Article Contents

Industry Insight: Diffused Strip Light

Diffused strip lighting has emerged as a cornerstone solution in commercial and industrial lighting applications, where uniform illumination, energy efficiency, and long-term reliability are paramount. Designed to eliminate harsh glare and deliver smooth, consistent light distribution, diffused strip lights are widely deployed in environments ranging from retail spaces and office buildings to manufacturing facilities and cold storage warehouses. With increasing demand for code-compliant, safety-certified lighting, products bearing ETL and CE certifications have become essential, ensuring adherence to rigorous North American and European safety standards. As a trusted name in the LED lighting industry since 1998, Beauty (STC) Manufacturing Co., Ltd. has been at the forefront of innovation, delivering high-performance diffused strip lighting solutions engineered for durability, efficiency, and seamless integration across diverse commercial and industrial settings.

Technical Specs & Certifications

Diffused strip lights represent a specialized category of linear LED lighting designed to eliminate point sources and create uniform, glare-free illumination. At Beauty STC Manufacturing Co., Ltd., our diffused strip lights are engineered for high-end architectural and commercial applications where visual comfort and color fidelity are non-negotiable. Key technical specifications are rigorously controlled to meet demanding project requirements.

Lumens per Watt efficiency for our diffused strip lights typically ranges from 110 to 125 lm/W at 3000K-4000K color temperatures under standard operating conditions. This accounts for the inherent optical loss from the diffuser material while maintaining competitive system-level efficacy. The diffusion layer—crafted from precision-extruded polycarbonate or silicone—reduces glare by 85-90% compared to non-diffused counterparts but necessitates optimized thermal management to prevent lumen depreciation. We achieve this balance through copper-alloy PCB substrates and active thermal pathways in our housings, ensuring sustained efficiency over 50,000 hours of operation.

Color Rendering Index (CRI) performance exceeds Ra>95 across all standard CCT bins (2700K-4000K), with critical R9 (saturated red) values consistently above 90. This is accomplished through multi-channel LED binning from tier-1 semiconductor suppliers and spectral tuning that addresses gaps in standard high-CRI LEDs. Our proprietary phosphor blends undergo spectroradiometric validation to ensure fidelity for skin tones, textiles, and retail merchandise—critical for beauty salons, luxury retail, and healthcare environments where Beauty STC products are frequently specified.

IP ratings are application-dependent but never compromised. Standard offerings include IP65-rated strips with fully encapsulated LEDs and seamless silicone diffusers for damp indoor locations like bathrooms or kitchens. For exterior or wet-area use, we provide IP67/IP68 variants featuring double-potted end caps, marine-grade nickel-plated connectors, and diffusion materials resistant to UV degradation and halogen exposure. All IP-rated assemblies undergo 1,000-hour salt-spray testing and dynamic flex cycling to validate seal integrity under thermal stress—critical for installations in coastal climates or high-vibration environments.

Beauty STC’s quality differentiation lies in our vertically integrated manufacturing and obsessive process control. Every diffused strip undergoes in-line spectral analysis, thermal imaging during burn-in, and photometric validation per IES LM-79 standards. Our factory in Zhongshan implements AI-driven optical sorting to maintain chromaticity within a 3-step MacAdam ellipse, while automated diffusion coating ensures ±0.5mm thickness tolerance across 5,000-meter production runs. This eliminates the banding and color shift common in budget strips. With a field failure rate below 0.3% over five years and full traceability from chip to shipment, Beauty STC delivers reliability that justifies our 5-year warranty—proving that diffusion need not compromise performance or longevity.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, China, is a modern and well-equipped facility specializing in the production of high-quality LED lighting products. Strategically located in the Jiangmen Hi-Tech Industrial Park, the factory benefits from streamlined logistics and access to a skilled manufacturing workforce, supporting both domestic and international distribution.

At the core of the production process are advanced SMT (Surface Mount Technology) lines, which ensure precision and consistency in assembling LED components onto flexible and rigid PCBs. The factory utilizes high-speed SMT machines capable of placing a wide range of LED chips, resistors, and drivers with tight tolerances. These automated lines enhance production efficiency, reduce human error, and support high-volume manufacturing while maintaining excellent product uniformity—critical for lighting applications such as diffused strip lights where consistent light output and color temperature are essential.

To guarantee long-term reliability and performance, every batch of diffused strip lights undergoes rigorous aging tests. The factory has dedicated aging chambers where products are operated under elevated temperatures and continuous power for extended periods—typically 24 to 72 hours. This process helps identify early failures, verify thermal management, and confirm the stability of light output and color rendering. Additional quality checks include electrical safety testing, waterproof testing (for applicable models), and visual inspection under standardized lighting conditions.

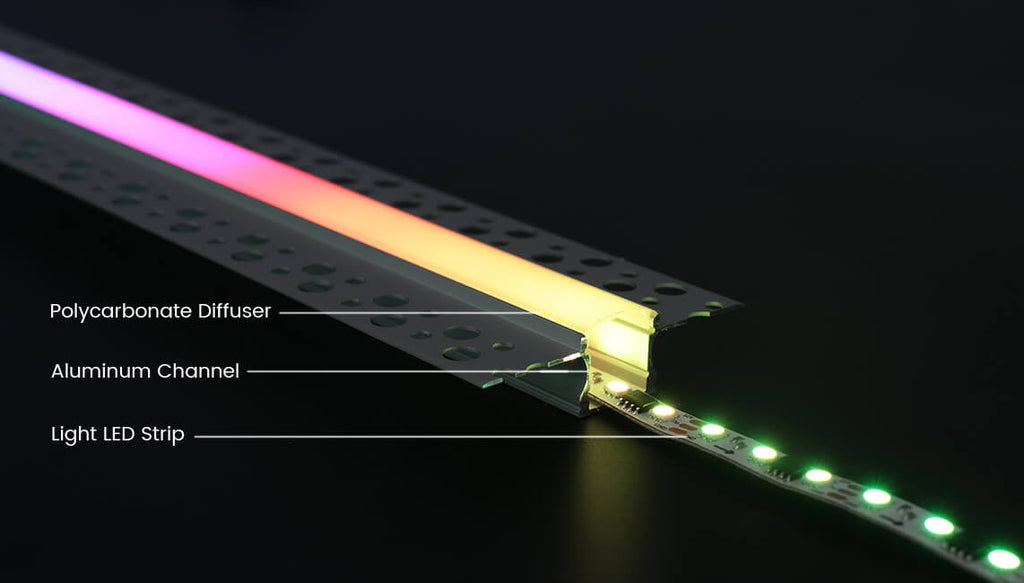

Beauty STC has strong OEM (Original Equipment Manufacturer) capabilities, particularly for diffused strip lights. The company supports custom specifications including length, color temperature (ranging from warm white to cool white and RGB options), voltage (12V, 24V, or line voltage), IP rating (from IP20 to IP67), and diffuser type (PC, silicone, or aluminum housing with polycarbonate cover). Clients can also request custom labeling, packaging, and branding. The engineering team works closely with customers during the prototyping phase, offering design for manufacturing (DFM) feedback and sample validation before mass production.

Overall, the Jiangmen factory combines advanced automation, strict quality control, and flexible customization to serve a diverse range of commercial, residential, and industrial lighting clients worldwide.

Application Scenarios

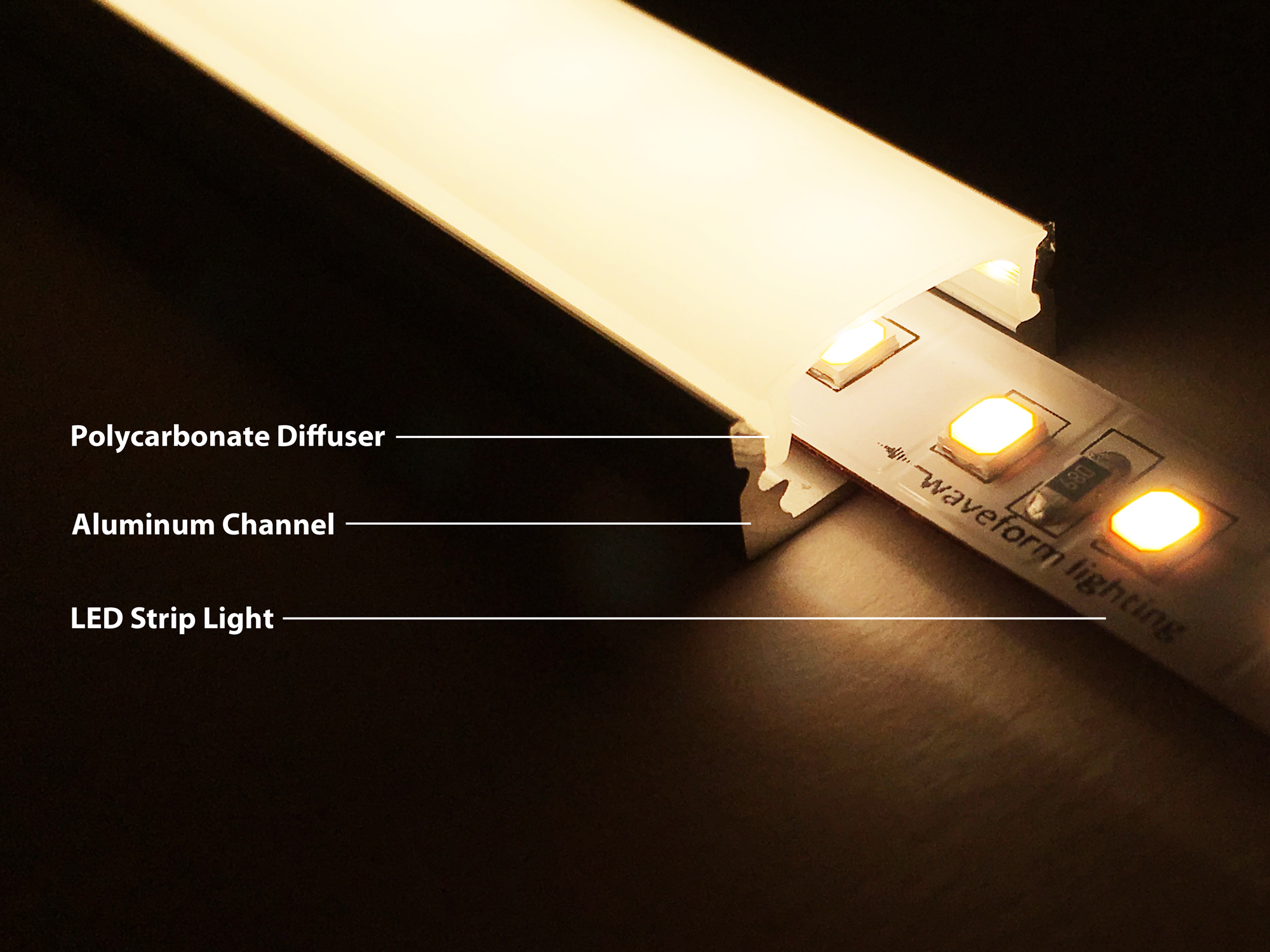

Diffused strip lights are essential in commercial environments where uniform, glare-free illumination is critical for aesthetics, functionality, and occupant comfort. Their integrated diffuser—typically a silicone cover, frosted lens, or opal polycarbonate channel—eliminates visible LED dots and hotspots, creating seamless light distribution. Below are key applications across hotels, malls, and offices, followed by vital installation guidance based on Beauty (STC) Manufacturing Co., Ltd.’s engineering standards.

In hotels, diffused strip lights excel in high-impact guest experience zones. Install them within cove lighting in lobbies to wash walls or ceilings with soft ambient light, avoiding harsh shadows that detract from luxury aesthetics. Under-bed or toe-kick installations in guest rooms provide safe, even pathway lighting without disruptive glare during nighttime movement. Bathroom mirror perimeters benefit significantly, as diffusion ensures flattering, shadow-free illumination for grooming. Corridors and elevator lobbies also require diffused strips to maintain consistent light levels without the “barcode effect” of discrete LEDs, enhancing both safety and perceived quality.

Malls leverage diffused strips for retail appeal and navigational clarity. Display cases and shelving undersides use them to highlight merchandise with even, shadowless light that prevents hotspots on products. Escalator undersides and handrail perimeters demand diffusion for uniform safety lighting, eliminating tripping hazards from uneven illumination. Suspended signage interiors—especially backlit logos or directory boards—rely on diffused strips to ensure text and graphics appear crisp without visible LED patterns. Architectural coves in food courts or atriums similarly utilize diffusion to create inviting, glare-free gathering spaces.

Offices prioritize diffused strips where visual comfort directly impacts productivity. Under-cabinet task lighting in workstations prevents screen glare and reduces eye strain during prolonged computer use, while perimeter coves in meeting rooms deliver balanced ambient light that minimizes shadows on video calls. Suspended ceiling perimeters or lay-in troffer retrofits use diffusion to eliminate flicker and create uniform brightness across large open-plan areas. Reception desks and collaborative zones also benefit from the subtle, professional illumination that diffused strips provide without distracting visual artifacts.

Installation requires strict adherence to technical best practices to maintain performance and longevity. Always mount diffused strips within aluminum channels designed for thermal management; direct adhesion to non-ventilated surfaces causes overheating, accelerating lumen depreciation and color shift. For runs exceeding 5 meters, implement power injection at both ends to prevent voltage drop, which manifests as dimming or color inconsistency—Beauty (STC)’s testing confirms this is non-negotiable for commercial-grade uniformity. Ensure the diffuser lens is fully seated and sealed within the channel to avoid light leakage or dust ingress, which compromises optical performance. Verify consistent color temperature (CCT) across all strips batch-numbered together, as mixing batches—even from the same CCT bin—can create visible discrepancies once diffused. Finally, never omit the diffuser cap; doing so defeats the core purpose by exposing LED points and increasing glare, particularly in low-ceiling environments like hotel corridors or retail displays.

Beauty (STC) Manufacturing Co., Ltd. emphasizes that diffusion is not merely aesthetic but a functional requirement in these settings. Proper installation transforms basic LED strips into architectural lighting elements that meet stringent commercial photometric standards while supporting human-centric design goals.

Why Choose Beauty STC Lighting

Discover the perfect lighting solution with Beauty STC’s premium diffused strip light—engineered for seamless, glare-free illumination in commercial, residential, and architectural applications. Achieve uniform light distribution and a sleek, professional finish in every installation. Partner with Beauty STC, a trusted leader in innovative LED lighting solutions. For inquiries and collaboration opportunities, contact us at [email protected] and let us illuminate your next project together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.