Article Contents

Industry Insight: Led Diffusers

In the rapidly evolving landscape of commercial and industrial lighting, LED diffusers have emerged as a critical component in achieving optimal light distribution, energy efficiency, and aesthetic integration. As facilities across warehouses, factories, office buildings, and retail spaces transition to LED technology, the demand for high-performance diffusers that minimize glare, ensure uniform illumination, and maintain long-term durability has never been greater. Today’s specifications increasingly require compliance with rigorous safety and performance standards—ETL and CE certifications have become essential markers of quality, confirming that lighting components meet North American and international regulatory requirements for electrical safety, photometric performance, and environmental resilience.

At the forefront of this innovation is Beauty (STC) Manufacturing Co., Ltd., a trusted name in optical solutions for LED lighting since 1998. With over two decades of engineering expertise, Beauty STC has established itself as a leading manufacturer of precision LED diffusers, serving a global clientele in the commercial and industrial sectors. By combining advanced materials science, in-house tooling capabilities, and a steadfast commitment to regulatory compliance, Beauty STC delivers diffuser solutions that enhance both the functionality and visual comfort of modern luminaires. From high-bay fixtures in manufacturing plants to sleek panel lights in corporate offices, Beauty STC’s products are engineered to perform under demanding conditions while supporting the industry’s shift toward smarter, more sustainable lighting ecosystems.

Technical Specs & Certifications

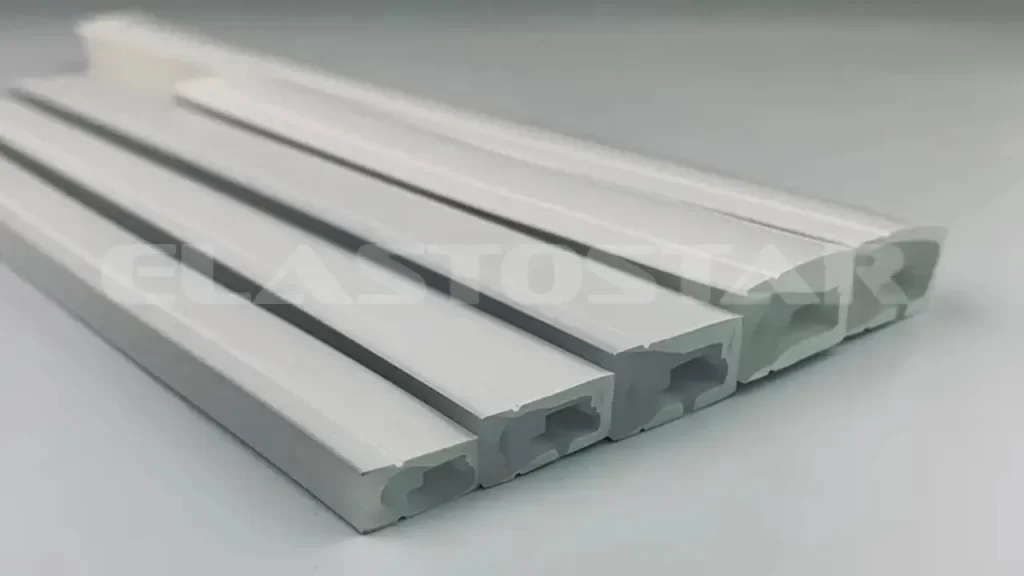

LED diffusers are optical components within complete luminaires, not standalone light sources, so technical specifications like lumens per watt and CRI are properties of the integrated LED system rather than the diffuser material alone. However, the diffuser significantly influences these performance metrics through its optical transmission, color neutrality, and ability to maintain integrity under environmental stress. At Beauty STC Manufacturing Co., Ltd., our engineering approach ensures diffusers are optimized to preserve the luminaire’s core performance while meeting stringent quality standards.

Lumens per watt efficacy is determined by the LED engine, driver efficiency, thermal management, and optical system. Beauty STC diffusers utilize high-transmission optical polymers such as modified polycarbonate or PMMA, typically achieving 85% to 92% light transmission depending on the specific diffusion pattern and thickness. This minimizes optical loss, ensuring the luminaire’s rated system efficacy of 120-150 lm/W for standard high-bay and panel fixtures, with premium designs reaching 160-180 lm/W. Critical to sustaining this efficacy over time, our diffusers incorporate UV stabilizers and thermal-resistant formulations that prevent yellowing or warping at operating temperatures up to 85°C ambient, maintaining transmission efficiency throughout the product’s 50,000-hour L70 lifetime. Inferior diffusers can degrade by 15-20% transmission within 2 years, directly reducing usable lumens per watt.

For Color Rendering Index (CRI >90), the primary factor is the LED chip and phosphor blend. Beauty STC specifies Nichia, Samsung, or Lumileds high-CRI LEDs with R9 >50 and TM-30 metrics included in datasheets. Our diffusers support this performance through spectrally neutral materials with ΔE < 1.5 color shift tolerance, preventing unwanted tinting that could distort the light spectrum. Quality control includes spectrophotometer validation of diffuser samples under accelerated aging tests (5,000 hours at 85°C/85% RH) to guarantee no measurable CRI degradation. This contrasts with commodity diffusers that may use recycled materials causing yellow shift, reducing effective CRI by 5-10 points within 12 months.

IP ratings depend on the luminaire’s mechanical design, but diffusers are critical sealing components. Beauty STC diffusers are engineered for specific ingress protection levels through precise material selection and gasket integration. For IP20 indoor applications, we use static-dissipative polycarbonate to prevent dust adhesion. IP44-rated diffusers for damp locations feature seamless perimeter sealing channels compatible with silicone gaskets, validated through 24-hour water spray testing. Outdoor IP65/IP66 diffusers employ co-extruded UV-resistant layers with Shore A 60-70 silicone edge seals, surviving 100+ freeze-thaw cycles without delamination. All materials pass IEC 60598-1 Annex H UV exposure tests with <2 ΔE color shift, a key differentiator from suppliers using untested polymers that crack or haze after 18 months exposure.

Beauty STC’s quality commitment is embedded in every diffuser through ISO 9001:2015-certified processes. We conduct in-house material validation including FTIR spectroscopy for polymer composition, ASTM D1003 haze/transmission testing, and MIL-STD-883 thermal cycling. Diffusers undergo 100% visual inspection for micro-defects and batch-level photometric verification. This results in near-zero field failures related to optical components, supported by our industry-leading 5-year warranty. Unlike generic suppliers, Beauty STC provides full material traceability and aging data, ensuring diffusers don’t become the weakest link in high-performance luminaires for retail, healthcare, and architectural applications where color fidelity and reliability are non-negotiable.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for electronics and lighting production. The Jiangmen factory is purpose-built for the efficient and high-quality manufacturing of LED lighting products, with a strong focus on precision, reliability, and scalability to meet both domestic and international market demands.

At the core of the production process are advanced Surface Mount Technology (SMT) lines, which enable the accurate and rapid placement of electronic components onto printed circuit boards (PCBs). These SMT machines are fully automated, ensuring consistent soldering quality, high throughput, and minimal defect rates. The integration of automated optical inspection (AOI) systems further enhances quality control by detecting placement and soldering anomalies in real time, ensuring only fully compliant boards move forward in the assembly process.

To guarantee product longevity and performance under real-world conditions, the Jiangmen facility conducts comprehensive aging tests. Completed LED lighting units undergo extended operational testing—typically 4 to 12 hours or more—at elevated temperatures and full power. This process identifies early failures and verifies thermal management, driver stability, and overall system reliability before products are cleared for shipment. Environmental simulation chambers are also used to test performance under varying humidity and temperature conditions, ensuring compliance with international standards.

Beauty STC has strong OEM (Original Equipment Manufacturer) capabilities, particularly in the production of LED diffusers and complete LED luminaires. The company provides customized solutions for clients seeking private-label or design-specific lighting products. Their expertise in optical engineering allows for tailored diffuser designs—using materials such as polycarbonate (PC), polymethyl methacrylate (PMMA), or silicone—to achieve desired light distribution, glare control, and aesthetic finishes. From initial concept and optical simulation to mold development, tooling, and mass production, Beauty STC supports clients throughout the entire product development cycle.

The combination of advanced SMT automation, rigorous aging and reliability testing, and flexible OEM services positions Beauty STC’s Jiangmen factory as a capable and trusted partner for brands seeking high-quality, custom LED lighting solutions with strong manufacturing scalability.

Application Scenarios

LED diffusers serve a critical function in commercial lighting by softening light output, eliminating harsh glare, and creating uniform illumination essential for occupant comfort and visual appeal. In hotels, they are indispensable in guest rooms to provide a relaxing ambiance free from distracting LED hotspots, particularly over bedside areas and vanities. Lobbies and corridors benefit significantly from diffusers in linear cove lighting and suspended fixtures, ensuring smooth transitions between light and shadow that enhance the perceived quality of the space. High-end restaurants and bars within hotels require diffusers to maintain a warm, inviting atmosphere while highlighting decor without creating uncomfortable glare for diners.

For shopping malls, diffusers are non-negotiable in large atriums and skylight replacements where even light distribution across expansive areas prevents dark zones and reduces visual fatigue for shoppers. Retail storefronts and display cases rely on diffusers to showcase merchandise accurately without specular reflections or harsh shadows that distort product appearance. Escalator soffits and circulation paths use diffused lighting to guide movement safely, while food court areas demand diffusers to create a clean, hygienic appearance under bright yet comfortable illumination.

Offices represent perhaps the most critical application due to prolonged occupant exposure. Open-plan workstations require diffusers with low Unified Glare Rating (UGR < 19) to minimize eye strain during computer use, especially in suspended troffer or panel fixtures. Meeting rooms need diffusers that balance brightness for video conferencing while avoiding reflections on tables. Executive offices and reception areas use diffusers to project professionalism through shadow-free lighting that highlights architectural features without visual discomfort.

Installation requires precise attention to detail. Always verify the diffuser material—polycarbonate offers superior impact resistance for high-traffic mall areas while optical-grade acrylic provides higher clarity for retail displays—and ensure it aligns perfectly with the fixture’s optical design to prevent light leakage at edges. Mount diffusers securely using manufacturer-specified clips or frames to avoid sagging over time, particularly in suspended ceiling grids where thermal expansion can cause misalignment. Maintain a minimum 5mm gap between the diffuser and LED modules to prevent heat buildup that accelerates lumen depreciation. For suspended linear systems in hotel corridors, level each segment meticulously before attaching diffusers to avoid visible brightness variations. In offices, prioritize easy-access diffuser designs that allow maintenance staff to clean lenses without removing entire fixtures—dust accumulation on diffusers can reduce light output by up to 30% within six months. Finally, never install diffusers over incompatible optics; mismatched diffusion patterns create distracting artifacts that defeat the purpose of glare control.

Why Choose Beauty STC Lighting

Transform your lighting projects with high-quality LED diffusers designed for optimal light distribution and durability. Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in LED lighting solutions. For inquiries and collaboration opportunities, contact us at [email protected] and let us illuminate your success together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.