Article Contents

Industry Insight: Led Strip Supplier

The commercial and industrial lighting sector increasingly relies on high-performance LED strip solutions for applications demanding precision, durability, and energy efficiency, from architectural cove lighting and retail displays to factory task lighting and warehouse aisle marking. Specifiers and facility managers now prioritize suppliers who deliver not only superior photometric performance and thermal management but also unwavering adherence to critical safety and regulatory standards. In this demanding environment, certifications like ETL (indicating compliance with North American safety standards) and CE (demonstrating conformity with European health, safety, and environmental requirements) are non-negotiable prerequisites, ensuring products are safe for installation, reduce liability risks, and meet stringent building codes. Failure to provide properly certified strips can lead to project delays, costly rework, insurance complications, and potential safety hazards, making certified supply chains essential.

Operating at the forefront of this evolution since 1998, Beauty STC Manufacturing Co., Ltd. brings over 25 years of dedicated expertise in engineering and manufacturing LED strip lighting solutions specifically engineered for the rigors of commercial and industrial environments. We understand the unique pressures faced by contractors, designers, and facility operators – the need for long-term reliability under continuous operation, resistance to challenging conditions, and absolute confidence in compliance. Beauty STC is committed to exceeding these expectations through rigorous in-house testing, robust construction using premium components, and a steadfast focus on delivering ETL and CE certified products that form the reliable backbone of professional lighting installations worldwide. Our heritage is built on providing the performance assurance and technical partnership the professional lighting industry requires.

Technical Specs & Certifications

Beauty (STC) Manufacturing Co., Ltd. is a trusted LED strip supplier known for delivering high-performance, energy-efficient lighting solutions that meet rigorous international standards. Our LED strips are engineered for superior optical quality, durability, and consistency, making them ideal for both commercial and high-end residential applications.

In terms of efficiency, our LED strips achieve a luminous efficacy ranging from 110 to 150 lumens per watt, depending on the specific configuration and color temperature. This high lumens/watt ratio ensures optimal energy savings without compromising brightness, supporting sustainable lighting designs and reducing operational costs over time.

A key differentiator of Beauty STC’s LED strips is the exceptional color rendering capability. All premium-grade strips feature a Color Rendering Index (CRI) greater than 90, with select models reaching CRI >95. This ensures accurate and vibrant color representation, which is critical in retail, hospitality, art galleries, and architectural accent lighting where visual fidelity matters.

We offer LED strips with a range of Ingress Protection (IP) ratings to suit diverse environments. Our standard non-rated strips (IP20) are designed for indoor, dry locations. For damp or outdoor applications, we provide IP65-rated strips, which are protected against low-pressure water jets and dust ingress, making them suitable for cove lighting, under-cabinet use in kitchens, or outdoor signage. For fully outdoor or washdown environments, our IP67 and IP68-rated strips offer complete dust tightness and immersion resistance up to 1 meter, ideal for landscape lighting, pool perimeters, and marine applications.

Beauty STC maintains strict quality control throughout the manufacturing process, using high-grade SMD LEDs, robust flexible PCBs, and premium silicone or PVC jackets for enhanced durability. Our products undergo extensive testing for thermal management, color consistency, and long-term reliability, ensuring a rated lifespan of up to 50,000 hours. With UL, CE, and RoHS certifications, Beauty STC’s LED strips reflect a commitment to safety, performance, and environmental responsibility—hallmarks of our reputation as a leading LED strip supplier.

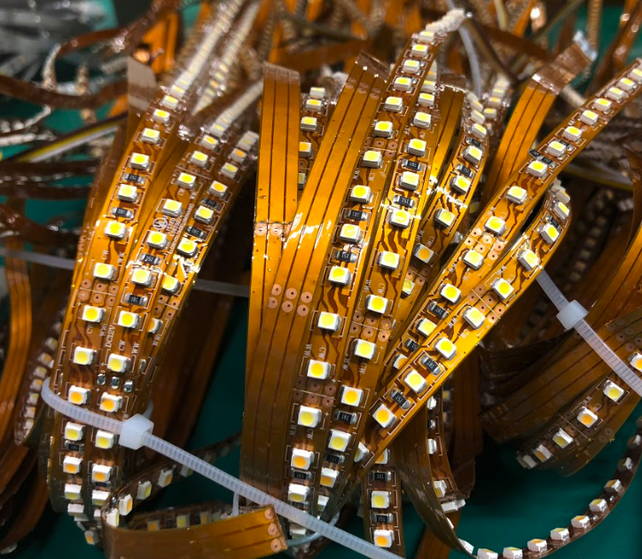

Factory Tour: Manufacturing Excellence

Beauty STC Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within the Pearl River Delta region. This factory serves as a primary hub for the production of high-quality LED lighting products, with a significant focus on flexible and rigid LED strip solutions. The Jiangmen facility is designed for efficiency and scalability, incorporating advanced manufacturing technologies and stringent quality control processes throughout the production flow.

The Surface Mount Technology (SMT) production lines form the core of our LED strip assembly capability. We utilize multiple high-speed, precision SMT lines featuring state-of-the-art machinery from leading manufacturers such as Yamaha and Siemens. These lines are capable of handling components ranging from ultra-small 0201 passives to larger power LEDs and ICs commonly used in LED strip designs. Each line integrates automatic solder paste printers with high-accuracy stencils, high-speed multi-head pick-and-place machines offering micron-level placement accuracy, nitrogen-assisted reflow soldering ovens for optimal thermal profiles and reduced oxidation, and automated optical inspection (AOI) systems for real-time solder joint and component placement verification. This SMT infrastructure ensures consistent, high-yield assembly of complex LED strip circuits, supporting both standard and custom designs with fine pitch components.

Rigorous aging and reliability testing are non-negotiable elements of our quality assurance protocol at the Jiangmen factory. Immediately following assembly and initial functional testing, all LED strip reels undergo an extended burn-in process within dedicated environmental aging chambers. Strips are operated at rated voltage, typically under elevated temperature conditions of 50-60°C, for a minimum duration of 24 to 48 hours. This accelerated aging process effectively identifies early-life failures such as infant mortality in LEDs, driver components, or solder joints, as well as potential issues like inconsistent brightness or color shift. Continuous monitoring during aging ensures any deviations are flagged for immediate investigation and corrective action before products proceed to final packaging. This commitment to thorough aging testing is fundamental to delivering LED strips that meet our stringent reliability standards and long lifespan expectations.

As a dedicated LED strip supplier, Beauty STC possesses extensive OEM manufacturing capabilities centered at the Jiangmen facility. We offer comprehensive turnkey solutions, supporting clients from initial concept through to mass production. Our engineering team collaborates closely with customers to develop custom LED strip specifications, including but not limited to PCB width, LED type and density, color temperature options, CRI levels, voltage requirements, waterproofing ratings (IP20 up to IP68), flexible or rigid substrate choices, and specialized connector configurations. We maintain in-house tooling and molding capabilities for custom profiles, diffusers, and connectors, enabling true differentiation. The factory is equipped to handle diverse order volumes, from prototyping and low-volume custom runs to high-volume production, all under strict quality management systems certified to ISO 9001 and IATF 16949 standards. This robust OEM infrastructure allows Beauty STC to be a strategic manufacturing partner for brands seeking reliable, high-performance, and uniquely specified LED strip lighting solutions.

Application Scenarios

LED strip suppliers play a crucial role in delivering high-quality, energy-efficient lighting solutions for various commercial and hospitality environments. When selecting an LED strip supplier for projects in hotels, malls, and offices, it’s essential to partner with a reputable manufacturer like Beauty (STC) Manufacturing Co., Ltd., which provides reliable, customizable, and long-lasting LED lighting products.

In hotels, LED strip lighting is ideal for enhancing ambiance and functionality. Common applications include under-cabinet lighting in hotel kitchens and minibars, cove lighting in lobbies and ballrooms, indirect lighting in guest room headboards or wardrobes, and accent lighting around mirrors and bathtubs. The soft, diffused glow of LED strips contributes to a luxurious and welcoming atmosphere. When installing in hotels, ensure the LED strips are compatible with dimming systems to allow guests to adjust lighting according to mood or time of day. Use aluminum channels to protect the strips and improve heat dissipation, especially in enclosed spaces.

Malls benefit from LED strip lighting in both aesthetic and practical ways. They are frequently used in signage backlighting, display window highlights, and architectural coving to draw attention to retail spaces. LED strips can also illuminate escalator handrails, stair treads, and ceiling features to enhance safety and visual appeal. When installing in malls, prioritize high CRI (Color Rendering Index) LED strips to ensure products and surroundings are displayed in true color. Always verify that the LED strips are rated for continuous operation and have proper IP ratings if used in areas exposed to dust or occasional moisture.

In office environments, LED strip lighting supports productivity and comfort. They are commonly installed under shelves, in ceiling coves, or behind monitors to reduce eye strain and create a modern workspace. Task lighting in reception areas or meeting rooms can also benefit from discreet LED strip integration. Choose neutral white or cool white color temperatures (4000K–5000K) for better focus and alertness. When installing in offices, ensure proper spacing to avoid flicker and glare, and connect strips to a stable power source with surge protection to prevent premature failure.

General installation tips include measuring the required length accurately, cleaning surfaces thoroughly before applying adhesive-backed strips, using connectors or soldering for seamless joints, and securing power supplies in accessible locations for maintenance. Always follow local electrical codes and consider hiring a licensed electrician for large-scale installations. Partnering with a trusted LED strip supplier ensures access to technical support, quality certifications, and suitable products tailored to each application.

Why Choose Beauty STC Lighting

Elevate your product offerings by partnering with Beauty STC, a trusted leader in precision-engineered LED lighting solutions. As a premier manufacturer specializing in high-performance LED strips, we deliver exceptional quality, reliability, and innovation tailored to meet rigorous industry standards. Our advanced SMD5050 and SMD2835 strips feature superior color rendering, robust waterproofing options, and extended lifespans, ensuring your projects achieve optimal results. Partner with Beauty STC to access scalable production capabilities, stringent quality control, and engineering expertise that drives customer satisfaction. Contact our dedicated partnership manager at [email protected] to discuss how our LED strip solutions can enhance your portfolio and support your growth objectives. Let us collaborate to illuminate your success with technology engineered for excellence.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.