Article Contents

Industry Insight: Led Uv Light Bulb

The commercial and industrial lighting sector continues to evolve with increasing demand for energy-efficient, durable, and environmentally sustainable solutions. Among the most transformative innovations in recent years is the adoption of LED UV light bulbs, which are redefining applications ranging from sterilization and curing processes to counterfeit detection and HVAC sanitation. These high-performance bulbs offer significant advantages over traditional UV sources, including longer lifespans, lower heat output, instant on/off functionality, and reduced energy consumption—critical factors for operational efficiency in industrial environments. As regulatory standards tighten globally, compliance with safety and performance certifications such as ETL and CE has become essential, ensuring that LED UV products meet rigorous North American and European requirements for electrical safety, electromagnetic compatibility, and environmental resilience.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has emerged as a trusted leader in the LED lighting industry, specializing in advanced commercial and industrial solutions. With over two decades of engineering expertise, Beauty STC combines innovation with reliability, delivering high-quality LED UV light bulbs designed for demanding applications. Backed by stringent quality control and full compliance with ETL and CE standards, Beauty STC’s products are engineered to perform consistently in critical environments. As industries seek smarter, safer, and more sustainable lighting technologies, Beauty STC remains at the forefront, providing solutions that meet the evolving needs of modern commercial and industrial facilities worldwide.

Technical Specs & Certifications

LED UV light bulbs operate outside the visible spectrum and therefore do not produce lumens or possess a Color Rendering Index (CRI). Lumens quantify visible light output perceivable by the human eye, while CRI measures a light source’s ability to accurately render colors relative to a reference source, both of which are irrelevant for ultraviolet radiation. UV light is measured in terms of irradiance (typically microwatts per square centimeter, µW/cm²) at specific wavelengths (e.g., UVA 315-400 nm, UVB 280-315 nm, UVC 100-280 nm) and radiant flux (watts). Attempting to assign lumens or CRI values to genuine UV LED products is technically incorrect and misleading. For applications requiring high-quality visible light alongside UV functionality, such as certain counterfeit detection or mineralogy lamps, a dual-source design might incorporate a separate visible LED array. In such cases, the visible component could achieve >90 CRI and high lumens per watt, while the UV component remains specified by its radiant power and peak wavelength.

Regarding IP ratings, UV LED bulbs designed for demanding environments require robust ingress protection. Beauty STC rigorously tests its UV lighting solutions to appropriate IP standards based on the intended application. For industrial curing or outdoor disinfection fixtures, IP65 (dust-tight and protected against water jets) or IP67 (dust-tight and protected against temporary immersion) ratings are commonly achieved and verified through standardized testing protocols. Consumer-grade UV bulbs, like those for nail curing, typically target IP20 (basic protection against finger contact, no dust/water resistance) as they operate in controlled indoor settings. Beauty STC ensures all IP claims are validated through third-party laboratory testing, not merely design intent.

Beauty STC’s commitment to quality is paramount in UV LED manufacturing. We utilize high-binning UVC or UVA LEDs from Tier-1 semiconductor suppliers to ensure consistent spectral output and longevity. Our thermal management systems, featuring precision-engineered aluminum heat sinks and thermal interface materials, maintain junction temperatures well below critical thresholds, directly extending LED lifespan and stabilizing UV output – a critical factor where performance decay impacts efficacy. Each UV bulb undergoes 100% in-line testing for radiant flux, forward voltage, and beam pattern. For UVC disinfection products, we implement stringent biological validation protocols alongside radiometric calibration. Our ISO 9001-certified manufacturing processes include rigorous environmental stress screening, such as thermal cycling and humidity exposure tests, far exceeding basic industry requirements. This unwavering focus on material quality, thermal design, and comprehensive validation ensures Beauty STC UV LED bulbs deliver reliable, safe, and performance-consistent operation throughout their rated lifetime, meeting the exacting demands of professional and industrial applications.

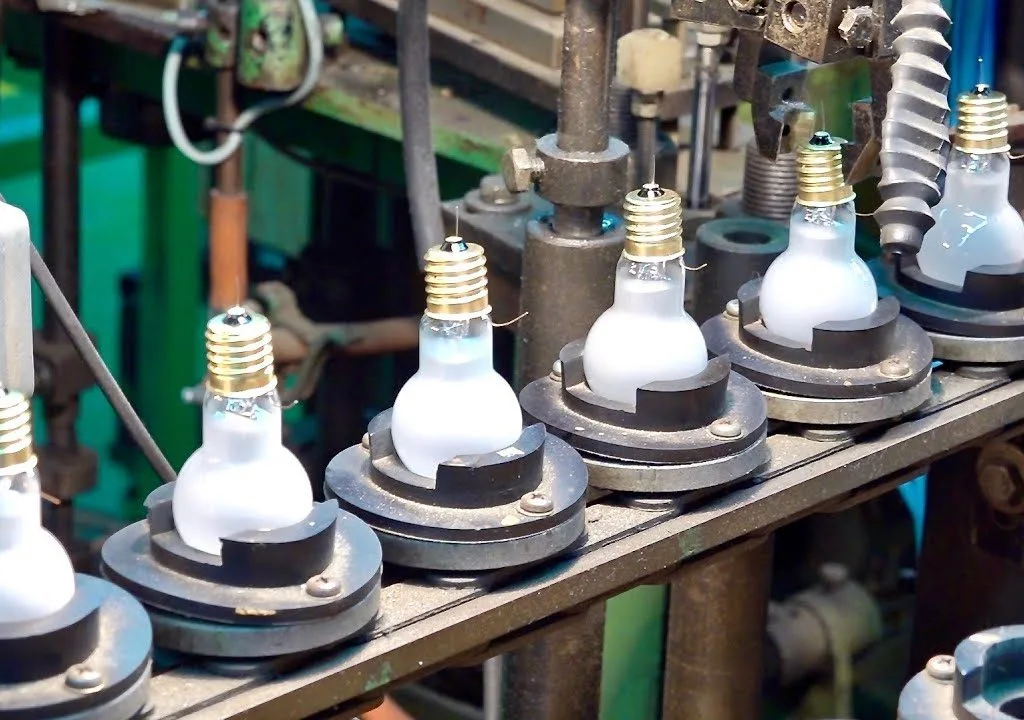

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility located in Jiangmen, Guangdong Province, China. The factory is strategically situated within the Pearl River Delta region, known for its strong industrial infrastructure and supply chain efficiency. The Jiangmen facility spans a substantial production area and is designed to support high-volume, precision manufacturing of LED lighting products, including specialized items such as LED UV light bulbs.

At the core of the production line are advanced SMT (Surface Mount Technology) machines, which ensure high-speed, accurate placement of electronic components onto printed circuit boards. These SMT lines are fully automated, featuring state-of-the-art pick-and-place machines, reflow ovens, and automated optical inspection (AOI) systems. This enables consistent quality, tight tolerances, and efficient throughput, critical for manufacturing reliable LED lighting products at scale.

Quality assurance is a key focus at the Jiangmen factory. All LED UV light bulbs undergo rigorous aging tests before shipment. These tests typically involve operating the bulbs at full power under elevated temperature conditions for an extended duration—commonly 12 to 24 hours or more—depending on product specifications. The aging process helps identify early-life failures, ensuring that only stable and durable units reach customers. Environmental testing chambers and continuous monitoring systems are integrated into the aging process to simulate real-world operating conditions and verify long-term performance.

Beauty STC has strong OEM (Original Equipment Manufacturing) capabilities, making it a preferred partner for brands seeking customized LED UV light bulb solutions. The company supports full-service OEM projects, from initial design and engineering to prototyping, production, packaging, and logistics. Customization options include different UV wavelengths (such as UVA at 365nm or 395nm), power ratings, base types (e.g., E27, E14, B22), form factors, and special features like dimming or smart control integration. The in-house R&D team works closely with clients to meet specific technical and regulatory requirements, including compliance with CE, RoHS, and UL standards.

Overall, the Jiangmen factory combines advanced automation, stringent quality control, and flexible manufacturing processes to deliver high-performance LED UV light bulbs tailored to diverse market needs.

Application Scenarios

LED UV light bulbs, specifically germicidal UV-C systems, serve distinct purposes in commercial environments but require precise application due to safety considerations. It is critical to clarify that standard LED “bulbs” emitting UV-C for disinfection are not typical consumer products; they are specialized fixtures requiring professional installation. True germicidal UV-C operates at 254nm and poses significant risks to skin and eyes, making them unsuitable for general illumination. Their use in hotels, malls, and offices is limited to targeted disinfection applications, not ambient lighting.

In hotels, germicidal UV-C systems are appropriate for HVAC ductwork to sanitize circulating air or within enclosed upper-room air disinfection units in lobbies or high-traffic corridors where continuous air cleaning is beneficial. Surface disinfection applications are highly restricted; they might be considered only in unoccupied spaces like vacant guest rooms using automated, timed systems with strict occupancy sensors and safety interlocks, but this is uncommon due to liability and practicality. Restroom disinfection via UV-C is generally impractical and unsafe in guest-accessible areas. For malls, the primary viable application is within the central HVAC system to treat air before distribution, particularly in large atriums or enclosed common areas. Surface disinfection of high-touch points like escalator handrails requires fully enclosed, interlocked systems that activate only when the handrail is within the shielded chamber and inaccessible to the public—open or exposed UV-C fixtures near shoppers are strictly prohibited. Offices may utilize upper-air UV-C fixtures in high-ceilinged meeting rooms or lobbies, mounted at least 2.4 meters high with louvers directing light upward, ensuring no direct exposure to occupants below. UV-C within office HVAC remains a standard application. Desktop “sanitizing boxes” using contained UV-C for small items like phones are acceptable if fully shielded and interlocked, but standalone bulbs for room disinfection are unsafe and ineffective in occupied offices.

Installation demands rigorous adherence to safety protocols. Always engage certified UV-C system specialists; this is not a DIY application. Fixtures must incorporate multiple redundant safety features: motion sensors that instantly cut power upon detection, physical key locks, and visible warning indicators. For upper-air systems, precise mounting height and tilt angles per ASHRAE guidelines are essential to prevent stray radiation. HVAC-integrated units require professional ductwork integration with UV-resistant materials and safety cut-offs. Never install UV-C where direct line-of-sight exposure to occupants is possible, even briefly. All installations must comply with IEC 62471 for photobiological safety and UL 8800 certification. Crucially, UV-C is supplementary to cleaning—it does not replace manual disinfection of soiled surfaces. Always verify local regulations, as many jurisdictions restrict UV-C use in public spaces. Beauty (STC) strongly advises against using consumer-grade “UV LED bulbs” marketed for disinfection; these often lack adequate UV-C output, safety certifications, and can create hazardous ozone. For any application, prioritize third-party tested systems with full safety documentation and professional commissioning.

Why Choose Beauty STC Lighting

Looking for high-quality LED UV light bulbs? Partner with Beauty STC, a trusted manufacturer in advanced lighting solutions. Our LED UV bulbs are engineered for performance, durability, and energy efficiency, ideal for a wide range of industrial, commercial, and specialty applications. To learn more or discuss a custom solution for your business, contact us today at [email protected]. Let Beauty STC power your next project with reliable, innovative UV lighting technology.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.