Article Contents

Industry Insight: Sauna Lighting

Commercial and industrial sauna environments present one of the most demanding lighting challenges within the built environment. The combination of extreme heat, sustained high humidity, and condensation creates a hostile setting where standard luminaires rapidly fail, posing significant safety hazards and operational disruptions. For facility managers and specifiers in wellness centers, luxury resorts, athletic facilities, and industrial processing plants utilizing steam environments, lighting solutions are not merely about ambiance but are critical infrastructure requiring rigorous engineering for safety, reliability, and longevity. Compliance with stringent safety certifications like ETL (North America) and CE (Europe) is non-negotiable, serving as the fundamental baseline for any fixture intended for these spaces, ensuring protection against electrical hazards and material degradation under thermal stress.

Beauty STC Manufacturing Co., Ltd., established in 1998, has dedicated over 25 years to mastering this specialized niche within commercial and industrial lighting. We understand that in a commercial sauna, fixture failure means lost revenue and compromised guest safety, not just inconvenience. Our engineering focus centers on developing purpose-built LED sauna lighting systems that exceed basic certification requirements, incorporating advanced thermal management, hermetic sealing, and robust material science to deliver unwavering performance where ordinary fixtures cannot survive. We partner with facility owners and designers to provide lighting solutions that are as resilient and dependable as the demanding environments they serve.

Technical Specs & Certifications

Sauna lighting requires specialized technical considerations due to the extreme environmental conditions, including high temperatures, humidity, and exposure to steam and water. At Beauty (STC) Manufacturing Co., Ltd., our sauna lighting solutions are engineered to meet and exceed industry standards, ensuring long-term reliability, safety, and optimal visual performance.

Luminous efficacy is a key performance metric, and our LED sauna lights deliver a high lumen output relative to power consumption, typically ranging from 100 to 130 lumens per watt. This efficiency ensures bright, consistent illumination while minimizing energy use and heat generation—critical in a sauna environment where excess thermal load can compromise comfort and fixture longevity.

Color Rendering Index (CRI) is another critical factor for sauna lighting, as accurate and natural color representation enhances the user experience and contributes to a relaxing ambiance. All Beauty STC sauna lighting products feature a CRI greater than 90, with many models achieving CRI values of 95 or higher. This high color fidelity ensures that skin tones, wood finishes, and interior materials appear true to life under illumination, supporting the therapeutic and aesthetic goals of the sauna space.

Given the wet and high-moisture conditions, ingress protection is paramount. Our sauna lighting fixtures are designed with a minimum IP65 rating, and many models achieve IP67 protection. IP65 ensures complete protection against dust and resistance to low-pressure water jets from any direction, while IP67 adds protection against temporary immersion in water up to 1 meter. This robust sealing safeguards internal components against moisture and corrosion, ensuring operational safety and durability in demanding environments.

Beauty (STC) Manufacturing Co., Ltd. maintains rigorous quality control throughout the production process. Our sauna lights are constructed using high-grade materials such as tempered glass, marine-grade stainless steel, and thermally stable polycarbonate housings that resist warping and degradation at elevated temperatures—typically rated for continuous operation up to 80°C (176°F) or higher. Each unit undergoes extensive thermal, humidity, and electrical stress testing to ensure compliance with international safety standards including IEC, EN, and UL.

In summary, Beauty STC’s sauna lighting combines high efficiency (100–130 lm/W), exceptional color rendering (CRI >90), and superior ingress protection (IP65–IP67), all backed by our commitment to engineering excellence and long-term reliability in challenging environments.

Factory Tour: Manufacturing Excellence

Beauty STC’s primary manufacturing facility is strategically located in Jiangmen, Guangdong Province, China. This modern factory serves as the core production hub for our LED lighting solutions, integrating advanced manufacturing processes with rigorous quality control systems under one roof. The Jiangmen site is designed to handle high-volume production while maintaining the flexibility required for specialized product lines, including demanding applications like sauna lighting.

Our Surface Mount Technology (SMT) production line within the Jiangmen factory utilizes state-of-the-art automated placement machines from leading manufacturers. These machines feature high-precision nozzles capable of handling components down to 0201 package sizes, ensuring accurate placement for complex LED driver and control circuitry. The SMT lines operate within a controlled environment meeting ISO Class 8 cleanroom standards to minimize contamination, critical for the long-term reliability of LED modules. Integrated automated optical inspection (AOI) systems perform real-time checks after component placement and solder reflow, verifying solder joint integrity and component alignment before boards proceed to assembly. This level of SMT capability is essential for producing the compact, thermally efficient PCBs required in moisture-resistant sauna luminaires.

Aging and reliability testing represent a cornerstone of our quality assurance process at the Jiangmen facility. We operate extensive dedicated aging chambers capable of subjecting finished luminaires to accelerated life testing under controlled thermal and electrical stress conditions. For standard products, this typically involves 48-hour continuous operation at elevated temperatures. However, for sauna lighting applications, we implement significantly more stringent protocols. Sauna-specific products undergo a minimum 72-hour aging cycle where units are operated continuously at temperatures exceeding 85°C and 90% relative humidity, simulating the extreme thermal cycling and condensation challenges encountered in real-world sauna environments. This extended aging process, combined with post-aging photometric and electrical parameter verification, ensures only units demonstrating stable thermal management and consistent light output are released for shipment.

Our OEM capability for sauna lighting is a particular strength developed and executed at the Jiangmen factory. We offer comprehensive turnkey solutions for partners requiring custom sauna luminaires, leveraging our deep expertise in thermal management for high-heat environments, IP68-rated sealing techniques, and specialized material selection resistant to both high humidity and common sauna chemicals. The engineering team collaborates closely with clients from initial concept through to量产, providing thermal simulation support, optical design for optimal light distribution within confined spaces, and chromotherapy integration if required. The factory’s vertical integration allows us to control critical processes in-house, including aluminum extrusion for robust heat sinks, precision injection molding for optical lenses and gaskets, and final assembly in a humidity-controlled clean zone. This end-to-end control, coupled with our adherence to IEC 60598-1 and sauna-specific safety standards, ensures OEM partners receive luminaires engineered for exceptional durability and performance under the unique stresses of sauna use. Recent successful OEM projects include fully customizable, app-controlled chromotherapy systems with integrated moisture sensors for premium wellness facilities.

Application Scenarios

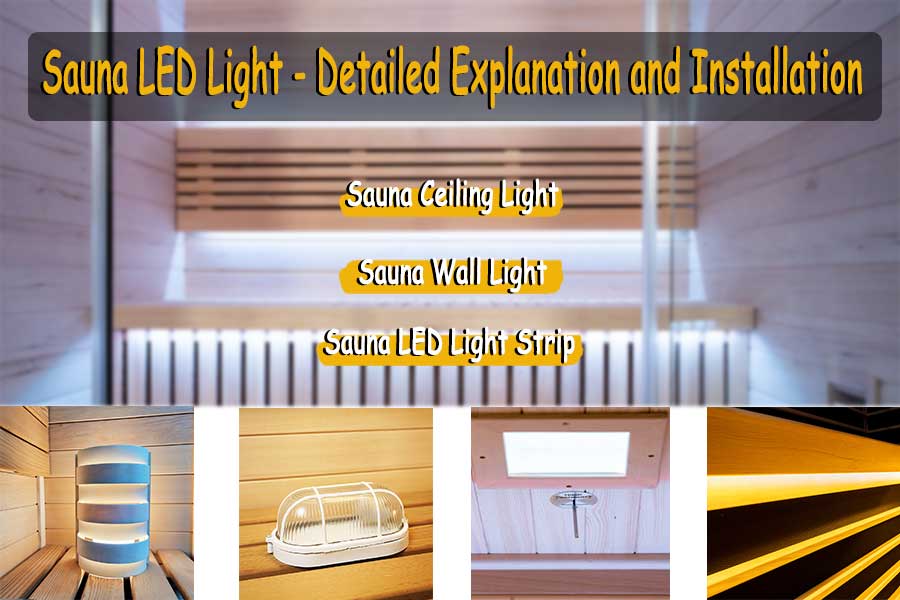

Sauna lighting is specifically designed for high-temperature and high-humidity environments, making it essential in spaces where standard lighting would fail or pose safety risks. While saunas themselves are the primary application, the use of sauna-rated lighting can extend to other areas in certain commercial and hospitality settings, though with important distinctions.

In hotels, sauna lighting is most appropriately used within the sauna rooms of spa and wellness facilities. These areas typically include both dry and steam saunas where temperatures can exceed 80°C and humidity levels are extreme. Standard lighting fixtures would deteriorate quickly under such conditions, so sauna-rated LED fixtures—constructed with heat-resistant materials such as tempered glass, stainless steel, or silicone gaskets—are necessary. Additionally, these lights must have a high IP rating, typically IP65 or higher, to ensure protection against moisture and dust. In some cases, hotels may also use sauna-rated fixtures in adjacent changing rooms or steam rooms if environmental conditions are similarly demanding.

In malls, sauna lighting is generally not required unless the mall includes a wellness or spa center with sauna facilities. Common mall areas such as corridors, restrooms, or retail spaces do not require sauna-rated fixtures, as they do not experience the same thermal or humidity conditions. However, if a mall houses a fitness center or public spa, then sauna lighting would be necessary within those dedicated spaces.

In office buildings, sauna lighting is typically not applicable unless the office complex includes an employee wellness area with a sauna. Most office environments maintain controlled temperature and humidity, making standard commercial lighting sufficient. Installing sauna-rated lighting in regular office spaces would be unnecessarily costly and technically redundant.

When installing sauna lighting, several key tips should be followed to ensure safety, durability, and optimal performance. First, always select fixtures rated for the specific sauna type—dry saunas require lights rated for higher temperatures (up to 130°C), while steam saunas demand superior moisture resistance. Fixtures should be installed away from direct water spray and positioned to avoid contact with users, typically on ceilings or high walls. Wiring must be done with heat-resistant cables, and connections should be sealed to prevent moisture ingress. It is also important to follow local electrical codes and use low-voltage lighting (e.g., 12V or 24V) where possible, especially in wet zones, to enhance safety. Finally, avoid using plastic-based fixtures or standard LED drivers inside the sauna; instead, use remotely mounted drivers located outside the high-heat zone to prolong lifespan.

In summary, sauna lighting is best reserved for actual sauna and steam environments, primarily found in hotel spas or wellness centers within larger complexes like malls or office buildings. Proper selection and installation are critical to ensure long-term functionality and user safety.

Why Choose Beauty STC Lighting

Elevate your sauna installations with lighting engineered specifically for extreme heat and humidity environments. Beauty STC Manufacturing Co., Ltd. delivers commercial-grade LED sauna lighting solutions that prioritize safety, longevity, and ambiance without compromise. Our fixtures feature IP68 waterproofing, advanced thermal management systems, and specialized color temperatures scientifically tuned to enhance the relaxation experience while meeting stringent international safety certifications. Partner with us to integrate lighting that withstands 100°C+ conditions and 100% humidity for over 50,000 hours of maintenance-free operation.

We collaborate closely with sauna manufacturers and wellness facility designers to develop custom lighting configurations that align with your technical requirements and aesthetic vision. Our engineering team provides full support from thermal simulation to final certification, ensuring seamless integration into your steam rooms, infrared cabins, and traditional saunas. Discover how Beauty STC’s military-grade components and moisture-resistant optical designs eliminate fogging, corrosion, and premature failure common in standard lighting.

Contact our lighting solutions manager today at [email protected] to request technical specifications, thermal performance data, or a customized proposal for your next project. Let Beauty STC become your trusted partner in creating sauna environments where exceptional lighting performance meets uncompromising reliability.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.