Article Contents

Industry Insight: 2Ft Led

The commercial and industrial lighting sector continues its decisive shift towards LED technology, driven by relentless demands for operational efficiency, reduced maintenance burdens, and stringent energy conservation mandates. Within this critical transition, the 2ft LED fixture has emerged as a fundamental workhorse, particularly vital for retrofitting the vast installed base of legacy fluorescent T8 and T5 systems in offices, warehouses, retail spaces, and manufacturing facilities. Its compact form factor offers unmatched versatility for tight ceiling grids, under-cabinet applications, and task lighting scenarios where space is constrained, while delivering the significant energy savings and extended lifespans that define modern LED performance.

Understanding the specific requirements of commercial and industrial environments is paramount. These settings demand fixtures engineered for continuous operation, superior thermal management to sustain lumen output over tens of thousands of hours, robust construction to withstand demanding conditions, and precise optical control to ensure adequate, uniform illumination for productivity and safety. The 2ft segment is no exception; performance metrics like lumen maintenance, color rendering accuracy, and driver reliability become critical differentiators beyond simple wattage reduction. Equally non-negotiable are the essential safety and compliance certifications. Products must reliably carry ETL listing for the North American market, signifying adherence to rigorous safety standards under the Nationally Recognized Testing Laboratory program, and CE marking for the European Union, demonstrating conformity with health, safety, and environmental protection legislation. These certifications are not mere checkboxes but fundamental requirements for legal installation and user safety in professional settings.

Beauty STC Manufacturing Co., Ltd. has been at the forefront of addressing these complex industry needs since our establishment in 1998. With over 25 years of dedicated expertise in LED lighting innovation and manufacturing, we possess deep institutional knowledge of the evolving demands within commercial and industrial sectors. Our engineering focus centers on developing 2ft LED solutions that deliver exceptional photometric performance, unwavering reliability under real-world operating conditions, and seamless compliance with global regulatory frameworks including ETL and CE. We recognize that for facility managers and lighting specifiers, a 2ft LED fixture is far more than a simple bulb replacement; it is a critical component of a facility’s operational infrastructure, demanding solutions built on a foundation of proven engineering and manufacturing excellence.

Technical Specs & Certifications

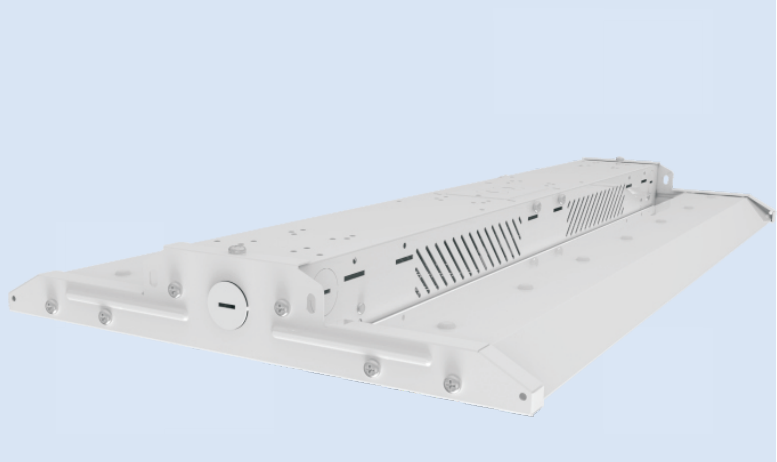

The 2ft LED lighting fixtures offered by Beauty (STC) Manufacturing Co., Ltd. are engineered for high performance and reliability across commercial and industrial applications. These linear LED luminaires typically feature a length of 24 inches (600mm), making them ideal for standard troffer and recessed installations.

In terms of energy efficiency, Beauty STC’s 2ft LED products achieve a luminous efficacy ranging from 140 to 160 lumens per watt, depending on the specific model and configuration. This high lumen-to-watt ratio ensures significant energy savings compared to traditional fluorescent lighting, reducing operational costs while maintaining bright, consistent illumination.

Color Rendering Index (CRI) is a critical factor in lighting quality, particularly in environments where accurate color representation is essential. Beauty STC ensures that its 2ft LED fixtures deliver a CRI greater than 90, enabling natural and vibrant color perception. This high CRI performance is achieved through the use of premium-grade LED chips and optimized phosphor coatings, making these lights suitable for retail spaces, healthcare facilities, and precision work environments.

Regarding environmental protection, Beauty STC offers 2ft LED models with varying IP (Ingress Protection) ratings to suit different installation conditions. Standard indoor models typically carry an IP20 rating, providing protection against solid objects larger than 12mm and no protection against water—suitable for dry, indoor environments. For damp or washdown areas, enhanced versions are available with IP44 or IP65 ratings, offering protection against dust and low-pressure water jets, making them ideal for use in restrooms, kitchens, or utility corridors.

Beauty STC’s commitment to quality is evident in the robust construction, thermal management, and long-term reliability of its LED products. Each 2ft LED fixture undergoes rigorous testing for photometric performance, thermal stability, and electrical safety. The use of high-quality drivers, durable aluminum heat sinks, and impact-resistant polycarbonate diffusers ensures extended lifespan—typically rated at 50,000 hours or more—while maintaining consistent light output over time. With strict adherence to international standards and a focus on innovation, Beauty STC delivers lighting solutions that combine efficiency, durability, and superior optical performance.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, represents a significant production hub for the company, specifically engineered for high-volume, precision LED lighting manufacturing. The factory is strategically located within Jiangmen’s industrial zone, benefiting from robust infrastructure and supply chain access while maintaining strict adherence to international quality and environmental standards.

The surface mount technology (SMT) production lines form the core of the factory’s assembly capability. We operate multiple high-speed, fully automated SMT lines featuring advanced placement machines from leading brands such as Yamaha and Siemens. These systems handle components as small as 0201 package sizes with exceptional placement accuracy, critical for the dense circuitry of modern LED modules. The lines integrate automated solder paste inspection (SPI) and automated optical inspection (AOI) stations to ensure first-pass yield rates exceed 99%, minimizing defects at the earliest production stage. This SMT capacity is specifically optimized for linear LED products, including the standard 2ft (600mm) T8/T5 LED tube formats, enabling efficient handling of both standard and custom PCB designs.

Rigorous aging and reliability testing are non-negotiable elements of our quality assurance process at the Jiangmen site. Completed LED tubes, particularly the 2ft variants, undergo mandatory burn-in testing in dedicated environmental chambers. Standard protocols involve 24 to 72 hours of continuous operation at elevated temperatures (typically 50-60°C) and full rated voltage, simulating years of real-world use in a compressed timeframe. These chambers are equipped with automated monitoring systems that log voltage, current, and lumen output, flagging any units exhibiting premature lumen depreciation or electrical instability. Beyond basic aging, we conduct extended life testing, thermal cycling, and humidity exposure tests to validate long-term performance under diverse global operating conditions, ensuring compliance with IEC and ENERGY STAR reliability benchmarks.

Our OEM capabilities for 2ft LED tubes are comprehensive and tailored to client specifications. The Jiangmen factory supports full customization from initial design through to finished goods. This includes adapting optical systems (lens types, beam angles), driver configurations (constant current/voltage, dimming protocols like 0-10V or DALI), mechanical housing (material finishes, end cap styles), and electrical parameters (voltage ranges, wattage). We accommodate both retrofit tube designs (for fluorescent fixture replacement) and dedicated LED fixture integration. The facility manages all aspects of OEM production, including custom labeling, packaging design and assembly, and documentation. Crucially, we support clients through the entire certification process, leveraging our in-house testing lab to facilitate UL, CETL, ETL, TÜV, and CCC approvals specific to the 2ft product configuration. Minimum order quantities are flexible, scaling from mid-volume production runs to large-scale contracts, with dedicated project management ensuring seamless transition from prototype to mass production. The integration of our SMT precision, validated by stringent aging protocols, provides OEM partners with a reliable foundation for branded 2ft LED tube solutions meeting global market demands.

Application Scenarios

A 2ft LED light, typically measuring 24 inches in length, is a compact and energy-efficient lighting solution ideal for use in various commercial and institutional environments. Its smaller size makes it particularly suitable for spaces where ceiling height is limited or where a more discreet lighting layout is desired.

In hotels, 2ft LED lights are commonly used in guest room corridors, restrooms, utility rooms, and back-of-house areas such as laundry rooms and storage spaces. They provide consistent illumination without overwhelming the space, making them perfect for lower-ceilinged areas. In guest bathrooms, recessed or surface-mounted 2ft LED fixtures offer bright, glare-free lighting that enhances functionality while maintaining a clean aesthetic.

Shopping malls benefit from 2ft LED lights in service corridors, electrical rooms, restrooms, and administrative offices. These areas require reliable and low-maintenance lighting, and the long lifespan and energy efficiency of 2ft LEDs reduce operational costs. Additionally, they can be used in display backlights or under-counter lighting in kiosks where space is constrained.

Offices widely use 2ft LED fixtures in workstations with drop ceilings, meeting rooms, server rooms, and pantry areas. Their uniform light distribution helps reduce eye strain, contributing to a productive work environment. The compact size allows for flexible layout designs, especially in modular office setups or spaces with low ceiling clearance.

When installing 2ft LED lights, ensure compatibility with the existing ceiling grid or mounting surface. For drop ceiling applications, verify that the fixture matches the T-bar layout and is securely supported. Use clips or brackets as recommended by the manufacturer to prevent sagging or vibration. Always follow local electrical codes and ensure power is disconnected before installation. For surface-mounted applications, confirm that the mounting surface is flat and secure, and allow adequate ventilation to prolong the LED driver’s life. Consider using LED fixtures with diffusers to minimize glare and provide even light distribution. Finally, group installations in a consistent grid pattern to maintain visual uniformity across the space.

Why Choose Beauty STC Lighting

Upgrade to premium 2ft LED lighting solutions engineered for exceptional performance and reliability by Beauty STC Manufacturing Co., Ltd. Our rigorously tested 2ft LED tubes deliver superior lumen maintenance, extended 50,000-hour lifespans, and precision-engineered thermal management to reduce maintenance costs and energy consumption for your commercial and industrial projects. As a trusted manufacturing partner, Beauty STC provides OEM/ODM flexibility, stringent quality control adhering to international safety standards, and dedicated engineering support to tailor lighting systems to your specific requirements. Elevate your lighting solutions with components built for durability and efficiency in demanding environments.

Partner with Beauty STC to integrate industry-leading 2ft LED technology into your product portfolio or infrastructure projects. Contact our partnership manager directly at [email protected] to discuss technical specifications, volume pricing, and collaborative opportunities. Let our engineering expertise drive your next lighting innovation forward.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.