Article Contents

Industry Insight: Triac Dimmer Switch

In commercial and industrial lighting applications, precise control over illumination levels is essential for optimizing energy efficiency, enhancing occupant comfort, and extending the lifespan of lighting systems. The TRIAC dimmer switch has emerged as a reliable and cost-effective solution for phase-cut dimming, particularly with LED and fluorescent lighting technologies commonly deployed in large-scale facilities. Designed to deliver smooth, flicker-free dimming performance, TRIAC dimmers are widely used in offices, warehouses, retail spaces, and manufacturing plants where adaptable lighting environments are critical. As regulatory standards and energy codes become more stringent, compliance with safety and performance certifications such as ETL and CE has become paramount, ensuring that dimming solutions meet rigorous electrical, electromagnetic, and operational requirements for use in North American and international markets.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of innovative lighting control solutions for over two decades. Specializing in high-performance dimming technologies, Beauty STC combines advanced engineering with stringent quality control to deliver TRIAC dimmer switches that meet the demanding needs of commercial and industrial environments. With a strong commitment to compliance, every product is rigorously tested to achieve ETL and CE certifications, guaranteeing safety, reliability, and seamless integration with modern lighting systems. As the industry moves toward smarter, more energy-conscious infrastructure, Beauty STC continues to lead with durable, code-compliant dimming solutions that empower efficient and sustainable lighting design.

Technical Specs & Certifications

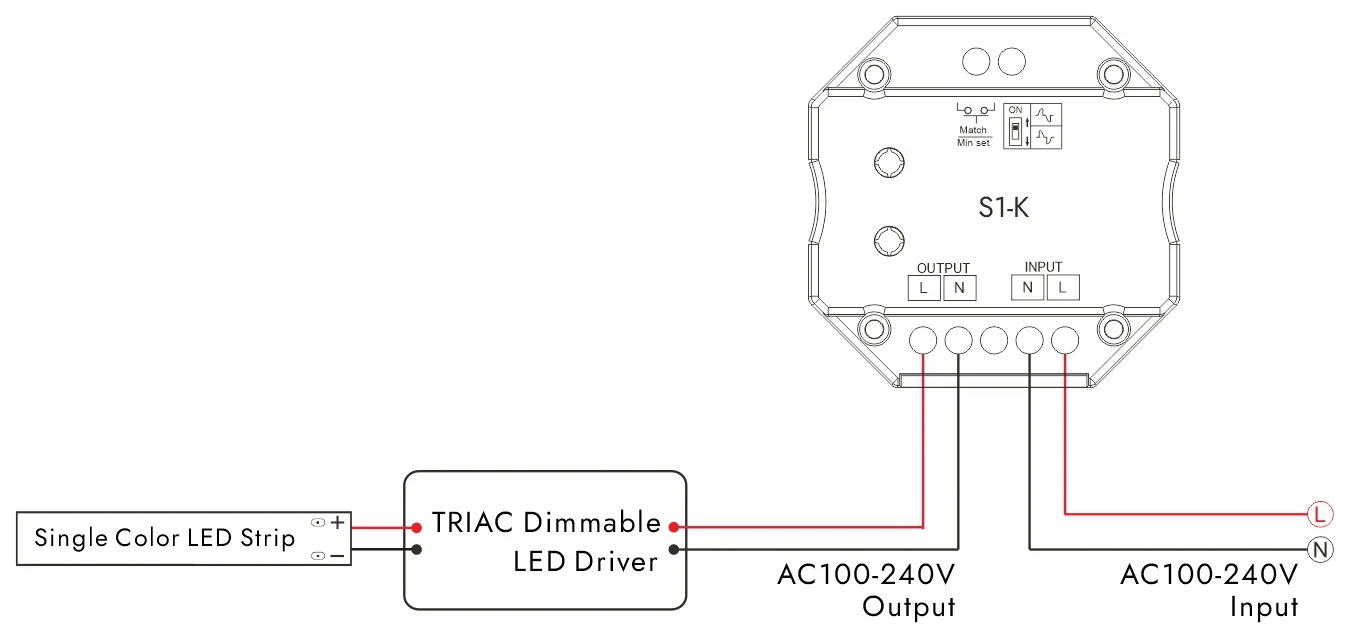

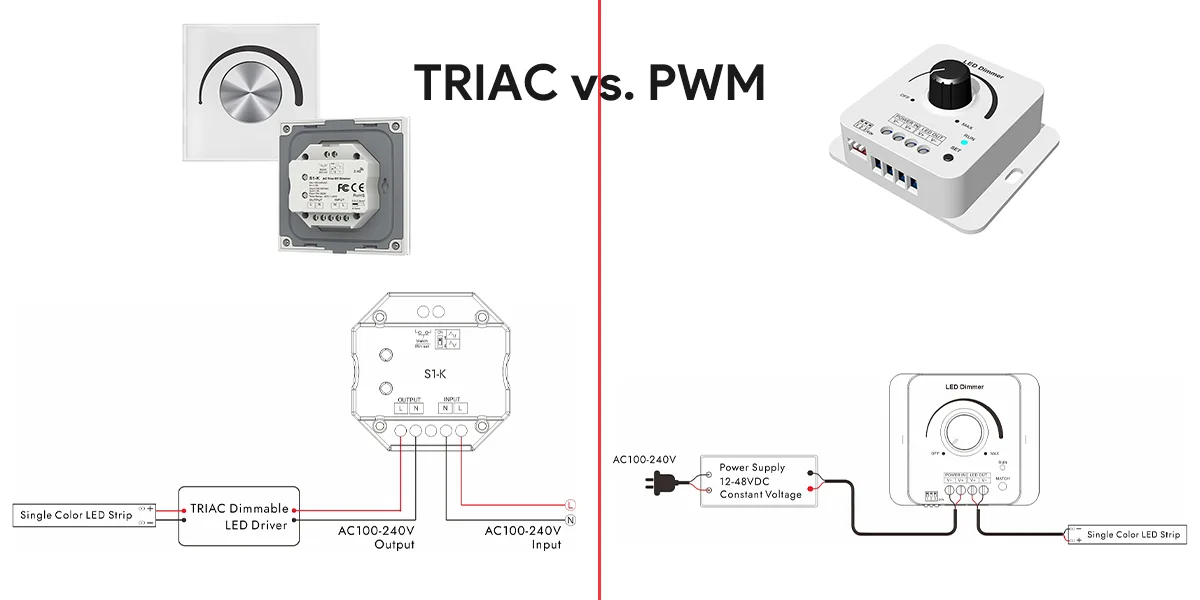

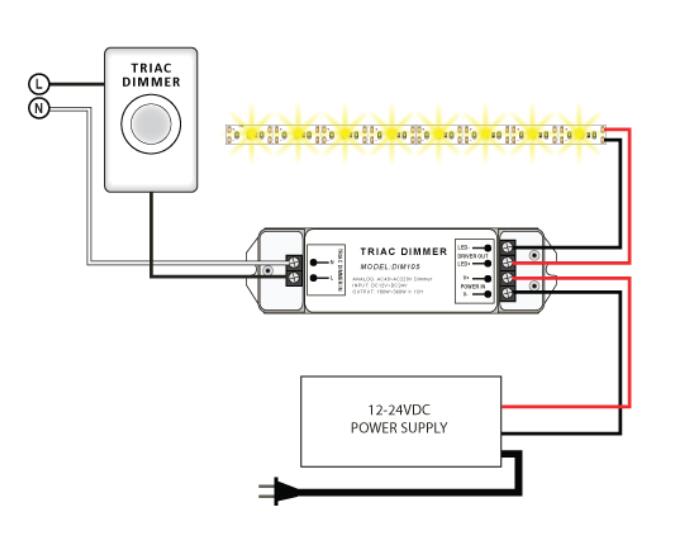

Triac dimmer switches are control devices for AC lighting circuits and do not possess inherent lumens per watt or CRI specifications. These metrics apply exclusively to the light source itself, such as LED lamps or luminaires controlled by the dimmer. A triac dimmer’s technical role is to modulate the AC waveform to reduce power delivery to the load. Key electrical specifications for triac dimmers include phase control range typically spanning 9° to 150° for leading-edge dimming, minimum load requirements usually between 5W and 40W depending on the model, and maximum load capacities commonly rated at 600W resistive or 150W inductive for standard residential units. Compatibility with LED drivers is critical, requiring the dimmer to support low-wattage electronic loads and minimize harmonic distortion to prevent flicker. Beauty STC rigorously tests its triac dimmers with a wide range of LED products to ensure stable operation down to 1% dimming levels without audible noise or visible artifacts.

Lumens per watt and CRI values are properties of the LED light source, not the dimmer switch. Beauty STC manufactures high-efficiency LED luminaires designed to work seamlessly with triac dimmers, consistently achieving 130+ lumens per watt in downlight and panel product lines. Our architectural-grade fixtures incorporate carefully selected LED arrays and drivers that maintain CRI values exceeding 90 Ra, with R9 values above 50 to ensure accurate red rendering, even at low dimming levels. This performance is validated through independent LM-79 testing reports available for each product family.

IP ratings define the ingress protection level of the dimmer switch’s physical enclosure. Beauty STC triac dimmer switches for standard indoor residential and commercial use carry an IP20 rating, protecting against finger contact and larger solid objects but not moisture. For outdoor or harsh environment applications, such as covered patios or marine settings, we offer weatherproof triac dimmer models housed in robust polycarbonate enclosures rated IP65, providing complete dust protection and resistance to low-pressure water jets from any direction. All IP-rated enclosures undergo extended environmental testing including 500-hour salt spray exposure and thermal cycling from -30°C to +70°C.

Beauty STC’s commitment to quality is evident in every triac dimmer switch. Our engineering team implements a dual-certification process where each dimmer model undergoes both UL 1472 safety certification and rigorous in-house performance validation exceeding IEC 60669-2-1 standards. Critical quality measures include 10,000+ mechanical cycle testing at full load, thermal imaging verification to ensure no hotspots exceed 60°C above ambient at maximum rating, and harmonic distortion analysis kept below 15% THD at 20% load. We utilize 5-layer PCBs with 2oz copper traces for superior heat dissipation and incorporate dual-stage EMI filtering to prevent interference with sensitive electronics. Every production batch undergoes 100% functional testing including dimming curve verification and minimum load stability checks, supported by our 5-year warranty that reflects confidence in long-term reliability. This disciplined approach ensures our dimmers deliver flicker-free performance with compatible Beauty STC LED luminaires while maintaining the high photometric standards our customers expect.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern manufacturing facility in Jiangmen, Guangdong Province, China, strategically located within the Pearl River Delta’s industrial hub. The factory is equipped with advanced production and quality control systems to support high-volume, precision manufacturing of LED lighting products and related components.

The facility features fully automated Surface Mount Technology (SMT) production lines, which include state-of-the-art pick-and-place machines, reflow ovens, and automated optical inspection (AOI) systems. These SMT lines enable precise and efficient mounting of surface-mounted components onto printed circuit boards (PCBs), ensuring consistent quality and high reliability for lighting electronics. The integration of automation reduces human error, increases throughput, and supports the production of compact, high-performance LED drivers and control modules.

To ensure long-term product reliability, the Jiangmen factory conducts comprehensive aging tests on finished products. Units are subjected to extended operation under elevated temperature and load conditions to simulate real-world usage over time. This aging process helps identify early-life failures and verifies thermal management, driver stability, and overall product durability before shipment.

Beauty STC has strong OEM/ODM capabilities and can support customized development and manufacturing, including for products such as triac dimmer switches. The company can design, prototype, and mass-produce dimmer modules compatible with standard triac-based phase-cut dimming systems, tailored to specific voltage, load, and form factor requirements. Their engineering team works closely with clients to integrate these dimmers into various LED lighting fixtures, ensuring smooth dimming performance, reliability, and compliance with international safety and EMC standards.

Overall, the Jiangmen factory combines automation, rigorous testing, and flexible engineering support to deliver high-quality, customized lighting control solutions for global markets.

Application Scenarios

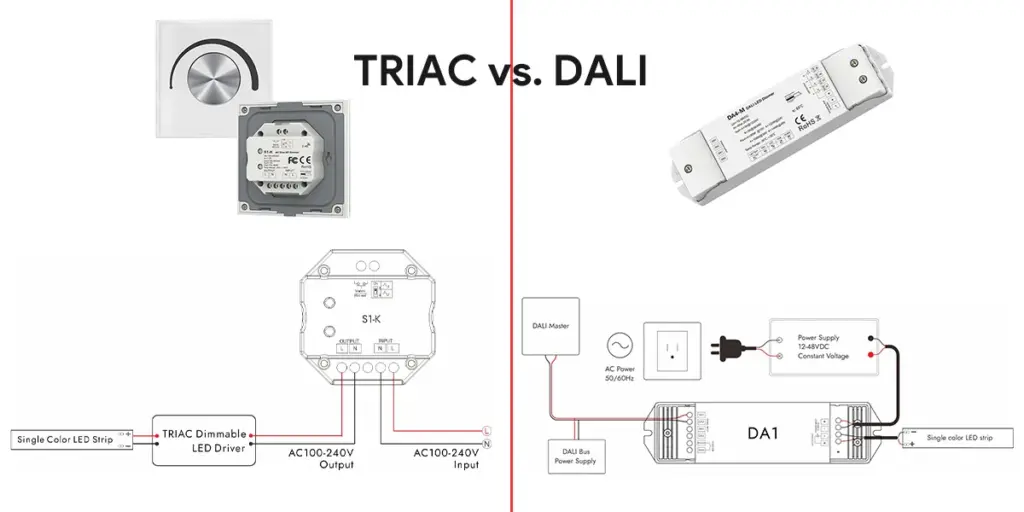

TRIAC dimmer switches are legacy phase-cut dimming devices originally designed for incandescent and halogen lamps. While they can be used in specific commercial applications with compatible LED systems, significant caution is required due to widespread compatibility issues with modern LED drivers. Their use in hotels, malls, and offices is generally limited to retrofit scenarios where existing wiring and dimmer infrastructure must be preserved, and only when paired with specifically certified TRIAC-dimmable LED products. They are rarely ideal for new commercial installations due to performance limitations and the availability of superior dimming protocols like 0-10V or DALI.

In hotels, TRIAC dimmers may be considered for guest room ambiance lighting such as bedside lamps or bathroom vanity lights where low-cost retrofit is prioritized over optimal performance. Lobbies or lounge areas with decorative incandescent/halogen legacy fixtures might also use them during phased upgrades. However, TRIAC dimmers are strongly discouraged in hotel corridors, stairwells, or emergency lighting circuits due to flicker risks and potential non-compliance with safety standards. Malls should avoid TRIAC dimmers in high-traffic common areas, food courts, or security zones; they might only be tentatively used in individual retail tenant spaces for display lighting if the tenant insists on reusing existing residential-grade dimmers, though 0-10V is vastly preferable for consistent retail lighting control. Offices present the least suitable environment; TRIAC dimmers should never be installed in open-plan workspaces, conference rooms requiring precise light tuning, or near sensitive electronics due to electromagnetic interference risks. Limited use might occur in executive suites for non-critical decorative lighting, but even there, modern protocols are recommended.

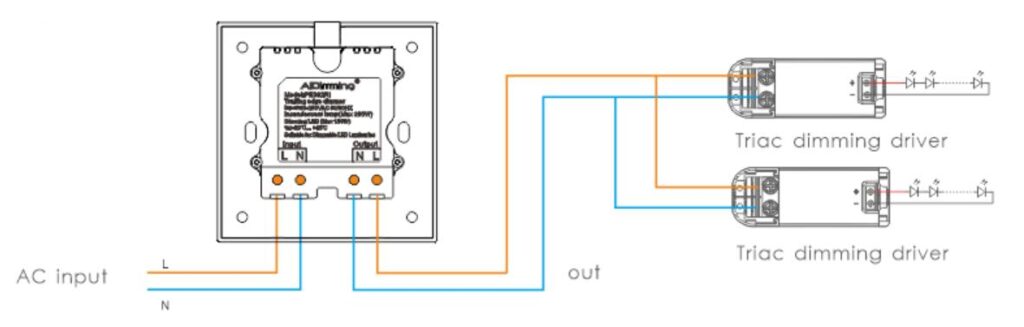

Critical installation tips must be followed rigorously to avoid field failures. Always verify LED driver compatibility by cross-referencing the dimmer manufacturer’s compatibility list with the specific LED product model—never assume generic “dimmable” labeling is sufficient. Ensure the total connected LED load meets the dimmer’s minimum wattage requirement, typically 10-25W for commercial TRIAC units; underloading causes flicker or drop-out, so calculate carefully for spaces like hotel rooms with few fixtures. A neutral wire must be present at the switch box in commercial installations, as floating neutrals cause erratic behavior. Confirm the dimmer is rated for the full circuit load including all parallel fixtures, not just a single lamp. Install a dedicated dimmer for each lighting zone to prevent overloading, and avoid mixing LED types or drivers on the same dimmer circuit. Thermal management is crucial—ensure adequate airflow around the dimmer in wall boxes, especially in enclosed commercial junction boxes, as overheating causes premature failure. Finally, always test the full system at 10%, 50%, and 100% intensity before finalizing the installation to catch compatibility issues.

For new construction or major renovations in these commercial settings, Beauty (STC) strongly advises against TRIAC dimming. We recommend specifying 0-10V or DALI systems which offer smoother dimming, broader LED compatibility, easier grouping, and integration with building management systems. TRIAC dimmers should only be considered as a last-resort retrofit solution where rewiring is prohibitively expensive, and even then, only with rigorously tested component pairings. The operational headaches and compromised light quality typically outweigh the minor upfront cost savings in professional commercial environments.

Why Choose Beauty STC Lighting

Looking for reliable and high-performance TRIAC dimmer switch solutions? Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in LED lighting technology and smart control systems. Our TRIAC dimmer switches are engineered for seamless integration, exceptional durability, and smooth dimming performance across a wide range of lighting applications.

At Beauty STC, we combine innovative design with rigorous quality control to deliver products that meet international standards. Whether you’re a distributor, contractor, or lighting brand, we offer customized solutions, OEM/ODM support, and competitive pricing to help your business stand out.

Take the next step toward excellence. Contact us today at [email protected] to discuss your project and discover how Beauty STC can power your success.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.