Article Contents

Industry Insight: Full Spectrum Led Light Strips

The demand for full spectrum LED light strips in commercial and industrial lighting applications has seen significant growth as businesses prioritize visual clarity, energy efficiency, and occupant well-being. Unlike traditional lighting solutions, full spectrum LEDs replicate natural daylight by delivering a balanced spectral output across the visible light range, enhancing color rendering and reducing eye strain—critical factors in environments such as retail spaces, manufacturing facilities, healthcare settings, and design studios. As industry standards become more stringent, compliance with certifications like ETL and CE ensures these lighting systems meet rigorous safety, performance, and electromagnetic compatibility requirements, offering peace of mind for facility managers and contractors alike.

At the forefront of this innovation is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED lighting solutions since its founding in 1998. With over two decades of engineering expertise, Beauty STC has consistently delivered high-performance, code-compliant lighting products tailored for demanding commercial and industrial applications. Their full spectrum LED light strips combine advanced optical design with robust construction, supporting sustainable lighting upgrades that improve both functionality and ambiance in professional environments.

Technical Specs & Certifications

Full spectrum LED light strips from Beauty STC Manufacturing Co., Ltd. are engineered to deliver exceptional color accuracy and visual performance for demanding applications such as retail merchandising, art galleries, photography studios, and healthcare environments where true color representation is critical. Our definition of “full spectrum” centers on achieving a balanced spectral power distribution that closely mimics natural daylight, specifically targeting a minimum Color Rendering Index (CRI) of Ra 90+ across all correlated color temperatures (CCTs) from 2700K to 6500K. This requires precise phosphor formulation and rigorous binning of high-grade LED chips, typically utilizing industry-leading mid-power packages like Samsung LM301B-H or Nichia 219C, which form the foundation of our premium strips.

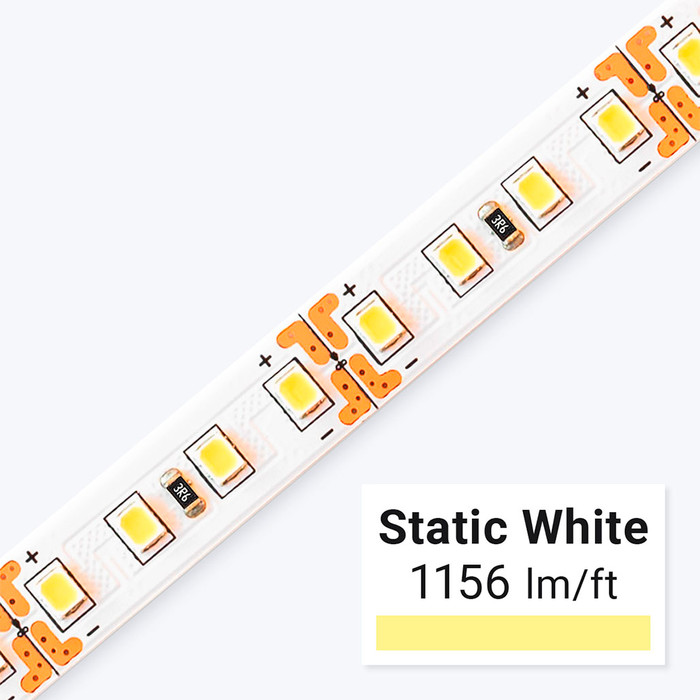

Luminous efficacy for our full spectrum strips ranges from 110 to 125 lumens per watt at typical operating currents, depending on the specific CCT and density configuration. This high efficiency is achieved through the use of these advanced LED packages combined with optimized thermal management in our flexible PCB design. While standard LED strips might sacrifice efficacy for high CRI, Beauty STC’s engineering ensures minimal trade-off; our 4000K strips consistently achieve 118-122 lm/W while maintaining Ra 95+ and R9 (saturated red) values exceeding 90. This balance is critical for applications requiring both energy savings and uncompromised color fidelity. We achieve this through proprietary driver IC selection and copper trace thickness calibration to minimize resistive losses, ensuring the efficacy remains stable over the strip’s operational life.

Color Rendering Index performance is non-negotiable in our full spectrum product line. Every strip undergoes spectrophotometric testing to guarantee a minimum Ra 92 across all CCTs, with Ra 95+ being standard for 3000K-5000K variants. Crucially, we emphasize high R9 values (typically 92-95) and extended spectrum coverage including R12 (blue) and R13 (skin tone), which are often neglected by competitors claiming “CRI 90+”. Our quality control process involves batch testing under multiple standard illuminants (D50, D65) to ensure consistency in real-world conditions, not just lab benchmarks. Beauty STC’s commitment to spectral quality is reflected in our tight binning tolerances—MacAdam Ellipse steps are consistently ≤ 3 SDCM, preventing visible color variation between strips in continuous installations.

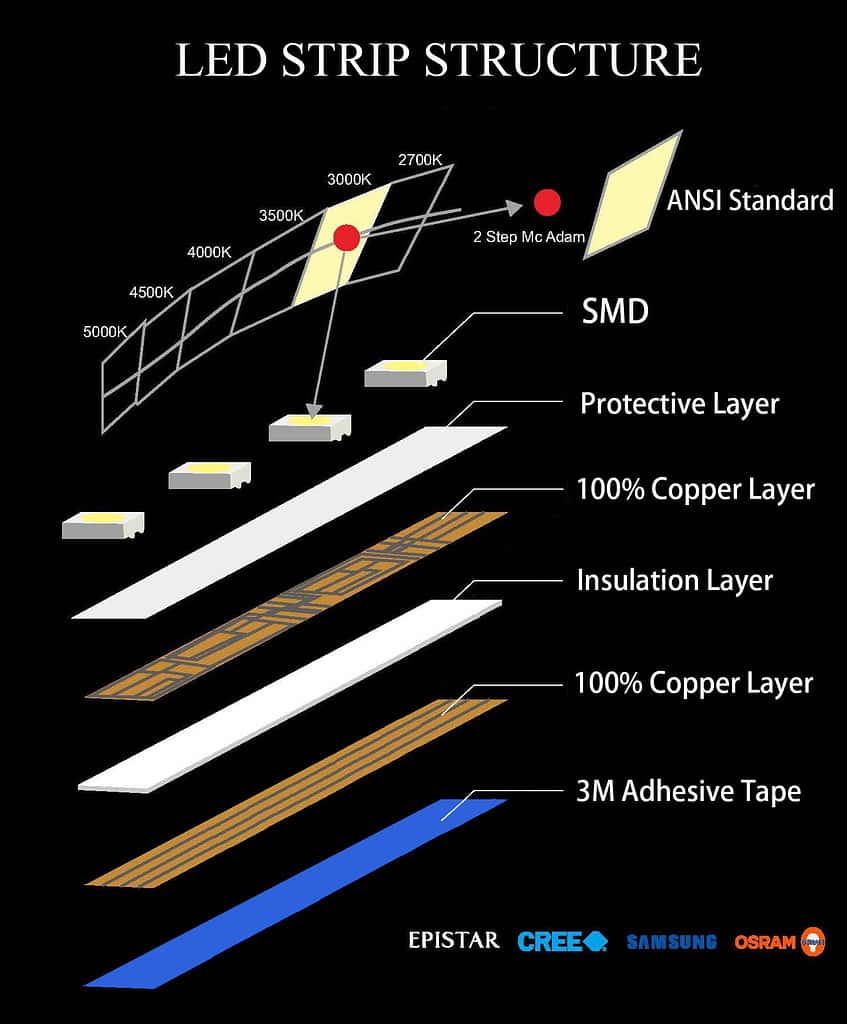

IP rating options are selected based on application requirements without compromising optical performance. Our standard full spectrum strips feature an IP20 rating for dry indoor use, utilizing high-purity silicone encapsulants that protect against dust ingress while maintaining light transmission. For damp or outdoor environments, we offer IP65-rated strips where the entire assembly—including solder joints and connectors—is sealed with a flexible, UV-stable silicone overmolding that withstands -40°C to +70°C operating temperatures. For submersion applications like pool lighting or marine use, our IP67-rated strips undergo 30-minute submersion testing at 1m depth per IEC 60529 standards, achieved through a dual-layer encapsulation process that prevents moisture wicking along the copper traces. Beauty STC’s quality assurance includes 100% automated optical inspection (AOI) for seal integrity and accelerated lifecycle testing simulating 50,000 hours of operation under humidity cycling.

Beauty STC’s manufacturing excellence ensures these specifications are not just theoretical. Our Shenzhen facility implements ISO 9001-certified processes with six-sigma tolerances in phosphor coating thickness and solder paste deposition. Every full spectrum strip batch includes third-party TM-30-15 reports verifying spectral fidelity beyond basic CRI metrics. We enforce 0.5% maximum variation in lumen output between production runs—significantly tighter than industry norms—through in-line spectrometer calibration. This relentless focus on consistency, from raw material sourcing to final aging tests, guarantees that our full spectrum LED strips deliver the promised lumens per watt, CRI stability, and environmental resilience expected in professional lighting installations. Long-term performance is further assured by L90 lifetime ratings exceeding 50,000 hours at 25°C ambient, validated through IES LM-80 testing of our core LED components.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for electronics and lighting production. The Jiangmen factory is purpose-built for the efficient and high-quality manufacturing of LED lighting products, with a strong focus on innovation, reliability, and customization.

The factory is equipped with advanced Surface Mount Technology (SMT) production lines, featuring high-precision automated SMT machines from leading global manufacturers. These machines ensure accurate placement of LED components and other surface-mount devices onto flexible and rigid printed circuit boards used in LED light strips. The SMT lines are integrated with automated optical inspection (AOI) systems to verify solder joint quality and component alignment, ensuring consistent product performance and minimizing defects.

To guarantee long-term reliability, all LED light strips—especially the full spectrum series—undergo comprehensive aging tests. The factory has dedicated aging chambers where products are subjected to continuous operation under elevated temperatures and voltage stress for extended periods, typically 24 to 72 hours. This rigorous testing simulates real-world usage over time, allowing early detection of potential failures and ensuring that only stable, durable products reach customers.

Beauty STC has robust OEM (Original Equipment Manufacturing) and ODM (Original Design Manufacturing) capabilities, particularly for full spectrum LED light strips. The company supports custom solutions including tailored spectral outputs that closely mimic natural sunlight, specific color temperatures (ranging from 2700K to 6500K), high CRI (Color Rendering Index) values of 95 or above, custom lengths, voltages, and waterproof ratings (such as IP20, IP65, IP67). Clients can also customize packaging, labeling, and branding. The engineering team works closely with partners to develop application-specific lighting solutions for uses in horticulture, healthcare, retail display, photography, and home wellness environments.

Overall, the Jiangmen factory combines automated precision, rigorous quality control, and flexible manufacturing to deliver high-performance full spectrum LED light strips tailored to global market demands.

Application Scenarios

Full spectrum LED light strips, characterized by high CRI (typically Ra >90) and a balanced spectral power distribution that closely mimics natural daylight, serve specific functional and experiential purposes in commercial environments. Their application goes beyond mere illumination to influence perception, well-being, and operational efficiency. In hotels, prioritize guest experience zones where accurate color rendering and adaptable light quality matter most. Install these strips in high-end lobby feature walls or cove lighting to create a welcoming ambiance that transitions smoothly from warm morning tones to energizing cooler afternoon hues, enhancing the perceived luxury. Within guest rooms, integrate them under vanities and in wardrobe areas to ensure precise color judgment for grooming and clothing selection, directly impacting guest satisfaction. Critical for wellness areas, spas and premium bathrooms benefit immensely from full spectrum lighting at mirror perimeters, allowing guests to apply makeup or skincare with confidence under light that reveals true skin tones and product colors, avoiding the pitfalls of poor lighting that can ruin the experience. Avoid overuse in corridors or service areas where task lighting suffices, as the investment is best justified where human interaction with color is frequent.

For malls and retail environments, strategic placement targets areas where product presentation drives purchasing decisions. Focus on high-value merchandise displays such as jewelry counters, cosmetic sections, and apparel fitting rooms where color fidelity is non-negotiable; a diamond’s sparkle or fabric dye accuracy under full spectrum light builds consumer trust and reduces returns. Integrate strips within display case undersides or shelf edges in premium fashion boutiques to eliminate shadows and render textiles authentically, making colors pop without artificial saturation. Food courts and gourmet sections also gain significantly, as proper lighting enhances the visual appeal of fresh produce and prepared dishes, influencing perceived freshness and quality. Exercise caution in general circulation areas—while full spectrum lighting in common seating zones can improve spatial perception and comfort, it is often cost-prohibitive compared to standard high-CRI options. Instead, reserve it for anchor tenant spaces or flagship brand installations where the lighting directly supports brand image and sales conversion.

In office settings, leverage full spectrum strips to support human-centric lighting strategies that align with circadian rhythms and visual tasks. Install them in perimeter cove lighting systems within open-plan areas to provide glare-free, high-quality ambient light that reduces eye strain during prolonged screen work, particularly when tuned to 4000K-5000K during core working hours. Conference rooms demand neutral, high-CRI illumination for video conferencing and document review; embedding strips in table edges or ceiling coves ensures faces and materials appear natural on camera and in person. Specialized areas like design studios, print proofing rooms, or medical consultation spaces benefit from tunable full spectrum strips that maintain consistent color evaluation throughout the day. Avoid uniform deployment across all workstations; instead, target zones where visual acuity and color discrimination are critical, complementing rather than replacing task lighting. The circadian stimulus should be implemented thoughtfully—excessive cool light late in the day may disrupt employee well-being.

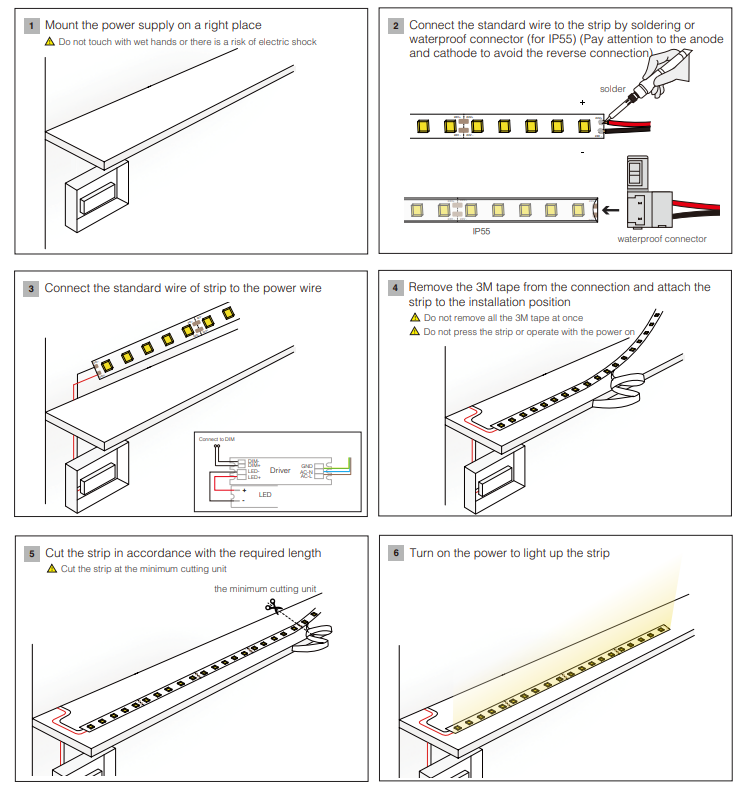

Installation requires meticulous attention to technical details for optimal performance and longevity. Always mount strips in aluminum channels with integrated diffusers to manage heat dissipation; inadequate thermal management drastically shortens LED lifespan and causes color shift, especially critical for spectral consistency in full spectrum products. Maintain strict voltage drop discipline—limit continuous runs to 5 meters for 24V strips and use parallel wiring or power injection for longer installations to prevent dimming at the strip’s end, which compromises light uniformity. Ensure all connections utilize waterproof solder joints or high-quality snap connectors rated for the current load, as poor connections generate heat and failure points. Integrate with compatible dimming systems like 0-10V or DALI for circadian tuning, verifying driver compatibility beforehand to avoid flicker. Position strips at least 30cm above the work plane in cove applications to minimize direct glare, and align them parallel to primary sightlines in retail displays to avoid hotspots. Crucially, handle strips with gloves during installation to prevent oil contamination on the LEDs, which degrades output, and always power-test before final mounting. Adherence to local electrical codes for low-voltage wiring and proper circuit protection remains non-negotiable, particularly in high-occupancy venues like hotels and malls where safety compliance is paramount.

Why Choose Beauty STC Lighting

Discover the future of lighting with Beauty STC’s premium full spectrum LED light strips—engineered for superior color rendering, consistent performance, and energy efficiency. Whether you’re designing high-end retail spaces, wellness environments, or advanced photography studios, our full spectrum solutions deliver natural daylight quality in any setting.

Partner with Beauty STC, a trusted leader in innovative LED technology, and gain access to custom manufacturing, scalable production, and technical support tailored to your project needs. Elevate your lighting offerings with products built to meet the highest international standards.

To learn more or discuss a custom solution, contact our sales manager today at [email protected]. Let’s illuminate the possibilities—together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.