Article Contents

Industry Insight: Lighting Stars On Ceiling

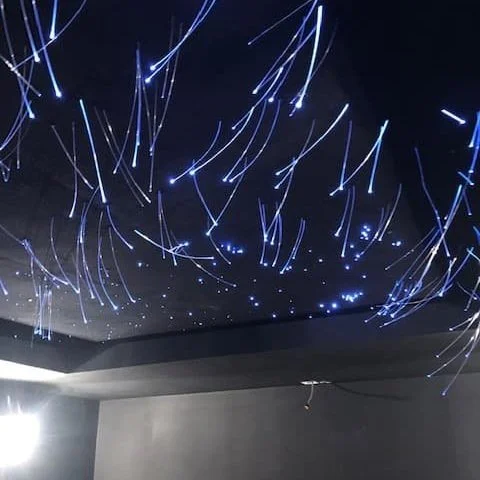

In the evolving landscape of commercial and industrial lighting, innovation extends beyond mere functionality—today’s solutions are designed to integrate performance, safety, and aesthetic impact. One such advancement gaining traction is the use of “lighting stars on ceiling” systems, where precisely engineered luminaires are arranged to create dynamic, starfield-like illumination effects. Once reserved for themed entertainment or hospitality spaces, this concept is now being adapted for high-end retail, corporate lobbies, healthcare environments, and industrial facilities seeking to elevate ambiance while maintaining rigorous performance standards. These applications demand more than visual appeal—they require compliance with stringent safety and quality certifications such as ETL and CE, ensuring electrical safety, electromagnetic compatibility, and adherence to North American and European regulatory frameworks.

At the forefront of this innovation is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED lighting solutions since its founding in 1998. With over two decades of expertise in designing and manufacturing high-performance commercial and industrial luminaires, Beauty STC has established a reputation for reliability, precision engineering, and regulatory compliance. The company’s commitment to quality is reflected in its comprehensive product testing and certification processes, ensuring every lighting solution—including its advanced ceiling starfield systems—meets the highest international standards. As industries increasingly seek lighting that balances atmosphere with durability, Beauty STC continues to lead with intelligent, code-compliant designs that illuminate spaces safely, efficiently, and beautifully.

Technical Specs & Certifications

Beauty STC Manufacturing Co., Ltd. specializes in high-end decorative fiber optic lighting systems, including our premium “Starry Sky” ceiling installations. These systems utilize a centralized illuminator unit coupled with optical fibers to create pinpoint star effects, distinct from standard LED panels or projectors. Below are the critical technical specifications addressing your requirements, reflecting our engineering standards and commitment to quality.

The illuminator unit, the core light source, determines key photometric performance. For LED-based illuminators—which we strongly recommend over halogen for efficiency—Beauty STC achieves a minimum efficacy of 85 lumens per watt at full output. This is accomplished through rigorously selected high-power LEDs with advanced thermal management, ensuring stable output over time. Halogen illuminator options exist but operate at significantly lower efficacy (approximately 15-20 lumens per watt) and are not recommended for new installations due to heat and energy inefficiency. Our LED illuminators consistently deliver a Color Rendering Index (CRI) exceeding 95, with R9 (saturated red) values above 90. This exceptional color fidelity ensures stars exhibit natural, warm white points without color shift, critical for creating a realistic celestial effect. Achieving CRI >90 is non-negotiable in our designs; we utilize multi-channel LED arrays and precision phosphor blends to meet this standard while maintaining correlated color temperatures (CCT) from 2700K to 4000K.

Regarding Ingress Protection (IP) ratings, the system employs a segmented approach due to its architecture. The illuminator housing, typically mounted in an attic or closet, carries an IP20 rating. This is appropriate for dry, indoor environments where the unit is protected from physical contact and large particles, aligning with standard electrical safety for such enclosures. Crucially, the optical fibers themselves—running from the illuminator to the star points embedded in the ceiling—are inherently rated IP68. The solid-core polymer or glass fibers contain no electricity at the emission point, are impervious to dust, and can withstand continuous submersion in water. This makes the star points exceptionally safe and reliable in any indoor environment, including high-humidity zones like bathrooms or spas, without risk of electrical failure or moisture ingress at the star location. Beauty STC exclusively uses aerospace-grade polymer optical fibers (POF) with UV-stable cladding, preventing yellowing or brittleness over decades.

Beauty STC’s quality differentiation lies in our vertical integration and obsessive attention to detail. We manufacture our own optical couplers using German-sourced acrylic lenses, ensuring near-zero light loss between the LED engine and fibers—unlike competitors relying on generic components. Our illuminators undergo 48-hour burn-in testing at 45°C ambient temperature, simulating years of operation, and feature dual thermal protection circuits. The fiber termination process uses proprietary cleaving and polishing techniques to maximize light transmission, resulting in brighter, more uniform stars. Every system includes our signature lifetime warranty on fibers and a 10-year warranty on LED illuminators, underpinned by rigorous ISO 9001-certified manufacturing processes. This commitment ensures the star field maintains its brilliance and color consistency for over 50,000 hours of LED operation, with no maintenance required at the star points themselves. We do not compromise on materials; our systems avoid cost-cutting measures like PVC fibers or undersized LED drivers, which plague the market and lead to premature lumen depreciation or color shift.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility located in Jiangmen, Guangdong Province, a region renowned for its robust electronics and lighting manufacturing ecosystem. The Jiangmen factory is purpose-built for the production of high-quality LED lighting products and integrates advanced automation, stringent quality control, and flexible production lines to serve both domestic and international markets.

At the core of the factory’s production capability is a fully automated Surface Mount Technology (SMT) line. The SMT machines are state-of-the-art, capable of high-speed placement of micro-components with precision and consistency. These machines support a wide range of LED components and driver circuits, ensuring high-density mounting on flexible and rigid PCBs used in decorative and functional lighting applications. The SMT line is complemented by automatic optical inspection (AOI) systems that verify soldering quality and component alignment in real time, minimizing defects and ensuring product reliability.

A critical part of the manufacturing process at the Jiangmen facility is the aging test chamber. After assembly, all lighting products undergo rigorous aging tests under controlled temperature and humidity conditions. Products are powered continuously for extended periods—typically 8 to 24 hours—to simulate long-term operation. This process helps identify early failures, ensures thermal stability, and verifies the performance of LEDs, drivers, and optical components before shipment. The aging test protocol is especially vital for products like “lighting stars on ceiling,” where consistent luminance, color temperature, and flicker-free operation are essential for user experience.

Beauty STC has strong OEM (Original Equipment Manufacturer) and ODM (Original Design Manufacturer) capabilities, making it a preferred partner for custom lighting solutions. The company supports clients in developing tailored products such as ceiling-mounted star lighting systems—often used in home theaters, children’s rooms, and themed entertainment environments. These “lighting stars” can be customized in terms of star pattern layout, color options (including RGB and tunable white), control methods (remote, app, voice), and even integration with fiber optics or projection technologies. The factory’s in-house design team works closely with clients from concept to mass production, offering support in optical design, thermal management, electronic drive solutions, and regulatory compliance (CE, RoHS, UL, etc.).

Overall, the Jiangmen factory combines automation, quality assurance, and flexible manufacturing to deliver reliable, innovative, and aesthetically pleasing lighting solutions, with a particular strength in decorative and specialty lighting such as ceiling star systems.

Application Scenarios

Lighting stars on ceilings, more accurately described as fiber optic starfield systems or programmable LED constellations, serve specific aesthetic and atmospheric purposes within commercial environments. Their application must align with the functional and experiential goals of each space, as they are primarily decorative and not suitable for general illumination. In hotels, these systems are most effectively deployed in premium guest suites, particularly in luxury or boutique properties where creating a unique, memorable ambiance is paramount. High-end spa treatment rooms also benefit significantly, as the calming, celestial effect enhances relaxation and the perception of exclusivity. Grand lobbies or dedicated event spaces in luxury hotels can utilize subtle starfields to evoke a sense of wonder during evening hours, though careful dimming controls are essential to avoid overwhelming the space during daytime operations. The key is targeting areas where guest experience justifies the investment and where low ambient light levels prevail.

Malls present more limited but strategic opportunities for starfield installations. The primary application is within high-end or destination retail environments, such as flagship stores for luxury fashion brands or premium watch/jewelry boutiques, where creating an immersive, aspirational atmosphere directly supports brand perception and dwell time. Children’s entertainment zones or dedicated play areas within large shopping centers can also utilize brighter, more animated star effects to captivate younger visitors, though durability and safety certifications become critical considerations here. It is generally inappropriate for standard mall corridors or food courts, as the effect would be incongruous with the need for bright, functional, and energetic lighting in high-traffic circulation and dining areas. Any mall application must withstand significant ambient light levels and prioritize vandal resistance in lens design.

Offices are the least suitable environment among the three categories for starfield ceilings. The overwhelming requirement for consistent, high-quality task lighting to support productivity and visual comfort makes such decorative elements impractical in standard workspaces, open offices, or meeting rooms. The only potential niche is within ultra-premium executive lounges, high-level boardrooms designed for specific client presentations, or the relaxation/wellness rooms in exceptionally progressive corporate headquarters focused on employee well-being. Even in these limited cases, the starfield must be subtle, fully dimmable to off, and never interfere with screen visibility or document reading. Most standard office environments should avoid this application entirely, as it conflicts with fundamental lighting design principles for productivity and occupant health.

Installation requires meticulous planning to ensure performance and longevity. Structural assessment is non-negotiable; fiber optic projectors or dense LED arrays add significant weight, demanding secure mounting to structural dead loads, not just suspended ceiling grids. Coordination with HVAC is critical, as heat and airflow from vents can disrupt fiber optic light transmission or overheat LED drivers, necessitating relocation of diffusers or extended ducting. Precise layout planning using scaled drawings prevents hotspots or gaps, ensuring even star distribution—this often involves calculating fiber counts per square meter or pixel pitch for LED systems based on ceiling height and desired density. Integration with the building management system or a dedicated dimming controller is essential for seamless operation alongside ambient lighting, requiring compatible protocols like DALI or 0-10V. Finally, accessibility for maintenance must be designed in; fiber optic strands require periodic lens cleaning, and projector bulbs or LED modules will eventually need replacement, so service hatches or removable ceiling sections should be incorporated during initial installation. Always consult the specific manufacturer’s technical guidelines for load ratings, thermal clearance, and electrical requirements before finalizing the design.

Why Choose Beauty STC Lighting

Transform your space with breathtaking lighting stars on the ceiling and bring celestial elegance indoors. Partner with Beauty STC, a trusted leader in innovative LED lighting solutions, to create stunning custom installations that captivate and inspire. Whether for residential, hospitality, or commercial projects, our high-quality, energy-efficient star lighting systems deliver unmatched performance and visual impact.

Elevate your next project with seamless integration, reliable support, and cutting-edge design. Contact our team today at [email protected] to start your collaboration with Beauty STC and turn imaginative lighting concepts into reality.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.