Article Contents

Industry Insight: Led Strip Exterior

The commercial and industrial lighting landscape has undergone a transformative shift with the widespread adoption of LED strip lighting for exterior applications. As businesses and facility managers prioritize energy efficiency, durability, and design flexibility, LED strips have emerged as a go-to solution for architectural accenting, building facades, signage illumination, and outdoor task lighting. Their low-profile form factor, combined with high lumen output and long operational life, makes them ideal for demanding environments where performance and reliability are paramount. Increasingly, compliance with international safety and performance standards such as ETL and CE has become a critical benchmark, ensuring that exterior LED strip products meet rigorous requirements for electrical safety, environmental resistance, and consistent operation under varying conditions.

At the forefront of this evolution is Beauty (STC) Manufacturing Co., Ltd., a trusted name in LED lighting innovation since its founding in 1998. With over two decades of engineering expertise, Beauty STC has established itself as a leading manufacturer of high-performance LED strip solutions tailored specifically for commercial and industrial applications. The company’s exterior-grade products are designed to withstand harsh weather, UV exposure, and temperature extremes, while maintaining full compliance with ETL and CE certifications. By combining robust construction, cutting-edge thermal management, and strict quality control, Beauty STC delivers lighting solutions that support long-term sustainability goals and reduce total cost of ownership across a wide range of outdoor installations.

Technical Specs & Certifications

Beauty STC’s exterior LED strip lighting solutions are engineered for demanding outdoor applications where performance, longevity, and visual fidelity are non-negotiable. Our technical specifications prioritize measurable efficiency and reliability, starting with luminous efficacy. Standard high-output exterior strips achieve 120-130 lumens per watt at 25°C ambient temperature, utilizing premium Epistar or Samsung LED chips coupled with optimized constant-current drivers. This efficacy range accounts for real-world factors like thermal management and driver losses, not just ideal lab conditions. Crucially, we maintain this efficiency across the full operating temperature range of -30°C to +50°C through proprietary thermal shunt technology embedded in the flexible PCB, preventing significant lumen depreciation even in extreme climates.

Color rendering is rigorously controlled to exceed CRI >90 (Ra) across all correlated color temperatures (2700K to 6500K), with a minimum R9 value of 50 to ensure accurate red tones critical for architectural and landscape lighting. This is achieved through multi-phosphor coating formulations and strict binning processes during manufacturing, guaranteeing consistent color appearance within a 3-step MacAdam ellipse tolerance. Unlike budget alternatives that sacrifice spectral quality for brightness, Beauty STC strips deliver true-to-life color rendition essential for high-end residential, hospitality, and commercial facades.

For environmental protection, all exterior strips carry a minimum IP67 rating as standard, with IP68 (1.5m submersion for 30+ days) and IP69K options available for high-pressure washdown or marine environments. This is accomplished through dual-layer sealing: a primary silicone encapsulation over the LEDs and circuitry, followed by a secondary seamless silicone overmold extrusion that eliminates end-cap vulnerabilities common in competitor products. Our strips undergo 1,000+ hours of accelerated weathering tests per IEC 60598, including UV exposure, thermal cycling, and salt spray resistance, ensuring no delamination or silicone yellowing occurs.

Beauty STC’s quality differentiation lies in our vertically integrated manufacturing and obsessive attention to failure points. We utilize 2oz copper PCBs (vs. standard 1oz) for superior heat dissipation, aerospace-grade silicone with anti-hydrolysis additives, and automated optical inspection at every production stage. Each reel undergoes 100% functional testing at full operating current for 24 hours before shipment, not just spot checks. This commitment results in a field-proven 50,000-hour L70 lifetime (vs. industry-standard 30,000 hours) and a market-leading 5-year warranty backed by comprehensive lumen maintenance data. For exterior installations where maintenance access is difficult or costly, this reliability translates directly to reduced total cost of ownership and client satisfaction.

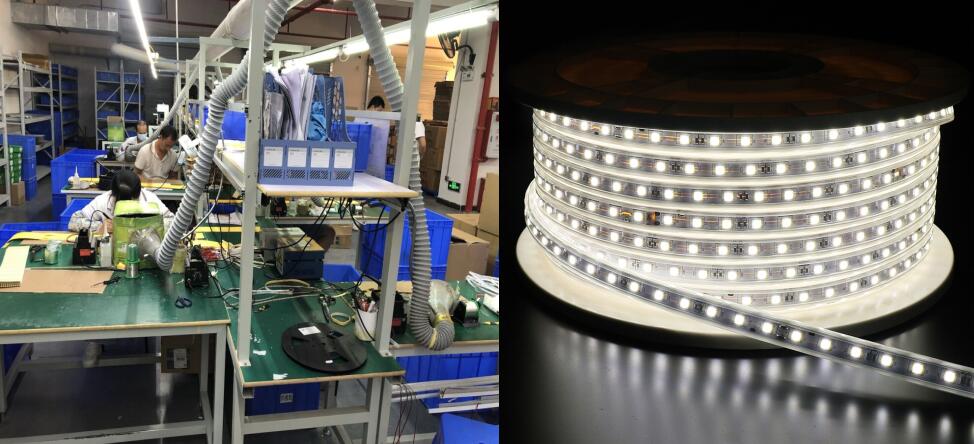

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd.’s factory in Jiangmen, Guangdong Province, is a modern, well-equipped facility specializing in the production of high-quality LED lighting products. Strategically located in the Pearl River Delta region, the Jiangmen factory benefits from excellent logistics and access to a mature supply chain, enabling efficient manufacturing and timely delivery.

The facility is outfitted with advanced Surface Mount Technology (SMT) production lines, which ensure precise and consistent assembly of LED components onto flexible and rigid circuit boards. These SMT machines are capable of handling high-speed placement with tight tolerances, supporting the production of both high-density and fine-pitch LED strips. The automated process enhances product reliability, reduces human error, and allows for scalable output to meet large-volume demands.

To ensure durability and long-term performance, especially for outdoor and exterior applications, the factory conducts comprehensive aging tests. Finished LED strip products undergo extended burn-in procedures under controlled thermal and electrical conditions, simulating real-world usage over prolonged periods. This includes thermal cycling, humidity exposure, and constant-on testing, which help identify early failures and verify product stability. For exterior-grade LED strips, additional environmental testing such as IP rating verification (e.g., IP65, IP67) is performed to confirm resistance to dust, moisture, and harsh weather conditions.

Beauty STC has strong OEM capabilities tailored specifically for LED strip lights used in exterior applications. The company supports full customization, including length, color temperature, luminosity, PCB design, silicone jacketing, and branding. Clients can collaborate with Beauty STC’s engineering team to develop bespoke solutions that meet specific project requirements, such as architectural lighting, facade illumination, or outdoor signage. The factory also offers custom packaging, private labeling, and compliance support for international standards (such as UL, CE, RoHS), making it a reliable partner for global brands seeking high-performance, durable LED strip lighting solutions for exterior use.

Application Scenarios

LED strip exterior lighting serves distinct purposes across hotels, malls, and offices, enhancing aesthetics, functionality, and brand identity while demanding careful installation for durability and performance. In hotels, exterior LED strips are primarily used for architectural accentuation and ambiance creation. Key applications include outlining building facades to highlight design features, illuminating porte-cochères and entrance canopies for a welcoming glow, defining pool edges and outdoor lounge perimeters for safety and mood, and tracing landscape elements like pathways or water features. The lighting should prioritize warm color temperatures (2700K–3000K) to evoke luxury and comfort, with high CRI (90+) to render natural skin tones and materials accurately. For malls, LED strips function heavily in branding, navigation, and dynamic visual interest. They are ideal for outlining signage and storefronts to ensure visibility after dark, wrapping structural columns or facade elements to create rhythmic visual guides, illuminating handrails on external staircases for safety, and adding subtle glow to outdoor seating zones. Malls often leverage color-changing (RGBW) capabilities for seasonal campaigns or events, requiring robust control systems and consistent color calibration across long runs. Offices employ exterior LED strips more conservatively, focusing on professionalism and safety. Typical uses include under-eave lighting to softly wash walls and reduce harsh shadows, illuminating building entrances and step edges for security, highlighting corporate logos on facades, and providing low-level pathway lighting in executive parking areas. Cooler color temperatures (3000K–4000K) are preferred to convey efficiency and modernity, with strict glare control to avoid disturbing occupants.

Installation demands rigorous adherence to environmental and structural requirements for all settings. Always select strips and accessories rated IP67 or higher, with silicone encapsulation preferred over PVC for superior UV and temperature resistance. Aluminum mounting channels are non-negotiable; they provide critical heat dissipation, physical protection, and a clean finish. Ensure channels include a diffuser to eliminate pixelation and reduce glare. Voltage drop is a critical concern—limit 12V runs to 5 meters or use 24V strips for runs up to 10 meters, calculating wattage per meter to avoid overloading power supplies. Power supplies must be housed in NEMA 3R or IP66-rated enclosures, located near the strip run’s midpoint for long installations to minimize voltage drop. All wiring must use direct-burial or outdoor-rated cable (e.g., UF-B) in conduit where exposed, with waterproof connectors (IP68-rated) for all splices and terminations. Never rely solely on adhesive backing; mechanically secure strips within channels using screws or clips every 15–20 cm, especially on vertical or overhead surfaces. Account for thermal expansion by leaving 2–3 mm gaps between channel sections and using flexible mounting brackets at expansion joints in large facades. Finally, conduct a full-power test for at least 30 minutes before final sealing to verify performance and thermal behavior, and document exact color temperatures and control protocols for future maintenance consistency. Proper execution ensures longevity, safety, and the intended visual impact across demanding commercial environments.

Why Choose Beauty STC Lighting

Transform your outdoor lighting projects with high-quality LED strip solutions designed for durability and brilliance. Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in innovative LED technology. Our exterior LED strips are engineered to withstand harsh weather conditions while delivering consistent, vibrant illumination for architectural, landscape, and commercial applications.

Elevate your next project with customized lighting options, competitive pricing, and reliable performance—all backed by years of manufacturing expertise. Contact us today to discuss your requirements and discover how we can support your business goals.

Reach out to our sales team at [email protected] and take the first step toward a brighter, more efficient future.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.