Article Contents

Industry Insight: Water Resistant Led Strip

The commercial and industrial lighting sector faces relentless demands for solutions that deliver unwavering performance in challenging environments. Harsh conditions – from the humidity of food processing facilities and the dust of manufacturing floors to the constant exposure of outdoor architectural installations and the rigorous washdown requirements of cold storage – necessitate lighting systems engineered for resilience. Water resistant LED strips have rapidly evolved from a niche consideration to an essential component in these demanding applications, moving far beyond basic moisture protection to become critical infrastructure for safety, operational continuity, and long-term cost efficiency. Specifiers and facility managers increasingly prioritize strips that not only illuminate but also withstand the rigors of their specific operational context without degradation, where failure is not an option due to safety hazards or costly downtime.

Critical to the adoption and trust in these products within professional settings are stringent safety and performance certifications. Compliance with ETL (indicating adherence to North American safety standards under the OSHA Nationally Recognized Testing Laboratory program) and CE marking (demonstrating conformity with health, safety, and environmental protection standards for products sold within the European Economic Area) is non-negotiable. These certifications provide essential assurance that the water resistant LED strips have undergone rigorous independent testing for electrical safety, ingress protection reliability, and material integrity under specified conditions, mitigating risk for both installers and end-users in critical commercial and industrial deployments.

Beauty STC, established in 1998, has been at the forefront of this evolution, leveraging over two decades of specialized engineering expertise in LED technology. We understand that true water resistance in professional lighting goes beyond a simple IP rating sticker; it demands precision-engineered materials, robust construction methodologies, and an uncompromising commitment to validation. Our focus is squarely on developing water resistant LED strip solutions specifically designed to meet and exceed the exacting demands of commercial and industrial environments, where reliability, safety certification, and long-term value are paramount. We engineer for the realities of the job site, the factory floor, and the elements.

Technical Specs & Certifications

Beauty (STC) Manufacturing Co., Ltd. offers high-performance water-resistant LED strips engineered for both indoor and outdoor applications where durability, color accuracy, and energy efficiency are critical. Our water-resistant LED strips are designed with superior build quality and advanced optical components to meet the demands of commercial, architectural, and residential lighting projects.

Each water-resistant LED strip delivers an exceptional luminous efficacy of 110 to 130 lumens per watt, depending on color temperature and density configuration (e.g., 60 or 120 LEDs per meter). This high lumens-per-watt ratio ensures optimal energy savings without compromising brightness, making our strips ideal for long-term installations where operational efficiency is key.

Color Rendering Index (CRI) is a core focus in our product development. All water-resistant LED strips from Beauty STC achieve a CRI greater than 90, with select high-end models reaching CRI 95+. This ensures accurate and vibrant color representation, making them suitable for applications such as display lighting, retail environments, kitchens, and art galleries where true-to-life color rendering is essential.

In terms of environmental protection, our water-resistant LED strips are available in multiple Ingress Protection (IP) rated variants to suit different installation conditions. The most common configurations include:

IP65-rated strips feature a silicone coating that protects against dust ingress and low-pressure water jets from any direction. These are ideal for outdoor signage, under-eave lighting, and damp indoor areas like bathrooms and kitchens.

IP67-rated strips offer a higher level of protection, with full dust tightness and the ability to withstand temporary immersion in water up to 1 meter for 30 minutes. These are recommended for more demanding environments such as landscape lighting, outdoor steps, and marine applications.

IP68-rated versions provide the highest level of water resistance, with continuous submersion protection under deeper water conditions, based on specific design parameters. These are custom-built for permanent underwater installations, fountains, and pool lighting.

Beauty STC maintains rigorous quality control throughout the manufacturing process. Our LED strips use high-grade SMD LEDs (typically 2835 or 5050 packages), precision-printed circuit boards, and consistent silicone encapsulation to ensure long life, thermal stability, and uniform light output. All products undergo extended burn-in testing, thermal cycling, and photometric validation to guarantee reliability and performance consistency across batches.

With over two decades of expertise in LED lighting innovation, Beauty STC is committed to delivering water-resistant LED strips that combine high efficiency, excellent color fidelity, and robust environmental protection—backed by stringent quality standards and global compliance certifications.

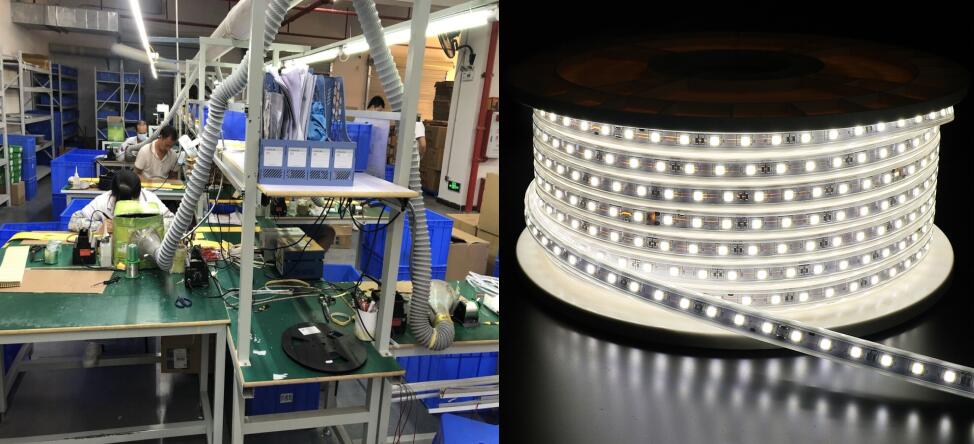

Factory Tour: Manufacturing Excellence

Beauty STC operates a modern, dedicated LED lighting manufacturing facility in Jiangmen, Guangdong Province, strategically located within the Pearl River Delta’s robust electronics supply chain ecosystem. This factory is purpose-built for high-volume, precision LED product assembly with a strong emphasis on quality control and process efficiency, serving both our branded lines and extensive OEM/ODM client base.

The Surface Mount Technology (SMT) production lines form the core of our component assembly capability. We utilize multiple high-speed, high-precision automated SMT lines featuring equipment from leading manufacturers such as Yamaha and Siemens. These lines handle the entire process from solder paste application through to component placement and reflow soldering. The machines are calibrated for the fine-pitch components common in modern LED strips, ensuring consistent solder joint quality and accurate placement of LEDs, resistors, and ICs onto flexible PCBs. This precision is particularly critical for water-resistant strip production where component alignment and solder integrity directly impact the effectiveness of subsequent encapsulation processes. Regular maintenance and operator training protocols ensure optimal machine performance and yield.

Rigorous aging and burn-in testing are non-negotiable steps in our quality assurance process, especially for water-resistant LED strips destined for demanding environments. Following assembly, all strips undergo extended operational aging tests within our dedicated environmental test chambers. Products are powered at full rated voltage and current for periods typically ranging from 24 to 72 hours, significantly exceeding standard industry practices. During this phase, we continuously monitor for early failures, light output consistency, color stability, and thermal performance under load. Crucially, for water-resistant variants, this aging occurs before the final waterproofing encapsulation step for certain IP ratings, allowing us to identify and eliminate any latent defects that could be masked or exacerbated by the sealant. Post-encapsulation, final IP verification testing is conducted to confirm the integrity of the waterproof barrier after the thermal stress of aging.

Our OEM capability for water-resistant LED strips is a significant strength of the Jiangmen facility. We offer comprehensive customization services starting from the ground up. Clients can specify exact IP ratings (from IP65 silicone coating to IP67/IP68 fully potted or jacketed constructions), LED density, color temperature, CRI, voltage, cut points, and dimming protocols. Our engineering team collaborates closely with clients to adapt PCB layouts, select appropriate waterproofing materials like specialized silicones or PVC/PUR jackets, and develop robust sealing methodologies tailored to the application’s environmental demands. The factory supports full turnkey OEM solutions, including custom reel labeling, unique packaging configurations, and private labeling. Our SMT flexibility and in-house tooling allow us to efficiently manage both low-volume prototyping runs and large-scale production orders for water-resistant strips, maintaining strict adherence to client specifications and international quality standards throughout the manufacturing process. This integrated approach ensures reliable, high-performance waterproof LED strip products delivered consistently for our OEM partners.

Application Scenarios

Water resistant LED strips are ideal for environments where moisture, humidity, or occasional water exposure is present. While they are not fully waterproof (submersible), their protective coating or silicone jacketing makes them suitable for damp or wet locations when properly installed. In commercial settings such as hotels, malls, and offices, these strips offer both functional and decorative lighting solutions with enhanced durability.

In hotels, water resistant LED strips are commonly used in bathrooms, spas, swimming pool areas, and outdoor patios. They can be installed under vanity cabinets, along shower niches, or within cove lighting in guest rooms to create ambient lighting that withstands high humidity. In spa and wellness areas, they enhance the atmosphere while resisting moisture damage. Outdoor signage and architectural lighting on hotel exteriors also benefit from their durability.

Malls utilize water resistant LED strips in restrooms, drinking fountains, food courts with open-air sections, and decorative displays near water features. They are often applied in cove lighting around ceilings or under handrails in covered walkways where condensation or rain exposure may occur. Their flexibility allows integration into curved display units and signage, providing consistent illumination in high-traffic, variable-humidity environments.

Offices typically install these strips in kitchenettes, restrooms, server rooms with cooling systems, and near windows or exterior entrances where condensation builds up. They are also used in modern architectural features such as under floating desks, within partition lighting, or in reception area accents where a sleek, durable lighting solution is needed.

For proper installation, ensure the power supply and connectors are also rated for damp locations and housed in protective enclosures if necessary. Use compatible aluminum channels with diffusers to enhance heat dissipation and provide additional protection. Always follow the manufacturer’s bending radius guidelines to avoid damaging the strip. Secure the strip with clips or adhesive backing on clean, dry surfaces, and seal end caps properly to prevent moisture ingress. For outdoor or high-moisture areas, consider using IP67 or IP68 rated strips and ensure all joints are sealed with silicone or waterproof connectors. Finally, connect the system to a grounded power source and consider using a low-voltage transformer for added safety in wet locations.

Why Choose Beauty STC Lighting

Elevate your lighting projects with Beauty STC’s premium water resistant LED strips, engineered for resilience in demanding environments. Our rigorously tested solutions feature industry-leading IP65 and IP67 ratings, ensuring reliable performance against moisture, dust, and harsh conditions for both indoor and outdoor applications. Partner with Beauty STC to access cutting-edge technology, consistent quality, and flexible customization that meets global safety standards while reducing long-term maintenance costs.

As your dedicated manufacturing partner, we provide seamless integration support, competitive pricing, and scalable production to help you deliver exceptional value to your clients. Trust our engineering expertise to enhance your product offerings with durable, high-efficiency lighting solutions built to last.

Contact our partnership team today at [email protected] to discuss how Beauty STC’s water resistant LED strips can strengthen your portfolio and drive mutual growth. Let us engineer brilliance together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.