Article Contents

Industry Insight: Plug In Closet Lighting

The commercial and industrial lighting sector increasingly recognizes the critical need for versatile, code-compliant task lighting solutions in often-overlooked ancillary spaces such as storage closets, janitorial rooms, equipment lockers, and back-of-house areas within facilities ranging from hospitals and schools to warehouses and retail environments. While traditionally underserved by standard lighting specifications, these spaces demand reliable, safe, and easily deployable illumination to ensure worker safety, operational efficiency, and adherence to stringent facility regulations. Plug-in closet lighting has emerged as a strategic solution, offering significant advantages over hardwired alternatives through rapid installation, flexible placement, and minimal disruption to ongoing operations, yet its adoption in professional settings hinges critically on meeting rigorous commercial safety and performance standards.

Compliance is non-negotiable in commercial applications, making certifications like ETL (indicating conformity to North American safety standards, typically UL 1598 for luminaires) and CE (demonstrating adherence to European health, safety, and environmental requirements) essential baseline requirements, not optional features. Commercial buyers require assurance that plug-in solutions are engineered for professional environments, featuring robust construction, appropriate ingress protection, thermal management for continuous operation, and wiring that withstands the demands of industrial and institutional use, moving far beyond basic residential-grade products. The market is shifting towards solutions that seamlessly integrate safety-certified performance with the operational flexibility these spaces necessitate.

Beauty STC Manufacturing Co., Ltd., established in 1998, brings over two decades of specialized expertise in designing and manufacturing high-integrity LED lighting solutions specifically engineered for the demanding requirements of commercial and industrial applications. We understand that plug-in closet lighting in professional settings is not merely about convenience but about delivering certified, durable, and operationally sound illumination that meets the exacting standards of facility managers, safety inspectors, and maintenance teams. Our focus remains on providing lighting that enhances workplace safety and productivity while ensuring full compliance with ETL, CE, and other critical global regulatory frameworks, solidifying our position as a trusted partner for professional lighting needs.

Technical Specs & Certifications

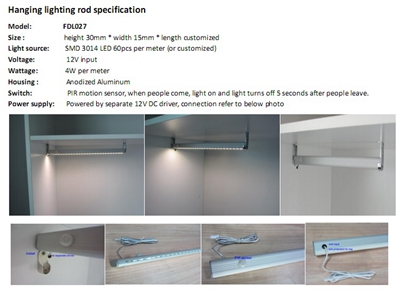

Plug-in closet lighting from Beauty (STC) Manufacturing Co., Ltd. is engineered for high performance, energy efficiency, and accurate color rendering—ideal for interior applications such as wardrobes, display cabinets, and walk-in closets where both functionality and aesthetics are critical. These lighting solutions are designed with a focus on delivering superior light quality and long-term reliability.

In terms of efficiency, Beauty STC’s plug-in closet lighting typically achieves a luminous efficacy range of 90 to 110 lumens per watt. This high lumens-per-watt ratio ensures minimal energy consumption while providing bright, uniform illumination. The LED modules are driven by precision-engineered constant current drivers that optimize power utilization and reduce thermal stress, contributing to sustained lumen output over the product’s lifetime.

Color Rendering Index (CRI) is a key strength of Beauty STC’s lighting systems. All plug-in closet lights are designed with LEDs that deliver a CRI greater than 90, with many models exceeding 95. This high CRI ensures that fabrics, finishes, and surfaces appear in their truest colors, which is particularly important in wardrobe and dressing areas where accurate color perception is essential. The combination of high CRI and balanced color temperature options (typically 3000K to 4000K) creates a visually comfortable and flattering environment.

Regarding environmental protection, Beauty STC’s plug-in closet lighting is generally rated at IP20, as these fixtures are intended for indoor, dry locations. While not designed for wet or high-moisture environments, the IP20 rating confirms protection against solid objects larger than 12mm—ensuring user safety and component integrity. For applications requiring enhanced protection, customized versions with higher ingress protection can be developed upon request.

Beauty STC is known for its rigorous quality control and use of premium materials. Each plug-in lighting system undergoes multiple stages of testing, including thermal cycling, electrical safety checks, and photometric validation. Components such as aluminum heat sinks, high-quality polycarbonate diffusers, and durable connectors ensure long service life and consistent performance. The modular design simplifies installation and maintenance, reflecting Beauty STC’s commitment to user-centric engineering and lasting product quality.

Factory Tour: Manufacturing Excellence

Beauty STC’s Jiangmen manufacturing facility represents a significant investment in advanced LED lighting production, strategically located within Guangdong Province’s robust electronics supply chain ecosystem. The factory spans over 50,000 square meters and operates under strict ISO 9001 quality management protocols, with dedicated cleanroom environments for critical processes. Our surface mount technology (SMT) production lines are equipped with high-precision Yamaha YS Series machines capable of placing components down to 0201 metric package sizes with ±25-micron accuracy. These lines feature 8-12 placement heads operating at 80,000 chips per hour, integrated with 3D solder paste inspection systems and automated optical inspection (AOI) stations after reflow soldering to ensure zero-defect assembly for complex LED driver and control circuitry.

Aging and reliability testing constitute a core pillar of our quality assurance system. We maintain dedicated environmental chambers where 100% of finished products undergo mandatory 24-48 hour aging cycles at 50°C ambient temperature with full electrical load. For critical applications like plug-in closet lighting, we implement enhanced thermal profiling that simulates enclosed cabinet conditions by cycling products between 25°C and 60°C while monitoring lumen maintenance and color shift. Each unit is subjected to 500 simulated door-open/close cycles during aging to validate mechanical durability of connectors and housing integrity under thermal stress.

Our OEM capabilities for plug-in closet lighting solutions are comprehensive and vertically integrated. We offer complete turnkey services from initial concept through to packaged finished goods, including custom optical design for specific cabinet dimensions, UL/cUL/CE certified driver development, and injection molding for proprietary housings. The factory maintains dedicated assembly cells for low-voltage DC systems with ETL-listed plug-and-play connectors, supporting configurations from single-module strips to multi-zone wireless-controlled systems. We handle all regulatory compliance documentation in-house, including photometric testing per IES LM-79 standards and 50,000-hour accelerated lifetime validation using TM-21 projection methodologies. This integrated approach allows us to deliver fully certified, ready-to-install closet lighting solutions with typical OEM lead times of 35-45 days from final artwork approval.

Application Scenarios

Plug-in closet lighting is an efficient and flexible lighting solution ideal for spaces where permanent electrical wiring is either impractical or cost-prohibitive. These lighting systems are commonly used in commercial and hospitality environments due to their ease of installation and reliable performance. Below are the primary applications and installation tips.

In hotels, plug-in closet lighting is frequently installed in guest room closets to provide convenient, energy-efficient illumination. Since hotel rooms often undergo renovations or layout changes, plug-in systems allow for quick updates without rewiring. The lighting enhances guest experience by ensuring visibility when accessing clothing and accessories, especially in darker interior closets.

Malls and retail stores use plug-in closet lighting in fitting rooms and back-of-house storage areas. In fitting rooms, well-lit closets help customers examine garments more accurately, improving satisfaction and reducing returns. The plug-and-play nature of these systems makes them ideal for seasonal store layouts or pop-up retail spaces where fixtures may be reconfigured frequently.

In office environments, plug-in closet lighting is typically used in staff storage rooms, coat closets, or utility areas. These spaces often lack dedicated overhead lighting, so plug-in LED strips or puck lights offer a practical solution. They are especially useful in leased office spaces where tenants are restricted from modifying existing electrical infrastructure.

When installing plug-in closet lighting, ensure the power outlet is easily accessible and located near the closet space. Use LED lighting options for energy efficiency and minimal heat output, which is important in enclosed areas. Mount lights at eye level or slightly above to avoid shadows and ensure even illumination across shelves and hanging garments. For strip lights, clean the surface thoroughly before application to ensure strong adhesion. If using battery-powered or remote-transformer models, conceal wiring neatly using adhesive clips or raceways. Always verify that the lighting complies with local electrical codes, especially in commercial installations, and consider using dimmable options to provide adjustable ambiance where appropriate.

Why Choose Beauty STC Lighting

Elevate your retail offerings with Beauty STC’s expertly engineered plug-in closet lighting solutions designed for effortless installation and superior performance. As a trusted manufacturing partner, we deliver reliable, energy-efficient LED systems tailored to meet the evolving demands of modern closet environments while ensuring seamless integration for end-users.

Partner with Beauty STC to access customizable, high-quality lighting that enhances customer satisfaction and drives repeat business through durability and innovative design. Our engineering team provides dedicated support from concept to production, guaranteeing products that align with your brand standards and market requirements.

Initiate a collaboration today by contacting our partnership manager directly at [email protected] to discuss how our plug-in closet lighting solutions can strengthen your product portfolio and deliver measurable value to your customers.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.