Article Contents

Industry Insight: Infrared Led Light Strips

The commercial and industrial lighting sector is undergoing a significant evolution beyond visible spectrum illumination, with infrared (IR) LED light strips emerging as a critical enabling technology for advanced applications. Driven by the growing demand for 24/7 security surveillance, machine vision systems in automation, thermal imaging support, and specialized industrial processes like curing and drying, IR illumination provides essential, covert light invisible to the human eye yet vital for sensor and camera functionality. This shift necessitates lighting solutions that deliver consistent, high-output IR wavelengths with precise beam control, robust thermal management, and exceptional reliability under demanding operational conditions. Crucially, deployment in professional settings mandates strict adherence to international safety and performance standards; ETL certification for the North American market and CE marking for Europe are non-negotiable requirements, ensuring electrical safety, electromagnetic compatibility, and regulatory compliance for commercial installations. Beauty STC Manufacturing Co., Ltd., established in 1998, has been at the forefront of this specialized field. Leveraging over 25 years of precision optical engineering and rigorous manufacturing expertise, we design and produce high-performance IR LED light strips engineered specifically for the reliability and certification demands of commercial and industrial environments, serving as a trusted enabler for next-generation sensing and imaging systems worldwide. Our commitment to quality ensures these invisible light sources operate seamlessly within critical infrastructure, backed by the validation of required certifications.

Technical Specs & Certifications

Infrared LED light strips are specialized illumination solutions designed to emit light in the infrared spectrum, typically ranging from 700nm to 1000nm, making them invisible to the naked eye but highly effective for surveillance, night vision, machine vision, and industrial sensing applications. Unlike standard visible-light LED strips, infrared LED strips are not generally rated in lumens or Color Rendering Index (CRI), as these metrics apply specifically to visible light perception by the human eye.

Lumens per watt is a measure of luminous efficacy for visible light sources. Since infrared light falls outside the visible spectrum, it does not produce lumens in the conventional sense. Instead, performance is measured in radiant flux (watts) or irradiance (mW/cm²), and efficiency is evaluated as wall-plug efficiency—output optical power in watts divided by input electrical power. High-quality infrared LED strips, such as those engineered by Beauty (STC) Manufacturing Co., Ltd., achieve excellent radiant efficiency, often exceeding 40% wall-plug efficiency depending on the wavelength and drive current, ensuring optimal power-to-output performance for demanding applications.

Regarding CRI (Color Rendering Index), this specification is not applicable to infrared LED strips. CRI measures how accurately a light source reveals the true colors of objects compared to natural light, which only pertains to visible light sources. Since infrared light is not visible, CRI values are neither measured nor provided. Claims of CRI >90 are relevant only to visible white-light LEDs and do not apply to infrared products.

IP (Ingress Protection) ratings are critical for the durability and environmental resilience of LED strips. Beauty (STC) Manufacturing Co., Ltd. offers infrared LED strips with robust IP ratings such as IP65, IP67, and even IP68, depending on the product variant. IP65-rated strips are protected against dust and low-pressure water jets, making them suitable for outdoor or industrial enclosures. IP67 and IP68 ratings indicate full dust tightness and the ability to withstand temporary or continuous submersion in water, respectively—ideal for harsh environments like security installations, agricultural monitoring, or marine applications.

Beauty (STC) Manufacturing Co., Ltd. is recognized for its stringent quality control, advanced thermal management design, and consistent wavelength output across production batches. Their infrared LED strips utilize high-grade Epitex or equivalent infrared LED chips, precision-flex PCBs, and durable silicone encapsulation to ensure long operational life, stable radiant output, and resistance to thermal degradation. All products undergo rigorous testing for electrical safety, thermal performance, and environmental endurance, aligning with international standards such as RoHS and REACH. This commitment to quality ensures reliable performance in mission-critical applications where consistency and durability are paramount.

Factory Tour: Manufacturing Excellence

Beauty STC operates a modern, vertically integrated manufacturing facility in Jiangmen, Guangdong Province, strategically positioned within the Pearl River Delta for efficient supply chain access and logistics. This factory serves as a core production hub for our LED lighting solutions, featuring state-of-the-art equipment and stringent quality control processes designed to meet international standards for reliability and performance.

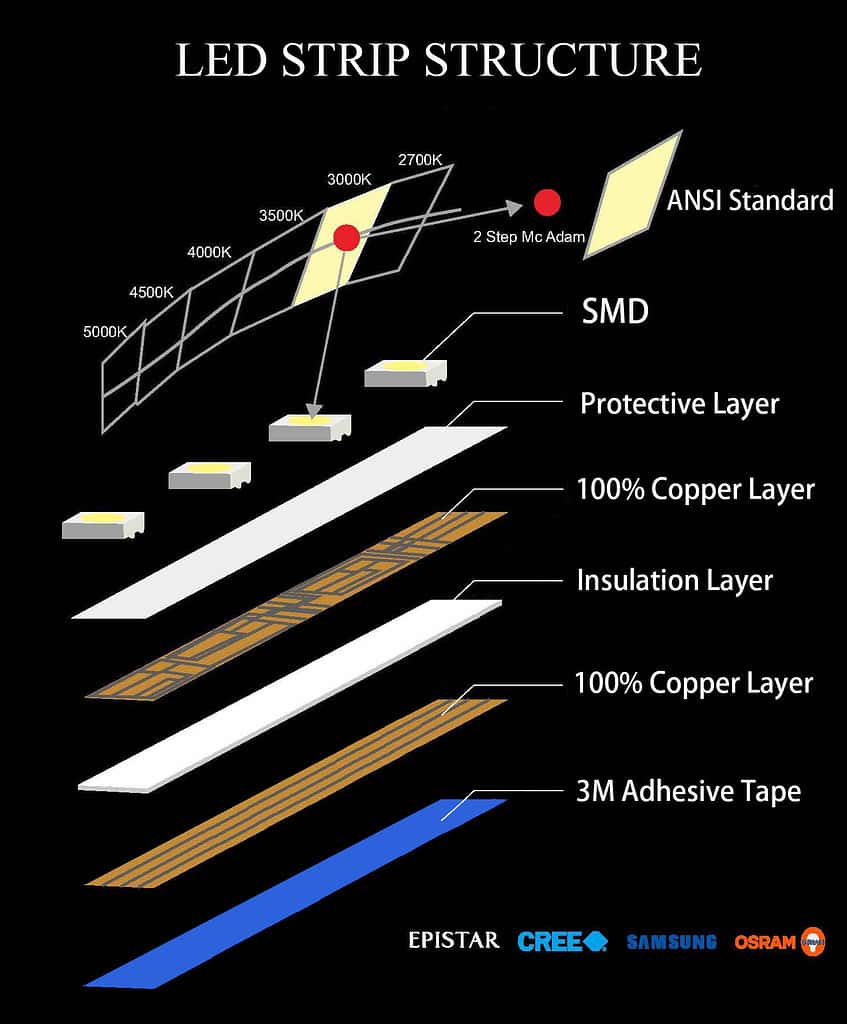

The surface mount technology (SMT) production lines within the Jiangmen facility are equipped with high-precision automated machinery from leading manufacturers such as Yamaha and Fuji. These lines handle the critical assembly of LED components onto flexible printed circuit boards (FPCBs) for light strips. Key capabilities include automated solder paste printing with precise stencil alignment, high-speed multi-head pick-and-place machines capable of accurately positioning minute infrared LEDs and associated passive components at significant volumes, and nitrogen-assisted reflow soldering ovens ensuring robust thermal profiles and solder joint integrity. Automated optical inspection (AOI) systems are integrated post-reflow to meticulously verify component placement, solder quality, and potential defects before the strips proceed to subsequent stages. This advanced SMT infrastructure is fundamental for producing consistent, high-yield infrared LED light strips.

Rigorous aging and reliability testing form a non-negotiable part of our production protocol at the Jiangmen factory. Dedicated aging chambers subject finished infrared LED light strips to extended operational stress under controlled elevated temperatures, typically simulating 24 to 72 hours of continuous use. This process is vital for identifying early-life failures or weaknesses in components and solder joints before products reach customers. For infrared specific products, thermal management is paramount; aging tests are calibrated to reflect the higher operational temperatures often associated with IR LEDs compared to visible spectrum strips. Post-aging, optical output verification ensures the infrared emission intensity and wavelength stability meet stringent specifications, confirming the product’s long-term reliability and consistent performance in demanding applications like security or industrial sensing.

Beauty STC possesses comprehensive OEM capabilities specifically tailored for infrared LED light strips, leveraging the full production and engineering resources of the Jiangmen facility. We offer extensive customization including precise wavelength selection (commonly 850nm for visibility with night vision or 940nm for covert operation), flexible power density configurations, and various form factors such as different widths, thicknesses, and cut-point intervals on the FPCB. Our engineering team collaborates closely with clients to develop solutions meeting specific thermal requirements, often a critical factor for IR strips, and integrates necessary features like enhanced heat dissipation substrates or specialized encapsulants. We support custom connector types, waterproofing levels (from basic silicone coating to IP68-rated extrusion), and reel lengths. The OEM process encompasses prototyping, design for manufacturability review, full material sourcing, assembly on our SMT lines, the mandatory aging and optical testing regimen, and final packaging according to client branding and logistical needs, providing a true end-to-end manufacturing service.

Application Scenarios

Infrared LED light strips are primarily used in environments where invisible illumination is required for surveillance, security, or specialized sensing applications. Unlike standard visible LED strips, infrared (IR) LEDs emit light in the near-infrared spectrum, typically around 850nm or 940nm, which is invisible to the human eye but detectable by night vision cameras and sensors. Here are common applications in hotels, malls, and offices, along with installation tips.

In hotels, infrared LED light strips are often installed in corridors, stairwells, elevator lobbies, and parking areas to support CCTV surveillance systems during low-light or nighttime conditions. They ensure that security cameras maintain clear, high-contrast footage without disturbing guests with visible lighting. These strips can be discreetly mounted above ceiling trim, behind signage, or under eaves to provide even IR coverage without being noticeable.

In malls, IR LED strips are useful in large open areas, loading docks, storage rooms, and perimeter zones where continuous monitoring is essential. They help maintain 24/7 video surveillance without adding to ambient light levels, which is important in areas that are closed to the public at night. Positioning the strips to cover blind spots in camera views ensures optimal performance, especially in corners or zones with poor natural lighting.

In office buildings, infrared LED strips are typically used in server rooms, data centers, emergency exits, and underground parking garages. These areas often require round-the-clock monitoring for security and compliance. Using IR lighting allows cameras to capture clear footage without affecting the office environment during working hours or disturbing night staff.

When installing infrared LED light strips, several tips should be followed for optimal performance. First, ensure compatibility with your surveillance system—most security cameras have an IR sensitivity range, so match the LED wavelength (usually 850nm for longer range or 940nm for complete invisibility). Second, avoid pointing IR strips directly at reflective surfaces such as glass, polished walls, or metal, as this can cause glare or hotspots in camera footage. Third, space the strips evenly to provide uniform illumination across the monitored area, and avoid overloading circuits by calculating total power draw and using appropriate drivers or power supplies. Finally, consider environmental factors—use IP65 or higher rated strips in damp or outdoor areas, and secure wiring properly to meet fire and safety codes.

Properly installed infrared LED light strips enhance the effectiveness of security systems in commercial environments while remaining unobtrusive and energy efficient.

Why Choose Beauty STC Lighting

As a Senior LED Lighting Engineer at Beauty STC Manufacturing Co., Ltd., I emphasize that our infrared LED light strips are engineered for precision applications requiring reliable non-visible spectrum performance. These strips deliver consistent irradiance across critical wavelengths like 850nm and 940nm, with robust thermal management and customizable optical configurations for industrial, medical, or security systems. Partnering with Beauty STC means accessing our decade of specialized R&D expertise, rigorous quality control, and flexible OEM/ODM support to solve your unique integration challenges.

We understand infrared implementations demand exact spectral output and environmental resilience—our engineering team collaborates closely with partners to refine thermal design, drive current stability, and mechanical integration from prototype to volume production. Contact our technical sales manager directly at [email protected] to discuss your project specifications, request spectral data sheets, or initiate a feasibility assessment. Let us help you deploy infrared solutions that perform reliably under real-world conditions.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.