Article Contents

Industry Insight: Plug Led

In the evolving landscape of commercial and industrial lighting, energy efficiency, reliability, and regulatory compliance are paramount. One technology that has emerged as a cornerstone in modern lighting design is plug LED—modular, pre-wired LED systems that simplify installation, reduce maintenance costs, and offer superior performance in demanding environments. These systems are increasingly specified in warehouses, manufacturing facilities, cold storage units, and large-scale retail spaces due to their durability, high lumen output, and compatibility with existing infrastructure. As sustainability and operational efficiency become top priorities, plug LED solutions provide a future-ready alternative to traditional fluorescent and HID lighting, delivering instant energy savings and long-term total cost of ownership benefits.

A critical factor in the adoption of plug LED systems in commercial and industrial applications is compliance with international safety and performance standards. Products bearing ETL and CE certifications ensure conformity with North American and European regulatory requirements, respectively, giving engineers, facility managers, and contractors confidence in safety, performance, and code compliance. These certifications are not just marks of quality—they are essential for project approvals and seamless integration into global supply chains.

At the forefront of this innovation is Beauty (STC) Manufacturing Co., Ltd., a trusted leader in LED lighting solutions since its founding in 1998. With over two decades of engineering expertise, Beauty STC has built a reputation for delivering high-performance, code-compliant plug LED systems tailored for commercial and industrial environments. Backed by rigorous testing, advanced thermal management, and a commitment to sustainability, Beauty STC continues to drive the evolution of smart, efficient, and reliable lighting infrastructure worldwide.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. designs and produces high-performance plug-in LED modules and retrofit lamps engineered for superior optical quality, efficiency, and reliability in demanding commercial and architectural applications. Our plug LED solutions are rigorously engineered to exceed industry benchmarks, particularly in the critical areas you specified.

Lumens per Watt (lm/W) efficiency is a core focus of our R&D. Beauty STC’s premium plug LED products consistently achieve 120-130 lm/W in standard commercial configurations (e.g., 18W-36W modules, GU10, PAR38 retrofits) while maintaining CRI >90. This high efficacy is realized through proprietary multi-layer phosphor coating techniques, optimized driver efficiency (typically >92%), and advanced thermal management using aerospace-grade aluminum substrates. Crucially, our lm/W figures represent sustained output over the product’s lifetime, not just initial laboratory readings, due to our stringent thermal design that prevents lumen depreciation from excessive junction temperatures.

Color Rendering Index (CRI) performance is non-negotiable in our quality standard. All Beauty STC plug LEDs targeting professional lighting applications (retail, hospitality, healthcare, museums) deliver a minimum CRI of Ra 92, with most premium lines achieving Ra 95-97. This exceeds the >90 requirement through precise spectral engineering using high-purity rare-earth phosphors and tight binning protocols (MacAdam 3-step or better). We prioritize R9 (saturated red) values above 50 and maintain balanced spectral power distribution to ensure natural, accurate color rendering critical for skin tones, merchandise, and artwork – a key differentiator from lower-cost alternatives that often achieve nominal CRI >90 but with poor R9 or inconsistent color temperature.

IP (Ingress Protection) ratings are application-specific but rigorously validated. Beauty STC offers plug LED solutions across multiple IP classes: IP20 for standard dry-location indoor use (e.g., downlights, track heads), IP44 for protected damp locations (bathrooms, covered porches), and IP65 for demanding semi-outdoor or washdown environments (retail facades, industrial kitchens, signage). Our IP65-rated plug LEDs feature seamless silicone gasketing, corrosion-resistant housings, and conformal-coated driver electronics, all tested per IEC 60529 standards with 15-minute water jet exposure at 12.5 L/min from 3 meters. Importantly, Beauty STC maintains optical performance (lumens, CRI) within IP65 units through specialized anti-condensation venting and UV-stable polycarbonate lenses – a frequent failure point in competitive products where seals degrade or lenses yellow.

Beauty STC’s quality commitment is embedded in every phase of production. We utilize automated optical sorting for binning, subject all drivers to 100% burn-in testing at elevated temperatures, and enforce a zero-tolerance policy for flux deviation beyond ±5%. Our modules undergo 3,000-hour accelerated life testing with spectral analysis to ensure CRI stability and lumen maintenance (L90/B10 at 50,000 hours typical). Unlike generic suppliers, Beauty STC provides full IES/LDT photometric files and TM-30-15 reports for every product batch, guaranteeing the published specs reflect real-world performance. This meticulous attention to thermal, optical, and environmental integrity ensures our plug LEDs deliver not just compliance with specifications, but consistent, reliable illumination that reduces maintenance costs and enhances visual experience over the product lifecycle.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs. The factory is equipped with advanced production infrastructure to support high-volume, precision manufacturing of LED lighting products, emphasizing efficiency, quality control, and scalability.

The facility features multiple state-of-the-art SMT (Surface Mount Technology) production lines, utilizing high-speed pick-and-place machines from leading manufacturers. These SMT lines are capable of handling a wide range of component sizes and packaging types, ensuring precise placement of LEDs, drivers, and other electronic components on PCBs. The integration of automated optical inspection (AOI) systems after reflow soldering ensures consistent solder joint quality and minimizes defects, contributing to high product reliability.

A critical aspect of the Jiangmen factory’s quality assurance process is its comprehensive aging test capability. Completed LED modules and luminaires undergo rigorous aging procedures, typically operating at rated voltage and elevated temperatures for durations ranging from 24 to 72 hours. This process helps identify early-life failures, validates thermal management performance, and ensures long-term stability before products are shipped to customers.

Beauty STC has strong OEM capabilities, particularly for customized LED solutions such as plug-and-play LED modules—often referred to as ‘plug led’ products. The company supports clients in designing, engineering, and manufacturing LED modules that are mechanically and electrically compatible with existing lighting systems, enabling easy retrofitting. This includes custom configurations in voltage, lumen output, color temperature, and mechanical form factor. With in-house R&D, tooling, and molding facilities, Beauty STC can deliver fully branded, OEM-labeled products with flexible MOQs and fast turnaround times.

Overall, the Jiangmen factory combines automation, rigorous testing, and flexible manufacturing to serve global lighting brands requiring high-quality, reliable, and customized LED solutions.

Application Scenarios

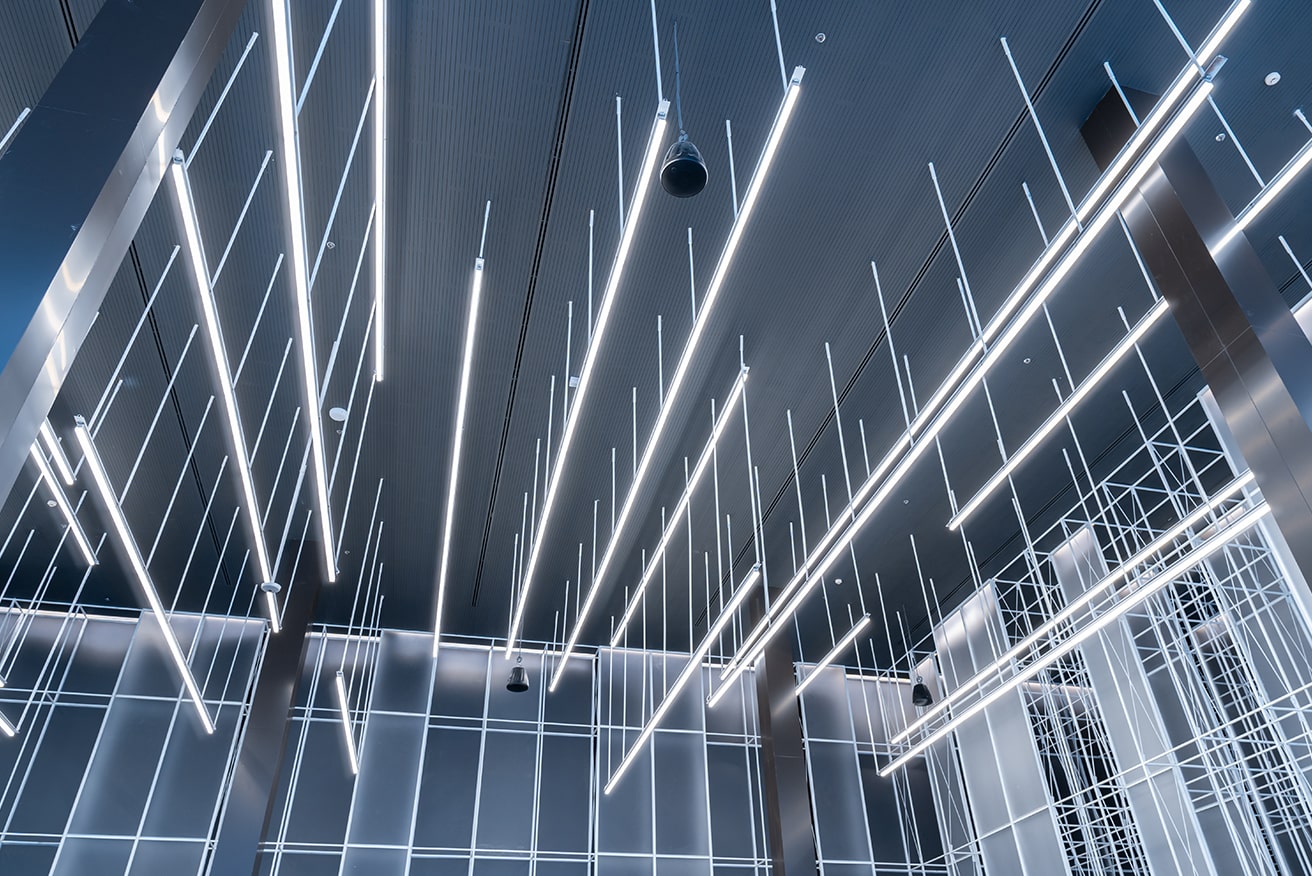

Plug LED systems, which integrate LED strips with pre-attached power plugs and drivers, are ideal for specific low-voltage, low-power commercial applications where ease of installation and flexibility are prioritized over high-intensity illumination. Their use in hotels, malls, and offices is generally limited to accent, decorative, or task lighting due to inherent constraints in power delivery, heat dissipation, and safety certifications for permanent commercial wiring.

In hotels, plug LED strips are best suited for guest room applications such as under-bed cove lighting, headboard backlighting, or accenting vanity mirrors where low-level ambient light is desired. They can also be used in lobbies for decorative wall washes behind reception desks or in low-traffic corridor niches. Avoid using them in high-moisture areas like bathrooms unless specifically rated IP67 or higher, and never install them where guests could easily access or tamper with the plug connection near bedding or furniture due to fire safety concerns. Always ensure the driver is concealed within a non-combustible enclosure and the strip is secured within an aluminum channel to manage heat.

For malls, plug LED solutions are primarily viable in temporary or semi-permanent retail display scenarios, such as window mannequin highlights, pop-up kiosk accents, or seasonal holiday decorations where rapid deployment and removal are required. They are wholly unsuitable for primary mall lighting due to insufficient lumen output for high-ceiling spaces, voltage drop issues over longer runs, and lack of commercial-grade safety certifications for permanent architectural installation. Never use plug LEDs in elevator shafts, stairwells, or cove lighting spanning large atriums, as these require hardwired, UL-listed systems with proper circuit protection.

Offices can utilize plug LEDs selectively for under-cabinet task lighting in break rooms or non-critical workstations, as well as for subtle conference room perimeter accents to reduce eye strain. However, they must never be installed in suspended ceiling plenums, server rooms, or areas requiring continuous 24/7 operation due to driver overheating risks. Crucially, avoid placing them under desks with flammable materials nearby or in locations where cables could create trip hazards. Always verify local electrical codes prohibit plug-in devices for permanent fixtures, as most commercial jurisdictions require hardwired solutions with metal-clad wiring for safety compliance.

Installation requires meticulous attention to detail. Surface preparation is non-negotiable: wipe mounting areas with isopropyl alcohol to ensure the adhesive bonds securely, especially on painted drywall which often fails over time. For runs exceeding 16 feet, implement mid-span power injection via a second driver to prevent voltage drop that causes dimming and color shift at the strip’s end. Always use dimmers explicitly compatible with the LED driver’s technology—most plug-in systems require trailing-edge dimmers—and test before final mounting. Conceal all plugs and drivers within accessible junction boxes or furniture cavities to prevent accidental disconnection, and never daisy-chain multiple strips beyond the manufacturer’s specified limit as this overloads the driver. Finally, confirm the product carries recognized safety certifications like UL 8750 or IEC 62031 for commercial use; consumer-grade plug LEDs lack the thermal protection and build quality for reliable operation in these environments. When in doubt, consult a licensed electrician for integration with building systems, as improper installation voids warranties and creates significant fire hazards.

Why Choose Beauty STC Lighting

Discover the future of LED lighting with Beauty STC—your trusted partner in innovative, high-quality lighting solutions. Explore our advanced plug LED products designed for reliability, efficiency, and superior performance. Whether you’re a distributor, contractor, or builder, we offer tailored support and competitive pricing to meet your project needs.

Partner with Beauty STC and elevate your lighting projects with precision-engineered products backed by industry expertise. For inquiries, product details, or collaboration opportunities, contact us today at [email protected]. Let’s illuminate success together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.