Article Contents

Industry Insight: Wire Stripes

Linear LED lighting systems featuring integrated wire management channels, commonly referred to as wire stripes or wireway stripes, are rapidly transforming the commercial and industrial lighting landscape. These sleek, modular solutions address a critical pain point in modern facility management: the need for flexible, easily serviceable, and aesthetically clean illumination in dynamic environments like offices, retail spaces, warehouses, and healthcare facilities. Moving decisively beyond the limitations of traditional troffers and rigid linear fixtures, wire stripes offer unparalleled adaptability. Their defining characteristic—the dedicated channel for power and data wiring—streamlines installation, significantly reduces maintenance downtime by allowing simple fixture access or repositioning without ceiling disruption, and delivers a refined, uncluttered visual profile essential for contemporary architectural design. Crucially, for specifiers and facility managers operating in regulated markets, adherence to stringent safety and performance standards is non-negotiable. Reputable manufacturers ensure these systems carry essential certifications such as ETL listing for North America and CE marking for Europe, providing assurance of electrical safety, reliability, and compliance with regional codes. Beauty STC Manufacturing Co., Ltd., a trusted leader in innovative LED lighting solutions since 1998, leverages its deep engineering expertise and commitment to quality to deliver high-performance wire stripe systems that meet these exacting global requirements while solving real-world commercial and industrial lighting challenges.

Technical Specs & Certifications

Wire stripes refer to linear LED lighting systems commonly known as LED strip lights or tape lights, often used for architectural accent lighting, cove lighting, under-cabinet illumination, and decorative applications. At Beauty (STC) Manufacturing Co., Ltd., our wire stripes are engineered for high performance, reliability, and superior light quality, meeting the demanding requirements of both residential and commercial environments.

In terms of efficiency, Beauty STC’s wire stripes deliver an impressive lumen output ranging from 18 to 22 lumens per watt for standard high-CRI configurations, with advanced models reaching up to 25 lumens per watt using the latest generation of SMD LED chips such as 2835 or 5050. This balance of efficiency and quality ensures optimal energy savings without compromising on brightness.

A defining feature of our wire stripes is the high Color Rendering Index (CRI), consistently exceeding 90, with select premium lines offering CRI values of 95 and above. This ensures accurate color representation, making our strips ideal for retail displays, art galleries, hospitality environments, and any application where true-to-life color is essential. The high CRI is achieved through carefully selected phosphor coatings and binning processes during LED manufacturing, ensuring uniformity and consistency across production batches.

Regarding environmental protection, Beauty STC offers wire stripes with a range of IP (Ingress Protection) ratings to suit various installation conditions. Our standard non-coated strips are rated IP20, suitable for dry indoor environments. For damp or outdoor applications, we provide variants with silicone coating or encapsulation, achieving IP65, IP67, and even IP68 ratings. These higher-rated strips are resistant to dust, moisture, and temporary submersion, making them reliable for outdoor signage, landscape lighting, and bathroom installations.

Quality is at the core of Beauty STC’s manufacturing philosophy. Our wire stripes undergo rigorous testing for thermal management, electrical safety, color consistency, and long-term lumen maintenance. We utilize high-quality flexible printed circuit boards (FPCBs) with excellent heat dissipation properties, premium constant-current drivers where applicable, and robust soldering techniques to ensure durability. All products comply with international standards including CE, RoHS, and UL certifications, reflecting our commitment to safety and performance.

In summary, Beauty STC’s wire stripes combine high lumens-per-watt efficiency, exceptional color rendering with CRI >90, and versatile IP protection levels from IP20 to IP68. Backed by stringent quality control and innovative engineering, our LED strips offer a reliable, long-lasting lighting solution trusted by professionals worldwide.

Factory Tour: Manufacturing Excellence

Beauty STC’s primary manufacturing facility is strategically located in Jiangmen, Guangdong Province, China. This modern factory serves as the company’s main production hub for LED lighting products, integrating advanced automation with stringent quality control processes across a purpose-built campus designed for efficient large-scale manufacturing. The facility houses comprehensive production lines dedicated to SMT assembly, LED module fabrication, and final product integration, all operating under ISO 9001 quality management systems.

The SMT production area is equipped with multiple high-speed Fuji NXT III modular placement systems. These machines handle components ranging from 0201 metric passives up to large LED modules and connectors with exceptional precision, achieving placement accuracy of ±25μm and throughput exceeding 100,000 components per hour per line. The dual-lane configuration allows for simultaneous production of different product variants, while automated optical inspection (AOI) stations after each critical process stage ensure solder joint integrity and component placement correctness before boards proceed to thermal curing. Stencil printers with laser alignment and automated paste management systems maintain consistent solder paste deposition, critical for the thermal reliability of high-power LED assemblies.

All LED products undergo rigorous aging and burn-in testing within dedicated environmental chambers at the Jiangmen factory. Standard aging protocols involve 72-hour continuous operation at elevated temperatures (typically 50-60°C ambient) with real-time monitoring of electrical parameters and thermal performance. For critical applications like linear lighting systems, we implement 10% overdrive testing during aging to accelerate potential early-life failures. Thermal imaging cameras track hotspot development across the entire product length during extended operation, while photometric sensors verify lumen maintenance and color stability. This comprehensive aging process occurs before final optical and electrical validation, ensuring only units meeting our stringent reliability thresholds reach customers.

Regarding OEM capability for flexible LED strip lights, which we internally reference as “flexible LED strip modules” or simply “LED strips” rather than “wire stripes”, Beauty STC offers full turnkey manufacturing services at the Jiangmen facility. Our OEM program supports custom strip configurations including specialized PCB widths, LED densities, color temperatures, CCT tuning, and IP ratings from IP20 to IP67. We handle reel-to-reel SMT processing of strips up to 5 meters in length per reel, with capabilities for custom cutting, connectorization, and reel labeling. The factory manages all aspects from PCB design and component sourcing to final testing and packaging, including custom branding, specification sheets, and compliance documentation. Our ESD-protected assembly lines and dedicated strip production zones ensure consistent quality for both standard and highly customized flexible strip solutions, with minimum order quantities adaptable to client requirements. This integrated OEM capability allows partners to leverage our manufacturing scale while maintaining product differentiation in their target markets.

Application Scenarios

Wire stripes are commonly used in commercial and hospitality environments such as hotels, malls, and offices due to their clean, linear appearance and flexibility in lighting design. In hotels, wire stripes are often installed in corridors, lobbies, guest room cove lighting, and behind reception desks to create ambient or indirect lighting that enhances guest comfort and visual appeal. In malls, they are ideal for illuminating signage, display areas, escalator soffits, and ceiling coves to guide customer movement and highlight architectural features. Offices utilize wire stripes in drop ceilings, under cabinets, above suspended ceilings for indirect lighting, and in partition walls to provide uniform, glare-free illumination that supports productivity and a modern aesthetic.

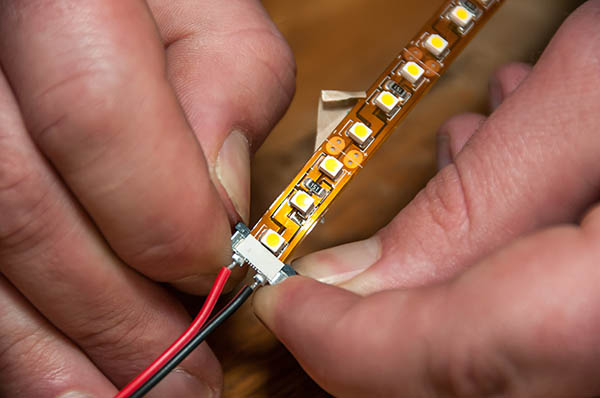

When installing wire stripe lighting, several key tips should be followed to ensure optimal performance and longevity. First, always verify that the mounting surface is clean, stable, and suitable for the fixture’s weight and length. Use appropriate mounting clips or brackets at regular intervals—typically every 12 to 24 inches—to prevent sagging and maintain alignment. Ensure proper electrical connections by using compatible drivers and connectors, and follow local electrical codes. It’s important to plan the layout in advance, considering power feed locations and minimizing visible wiring. For longer runs, consider central power feeding or multiple drivers to avoid voltage drop, especially with low-voltage LED wire stripes. Always handle the wire stripe carefully during installation to avoid damaging the LEDs or PCB. Finally, test the system before finalizing the installation and conduct routine inspections to ensure connections remain secure and lighting output remains consistent.

Why Choose Beauty STC Lighting

Elevate your product offerings with Beauty STC’s precision-engineered LED strip lighting solutions. Our advanced wire-based LED strips deliver exceptional luminous efficiency, thermal management, and design flexibility for architectural, commercial, and specialty applications. Partner with Beauty STC to access rigorously tested components built to international standards, including customizable color temperatures, IP-rated profiles, and seamless integration capabilities.

Leverage our engineering expertise to enhance your projects with reliable, high-performance lighting that reduces energy consumption without compromising quality. Beauty STC prioritizes technical collaboration, ensuring your partnership benefits from responsive support and scalable manufacturing tailored to your specifications.

Contact our partnership manager directly at [email protected] to discuss how Beauty STC’s LED strip solutions can strengthen your product portfolio and meet evolving market demands. Initiate a conversation today to receive technical documentation, sample kits, and dedicated engineering consultation.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.