Article Contents

Industry Insight: Waterproofing Led

Waterproofing in LED lighting represents a critical engineering imperative within the commercial and industrial sectors, where luminaires face relentless exposure to moisture, dust, chemicals, and extreme environmental conditions. Unlike residential applications, the failure of waterproofing in facilities such as manufacturing plants, warehouses, parking structures, cold storage units, or outdoor infrastructure can lead to catastrophic consequences including electrical hazards, significant operational downtime, costly asset damage, and compromised worker safety. Robust ingress protection, defined by rigorous standards like IP65, IP66, and IP67, is not merely a feature but a fundamental requirement for reliability and longevity in these demanding settings. Crucially, adherence to safety certifications such as ETL (indicating compliance with North American safety standards) and CE (demonstrating conformity with European health, safety, and environmental protection legislation) is non-negotiable for market access and liability mitigation, ensuring products meet stringent electrical safety and performance benchmarks under wet conditions. For over two decades, Beauty STC Manufacturing Co., Ltd., established in 1998, has been a trusted partner to the commercial and industrial lighting industry, leveraging deep expertise in thermal management, optical design, and material science to engineer LED solutions where uncompromising waterproofing and certified safety are foundational to every product.

Technical Specs & Certifications

Beauty (STC) Manufacturing Co., Ltd. produces high-performance waterproof LED lighting solutions engineered for durability, efficiency, and superior light quality. Our waterproof LED products are designed for demanding environments, combining advanced optical technology with robust sealing standards to ensure reliable operation in wet, humid, or outdoor conditions.

A key performance metric for our waterproof LED fixtures is luminous efficacy, typically ranging from 120 to 150 lumens per watt (lm/W), depending on the model and application. This high efficiency is achieved through the use of premium-grade LED chips and optimized thermal management systems, which maintain performance over extended operating periods while minimizing energy consumption.

Color Rendering Index (CRI) is critical in applications where accurate color representation is essential, such as retail, hospitality, and architectural lighting. Beauty STC ensures that its high-end waterproof LED products deliver a CRI greater than 90, with options available up to CRI 95+. This enables natural, vibrant color rendition, closely mimicking daylight and enhancing visual comfort and clarity.

In terms of environmental protection, Beauty STC’s waterproof LED fixtures are rated to rigorous Ingress Protection (IP) standards. Most products carry an IP65, IP66, or IP67 rating, with select models meeting IP68 for full submersion capability. IP65-rated fixtures are dust-tight and protected against low-pressure water jets from any direction. IP66 provides enhanced protection against powerful water jets, making it suitable for outdoor installations exposed to heavy rain or washdown environments. IP67-rated lights are dust-tight and can withstand temporary immersion in water up to 1 meter for 30 minutes, while IP68-rated units are designed for continuous submersion under specified conditions.

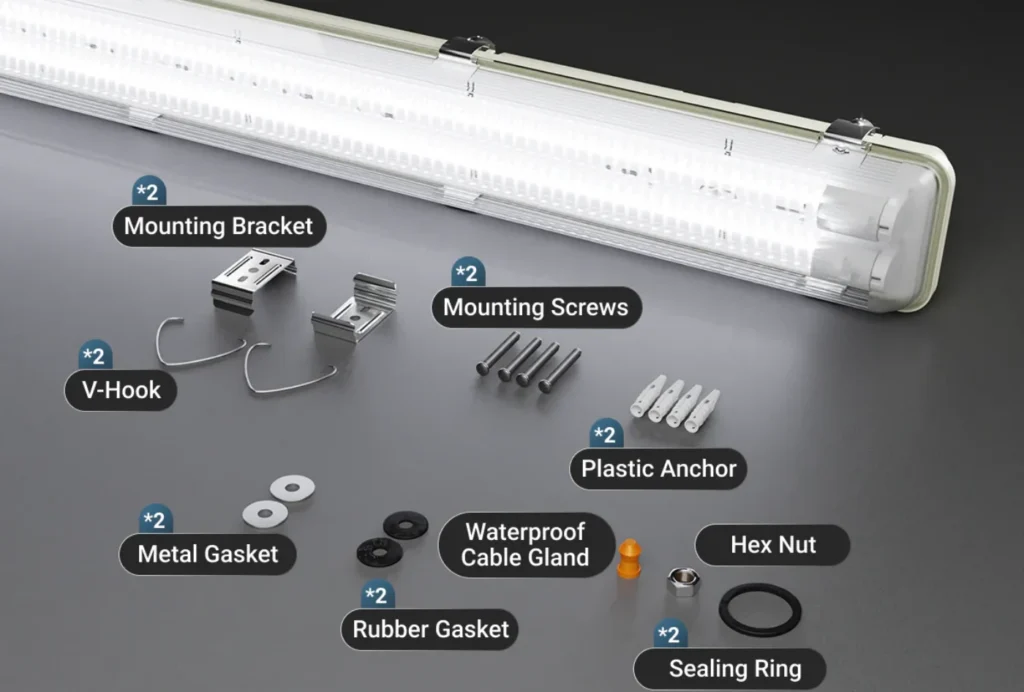

The quality of Beauty STC’s waterproof LED products is reinforced through strict manufacturing controls, extensive testing protocols, and the use of high-purity materials such as polycarbonate lenses, die-cast aluminum housings, and silicone gaskets. Each unit undergoes thermal cycling, humidity exposure, and IP verification testing to ensure long-term reliability and performance consistency across diverse operating conditions.

With a focus on innovation, durability, and optical excellence, Beauty (STC) Manufacturing Co., Ltd. delivers waterproof LED lighting solutions that meet and exceed industry standards for efficiency, color quality, and environmental resilience.

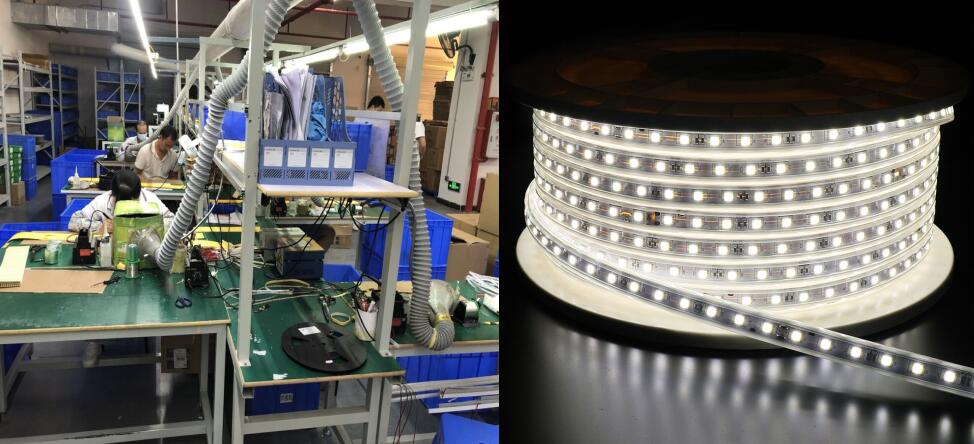

Factory Tour: Manufacturing Excellence

Beauty STC’s primary manufacturing facility is strategically located in the Jiangmen National High-Tech Industrial Development Zone within Guangdong Province. This modern campus spans over 100,000 square meters and serves as the company’s integrated hub for R&D, production, and quality control, specifically engineered to support high-volume, precision LED lighting manufacturing with a strong emphasis on reliability and waterproof performance. The factory environment adheres strictly to ISO 9001 and ISO 14001 standards, featuring climate-controlled production floors and dedicated clean rooms for critical processes to ensure consistent product quality.

Our Surface Mount Technology (SMT) production capability forms the backbone of LED assembly. The Jiangmen factory operates more than twenty fully automated SMT lines, predominantly utilizing state-of-the-art Panasonic NXT III and NXT HIII platforms. These machines deliver exceptional placement accuracy down to 25 microns, handling components from 0201 passives up to large LED modules and complex power ICs. Each line integrates advanced 3D automated optical inspection (AOI) systems immediately post-reflow, enabling real-time defect detection and process correction. The SMT section is optimized for high-mix production, supporting rapid changeovers essential for fulfilling diverse OEM/ODM orders while maintaining tight tolerances required for subsequent waterproofing stages.

Aging and reliability testing represent a critical, non-negotiable phase in our production flow, especially for waterproof LED products. We maintain a dedicated aging hall housing over 500 individual aging channels capable of simultaneously testing finished luminaires under controlled thermal and electrical stress. Standard aging protocols involve a minimum 72-hour continuous operation at 1.2 times rated voltage and elevated ambient temperatures up to 45°C, significantly exceeding typical industry practice. Crucially, for all waterproof-rated products (IP65, IP67, IP68), aging is integrated with sequential waterproof verification. Units undergo aging, then immediate IP testing in calibrated water immersion tanks or spray rigs per IEC 60529 standards, followed by functional re-checks. This integrated aging-waterproof validation loop ensures only units demonstrating sustained performance under stress receive final certification.

Beauty STC possesses extensive OEM capability specifically tailored for waterproof LED lighting solutions. Our engineering and production teams work collaboratively with clients from initial concept through to mass production. This includes custom thermal management design for sealed housings, material selection expertise for UV-resistant polycarbonates and robust silicones, and proprietary sealing techniques such as multi-stage gasket compression, laser welding for polycarbonate, and advanced conformal coating processes for internal PCB protection. We offer full customization of optical distributions, driver integration within waterproof enclosures, and tailored corrosion resistance treatments for marine or harsh industrial environments. Our OEM services encompass complete product lifecycle management, providing clients with certified waterproof solutions meeting global safety standards (UL, CE, TUV, PSE) with flexible minimum order quantities and rigorous batch traceability. The Jiangmen facility’s integrated capabilities allow us to deliver turnkey waterproof LED products that consistently exceed client durability expectations.

Application Scenarios

Waterproof LED lighting is essential in environments where exposure to moisture, humidity, or direct water contact is likely. While hotels, malls, and offices are typically indoor environments with controlled conditions, there are specific areas within these buildings where waterproof LED fixtures should be installed to ensure safety, durability, and long-term performance.

In hotels, waterproof LED lights are best suited for bathrooms, swimming pool areas, spas, saunas, outdoor terraces, and landscaping around the premises. These areas are prone to high humidity or direct water exposure. For guest bathrooms, use IP65-rated LED downlights or vanity lights to protect against steam and splashes. Around swimming pools and outdoor areas, fixtures should have a minimum IP67 or IP68 rating to withstand submersion or heavy rain.

In malls, waterproof LEDs are necessary for restrooms, food courts with frequent cleaning, indoor water features, basement parking lots, and any outdoor walkways or signage exposed to weather. Even if the area is indoors, high-traffic cleaning with water or exposure to rain from open atriums requires protection. Use sealed LED strips or troffer lights with appropriate IP ratings in ceiling coves near fountains or in parking areas where condensation and dampness are common.

In offices, the need for waterproof LEDs is more limited but still relevant in restrooms, pantry or kitchen areas, server rooms (where condensation might occur due to cooling systems), and outdoor entrances or covered walkways. Standard office workspaces do not require waterproofing, but localized wet zones do.

When installing waterproof LED lighting, always verify the IP (Ingress Protection) rating. For damp locations, IP65 is typically sufficient, while wet or submerged environments require IP67 or IP68. Ensure that all connections, junction boxes, and driver housings are also rated for moisture resistance. Avoid cutting waterproof LED strips unless they are specifically designed for resealing, as this can compromise protection.

Proper mounting is crucial. Use corrosion-resistant screws and clips, especially in outdoor or coastal installations. For recessed waterproof downlights, ensure the housing is sealed and compatible with insulated ceilings to prevent condensation buildup. Always follow local electrical codes and consider using low-voltage (12V or 24V) LED systems in high-moisture areas for added safety.

Finally, regular inspection and maintenance will extend the life of waterproof LED installations. Check for seal degradation, discoloration, or moisture ingress, particularly in high-humidity zones. Proper selection and installation ensure reliable, efficient, and safe lighting performance in any wet or damp location across hotels, malls, and offices.

Why Choose Beauty STC Lighting

For critical applications demanding reliable waterproof LED solutions, partner with Beauty STC where engineering excellence meets manufacturing precision. Our dedicated team of lighting specialists designs and builds waterproof LED systems that exceed standard IP ratings through advanced thermal management, robust material selection, and rigorous environmental testing protocols. We understand that true waterproofing goes beyond basic sealing to address long-term performance challenges like condensation, thermal cycling stress, and UV degradation in demanding installations.

When you collaborate with Beauty STC, you gain access to custom-engineered waterproof lighting solutions backed by our in-house R&D capabilities and stringent quality control processes. We work closely with your engineering team to ensure seamless integration of waterproofing features without compromising optical efficiency or thermal performance. This proactive approach prevents field failures and reduces lifecycle costs for outdoor architectural, marine, industrial, and infrastructure projects.

Elevate your next project with waterproof LED technology engineered for real-world reliability. Contact our technical management team directly at [email protected] to discuss your specific waterproofing requirements and discover how Beauty STC delivers performance you can trust in the most challenging environments.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.