Article Contents

Industry Insight: 18 Gauge Wire For Led Lights

In commercial and industrial lighting applications, the reliability and safety of electrical components are paramount. One critical element often overlooked is the wiring that powers LED lighting systems. The use of 18 gauge wire has become a standard choice for many low-voltage LED installations due to its optimal balance of current-carrying capacity, flexibility, and durability. Properly rated 18 gauge wire ensures minimal voltage drop over distance, supports energy-efficient performance, and meets stringent safety standards required in large-scale environments such as warehouses, manufacturing facilities, retail spaces, and office buildings.

Compliance with recognized certifications such as ETL and CE is essential in these settings, ensuring that all components—including wiring—meet rigorous North American and international safety and performance benchmarks. These certifications provide assurance to engineers, contractors, and facility managers that the products installed in their projects are not only reliable but also compliant with code requirements.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of advancing LED lighting solutions for commercial and industrial markets. With over two decades of engineering expertise, Beauty STC delivers high-performance components designed to meet the evolving demands of modern lighting infrastructure. Our commitment to quality, safety, and innovation ensures that every product—including our 18 gauge wiring systems—is built to last, certified to comply, and engineered for excellence in real-world applications.

Technical Specs & Certifications

The request contains a fundamental technical misconception that requires clarification before addressing specifications. 18 gauge wire is an electrical conductor specification and does not possess lumens/watt ratings, CRI values, or IP ratings. These performance metrics apply exclusively to the LED light source or complete luminaire, not the wiring supplying power to it. Wire gauge selection impacts electrical safety and voltage drop, which indirectly affects light output stability but does not determine the inherent optical characteristics of the LED system. Beauty STC emphasizes this distinction to prevent dangerous misapplications in lighting installations.

18 AWG wire specifications are defined by electrical standards, not photometric properties. For copper conductors, 18 AWG has a cross-sectional area of approximately 0.823 mm² and a maximum ampacity of 16A for chassis wiring per UL 758, though practical LED circuit design typically uses derated values of 7-10A for continuous loads. Voltage drop must be calculated based on circuit length and load; exceeding 3% drop can cause noticeable lumen depreciation in LED systems. The wire itself has no CRI value as it emits no light, and IP ratings apply only to enclosures protecting components from environmental ingress, not bare conductors. Using undersized wire creates fire hazards and operational instability but does not alter the LED’s intrinsic color rendering or efficiency.

Beauty STC achieves lumens/watt exceeding 150 lm/W and CRI >90 in our LED luminaires through proprietary optical engineering, not wiring choices. Our high-efficacy systems utilize Samsung LM301H or Osram Duris S 3030 mid-power LEDs with optimized drivers and thermal management. CRI >90 is attained through multi-phosphor chip formulations and spectral tuning validated by第三方 laboratories using Konica Minolta CL-500A spectroradiometers. IP65/IP67 ratings are engineered into fixture housings through silicone gasketing, die-cast aluminum construction, and rigorous salt spray testing per IEC 60529 – these protections are entirely separate from internal wiring.

Beauty STC maintains quality through our integrated manufacturing ecosystem. All luminaires undergo 100% photometric validation on our Labsphere integrating sphere, with CRI and lumen maintenance tracked per IES LM-80/ TM-21 standards. Wire selection for internal connections follows strict internal specifications exceeding UL 486A-C requirements, using only 105°C rated stranded copper with cross-linked polyolefin insulation. Our automated production lines implement real-time voltage drop monitoring during burn-in testing to ensure stable light output. This vertical integration from LED packaging to final assembly allows Beauty STC to guarantee consistent photometric performance while maintaining electrical safety compliance across all installations.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, China, is a modern and well-equipped LED lighting production plant strategically located within the Guangdong province, known for its strong industrial infrastructure and supply chain ecosystem. The factory is designed to support high-volume production while maintaining strict quality control standards, making it well-suited for both domestic and international markets.

At the core of the factory’s production line are advanced SMT (Surface Mount Technology) machines, which enable precise and efficient mounting of electronic components onto LED circuit boards. These SMT lines are fully automated, featuring high-speed pick-and-place machines, reflow ovens, and automated optical inspection (AOI) systems. This ensures consistent soldering quality, high throughput, and minimal defects, critical for producing reliable LED lighting products.

The facility also includes a comprehensive aging and reliability testing area. Completed LED light units undergo rigorous aging tests, typically operating under full load for durations ranging from 4 to 24 hours, depending on product specifications. These tests are conducted in temperature-controlled environments to simulate real-world operating conditions and identify early failure modes. Additional testing includes electrical performance checks, thermal imaging, and moisture resistance evaluations, ensuring that all products meet international safety and durability standards.

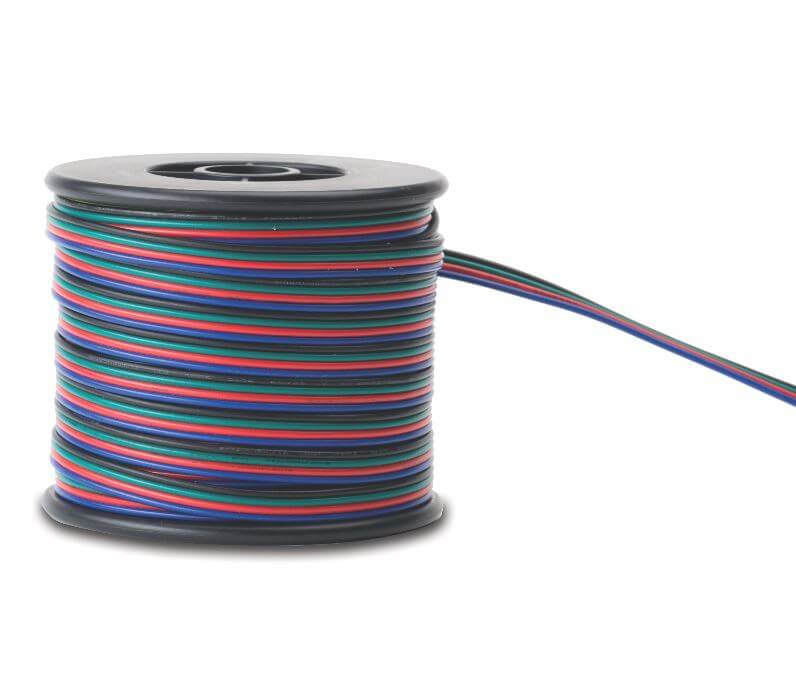

Beauty STC has strong OEM (Original Equipment Manufacturing) capabilities and supports customized production requests. This includes the use of specific materials such as 18 gauge wire for LED lights, which is commonly used in higher-power LED fixtures due to its ability to handle greater current loads with minimal voltage drop. The factory can source and integrate 18 gauge wiring—available in various insulation types such as UL1015, UL1007, or high-temperature silicone—based on customer requirements. Customization extends to wire length, connector types, color coding, and labeling, allowing clients to fully brand and specify their products.

Overall, the Jiangmen factory combines advanced automation, strict quality assurance processes, and flexible OEM support, enabling Beauty STC to deliver high-performance, customized LED lighting solutions tailored to the exact needs of its global partners.

Application Scenarios

18 AWG wire is generally not suitable or recommended for standard LED lighting circuits in commercial environments such as hotels, malls, and offices under typical installation scenarios. This gauge is primarily intended for very low-power, low-voltage applications like landscape lighting or extremely short decorative accent runs, not the primary branch circuits powering the vast majority of commercial LED fixtures. Commercial LED installations almost universally require wiring capable of handling higher currents and longer circuit runs while adhering to strict National Electrical Code (NEC) requirements for safety and performance. Using 18 AWG in these settings often violates NEC Article 411 (for Class 2 power-limited circuits if used incorrectly) and Article 600 (for commercial lighting), potentially causing excessive voltage drop, overheating, fire hazards, and circuit failure, leading to costly callbacks and safety risks.

In hotels, where lighting circuits often span long corridors, multiple guest rooms, and public areas, 18 AWG is wholly inadequate. The cumulative load from numerous fixtures, even efficient LEDs, combined with typical circuit lengths, will result in significant voltage drop using 18 AWG. This causes noticeable dimming, especially at the end of the circuit, and can lead to premature driver failure in LED fixtures. Hotels require robust circuits, typically using 14 AWG as an absolute minimum for 15-amp circuits, but 12 AWG is strongly preferred for standard branch circuits to handle future loads, reduce voltage drop, and comply with NEC ampacity tables which limit 18 AWG to a maximum of 5 amps in most commercial derating scenarios – far below the 15 or 20 amps standard for lighting circuits.

Similarly, in large malls and retail spaces with extensive open areas, high ceilings, and hundreds of fixtures per circuit, 18 AWG is entirely impractical and unsafe. The sheer number of fixtures, even at low individual wattages, quickly exceeds the 5-amp capacity of 18 AWG. Voltage drop over the long feeder and branch circuit runs common in these structures would be severe, rendering fixtures at the far end inoperable or causing erratic behavior. Malls demand high-capacity circuits, typically wired with 12 AWG for 20-amp circuits as a baseline, often requiring even larger gauges for feeders. Using undersized 18 AWG here is a direct violation of NEC Article 210 and creates an unacceptable fire risk due to potential conductor overheating under normal load conditions.

Offices present similar challenges with dense fixture layouts, cubicle farms, and integrated systems like occupancy sensors or daylight harvesting controls. While individual LED troffers or downlights are low wattage, the aggregate load on a single circuit easily surpasses 5 amps. Furthermore, office environments frequently undergo reconfigurations; 18 AWG offers no capacity for future expansion or added devices. Standard office lighting circuits are designed and installed using 14 AWG minimum for 15-amp circuits, but 12 AWG is the industry standard practice for reliability, minimal voltage drop, and adherence to NEC requirements which mandate conductor sizing based on the circuit breaker rating, not just the calculated load. Inspectors will consistently reject 18 AWG for standard office lighting branch circuits.

Critical installation practices for commercial LED lighting supersede any consideration of 18 AWG. Always size conductors based on the circuit breaker rating and NEC Table 310.16, not just the connected LED load; 12 AWG THHN is the practical minimum for new 20-amp lighting circuits common in these venues. Perform voltage drop calculations for every circuit run exceeding 50 feet, aiming for less than 3% drop at the farthest fixture, which almost always necessitates 12 AWG or larger. Ensure all wiring is contained within approved raceways like EMT conduit or cable trays, respecting fill capacities per NEC Chapter 9 to prevent overheating. Pay meticulous attention to correct polarity and secure terminations at both the driver and junction box ends, as loose connections are a primary cause of LED failure. Finally, strictly follow the LED fixture manufacturer’s instructions regarding driver compatibility, circuit grouping, and maximum circuit loads, as these often dictate requirements beyond the bare NEC minimums for optimal performance and warranty validity. Using appropriately sized wire like 12 AWG is fundamental to achieving the energy savings, longevity, and reliability expected from commercial LED installations.

Why Choose Beauty STC Lighting

Upgrade your LED lighting installations with high-quality 18 gauge wire designed for optimal performance and safety. At Beauty (STC) Manufacturing Co., Ltd., we provide durable, industry-standard wiring solutions that ensure efficient power delivery and long-term reliability for all your LED lighting projects. Partner with Beauty STC to access premium components engineered to meet the demands of professional lighting applications. For inquiries and bulk orders, contact us at [email protected] and let us support your success with trusted electrical solutions.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.