Article Contents

Industry Insight: Cool Lighting Vs Warm Lighting

The strategic selection between cool white and warm white lighting represents far more than a simple aesthetic preference in commercial and industrial environments; it is a critical operational decision impacting productivity, safety, energy efficiency, and occupant well-being. Cool white lighting, typically ranging from 4000K to 5000K, delivers a crisp, energizing light that enhances visual acuity and concentration. This makes it the dominant choice for demanding task-oriented settings like manufacturing floors, warehouses, laboratories, and healthcare facilities where precision and alertness are paramount. Conversely, warm white lighting, generally 2700K to 3500K, creates a more inviting, relaxed atmosphere suitable for hospitality lobbies, certain retail spaces, or break rooms, though its application in core industrial zones is limited. Crucially, regardless of color temperature selection, every fixture deployed in these professional settings must meet rigorous international safety and performance standards. Compliance with certifications such as ETL (North America) and CE (Europe) is non-negotiable, ensuring electrical safety, reliability, and adherence to regional market regulations – a fundamental requirement that cannot be compromised for operational integrity or legal market access. Beauty STC Manufacturing Co., Ltd., established in 1998, brings over two decades of specialized engineering expertise to this complex landscape. As a globally trusted manufacturer, we design and produce high-performance, certified commercial and industrial LED lighting solutions that precisely address the demanding requirements of modern facilities, balancing optimal light quality with uncompromising safety and efficiency.

Technical Specs & Certifications

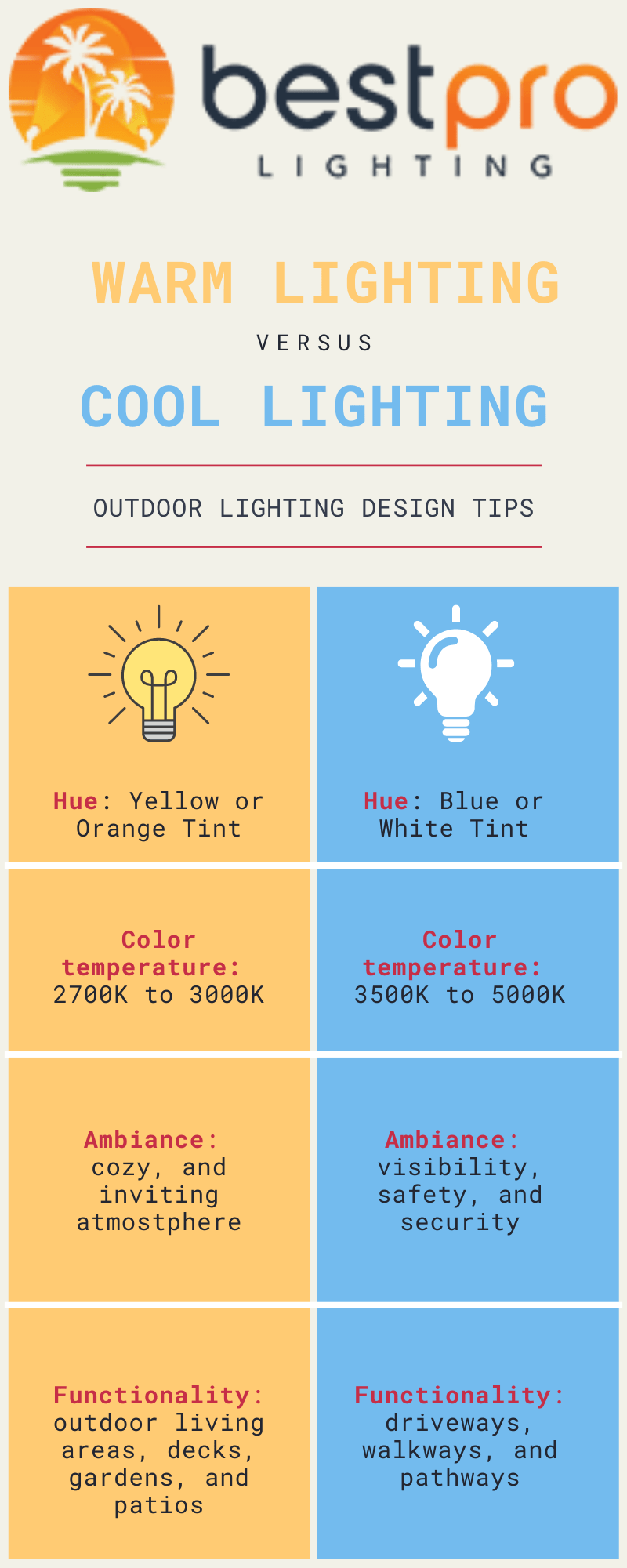

Cool lighting and warm lighting refer to the correlated color temperature (CCT) of white light, measured in Kelvin (K). Cool lighting typically ranges from 5000K to 6500K, producing a bright, bluish-white light that enhances alertness and visibility, making it ideal for task-oriented environments such as offices, garages, and industrial spaces. Warm lighting generally falls between 2700K and 3500K, emitting a softer, yellowish-white light that creates a cozy and inviting atmosphere, commonly used in residential settings, hospitality, and retail areas.

From a technical standpoint, both cool and warm LED lighting from Beauty (STC) Manufacturing Co., Ltd. deliver high performance in terms of lumens per watt (lm/W), with efficacy ranging from 110 to 140 lumens per watt depending on the specific product and lumen output. This high efficiency ensures minimal energy consumption while maintaining superior brightness, supporting energy-saving goals without compromising illumination quality.

Color Rendering Index (CRI) is a critical metric for evaluating light quality, indicating how accurately a light source reveals the true colors of objects compared to natural light. Beauty STC’s LED lighting solutions for both cool and warm variants consistently achieve a CRI greater than 90, ensuring excellent color fidelity. This high CRI is particularly beneficial in applications where color accuracy is essential, such as retail displays, art galleries, healthcare facilities, and makeup studios.

In terms of durability and environmental protection, Beauty STC offers lighting fixtures with robust IP (Ingress Protection) ratings. Many of our products feature IP65, IP66, or even IP67 ratings, providing excellent resistance to dust and water ingress. This makes our lighting solutions suitable for both indoor and outdoor applications, including damp or high-moisture environments like bathrooms, kitchens, parking areas, and exterior facades. The high IP ratings ensure long-term reliability and reduced maintenance, even under demanding conditions.

Beauty (STC) Manufacturing Co., Ltd. is committed to engineering excellence and product quality. Our lighting systems undergo rigorous testing for thermal management, electrical safety, and photometric performance. We utilize high-grade LED chips, precision optical components, and advanced drivers to ensure consistent output, longevity, and reliability. All products are designed and manufactured in compliance with international standards, including UL, CE, and RoHS certifications, reinforcing our reputation for delivering premium, high-performance lighting solutions tailored to diverse commercial and residential needs.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, represents a significant pillar of our production capacity and technical expertise. Spanning approximately 50,000 square meters, this modern factory is strategically located within the Pearl River Delta electronics manufacturing hub, benefiting from robust infrastructure and supply chain access. It operates as a fully integrated production site, housing design validation labs, multiple automated production lines, stringent quality control zones, and dedicated packaging areas, all adhering to international standards like ISO 9001 and ISO 14001.

The Surface Mount Technology (SMT) production lines form the core of our PCB assembly capability. We utilize multiple high-speed Fuji NXT III placement machines, renowned for their precision and flexibility in handling the miniature components essential for modern LED drivers and control circuitry. These lines feature advanced vision systems for component alignment and automated optical inspection (AOI) stations immediately post-reflow soldering. This setup ensures placement accuracy down to 25 microns and a combined throughput exceeding 1.5 million component placements per hour across the facility. The machines are seamlessly integrated with automated material handling systems and real-time process monitoring software, enabling consistent, high-yield production of complex lighting control boards required for both simple and intelligent luminaires.

Rigorous aging and reliability testing is a non-negotiable phase in our quality assurance process at the Jiangmen factory. Dedicated aging rooms house large-scale environmental test chambers capable of simulating extended operational life under controlled stress conditions. Finished LED modules and complete luminaires undergo standard 48 to 72-hour aging cycles at elevated temperatures, typically 65°C ambient, while operating at rated voltage. During this period, automated systems continuously monitor critical parameters including lumen output, chromaticity coordinates, forward voltage, and thermal performance. We meticulously track lumen maintenance (L70, L90) and color shift data against stringent internal specifications. For high-reliability or outdoor-rated products, protocols may extend to 100+ hours or incorporate thermal cycling. This comprehensive aging regimen, far exceeding basic industry norms, ensures only products demonstrating proven stability and longevity reach our customers.

Our OEM capabilities are particularly robust in tailoring lighting characteristics, specifically regarding correlated color temperature (CCT) for cool white versus warm white outputs. The Jiangmen factory possesses full spectral engineering control from chip level through to final assembly. We maintain precise phosphor dispensing and coating processes on blue LED chips, allowing us to consistently produce bins across the entire CCT spectrum from 2200K (ultra-warm) to 6500K (daylight cool). For OEM partners requiring specific cool or warm lighting profiles, our engineering team collaborates closely to define exact CCT targets, tolerance ranges (typically within 3-5 SDCM steps for premium projects), and R9 values for warm tones. We leverage our in-house spectroradiometer labs for real-time binning and quality checks during production, ensuring batch-to-batch consistency. Whether a client demands the crisp efficiency of 4000K-5000K cool white for commercial settings or the inviting ambiance of 2700K-3000K warm white for residential use, our Jiangmen facility executes these specifications with repeatability, supported by comprehensive photometric reports and flexible minimum order quantities. This deep control over the light spectrum is fundamental to our value proposition in the competitive OEM lighting market.

Application Scenarios

Cool lighting and warm lighting serve different functional and psychological purposes depending on the environment. Selecting the appropriate color temperature—measured in Kelvin (K)—is crucial for creating the desired atmosphere, enhancing productivity, and ensuring guest or user comfort in commercial spaces such as hotels, malls, and offices.

In hotels, warm lighting is typically preferred in guest rooms, lobbies, lounges, and restaurants. Lighting in the range of 2700K to 3000K creates a cozy, inviting, and relaxing ambiance that enhances the guest experience. Warm lighting supports the hospitality atmosphere by evoking feelings of comfort and elegance. In contrast, cool lighting (4000K to 5000K) is more suitable for back-of-house areas such as laundry rooms, service corridors, and maintenance zones where visibility and task performance are critical. Some modern boutique hotels may use cool lighting selectively in fitness centers or spas to promote alertness and a clean, contemporary feel.

Malls benefit from a balanced approach. Cool lighting in the 4000K range is commonly used in common walkways, escalator areas, and restrooms to ensure safety, clarity, and a clean appearance. This helps shoppers navigate the space easily and feel secure. Retail storefronts often use a mix: cool lighting to highlight product displays and signage for vibrancy and attention, while some high-end boutiques may use warm lighting to create a luxurious, intimate shopping experience. A well-planned lighting scheme in malls uses layered lighting—ambient, accent, and task—to guide foot traffic and enhance visual merchandising.

Offices predominantly use cool lighting, typically between 4000K and 5000K, to promote concentration, alertness, and productivity. This color temperature mimics natural daylight and helps reduce eye strain during prolonged screen work. Open-plan offices, meeting rooms, and workstations benefit from uniform cool white illumination. However, warm lighting can be introduced in break rooms, lounges, or reception areas to provide contrast and a more relaxed environment for employees during downtime. Task lighting at individual workstations should complement the general lighting to avoid glare and shadows.

When installing lighting in these environments, several best practices should be followed. First, consider the ceiling height and room layout to determine appropriate fixture placement and beam angles. In high-ceiling areas such as mall atriums or hotel lobbies, high-output LED fixtures with controlled optics help deliver even illumination without dark spots. Use dimmable systems in areas where ambiance adjustment is needed, such as hotel dining areas or executive offices. Ensure proper spacing between fixtures to avoid over-illumination or glare—typically following a spacing-to-mounting-height ratio of 1:1 for uniformity. Incorporate controls like motion sensors and daylight harvesting in low-traffic or naturally lit zones to improve energy efficiency. Finally, always prioritize high CRI (Color Rendering Index) LEDs—preferably above 80, and ideally 90+ in retail and hospitality—to ensure colors appear true and vibrant, enhancing the overall visual experience.

Why Choose Beauty STC Lighting

Choosing between cool lighting and warm lighting significantly impacts ambiance, functionality, and customer experience in any commercial or residential space. Cool lighting enhances focus and modern aesthetics, ideal for retail displays and workspaces, while warm lighting creates inviting, relaxing environments perfect for hospitality and living areas. Misalignment with your project’s goals can undermine design intent and user satisfaction, making expert guidance essential for optimal results.

Beauty STC specializes in precision-engineered LED lighting solutions that bridge this critical decision gap. Our senior engineering team leverages decades of industry expertise to tailor lighting specifications—whether cool, warm, or tunable—to your unique spatial requirements, energy goals, and aesthetic vision. We don’t just supply fixtures; we deliver calibrated illumination strategies that maximize visual comfort, energy efficiency, and commercial impact through rigorous photometric analysis and application-specific testing.

Partner with Beauty STC to transform your lighting challenges into competitive advantages. Contact our technical management team directly at [email protected] to discuss how our engineered solutions can elevate your next project with scientifically validated performance and seamless integration. Let us help you illuminate success with confidence.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.