Article Contents

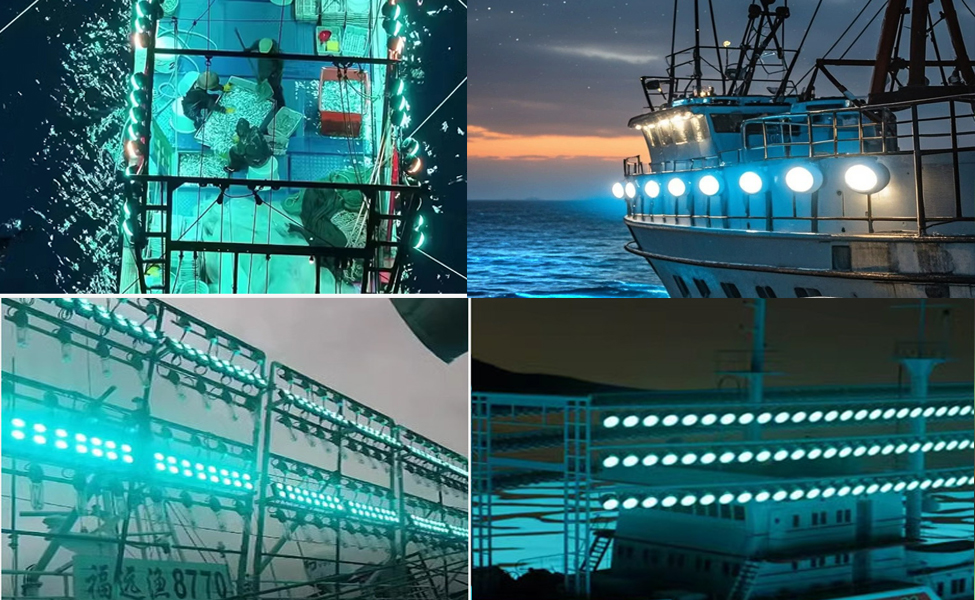

Industry Insight: Led Lights On A Boat

The marine environment presents one of the most demanding operational theaters for commercial and industrial lighting systems, where reliability, safety, and regulatory compliance are non-negotiable imperatives. As vessels transition from outdated halogen and fluorescent technologies to high-performance LED solutions, the focus intensifies on fixtures engineered specifically for the harsh realities of saltwater exposure, constant vibration, and critical safety requirements inherent in workboats, ferries, cargo ships, offshore platforms, and industrial maritime facilities. This shift is not merely about energy savings or longevity; it is fundamentally driven by the stringent need for lighting that consistently meets international safety certifications, with ETL and CE marks serving as essential gatekeepers for vessel approval and operator safety. These certifications validate that marine LED lighting adheres to rigorous electrical safety, electromagnetic compatibility, and environmental resilience standards, ensuring fixtures perform flawlessly under extreme conditions without compromising crew safety or vessel operations. For over 25 years, Beauty STC Manufacturing Co., Ltd. (Est. 1998) has been at the forefront of addressing these exact challenges, leveraging deep expertise in marine-grade LED engineering to deliver certified, robust, and high-efficiency lighting solutions trusted across the global commercial and industrial maritime sector. Our commitment lies in transforming demanding marine environments through lighting that prioritizes unwavering performance and regulatory assurance.

Technical Specs & Certifications

When specifying LED lights for marine environments such as boats, performance, durability, and visual quality are critical. At Beauty (STC) Manufacturing Co., Ltd., our LED lighting solutions are engineered to meet the rigorous demands of marine applications, combining high efficiency, excellent color rendering, and robust environmental protection.

One of the primary performance metrics for marine LED lighting is lumens per watt (lm/W), which indicates energy efficiency. Our high-performance marine-grade LED fixtures achieve an efficacy range of 110 to 130 lumens per watt. This ensures bright, effective illumination while minimizing power consumption—essential for vessels operating on limited battery or generator power. These efficiency levels are maintained across a wide voltage range (typically 10–30V DC), accommodating fluctuations common in marine electrical systems.

Color Rendering Index (CRI) is another vital specification, especially in areas where accurate color perception enhances safety and comfort, such as galleys, cabins, and helm stations. Beauty STC’s premium marine LED lights offer a CRI greater than 90, with select models exceeding 95. This high CRI ensures that interior colors appear natural and vibrant, reducing eye strain during extended periods at sea and improving visibility for critical tasks.

For protection against the harsh marine environment, our LED fixtures are designed with high Ingress Protection (IP) ratings. Most products meet or exceed IP65, with wet-location rated models achieving IP67 and IP68. IP65 provides complete dust protection and resistance to low-pressure water jets from any direction—ideal for deck and cockpit lighting. IP67-rated fixtures are dust-tight and can withstand temporary immersion in water up to 1 meter for 30 minutes, while IP68 indicates continuous submersion protection under specified conditions. These ratings ensure reliability in saltwater spray, heavy rain, and high-humidity conditions.

Beauty STC is committed to quality and long-term performance. Our marine LED lights are constructed with corrosion-resistant materials such as die-cast aluminum housings with marine-grade powder coating and tempered glass lenses. All components are rigorously tested for thermal management, vibration resistance, and longevity, with typical rated lifespans exceeding 50,000 hours. Each product undergoes stringent quality control processes in compliance with international standards, reflecting our reputation for delivering reliable, high-performance lighting solutions trusted by boat builders and marine professionals worldwide.

Factory Tour: Manufacturing Excellence

Beauty STC’s manufacturing facility in Jiangmen, Guangdong Province, serves as a core production hub for our LED lighting solutions, strategically positioned within one of China’s key industrial regions to leverage skilled labor and robust supply chain networks. The factory spans a significant footprint, incorporating modern, climate-controlled production halls dedicated to various stages of LED manufacturing, with a strong emphasis on precision engineering and quality control throughout the process. Central to our operations is a state-of-the-art Surface Mount Technology (SMT) production line. This line utilizes high-speed, high-precision machines from leading manufacturers such as Siemens and Yamaha. These systems handle complex PCB assemblies with placement accuracy down to 0.025mm, accommodating components ranging from ultra-miniature 0201 LEDs to larger power devices. The line features multiple placement heads operating concurrently, achieving throughputs exceeding 50,000 components per hour, and integrates fully automated optical inspection (AOI) stations immediately after solder paste application and component placement. The reflow soldering process employs advanced nitrogen-controlled ovens with precise thermal profiling capabilities, ensuring reliable, void-minimized solder joints essential for the long-term thermal management and performance of LED products, particularly critical for demanding applications. All SMT processes adhere strictly to lead-free RoHS and REACH compliance standards.

Rigorous reliability testing is fundamental to our quality assurance, especially for products destined for harsh environments. Aging tests are conducted comprehensively across all production batches. Finished LED lighting units undergo mandatory 72-hour continuous burn-in tests at elevated temperatures, typically 65°C, simulating years of operational stress in a compressed timeframe. During this period, units are monitored for lumen maintenance, chromaticity stability, and any early failures. For marine-specific products like LED lights designed for boats, this aging process is significantly intensified. Units are subjected to extended burn-in cycles under conditions replicating marine environments, including exposure to high humidity, salt mist via dedicated salt spray chambers simulating IP68 conditions, and vibration profiles that mimic the constant motion and shock experienced on watercraft. This multi-faceted aging and environmental stress screening ensures only units demonstrating exceptional resilience and consistent optical performance proceed to final packaging and shipment.

Beauty STC possesses substantial OEM and ODM capabilities specifically tailored for the marine lighting sector, making us a preferred partner for clients requiring “LED lights on a boat.” We offer comprehensive turnkey solutions, starting from initial concept development and optical engineering through to full-scale manufacturing and global certification support. Our engineering team has deep expertise in designing LED fixtures that meet stringent marine safety and performance standards, including UL 1156 for marine lighting, DNV-GL, RINA, and IP68/IP69K ratings for complete submersion and washdown resistance. We utilize marine-grade materials such as 316 stainless steel housings, corrosion-resistant marine aluminum alloys, and specialized UV-stable polycarbonate lenses. Our capabilities include custom optical design for precise beam control required in navigation lights, deck lighting, and underwater illumination, along with robust thermal management solutions critical for enclosed marine fixtures. We manage the entire supply chain for marine components, including sourcing specialized connectors, cabling rated for saltwater exposure, and drivers with wide input voltage ranges to handle unstable boat electrical systems. Clients benefit from our ability to handle low to high-volume production runs, provide extensive custom labeling and packaging, and deliver products fully certified for global marine markets, all backed by the rigorous quality systems implemented within our Jiangmen factory.

Application Scenarios

LED lights on a boat are not typically used in hotels, malls, or offices—those are land-based commercial environments. Instead, LED lights are specifically installed on boats for functional, safety, and aesthetic purposes in marine environments. Boats include recreational vessels, yachts, fishing boats, sailboats, and commercial watercraft.

Here are the most common and appropriate applications for LED lights on a boat:

Deck and cockpit lighting provides safe movement around the boat at night. LED strip lights or recessed deck lights are ideal for illuminating walkways without creating glare.

Navigation lights are essential for safety and legal compliance. These include red and green sidelights, a white stern light, and an all-around anchor light. LED navigation lights are preferred due to their low power consumption, long lifespan, and high visibility.

Cabin lighting enhances interior comfort. LED downlights, reading lights, and ambient strips can be used in cabins, galleys, and heads to provide efficient, cool-running illumination.

Underwater and hull lighting adds visual appeal and can improve visibility around the boat at night. Through-hull LED fixtures are used for underwater lighting, often in blue or white, to create a striking nighttime effect.

Bilge lighting helps inspect and maintain the bilge area. A simple, waterproof LED light installed in the bilge allows for easy detection of leaks or debris without draining the area.

Entertainment and accent lighting such as LED strips under gunwales, in handrails, or on steps can enhance the boat’s ambiance during evening gatherings.

When installing LED lights on a boat, consider the following tips:

Use marine-grade LED lights designed to resist moisture, salt, and vibration. Standard household LEDs are not suitable for marine use.

Ensure all wiring is tinned copper to prevent corrosion and use proper marine connectors sealed with heat-shrink tubing or waterproof tape.

Follow the American Boat and Yacht Council (ABYC) standards or local marine electrical codes for safe installation practices.

Mount lights in locations that avoid glare on the windshield or reflective surfaces, especially in the helm area.

Use a dedicated circuit with an appropriately sized fuse or circuit breaker for each lighting zone to prevent overloading and allow easy troubleshooting.

Secure all fixtures tightly to withstand constant movement and vibration. Use silicone sealant around mounting points to prevent water intrusion.

Consider using dimmable LED systems for interior lights to adjust brightness based on activity and time of day.

Always disconnect the battery before starting any electrical work to ensure safety during installation.

Properly installed LED lighting enhances safety, extends battery life, reduces maintenance, and improves the overall boating experience.

Why Choose Beauty STC Lighting

When outfitting vessels with reliable and high-performance lighting solutions, marine-grade LED technology is non-negotiable for safety, efficiency, and longevity. At Beauty STC Manufacturing Co., Ltd., we engineer LED lighting systems specifically designed to withstand the harsh marine environment, including saltwater exposure, constant vibration, and extreme weather conditions. Our products meet rigorous international certifications for marine applications, ensuring compliance and operational integrity while significantly reducing energy consumption and maintenance costs compared to traditional lighting.

We understand that every vessel has unique lighting requirements, whether for navigation, deck illumination, cabin ambiance, or specialized commercial operations. Partnering with Beauty STC means gaining access to our decade-long expertise in marine LED innovation, customizable solutions, and dedicated engineering support tailored to your specific project needs. Our team collaborates closely with boat builders, retrofit specialists, and fleet operators to deliver lighting that enhances both functionality and aesthetics without compromising on durability.

For professional-grade marine LED lighting that performs reliably voyage after voyage, contact our technical management team directly. Reach out to discuss your project specifications, request custom engineering support, or explore bulk partnership opportunities. Email [email protected] to initiate a conversation about how Beauty STC can illuminate your marine lighting challenges with precision and expertise.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.