Article Contents

Industry Insight: Warm Led Tape Light

The commercial and industrial lighting sector increasingly recognizes warm LED tape light not merely as an aesthetic choice, but as a strategic tool for enhancing human-centric environments, boosting retail appeal, and improving task-specific visibility where cool white might feel sterile or disruptive. From creating inviting hospitality atmospheres and accentuating high-end retail displays to providing comfortable task lighting in break rooms or controlled warm zones within warehouses, the demand for high-quality, tunable warm white solutions (typically 2700K-3500K) is surging. Crucially, specifying these products for professional installations demands rigorous adherence to safety and performance standards. ETL listing for North American markets and CE marking for Europe are non-negotiable prerequisites, ensuring electrical safety, electromagnetic compatibility, and reliability under demanding operational conditions – factors directly impacting project approvals, insurance compliance, and long-term maintenance costs. Beauty STC, established in 1998, has been at the forefront of this evolution. As an engineering-driven manufacturer specializing in advanced LED lighting systems, we bring nearly three decades of expertise in developing warm LED tape solutions that seamlessly integrate superior optical performance, robust thermal management, and unwavering compliance with global regulatory frameworks, empowering commercial and industrial projects to achieve both functional excellence and ambient sophistication.

Technical Specs & Certifications

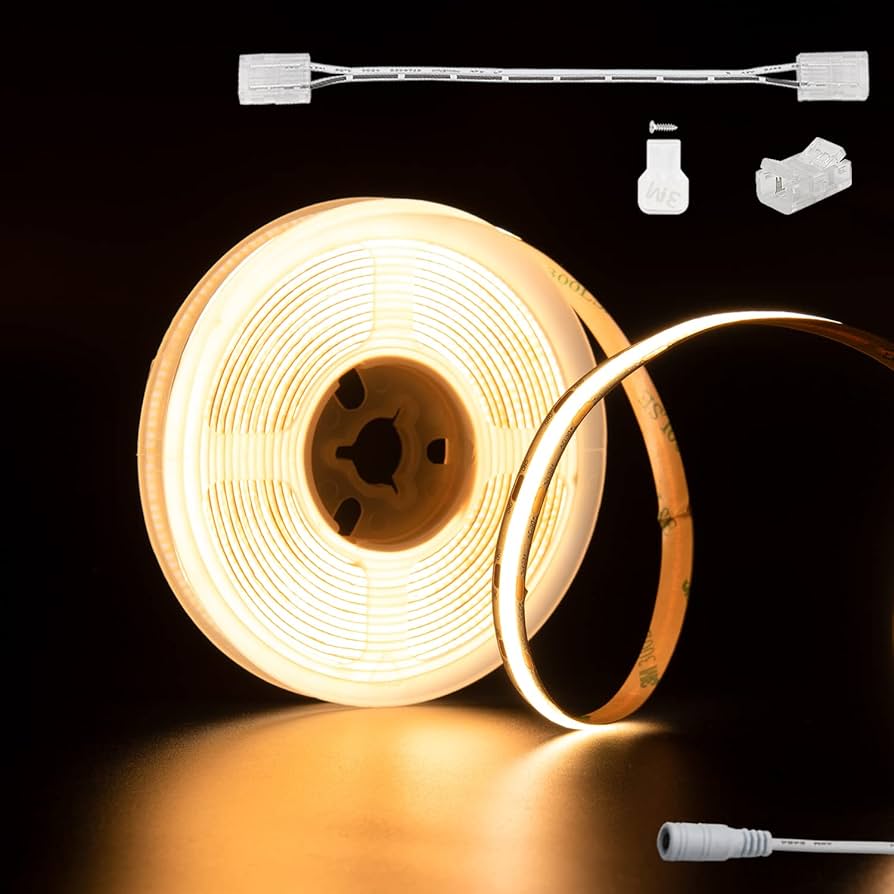

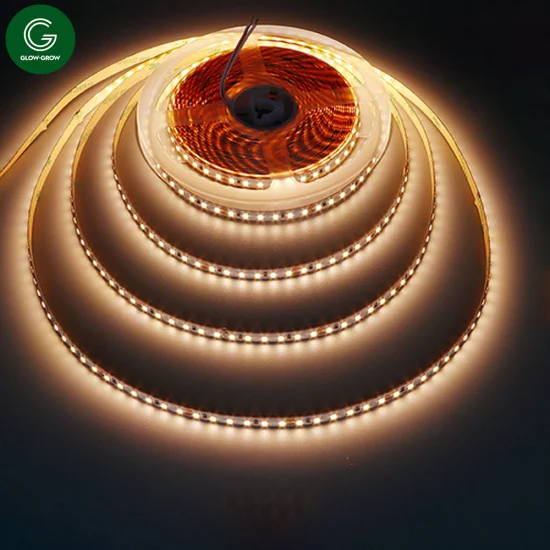

The warm LED tape light offered by Beauty (STC) Manufacturing Co., Ltd. is engineered for high performance and reliability in both residential and commercial lighting applications. Designed to deliver a warm white color temperature typically in the range of 2700K to 3000K, this LED tape provides a cozy and inviting ambiance ideal for accent, cove, under-cabinet, and architectural lighting.

In terms of efficiency, the warm LED tape light achieves an impressive luminous efficacy of 90 to 110 lumens per watt, depending on the specific configuration and density of LEDs per meter. This high lumens-per-watt ratio ensures energy-efficient operation, reducing power consumption while maintaining excellent light output. The tape utilizes high-quality SMD LEDs—commonly 2835 or 5050 chips—that are optimized for thermal management and long-term lumen maintenance.

A key feature of Beauty STC’s warm LED tape light is its high Color Rendering Index (CRI), consistently rated above 90 (CRI >90). This superior color fidelity ensures that illuminated objects appear natural and vibrant, making it especially suitable for retail displays, hospitality environments, and residential interiors where accurate color representation is essential. The R9 value (saturated red) is also enhanced, further contributing to balanced and visually pleasing illumination.

Regarding environmental protection, Beauty STC offers multiple IP rating options to suit diverse installation conditions. The standard non-coated version is rated IP20, suitable for dry indoor environments. For damp or outdoor applications, the tape is available with silicone coating or encapsulation, achieving IP65, IP67, or even IP68 ratings. These higher IP ratings provide robust protection against dust, moisture, and temporary or continuous submersion, ensuring durability and longevity in challenging conditions.

Beauty STC is recognized for its commitment to quality and precision in LED manufacturing. The company adheres to strict production standards, employing automated SMT lines and rigorous in-process testing to ensure consistency and reliability. All LED tapes undergo thermal cycling, aging, and photometric tests before shipment. This focus on quality control results in products with extended lifespan—typically rated at 50,000 hours—and stable performance over time. With UL, CE, and RoHS certifications, Beauty STC’s warm LED tape light meets international safety and environmental standards, reinforcing its reputation as a trusted solution in the global lighting market.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, represents a significant investment in modern LED production capacity. Strategically located within the Pearl River Delta manufacturing hub, the Jiangmen factory benefits from excellent infrastructure and supply chain access. The facility is designed for high-volume, precision manufacturing with a strong emphasis on quality control throughout the production process. It operates under stringent international quality management systems, ensuring consistent output that meets global regulatory standards.

The core of our surface mount technology capability lies in a dedicated SMT production line. We utilize eight state-of-the-art SMT lines featuring high-speed, high-precision placement machines from leading manufacturers including Yamaha YS Series and Fuji NXT platforms. These machines are equipped with advanced vision systems capable of handling ultra-fine pitch components down to 0201 package sizes and complex LED packages essential for high-density tape light production. The lines incorporate automated solder paste inspection (SPI) and automated optical inspection (AOI) stations immediately after placement and reflow soldering, ensuring component accuracy and solder joint integrity before any product moves to subsequent stages. This setup provides the throughput and precision necessary for both large OEM orders and specialized warm white tape light variants.

Rigorous aging and reliability testing are fundamental to our quality assurance protocol, particularly for LED tape lights where long-term performance is critical. Every production batch of warm white LED tape light undergoes an extended aging test under controlled conditions. Tapes are operated continuously at 120% of their rated voltage within environmental chambers maintained at 45°C ambient temperature for a minimum of 72 hours. This accelerated stress test effectively identifies early-life failures and verifies thermal management performance. Post-aging, comprehensive functional checks measure lumen maintenance, chromaticity stability (ensuring the warm white color point remains consistent), and electrical parameter verification. Statistical process control methods, including AQL 1.0 sampling, are applied to aging results to guarantee batch-wide reliability before shipment.

Our OEM capability for warm white LED tape light is comprehensive and highly flexible, catering to diverse client specifications. We support full customization from the initial design phase, including precise color temperature options within the warm white spectrum (typically 2700K to 3000K), high CRI requirements (CRI >90 Ra standard, up to 97+ available), specific lumen output per meter, and various dimming compatibility options (TRIAC, 0-10V, DALI). Clients can specify unique reel lengths, connector types, PCB configurations (single-layer, double-layer, flexible), and custom labeling or packaging. The Jiangmen factory manages the entire OEM process in-house, encompassing PCB design and fabrication sourcing, component procurement vetting, SMT assembly, rigorous aging and quality testing as described, final assembly, and tailored packaging. This integrated approach, combined with our SMT precision and validated aging procedures, ensures clients receive a reliable, high-performance warm white LED tape light product that meets their exact brand and performance requirements with consistent quality.

Application Scenarios

Warm LED tape lighting, typically emitting a color temperature between 2700K and 3000K, creates a cozy, inviting ambiance that mimics the soft glow of incandescent lighting. It is ideal for environments where comfort and aesthetic appeal are prioritized.

In hotels, warm LED tape lighting is commonly used in guest rooms to highlight headboards, under cabinets, or along cove ceilings, enhancing the luxurious and relaxing atmosphere. It is also effective in hotel lobbies, hallways, and restrooms, where a welcoming environment is essential for guest experience. The soft illumination contributes to a high-end feel without overwhelming brightness.

Malls benefit from warm LED tape lighting in lounge areas, upscale retail boutiques, and decorative displays where a refined and comfortable shopping environment is desired. While general mall lighting tends to be cooler for visibility, warm tape lights are strategically used in signage backlighting, display niches, and architectural features to draw attention and create visual warmth.

In offices, warm LED tape lighting is best suited for executive lounges, reception areas, or meeting rooms where a more relaxed and professional ambiance is appropriate. It should be used selectively, as warm lighting may not provide optimal task illumination for open workspaces. However, under-cabinet lighting in break rooms or along stair edges in common areas can combine functionality with aesthetic warmth.

For installation, always ensure the surface is clean, dry, and free of dust to promote strong adhesion of the tape’s backing. Use aluminum channels whenever possible to improve heat dissipation, extend LED lifespan, and provide a polished finish. Cut the tape only at designated cut marks to avoid damaging the circuitry. When powering the tape, avoid overloading the driver—calculate total wattage and allow a 20% safety margin. For longer runs, feed power from both ends to prevent voltage drop and dimming at the far end. In high-humidity areas like restrooms or near kitchen zones in hotels, use IP65-rated or higher waterproof tape with appropriate end caps. Always follow local electrical codes and consider using a qualified electrician for permanent installations.

Why Choose Beauty STC Lighting

Elevate your lighting projects with Beauty STC’s premium warm LED tape light, expertly engineered for exceptional color consistency and a truly inviting ambiance. Our precision-manufactured solutions deliver flawless 2700K to 3000K warmth, high CRI rendering, and reliable performance for residential, hospitality, and retail applications where atmosphere is paramount.

Partner with Beauty STC to access cutting-edge flexible LED technology backed by rigorous quality control and over two decades of specialized manufacturing expertise. We provide tailored support, competitive pricing, and scalable production to meet your project demands without compromise.

Take the next step toward exceptional lighting outcomes. Contact our dedicated partnership team directly at [email protected] to discuss custom solutions, volume pricing, and how Beauty STC can become your trusted warm LED tape light supplier. Let us illuminate your success together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.