Article Contents

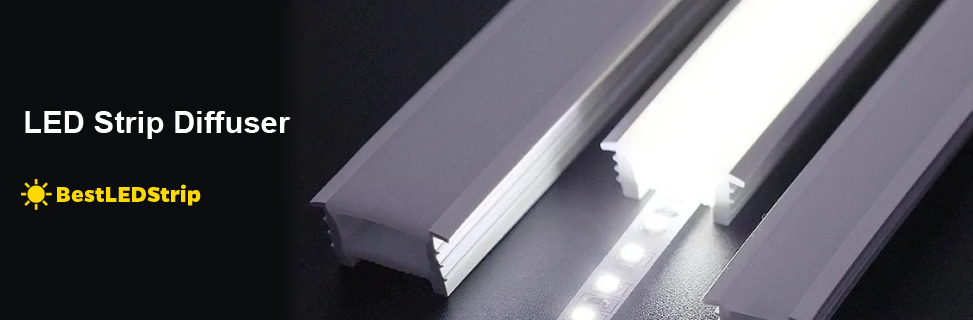

Industry Insight: Led Strip Diffuser

The evolution of commercial and industrial lighting has placed unprecedented demands on achieving not just energy efficiency, but also exceptional visual comfort and aesthetic precision. LED strip lighting, while offering transformative flexibility and performance, inherently presents challenges in these environments; raw, point-source LEDs create harsh glare and distracting hotspots, fundamentally undermining the professional ambiance required in retail displays, corporate offices, healthcare facilities, and demanding industrial workspaces. This is where the LED strip diffuser transcends its role as a simple cover, becoming a critical optical component essential for delivering uniform, glare-free illumination that meets stringent architectural and ergonomic standards. Success in these high-stakes applications hinges on diffusers engineered not merely for appearance, but for consistent light distribution, thermal management, and long-term reliability under continuous operation.

Meeting the rigorous safety and performance expectations of global commercial and industrial projects necessitates components that adhere to the highest regulatory benchmarks. Diffusers intended for permanent installation within luminaires or direct building integration must demonstrably comply with regional safety certifications. In North America, ETL listing signifies conformity with critical safety standards under the Nationally Recognized Testing Laboratory program, while CE marking remains a fundamental requirement for access to European markets, verifying adherence to essential health, safety, and environmental protection directives. These certifications are non-negotiable assurances for facility managers, architects, and electrical contractors, guaranteeing that the diffuser material itself will not compromise the safety or code compliance of the entire lighting system over its operational lifespan.

Beauty STC Manufacturing Co., Ltd. has been at the forefront of addressing these complex lighting challenges since our establishment in 1998. With over 25 years of dedicated specialization in advanced optical solutions for the professional lighting sector, we have navigated the full transition from traditional to solid-state lighting. Our deep expertise in material science, extrusion technology, and photometric performance allows us to develop and manufacture LED strip diffusers specifically engineered for the demanding realities of commercial and industrial environments. We understand that our components are integral to the success of projects where lighting quality directly impacts productivity, safety, and brand perception, driving our commitment to precision engineering, rigorous quality control, and unwavering compliance with global standards like ETL and CE.

Technical Specs & Certifications

The LED strip diffuser from Beauty (STC) Manufacturing Co., Ltd. is engineered to deliver optimal light distribution while maintaining high efficiency and superior color fidelity. When paired with compatible LED strips, the system achieves an efficacy of up to 120–140 lumens per watt, depending on the LED density and binning used. This high lumens-per-watt ratio ensures energy-efficient performance ideal for both residential and commercial lighting applications.

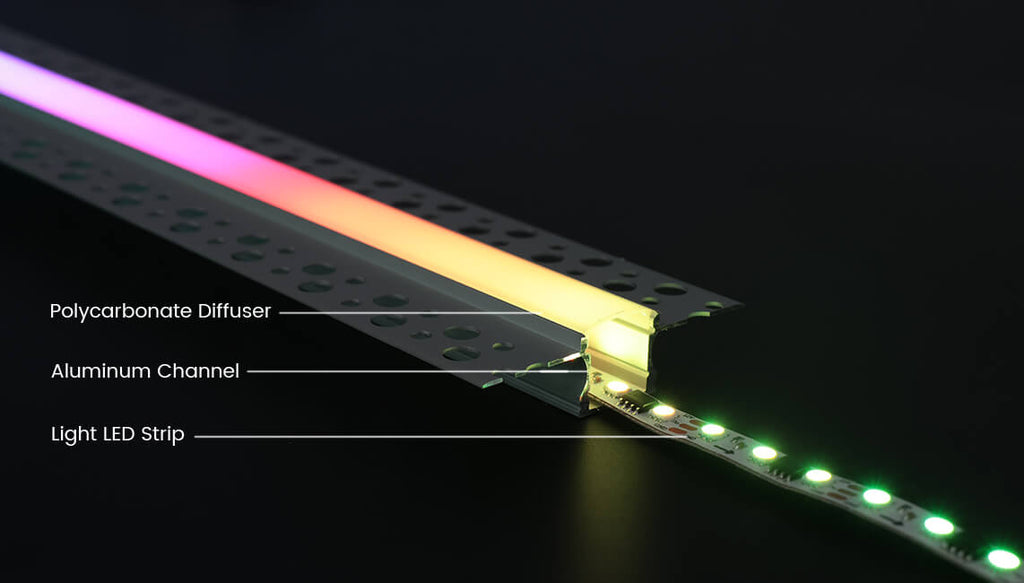

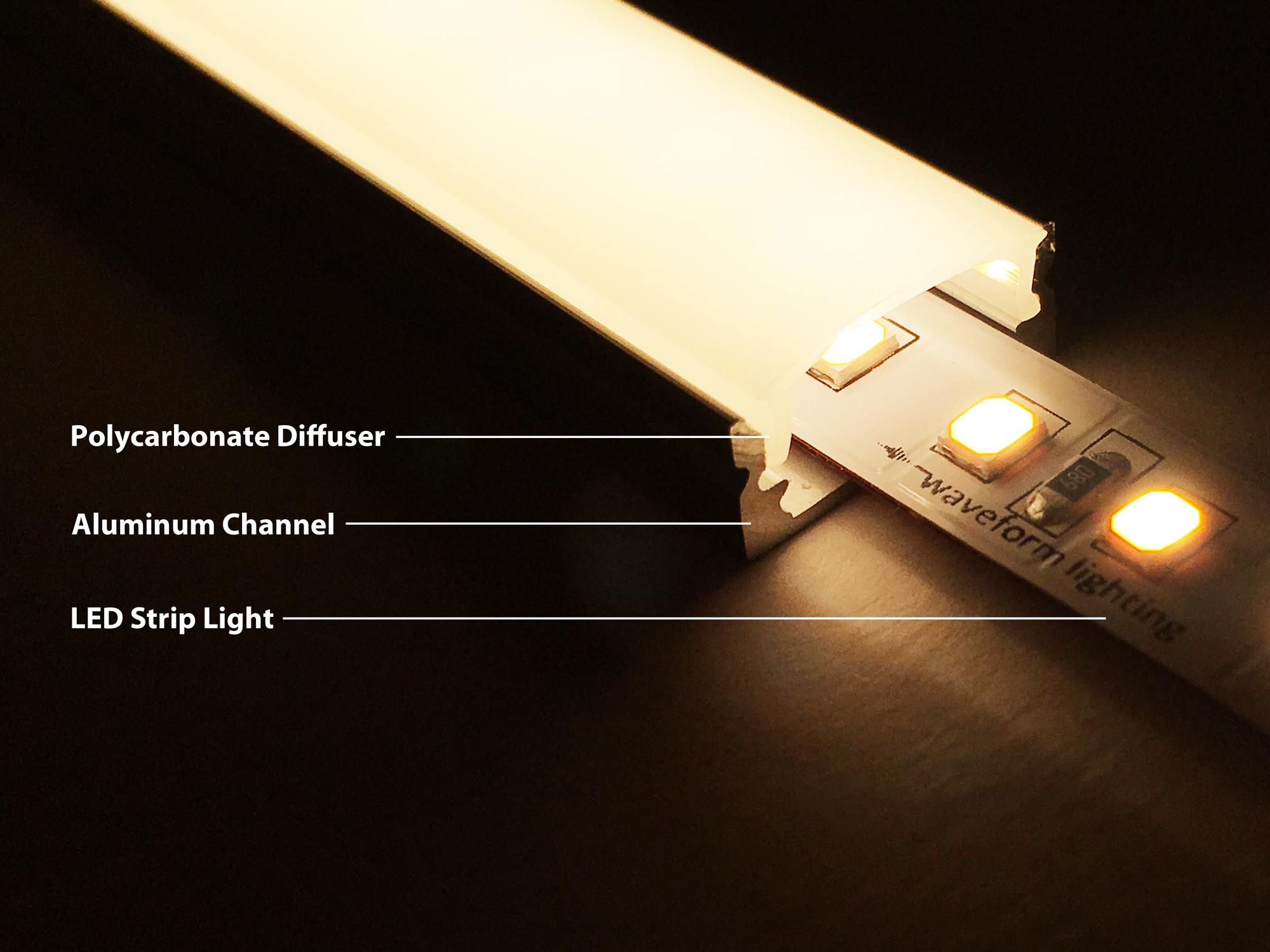

A key feature of Beauty STC’s LED strip and diffuser integration is the consistent Color Rendering Index (CRI) exceeding 90, with options available up to CRI 95+. This high CRI ensures accurate and vibrant color representation, making it particularly suitable for retail displays, architectural accent lighting, and environments where true color perception is critical. The diffuser material—typically made from high-transmission polycarbonate or PMMA—is designed to minimize hotspots and glare while preserving luminous efficacy and color consistency across the entire length of the strip.

In terms of environmental protection, Beauty STC offers LED strip diffuser systems with a range of IP (Ingress Protection) ratings to suit various installation conditions. Standard profiles include IP20 for indoor, dry locations, while fully encapsulated solutions provide IP65, IP67, and even IP68 ratings for outdoor, damp, or washdown environments. These ratings are achieved through precision extrusion techniques and seamless sealing methods, ensuring long-term reliability and resistance to dust, moisture, and mechanical stress.

Beauty (STC) Manufacturing Co., Ltd. is recognized for its stringent quality control processes, use of premium materials, and adherence to international standards such as UL, CE, and RoHS. Their diffusers are designed to maintain optical clarity over extended periods, resisting yellowing and UV degradation. This commitment to quality ensures consistent photometric performance and longevity, making Beauty STC a trusted partner for high-performance LED lighting systems.

Factory Tour: Manufacturing Excellence

Beauty STC operates a modern, ISO 9001 and IATF 16949 certified manufacturing facility in Jiangmen, Guangdong Province, strategically positioned within the Pearl River Delta electronics manufacturing hub. This location provides excellent access to supply chains and logistics infrastructure. The factory is designed for efficient, high-volume LED lighting production with a strong emphasis on process control and quality assurance.

Our surface mount technology capabilities are centered around multiple high-speed SMT production lines featuring Yamaha YS series placement machines, primarily the YS24 and YS12 models. These machines deliver exceptional precision, handling components down to 01005 package sizes with placement accuracy consistently within ±25 microns, critical for the dense layouts of modern high-density LED strips. Each line operates at high throughput, capable of placing approximately 80,000 components per hour, and is fully integrated with automated solder paste inspection (SPI) and multiple automated optical inspection (AOI) stations immediately post-reflow. This comprehensive inline inspection ensures solder joint integrity and component placement accuracy before boards proceed to subsequent assembly stages, minimizing defects early in the process.

Rigorous aging and reliability testing form a cornerstone of our quality system. Completed LED strip assemblies undergo mandatory aging procedures in dedicated environmental test chambers. Strips are operated continuously at 110% of their rated voltage and elevated temperatures typically ranging from 60°C to 70°C for durations of 24 to 48 hours, depending on the product specification and customer requirements. Thousands of meters of strip are aged simultaneously on custom-designed test racks that allow for individual segment monitoring. During this period, we meticulously monitor for early failures, lumen maintenance, color shift (measured via integrated spectrometers), and electrical parameter stability. This process effectively identifies and eliminates infant mortality units, ensuring only units meeting our stringent long-term reliability standards are shipped to customers.

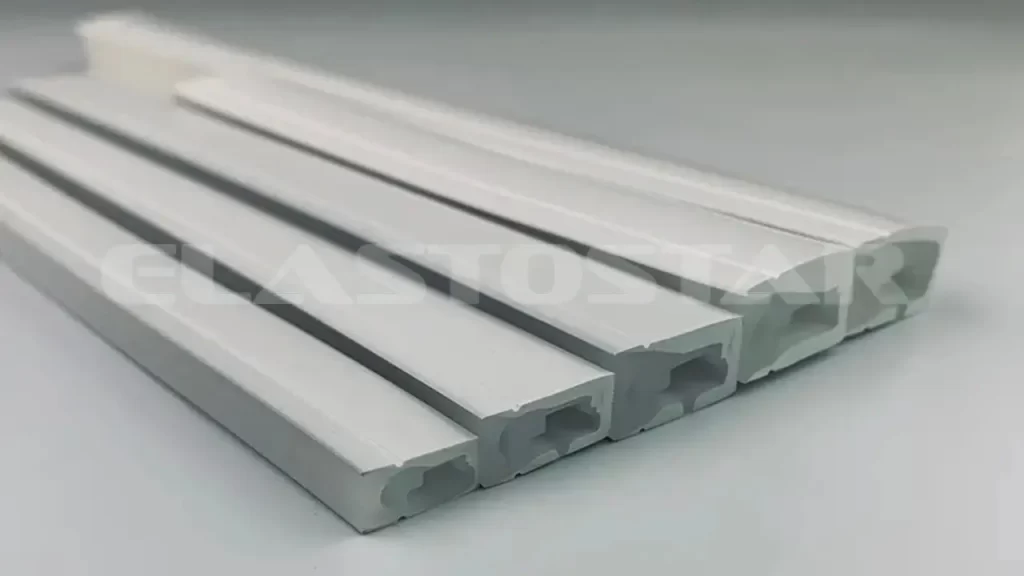

Regarding OEM capability for LED strip diffusers, it is important to clarify that Beauty STC provides comprehensive OEM manufacturing for complete LED strip light assemblies, where the diffuser is a critical integrated component. We do not typically supply only the diffuser tube as a standalone OEM component to external customers; our core strength lies in producing the finished, functional lighting product. For the diffuser element itself within the strip assembly, we possess significant in-house capability. We operate extrusion lines for producing diffuser profiles from various materials including polycarbonate (PC), polymethyl methacrylate (PMMA), and silicone, allowing us to customize optical properties (transmission, diffusion angle), color (clear, milky white, frosted), and physical profiles (round, square, flat, corner-mount) to meet specific customer optical and mechanical requirements. This diffuser production is fully integrated with our SMT and strip assembly processes. Our OEM service encompasses the entire value chain: designing and extruding the custom diffuser profile, populating the flexible PCB with LEDs and components using our SMT lines, integrating the diffuser, applying protective coatings if needed, performing electrical testing, conducting the mandatory aging cycle, and final packaging – all tailored precisely to the client’s specifications for performance, form factor, and branding. This end-to-end control ensures consistent quality and optical performance in the final LED strip product.

Application Scenarios

LED strip diffusers are essential components for achieving uniform, glare-free illumination when using LED strip lighting. They are widely used across various commercial and hospitality environments including hotels, malls, and offices due to their ability to soften light output and create a more visually comfortable atmosphere.

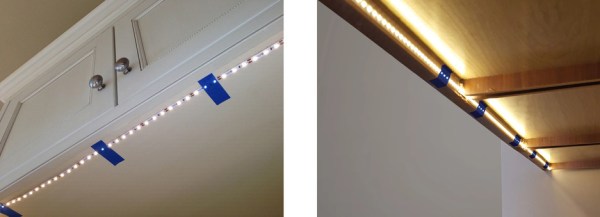

In hotels, LED strip diffusers are commonly used in guest rooms, hallways, lobbies, and under-cabinet lighting in minibars or desks. They help create a warm and inviting ambiance, especially when integrated into cove lighting, headboards, or vanity mirrors. The diffuser ensures that individual LED dots are not visible, providing a smooth and continuous glow that enhances the overall aesthetic appeal.

In malls and retail spaces, diffusers are often installed in cove lighting along ceilings, display cases, and signage. They help highlight architectural features and products without creating harsh shadows or glare. Uniform light distribution is crucial in retail environments to enhance product visibility and create an inviting shopping atmosphere.

In office environments, LED strip diffusers are typically used in suspended ceilings, under shelving, in partition coves, and along stairwells or corridors. They contribute to a professional and well-lit workspace by minimizing eye strain and providing consistent ambient lighting. Offices benefit from the sleek, modern appearance diffused LED strips offer, especially in reception areas and meeting rooms.

For successful installation, ensure the LED strip is mounted straight and securely within the channel or housing before attaching the diffuser. Clean the strip and housing to avoid dust particles becoming visible once diffused. Choose the appropriate diffuser type—milky white for soft diffusion or clear prismatic for higher light output with moderate diffusion—based on the desired brightness and aesthetic. Always cut the LED strip only at designated cut points to maintain functionality. When joining multiple strips, use proper connectors or solder joints to prevent flickering. Finally, secure the diffuser tightly into the channel to prevent gaps and ensure even light coverage along the entire length.

Why Choose Beauty STC Lighting

Transform your LED strip installations with Beauty STC’s precision-engineered diffusers designed for flawless light distribution and professional results. Our advanced diffuser profiles eliminate harsh hotspots and visible dots, delivering uniform, glare-free illumination that meets the highest standards for residential, commercial, and architectural applications. Engineered with optimal light transmission and thermal management, Beauty STC diffusers ensure consistent color rendering and longevity while simplifying installation across diverse mounting scenarios.

Partner with Beauty STC Manufacturing Co., Ltd. to access custom extrusion capabilities, volume production reliability, and dedicated engineering support tailored to your project specifications. We provide comprehensive OEM/ODM services with rigorous quality control from raw material sourcing to final packaging, ensuring your lighting solutions exceed market expectations.

Elevate your projects with diffusers that combine aesthetic excellence and technical performance. Contact our partnership team today to discuss your requirements and receive sample kits for evaluation. Email [email protected] to initiate a collaboration that drives value for your clients and strengthens your product portfolio.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.