Article Contents

Industry Insight: Strip Led Adapter

The commercial and industrial lighting landscape continues to evolve with increasing demand for flexible, energy-efficient, and code-compliant illumination solutions. Among the critical components enabling modern LED system integration, the strip LED adapter has emerged as a vital link between power sources and linear lighting installations. These adapters ensure seamless connectivity, stable voltage delivery, and reliable performance across a wide range of applications—from warehouse task lighting and retail accent displays to industrial facility retrofits and architectural cove lighting. As building standards and safety regulations become more stringent, certification marks such as ETL and CE have become essential, verifying that strip LED adapters meet rigorous electrical safety, electromagnetic compatibility, and environmental requirements for use in North American and international markets.

Since 1998, Beauty (STC) Manufacturing Co., Ltd. has been at the forefront of innovation in LED connectivity and power solutions. With over two decades of engineering expertise, Beauty STC specializes in high-quality, certified strip LED adapters designed to meet the demanding needs of commercial and industrial environments. Committed to reliability, safety, and performance, the company’s products are routinely tested and certified to ETL and CE standards, ensuring compatibility with global regulatory frameworks. As facilities managers, lighting designers, and electrical contractors seek trusted components for scalable and maintainable LED systems, Beauty STC continues to deliver solutions that combine precision engineering with long-term durability.

Technical Specs & Certifications

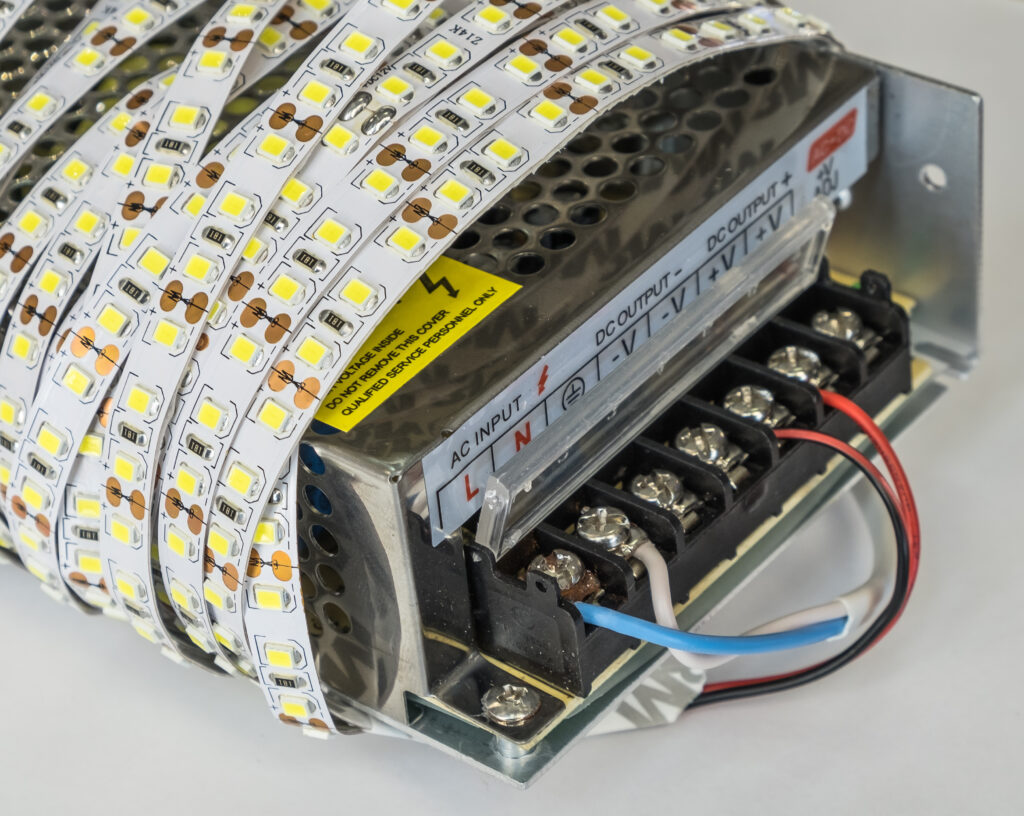

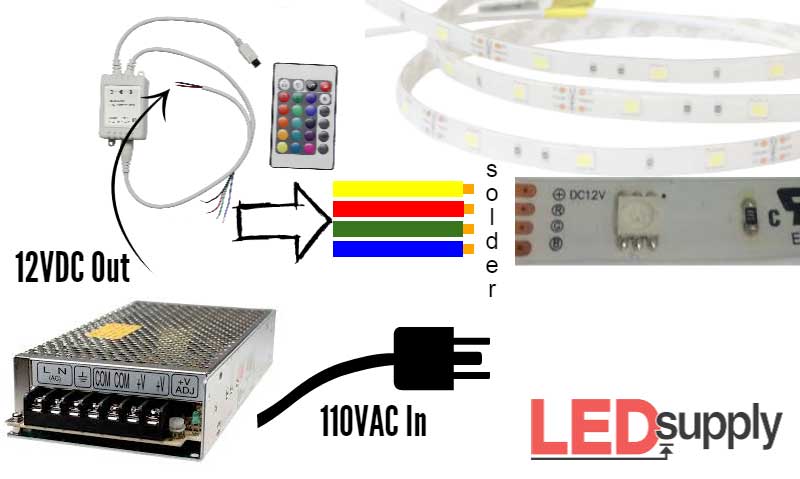

When discussing “strip LED adapter” specifications, it is critical to clarify terminology to avoid industry confusion. In LED lighting engineering, an “adapter” typically refers to a power supply (driver) or mechanical connector, neither of which directly produces light. Lumens/Watt and CRI are metrics for the LED light source itself (the strip), not the adapter. Below are precise technical explanations with relevant adapter specifications where applicable, emphasizing Beauty STC’s quality standards.

The adapter—specifically the constant-voltage LED driver—converts AC mains power to stable DC voltage (typically 12V or 24V) required by LED strips. It does not generate lumens; thus, Lumens/Watt is a measure of the LED strip’s efficacy, not the adapter. However, driver efficiency directly impacts system-level efficacy. Beauty STC drivers achieve ≥88% efficiency (per IEC 61347-2-13), minimizing energy loss as heat. For example, a 200W driver with 88% efficiency wastes only 24W as heat, preserving more input power for the LED strip to convert into light. This efficiency is validated through third-party testing per IEC 62301, ensuring optimal system-level lumens/Watt performance when paired with high-efficacy strips.

Color Rendering Index (CRI) is exclusively a property of the LED strip’s phosphor composition and binning process. Adapters do not influence CRI. Beauty STC LED strips consistently achieve CRI >90 (Ra) and R9 >50 through rigorous binning of high-CRI LEDs (e.g., Samsung LM301B/LM301H or Nichia 219B) and spectral optimization. Our manufacturing process includes spectrophotometer validation at multiple production stages, with strips tested under controlled conditions (LM-79) to guarantee CRI >90 across batches. Drivers support this by providing ripple-free DC output (<5% per IEC 62384), preventing color shift or flicker that could compromise perceived color quality.

IP ratings apply separately to LED strips and adapters. Adapters are rated for ingress protection based on their enclosure. Beauty STC offers adapters in IP20 (indoor use), IP65 (dust/water-jet resistant), and IP67 (temporary immersion) variants per IEC 60529. IP65/67 models feature aluminum housings with silicone gaskets and conformal-coated PCBs, validated through 8-hour water spray tests (IP65) and 30-minute immersion at 1m depth (IP67). Crucially, the adapter’s IP rating must match or exceed the LED strip’s rating in the installation environment. Beauty STC ensures compatibility by designing adapter cable glands and connectors to seal seamlessly with our IP65+ strips, eliminating weak points in the system.

Beauty STC’s quality commitment is embedded in every component. Our adapters undergo 100% burn-in testing at 40°C for 4 hours, with failure rates <0.3%—significantly below industry averages. We adhere to ISO 9001:2015 quality management and conduct accelerated life testing (ALT) per IEC 62628, simulating 50,000 hours of operation. All drivers include多重保护包括短路、过载、过压和过热,certified to UL 8750, EN 61347-1, and CE standards. This rigorous approach ensures that when paired with our CRI>90 LED strips, the total lighting system delivers sustained performance, energy efficiency, and color fidelity for demanding applications like retail, healthcare, and architectural lighting.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped factory located in Jiangmen, Guangdong Province, a region known for its strong manufacturing infrastructure and supply chain efficiency. The facility is designed to support high-volume production of LED lighting products with a strong emphasis on quality control, automation, and process optimization.

The factory is equipped with advanced SMT (Surface Mount Technology) production lines, which are essential for the precise and efficient assembly of LED lighting components. These SMT machines are capable of handling a wide range of component sizes and types, ensuring high-speed placement with excellent accuracy. The use of automated optical inspection (AOI) systems integrated into the SMT lines allows for real-time defect detection, ensuring consistent product quality from the earliest stages of production.

A critical part of the manufacturing process at the Jiangmen facility is the aging test procedure. Completed LED products, including strip light components and adapters, undergo rigorous aging tests under controlled conditions that simulate extended operation. These tests typically involve running products at full power for durations of 24 to 72 hours to identify early failures, verify thermal performance, and ensure long-term reliability. The data collected during aging tests is used to refine production processes and maintain high standards of durability and performance.

Beauty STC has strong OEM (Original Equipment Manufacturer) capabilities, particularly for products such as LED strip adapters. The company can customize design, packaging, labeling, and electrical specifications to meet the unique requirements of clients. This includes adapting input/output voltages, connector types, housing materials, and compliance with international safety and certification standards such as CE, RoHS, and UL. With in-house engineering support, tooling development, and flexible production scheduling, the factory efficiently supports both small-batch custom orders and large-scale OEM projects.

Overall, the Jiangmen factory combines automation, stringent quality assurance, and flexible manufacturing solutions to deliver reliable, high-performance LED products tailored to global market demands.

Application Scenarios

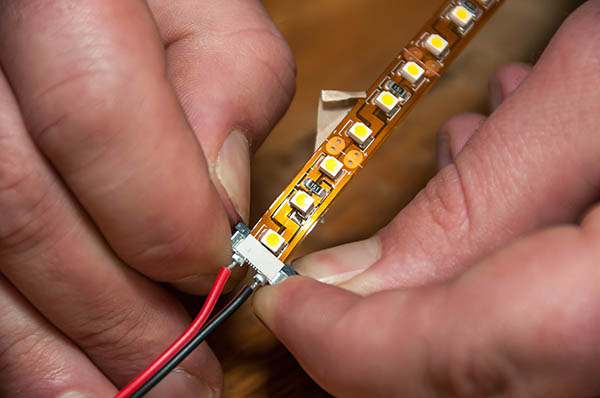

Strip LED adapters, more accurately termed LED strip power supplies or LED drivers, are essential components for converting mains voltage to the low-voltage DC power required by flexible LED strips. They are not mechanical mounting accessories but the electrical interface critical for safe and reliable operation. In commercial environments like hotels, malls, and offices, their application and correct installation are paramount for performance and longevity.

In hotels, these power supplies are predominantly used to drive LED strips in guest room ambient lighting coves, under-bed lighting, vanity mirrors in bathrooms, and feature walls in lobbies or suites. They power discreet signage such as room number indicators or emergency exit path markers. The focus here is on creating a consistent, high-quality light output that enhances guest experience without audible hum or visible flicker, which would be unacceptable in premium accommodations. Properly sized and installed power supplies ensure the subtle lighting remains reliable throughout the guest stay.

Malls utilize LED strip power supplies extensively for cove lighting in high-ceiling atriums, under handrails on escalators, within retail display cases, and for outlining architectural features or directional signage. The challenging aspect here is the scale; large installations require careful circuit planning to avoid voltage drop over long strip runs, which causes dimming at the far end. Power supplies must be selected to handle the total load with a 20% safety margin and often need to be housed in accessible electrical closets or service zones due to their heat output and the need for periodic maintenance in these high-traffic public areas.

Offices deploy these components for task lighting under cabinets in workstations, within partition walls for indirect glare-free illumination, in conference room feature walls, and for under-desk accent lighting. The key requirement here is compatibility with building management systems (BMS) or DALI controls for daylight harvesting and occupancy-based dimming to meet energy efficiency standards. Power supplies must support the required dimming protocol (0-10V, PWM, etc.) and be installed with adequate thermal management, as enclosed spaces like under desks can trap heat, significantly shortening the power supply’s lifespan if not ventilated.

Installation must begin with precise load calculation; sum the wattage of all LED strips connected to a single power supply and select a unit rated for at least 120% of that total to prevent overheating and premature failure. Never daisy-chain multiple power supplies to a single circuit breaker without verifying the breaker’s capacity and using appropriately gauged wiring—underrated cables are a fire hazard. Always mount power supplies in well-ventilated areas away from insulation or other heat sources; enclosures must allow airflow or incorporate cooling vents. For long LED strip runs exceeding 5 meters, inject power at both ends or use a higher voltage strip (24V instead of 12V) to mitigate voltage drop, which causes color shift and reduced brightness. Crucially, ensure all connections are secure and insulated, use wire nuts or connectors rated for the current, and verify the power supply is grounded per local electrical codes—especially vital in潮湿 environments like hotel bathrooms where Class II (double-insulated) power supplies are often mandated for safety. Finally, label each power supply clearly with its circuit and load details to simplify future maintenance or troubleshooting. Skipping these steps risks system failure, inconsistent lighting, and potential safety violations during building inspections.

Why Choose Beauty STC Lighting

Looking for a reliable strip LED adapter solution? Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in LED lighting technology. Our high-quality strip LED adapters are designed for performance, durability, and seamless integration in a wide range of applications. As your manufacturing partner, we offer competitive pricing, custom solutions, and consistent product quality backed by years of industry expertise.

To learn more or discuss your project requirements, contact us today at [email protected]. Let Beauty STC power your next lighting innovation.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.