Article Contents

Industry Insight: Electrical Wire For Led Lights

In the rapidly evolving landscape of commercial and industrial lighting, the demand for reliable, efficient, and code-compliant electrical components has never been greater. As LED technology continues to dominate the market due to its energy efficiency and long service life, the importance of high-quality electrical wire for LED lights has become a critical factor in ensuring system performance, safety, and longevity. In commercial and industrial applications—ranging from warehouses and manufacturing facilities to office complexes and retail spaces—the electrical wiring must not only support low-voltage LED systems but also meet stringent safety and regulatory standards.

Certifications such as ETL and CE have become essential benchmarks, verifying that wiring components comply with North American and international safety requirements, respectively. These certifications provide assurance to engineers, contractors, and facility managers that the products they install are rigorously tested for electrical integrity, heat resistance, and overall reliability under demanding operational conditions.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has emerged as a trusted leader in the development and production of premium electrical components for the LED lighting industry. With over two decades of engineering expertise, Beauty STC specializes in crafting high-performance electrical wire solutions tailored specifically for commercial and industrial LED lighting systems. Backed by a commitment to quality, innovation, and global compliance, Beauty STC delivers products that meet ETL and CE standards, supporting safe, scalable, and sustainable lighting infrastructure worldwide.

Technical Specs & Certifications

Electrical wiring for LED lighting systems serves as the critical power delivery infrastructure but does not directly determine lumens per watt, CRI, or IP ratings. These metrics pertain to the LED light source and luminaire design, not the wire itself. Beauty STC Manufacturing Co., Ltd. emphasizes this distinction while ensuring our wiring solutions support optimal fixture performance through rigorous electrical and safety standards.

Lumens per watt represents the efficacy of the LED chip and driver combination, measuring light output relative to power consumption. High-quality wiring from Beauty STC minimizes voltage drop through appropriate conductor sizing—typically 18 AWG to 14 AWG stranded copper with 99.99% oxygen-free purity—to maintain stable voltage at the LED module. This stability prevents lumen depreciation and ensures the fixture achieves its rated efficacy. Undersized or poor-conductivity wiring directly undermines lumens per watt by causing energy loss as heat in the circuit.

CRI (Color Rendering Index) exceeding 90 is a characteristic of the LED phosphor formulation and optical design, not the electrical wire. However, Beauty STC wiring contributes indirectly by enabling consistent current delivery. Our wires feature cross-linked polyethylene (XLPE) or thermoplastic elastomer (TPE) insulation rated for 105°C, which resists thermal degradation and prevents voltage fluctuations that could distort color consistency. We strictly avoid PVC alternatives that off-gas corrosive compounds over time, which might degrade sensitive LED components and indirectly affect CRI maintenance.

IP ratings relate to the luminaire’s ingress protection against dust and moisture, determined by housing seals, gaskets, and wire entry points—not the wire alone. Beauty STC addresses this through integrated system design. Our wiring solutions include UL 1581-certified cables with dual-layer insulation and optional silicone-jacketed variants for harsh environments. When paired with our IP65-rated cord grips or IP67-rated cable glands, these wires maintain the fixture’s overall ingress protection. For outdoor or wet-location applications, we specify wires with UV-resistant jackets and reinforced shielding to prevent moisture tracking along conductors, which could compromise the luminaire’s IP integrity.

Beauty STC’s quality commitment is evident in our wire specifications. All conductors exceed ASTM B3/B8 standards for copper purity and strand count, ensuring flexibility and current-carrying capacity. Insulation undergoes 100% spark testing and meets UL 758, CSA 22.2, and EN 50525 certifications. We prioritize halogen-free, flame-retardant materials compliant with IEC 60754-2 to eliminate toxic fumes during fire events. Every batch undergoes third-party validation for dielectric strength (2000V AC minimum), tensile strength, and cold-bend performance down to -40°C. This meticulous approach guarantees wiring that sustains peak LED performance—supporting high lumens per watt, stable CRI >90 operation, and reliable IP-rated protection throughout the product lifecycle.

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for lighting and electronics production. The Jiangmen factory is equipped with advanced automation and quality control systems to support high-volume, precision manufacturing of LED lighting components and related electrical accessories.

The facility features state-of-the-art SMT (Surface Mount Technology) production lines, which are essential for assembling compact and high-performance LED lighting products. These SMT machines are capable of placing small electronic components with high accuracy and speed, ensuring consistent product quality and reliability. The SMT lines are integrated with automated optical inspection (AOI) systems to detect placement errors and soldering defects in real time, minimizing defects and enhancing production efficiency.

To ensure product durability and performance, the factory conducts comprehensive aging tests on finished LED light components. These tests simulate extended operational periods under controlled thermal and electrical conditions, allowing engineers to identify early failure risks and verify long-term reliability. The aging process typically runs for 4 to 24 hours depending on product specifications and customer requirements, and includes monitoring for lumen output stability, color consistency, and driver performance.

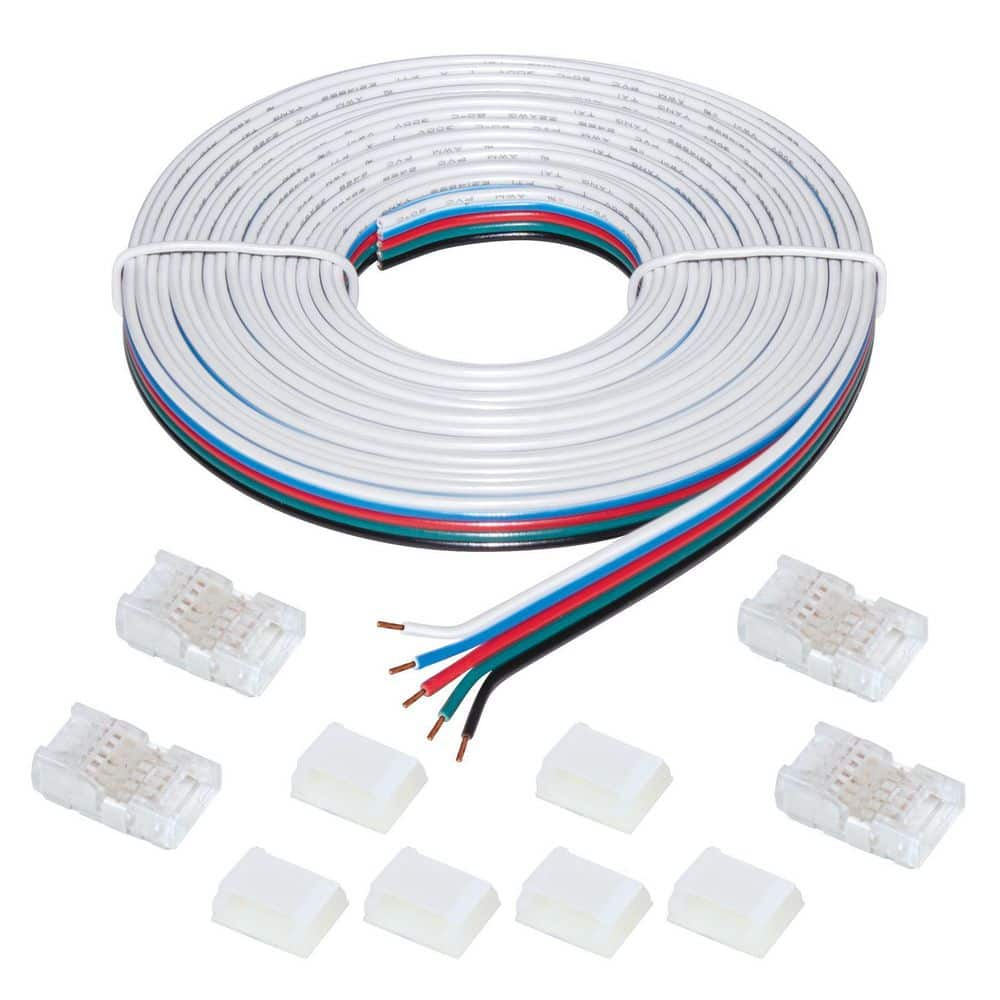

In addition to LED lighting products, Beauty STC has OEM (Original Equipment Manufacturer) capabilities for manufacturing electrical wires used in LED lighting systems. The factory can customize wire gauge, insulation material, length, connectors, and jacketing to meet specific client designs and international safety standards such as UL, CCC, and CE. This OEM service includes full design support, prototyping, material sourcing, and compliance testing, enabling clients to bring fully branded, application-specific wiring solutions to market efficiently.

Overall, the Jiangmen factory combines advanced automation, rigorous quality assurance, and flexible manufacturing capabilities to serve a global customer base with reliable, high-quality LED lighting components and accessories.

Application Scenarios

Electrical wiring for LED lighting installations in commercial environments such as hotels, malls, and offices serves as the foundational infrastructure connecting LED drivers, fixtures, and control systems to the main power supply. This wiring must comply with local electrical codes like the NEC in the United States or IEC standards internationally, and it is critical to distinguish that standard building wiring—such as NM-B (Romex) in residential zones or THHN/THWN conductors in EMT conduit for commercial spaces—is used rather than specialized “LED wires.” LED systems operate on low voltage DC, but the primary wiring from the electrical panel to the LED driver input remains standard AC building wiring. The driver then converts this to the appropriate DC voltage for the LEDs. Using incorrect wiring types or gauges can lead to voltage drop, overheating, or system failure, especially in large-scale commercial deployments where circuits span significant distances.

In hotels, electrical wiring for LED lighting is extensively used in guest room corridors, lobbies, ballrooms, restaurants, and exterior landscaping. Guest rooms require wiring for integrated ceiling coves, bedside task lighting, and bathroom vanity strips, where low-voltage wiring from the driver to the fixture must be separated from line-voltage circuits to prevent interference. Lobbies and ballrooms often employ dimmable LED systems, necessitating wiring compatible with 0-10V, DALI, or phase-cut dimming protocols, with careful attention to avoiding shared neutrals that cause flicker. Bathrooms and pool areas demand wet-location-rated wiring and GFCI protection per NEC Article 410. For hospitality ambiance, wiring must support smooth dimming curves, so dedicated circuits for lighting separate from HVAC or elevators in malls prevent voltage fluctuations that disrupt LED performance. High-bay fixtures in atriums or food courts require robust conduit runs to handle long cable distances, while emergency lighting circuits must integrate with backup generators using fire-rated wiring per NFPA 70 and 101. Retail zones need flexible wiring for track lighting reconfiguration, with junction boxes placed for easy future modifications.

Offices utilize this wiring for open-plan task lighting, private offices, conference rooms, and server rooms. Underfloor raceways or ceiling grids often house the wiring to allow reconfiguration as layouts change, with emphasis on minimizing voltage drop for consistent light output across large floors. Conference rooms require wiring for tunable-white LED systems supporting circadian lighting, demanding precise circuit separation to avoid noise from nearby data cables. Critical areas like server rooms need lighting on dedicated circuits with harmonic filtering since LED drivers can introduce distortion affecting sensitive IT equipment. Wiring must also integrate with occupancy sensors and daylight harvesting systems, where control wires (e.g., 18-22 AWG for 0-10V) are run in separate conduits from power lines to prevent signal interference. In all commercial settings, installation begins with meticulous circuit planning: calculate total load including driver inefficiencies, use 12 AWG for runs over 50 feet to mitigate voltage drop, and ensure all connections are torque-spec compliant to prevent arcing. Always terminate wires with wire nuts or Wagos rated for the conductor type, never twist-and-tape, and maintain strict separation between line-voltage, low-voltage control, and data wiring—minimum 6 inches or using shielded conduit where parallel runs are unavoidable. Finally, document all circuits and test each run with a multimeter for continuity and ground integrity before energizing, as commercial inspections frequently fail due to undocumented neutrals or improper grounding. These steps ensure reliability, safety, and optimal performance in high-traffic commercial LED lighting systems.

Why Choose Beauty STC Lighting

Looking for reliable electrical wire for LED lights? Partner with Beauty (STC) Manufacturing Co., Ltd., a trusted leader in high-quality LED lighting solutions. Our precision-engineered electrical wiring ensures optimal performance, durability, and safety for all your LED lighting applications. As a global supplier, we provide customized solutions tailored to your project needs.

To learn more or request a quote, contact us today at [email protected]. Let Beauty STC be your preferred partner in lighting excellence.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.