight: Spotlight Vs Flood Light

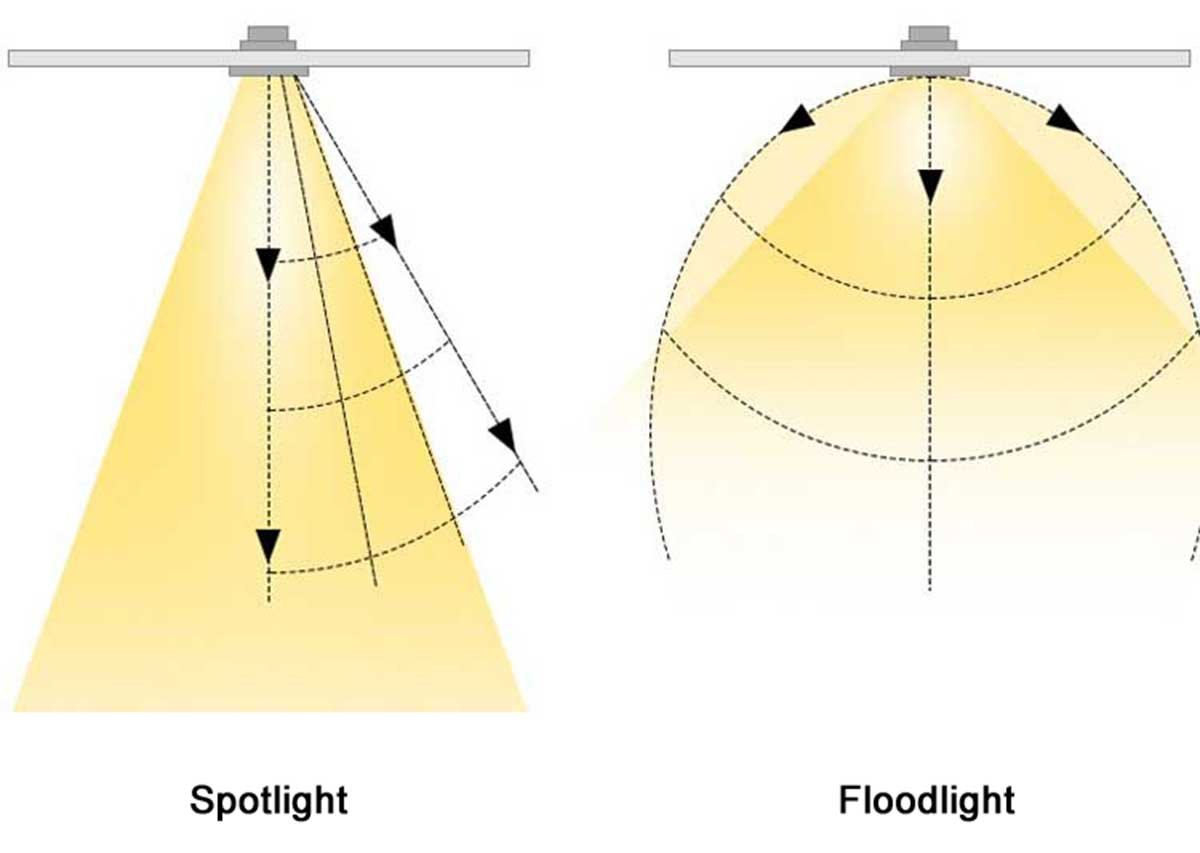

In commercial and industrial lighting applications, the strategic selection between spotlight and flood light configurations plays a critical role in achieving optimal illumination, energy efficiency, and operational safety. Spotlights, with their focused beam angles, are ideal for accentuating architectural features, highlighting inventory in retail warehouses, or providing targeted task lighting in manufacturing environments. In contrast, flood lights offer wide-angle dispersion, making them well-suited for large-area coverage such as parking lots, loading docks, and outdoor storage facilities. The performance, durability, and compliance of these lighting solutions are paramount in industrial settings, where reliability under demanding conditions is non-negotiable. Lighting products meeting ETL and CE standards ensure adherence to rigorous North American and European safety and performance criteria, providing assurance to facility managers and contractors alike.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of LED lighting innovation for over two decades. Specializing in high-performance commercial and industrial lighting solutions, Beauty STC combines advanced optics, robust construction, and strict compliance with international certifications—including ETL and CE—to deliver products that meet the evolving needs of global markets. With a commitment to quality, efficiency, and technical excellence, Beauty STC continues to empower businesses with intelligent lighting systems that enhance visibility, reduce maintenance costs, and support sustainable operations.

Technical Specs & Certifications

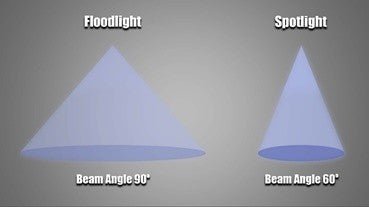

Spotlights and flood lights differ primarily in beam angle and application, though their core technical specifications share common metrics where performance and quality matter most. A spotlight typically features a narrow beam angle, usually between 10° and 30°, concentrating light intensity for accenting specific objects or areas. A flood light provides a wide beam angle, generally 60° to 120° or more, designed to uniformly illuminate broader surfaces or spaces. When evaluating both types for high-performance applications, lumens per watt efficacy, Color Rendering Index (CRI), and Ingress Protection (IP) ratings are critical technical benchmarks.

Lumens per watt (lm/W) measures luminous efficacy, indicating how efficiently electrical power converts to visible light. Both spotlight and flood light fixtures from Beauty STC consistently achieve 120-140 lm/W in standard commercial-grade LED designs. This high efficacy stems from our proprietary driver technology and optimized thermal management systems, ensuring minimal lumen depreciation over time. While beam angle itself doesn’t inherently alter efficacy, spotlights often use higher-intensity LEDs in tighter configurations, demanding superior heat dissipation; Beauty STC addresses this with die-cast aluminum housings and advanced thermal pathways, maintaining stable lm/W performance even under continuous operation. Flood lights, distributing light more broadly, benefit from our uniform phosphor coating processes to prevent hotspotting without sacrificing efficiency.

CRI values exceeding 90 are essential for applications requiring true-to-life color representation, such as retail displays, art galleries, or high-end hospitality. Beauty STC mandates CRI >90 (Ra) across our spotlight and flood light product lines, with many fixtures achieving Ra 95+ and strong R9 (saturated red) values above 90. This is accomplished through rigorously selected multi-layer phosphor-converted LEDs and spectral tuning during manufacturing. Our quality control includes spectroradiometer testing of every production batch, ensuring consistency. For spotlights used in critical color tasks like jewelry or textile lighting, we offer CRI 97+ options with extended spectral coverage, while flood lights for architectural wash applications maintain Ra 92+ to render building materials accurately.

IP ratings define protection against solid particles and moisture ingress, directly impacting fixture suitability for environments. Indoor spotlights often carry IP20 (basic dust protection), whereas outdoor or wet-location spotlights require IP65 (dust-tight and low-pressure water jets) or IP66 (powerful water jets). Flood lights for outdoor security or landscape use similarly demand IP65 minimum, with poolside or marine applications needing IP68 submersion resistance. Beauty STC subjects all outdoor-rated fixtures to stringent IP validation testing beyond standard requirements, including thermal cycling and extended water exposure. Our gasketing uses UV-stable silicone, and housings feature seamless die-cast construction with corrosion-resistant powder coating, ensuring IP ratings remain intact throughout the 50,000-hour L70 lifespan. Indoor fixtures for damp locations like bathrooms still incorporate IP44 safeguards as standard.

Beauty STC’s commitment to quality is evident in these specifications through rigorous engineering and validation. We utilize only Tier-1 LED chips with binning tolerances tighter than industry norms, ensuring lumen and chromaticity consistency. Our drivers feature active power factor correction (>0.95) and 0-10V dimming compatibility down to 1%, critical for integrated lighting control systems. Every fixture undergoes 100% photometric testing, thermal imaging, and IP verification in our in-house laboratory, adhering to IESNA LM-79/80 standards. This results in spotlights and flood lights that not only meet but exceed stated lm/W, CRI, and IP ratings reliably, backed by a 5-year warranty reflecting our confidence in durability and performance stability.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, Guangdong Province, is a modern, vertically integrated manufacturing facility specializing in high-quality LED lighting products. Strategically located in the Pearl River Delta region, the Jiangmen factory benefits from excellent supply chain connectivity and access to skilled labor, enabling efficient production and rapid scaling to meet global demand.

The facility is equipped with advanced Surface Mount Technology (SMT) production lines, featuring high-speed, precision SMT machines from leading manufacturers. These machines ensure accurate placement of LED components, drivers, and other surface-mount devices onto printed circuit boards (PCBs), supporting both small-batch prototyping and large-scale mass production. Automated optical inspection (AOI) systems are integrated into the SMT process to verify solder joint quality and component alignment, ensuring high reliability and consistency across every production run.

To guarantee product durability and performance, the Jiangmen factory conducts comprehensive aging tests on all LED lighting products. Completed units undergo extended burn-in periods—typically 48 to 72 hours—under controlled thermal and electrical conditions that simulate real-world operating environments. During this process, lights are monitored for lumen output stability, color consistency, thermal management, and driver performance. This rigorous testing helps identify early failures and ensures that only units meeting Beauty STC’s strict quality standards are shipped to customers.

Beauty STC has strong OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) capabilities, allowing clients to customize products to their exact specifications. For spotlight and flood light applications, the company offers full design and engineering support. Whether a client requires a narrow-beam spotlight for accent lighting or a wide-angle flood light for area illumination, Beauty STC can tailor optics, housing, thermal design, driver configuration, and finish options. The factory supports custom labeling, packaging, and branding, making it ideal for partners seeking private-label solutions in retail, commercial, or industrial lighting sectors.

Overall, the Jiangmen factory combines advanced automation, strict quality control, and flexible manufacturing processes to deliver reliable, high-performance LED lighting solutions tailored to diverse market needs.

Application Scenarios

Spotlights and flood lights serve distinct purposes in commercial lighting design, with selection driven by the need for focused accentuation versus broad, uniform illumination. In hotel environments, spotlights excel in lobbies to highlight architectural features, artwork, or reception desks, creating visual hierarchy and luxury. Guest room corridors benefit from spotlights to guide movement while minimizing light spill into room numbers. Conversely, flood lights are essential in hotel ballrooms for even general illumination during events, in staff back-of-house areas for safety, and around outdoor pools or spas where wide coverage prevents tripping hazards without creating harsh shadows. For guest room task lighting, spotlights (e.g., 30-degree beam) are ideal at vanities or bedside for focused activity, while flood lights (60+ degrees) suit closet interiors for full visibility.

Within malls, spotlights are critical for retail merchandising—narrow beams (15-25 degrees) spotlight high-value items like jewelry or featured displays to draw attention and enhance product texture. They also work well in feature staircases or atriums to accentuate vertical elements. Flood lights dominate in main pedestrian walkways, food courts, and escalator landings where consistent, shadow-free illumination across wide areas is non-negotiable for safety and comfort. Department store general sales floors typically require flood lights to avoid uneven lighting on merchandise, though spotlights may be layered for seasonal displays. High-ceilinged areas like food courts often use adjustable spotlights for menu boards while flood lights cover seating zones.

Office applications demand precision: spotlights (25-35 degrees) are optimal in conference rooms to illuminate presentation walls without glare on screens and in executive offices for desk task lighting. They also suit library-style shelving to highlight book spines. Flood lights (40-60+ degrees) are standard in open-plan workspaces, ensuring uniform desk illumination without hotspots, and in restrooms or print rooms where broad coverage is practical. Reception desks often combine both—flood lights for the front counter surface and spotlights for brand logos. Crucially, offices avoid narrow spotlights over workstations to prevent screen glare and eye strain.

Installation requires meticulous planning. Always calculate beam spread: a spotlight’s throw distance should be 1.5–2 times the target area diameter (e.g., a 30-degree beam at 10ft height covers ~5ft diameter), while flood lights suit distances ≤1.5x the coverage width. Mount spotlights closer to walls for wall-washing (grazing technique) or recessed in ceilings for direct focal points, ensuring no direct line-of-sight to avoid glare. Flood lights need lower mounting heights in narrow corridors (<8ft) to prevent dark zones at floor level. Verify beam angles match the fixture’s specifications—many “flood” LEDs still emit 40-degree beams unsuitable for true wide coverage. Use dimmable drivers compatible with building management systems, especially in hotels where ambiance shifts from day to night. Thermal management is non-negotiable; ensure adequate ceiling void space for heat dissipation in enclosed fixtures, particularly in 24/7 mall environments. Finally, mock up beam patterns onsite before full deployment—actual reflectance from materials like marble or dark fabrics drastically alters perceived coverage.

Why Choose Beauty STC Lighting

Discover the key differences between spotlight and flood light to elevate your lighting projects with precision and impact. Whether you need focused beams or wide coverage, Beauty STC delivers high-performance LED solutions tailored to your needs. Partner with Beauty STC today and experience unmatched quality, innovation, and reliability in commercial and industrial lighting. For expert guidance and customized support, contact us at [email protected] and let our team power your next success.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.