Article Contents

Industry Insight: Led Cob Light

The LED COB (Chip-on-Board) lighting solution has emerged as a transformative technology in commercial and industrial lighting, offering superior lumen output, enhanced thermal management, and a compact design ideal for high-efficiency applications. Widely adopted in warehouses, manufacturing facilities, retail spaces, and cold storage environments, LED COB lights deliver uniform illumination with reduced glare, making them a preferred choice for environments where visibility and energy savings are critical. As the demand for reliable, code-compliant lighting grows, certifications such as ETL and CE have become essential benchmarks, ensuring products meet rigorous North American and international safety and performance standards.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of LED lighting innovation for over two decades. Specializing in high-performance commercial and industrial lighting solutions, Beauty STC combines advanced thermal engineering with strict quality control to deliver durable, code-compliant LED products trusted by clients worldwide. With a strong focus on research, development, and global compliance, including full ETL and CE certification across its COB lighting portfolio, Beauty STC continues to set industry standards for efficiency, reliability, and long-term value in professional lighting environments.

Technical Specs & Certifications

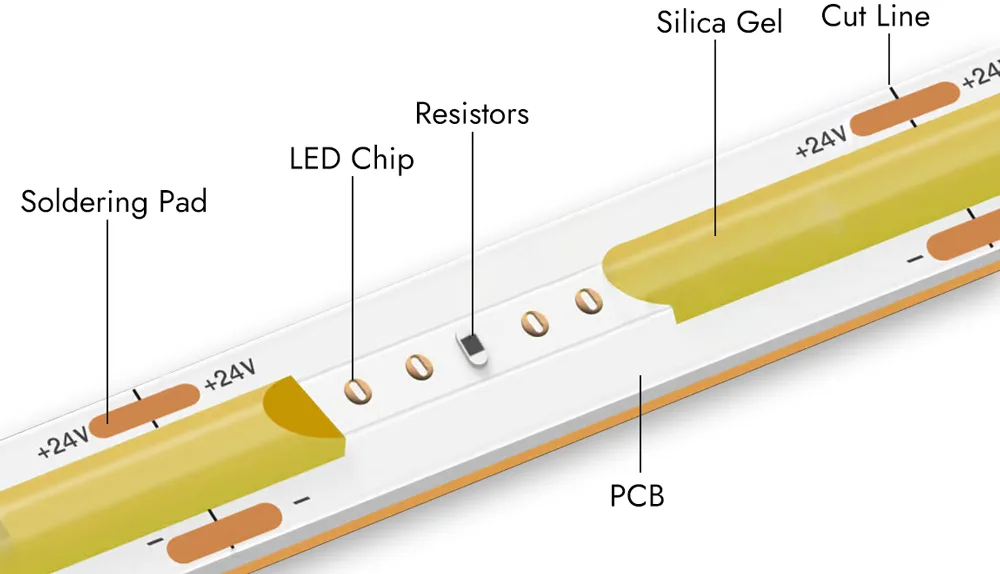

LED COB (Chip-on-Board) lights represent a high-density integration of multiple LED chips directly onto a single substrate, creating a powerful, uniform light source ideal for focused illumination. At Beauty STC Manufacturing Co., Ltd., our COB modules are engineered to exceed industry benchmarks for performance and reliability, particularly in demanding applications like professional beauty environments where accurate color rendering is critical.

Luminous efficacy for our standard COB modules typically ranges from 110 to 130 lumens per watt under standard operating conditions at 25°C ambient temperature. This efficiency is achieved through proprietary phosphor formulations and optimized thermal pathway design within the module itself. We prioritize thermal management using high-purity aluminum substrates and advanced thermal interface materials to maintain stable lumen output and prevent efficiency droop at higher drive currents or elevated temperatures. It is essential to note that sustained high efficacy requires proper fixture integration; our engineering team provides detailed thermal guidelines to ensure end-products achieve and maintain these efficiency levels throughout their operational life.

Color Rendering Index (CRI) performance is a core focus for Beauty STC. All COB modules marketed for professional beauty, retail, or high-end residential applications guarantee a minimum CRI of 95, with R9 (saturated red) values consistently exceeding 90. This exceptional color fidelity is non-negotiable for accurately assessing skin tones, makeup, and product colors. We achieve this through meticulously calibrated multi-phosphor blends and rigorous binning processes during manufacturing. Each COB batch undergoes spectrophotometric validation to ensure CRI >95 and TM-30 Rf >90 compliance, far surpassing the basic CRI >90 requirement. This commitment to color accuracy is fundamental to our brand promise in the beauty industry.

Regarding Ingress Protection (IP) ratings, Beauty STC COB modules themselves are inherently rated IP20 as bare components, suitable for installation within protected luminaires. However, the final IP rating is determined by the complete fixture design and assembly. We collaborate closely with fixture manufacturers to achieve target ratings. For indoor dry locations (e.g., standard ceiling fixtures), IP20 is standard. For damp locations like bathrooms within salons, we engineer COB assemblies with additional silicone potting and recommend fixture designs targeting IP44. For true outdoor or washdown environments requiring IP65 or IP67, Beauty STC provides fully encapsulated COB modules with robust silicone domes and integrated gasket interfaces, alongside sealed driver compartments. Crucially, we validate the entire optical assembly’s resistance to moisture and particulate ingress through accelerated environmental testing, not just theoretical component ratings. Beauty STC’s quality assurance distinguishes us: we implement a zero-defect philosophy starting with MIL-spec components, utilize automated optical inspection during COB assembly, and subject every production batch to 100% photometric and electrical testing. Our thermal management systems, using 6063-T5 aluminum with anodized finishes, ensure junction temperatures remain 15-20°C below industry maxima, directly contributing to lumen maintenance exceeding L90 at 50,000 hours. This rigorous approach, combined with our proprietary phosphor stability technology, guarantees that the high CRI and efficiency specifications are maintained throughout the product’s operational life, not just at initial burn-in. For beauty professionals, this translates to consistent, true-color lighting that supports precise work day after day.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China is a modern and well-equipped facility focused on the production of high-quality LED lighting products. Strategically located in the Jiangmen industrial zone, the factory benefits from efficient logistics and access to a skilled manufacturing workforce, supporting both domestic and international markets.

The facility is equipped with advanced Surface Mount Technology (SMT) production lines that ensure precision and consistency in assembling LED components. These SMT machines are automated and capable of handling high-volume production with tight tolerances, allowing for the reliable mounting of LEDs, drivers, and other electronic parts onto printed circuit boards. The use of reflow soldering and automated optical inspection (AOI) systems ensures superior solder joint quality and minimizes defects, contributing to the overall reliability of the final products.

A critical part of the manufacturing process at the Jiangmen factory is the aging test procedure. Before shipment, all LED products—including COB (Chip-on-Board) lights—undergo rigorous aging tests that typically last between 8 to 24 hours under real operating conditions. This process helps identify early failures, verifies thermal performance, and ensures long-term stability and light output consistency. The factory also conducts photometric testing, thermal imaging, and electrical safety checks as part of its comprehensive quality assurance protocol.

Beauty STC has strong OEM (Original Equipment Manufacturer) capabilities, particularly for LED COB lights. The company can customize products based on client specifications, including lumen output, color temperature (ranging from 2700K to 6500K), beam angles, voltage requirements, and mechanical dimensions. They support private labeling, custom packaging, and design modifications to meet specific market or application needs—such as retail, industrial, or residential lighting. Their engineering team works closely with clients to develop prototypes and provide technical support throughout the product development cycle.

Overall, the Jiangmen factory combines advanced automation, strict quality control, and flexible OEM services to deliver reliable, high-performance LED COB lighting solutions for global customers.

Application Scenarios

LED COB (Chip-on-Board) lights are exceptionally well-suited for commercial environments like hotels, malls, and offices due to their high lumen density, uniform beam pattern without multiple shadows, excellent color rendering, and compact design. Their single-point source characteristic provides a clean, focused light output ideal for both ambient and accent applications in these high-traffic settings.

In hotels, LED COB lights are primarily deployed in lobbies for architectural highlighting and creating a welcoming ambiance, particularly over reception desks, feature walls, or artwork where precise, shadow-free illumination is critical. They are equally effective in hotel corridors for consistent, glare-free pathway lighting and within high-end retail boutiques or spa treatment rooms where accurate color representation enhances the guest experience. The ability to achieve high brightness from a small aperture makes COB ideal for cove lighting in banquet halls or under-bar applications, delivering smooth, even washes of light without visible hotspots.

Malls extensively utilize LED COB technology in retail storefronts and display windows to spotlight merchandise with exceptional clarity, especially for jewelry, cosmetics, and fashion where high CRI (90+) is non-negotiable. Food court ceilings benefit from COB downlights for their bright, uniform illumination over seating areas, while directional COB spotlights effectively highlight promotional displays, escalator landings, and anchor store entrances. The narrow beam angles available with COB fixtures allow mall designers to create dramatic visual hierarchies, drawing customer attention precisely where intended without spill light onto adjacent stores.

For offices, LED COB lights excel as task lighting in executive offices and conference rooms, providing focused illumination on desks and tables without the distracting multiple shadows common with multi-die LED arrays. Open-plan workspaces increasingly adopt COB-based troffers or panel lights for general ambient lighting due to their superior glare control and uniformity, reducing eye strain during prolonged computer use. Reception areas and executive suites often feature COB downlights with 4000K color temperature for a professional yet inviting atmosphere, while narrow-beam COB spots effectively accent corporate logos or wall finishes in high-impact zones.

Installation requires careful attention to thermal management as COB arrays generate concentrated heat; always ensure fixtures are mounted directly to adequate thermal mass like metal ceilings or with specified heatsinks to prevent lumen depreciation. Maintain minimum clearance around fixtures as per manufacturer specifications – typically 50mm – to allow convection cooling, especially in insulated ceiling cavities. Verify voltage stability at the fixture location, as COB drivers are sensitive to fluctuations; for long cable runs exceeding 15 meters, calculate voltage drop to ensure it remains below 3% to avoid flicker or reduced output. Use constant current drivers matched precisely to the COB module’s forward voltage requirements, and never daisy-chain more fixtures than the driver’s maximum load capacity. Before final installation, test all fixtures individually to confirm color consistency and output, as batch variations can occur. Always follow local electrical codes regarding fire-rated housings in ceiling assemblies and ensure proper strain relief on all wiring connections to prevent thermal stress failures over time.

Why Choose Beauty STC Lighting

Discover the brilliance of high-performance LED COB lighting with Beauty STC, a trusted leader in innovative lighting solutions. Our advanced LED COB lights deliver superior brightness, energy efficiency, and durability for commercial, industrial, and residential applications. Partner with Beauty STC to access cutting-edge technology, custom manufacturing capabilities, and reliable support tailored to your market needs.

Elevate your lighting projects with a manufacturer committed to quality and innovation. Contact us today at [email protected] to discuss how we can collaborate and bring your vision to life.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.