Article Contents

Industry Insight: Led Mini Strip Lights

The commercial and industrial lighting landscape is undergoing a transformative shift as businesses increasingly adopt energy-efficient, flexible, and durable lighting solutions to meet evolving operational demands. Among the most impactful innovations in this space are LED mini strip lights—compact, high-performance lighting systems that deliver superior illumination in constrained or specialized environments. These versatile fixtures are now widely deployed in applications ranging from under-cabinet lighting in retail spaces and task lighting in manufacturing facilities to architectural accenting in corporate buildings and safety lighting in industrial settings. Their low profile, high lumen output, and long service life make them ideal for environments where space, efficiency, and reliability are paramount.

A critical factor in the adoption of LED mini strip lights in commercial and industrial projects is compliance with rigorous safety and performance standards. Products bearing ETL and CE certifications assure facility managers, engineers, and contractors that the lighting solutions meet North American and European regulatory requirements, ensuring electrical safety, electromagnetic compatibility, and consistent performance under demanding conditions.

Beauty (STC) Manufacturing Co., Ltd., established in 1998, has been at the forefront of this evolution in professional lighting. With over two decades of expertise in LED technology and lighting system design, Beauty STC has built a reputation for delivering high-quality, code-compliant lighting solutions tailored to the needs of commercial and industrial clients worldwide. The company’s LED mini strip lights combine cutting-edge engineering with robust construction, offering scalable, maintenance-friendly illumination that supports both operational efficiency and aesthetic integrity across a broad range of professional environments.

Technical Specs & Certifications

LED mini strip lights from Beauty STC Manufacturing Co., Ltd. are engineered for high performance in demanding architectural, retail, and residential applications where precise color rendering and environmental resilience are critical. Our standard technical specifications for premium CRI>90 mini strips are as follows. System efficacy typically ranges from 100 to 130 lumens per watt depending on configuration, with our high-efficiency 24VDC offerings consistently achieving 120+ lm/W under standard test conditions (25°C ambient, 350mA drive current). This efficiency is maintained through optimized driver integration and advanced thermal management in the flexible PCB design, minimizing lumen depreciation over time. Crucially, Beauty STC guarantees a minimum CRI (Ra) of 92 across all production batches for these strips, with R9 (saturated red) values exceeding 50 and TM-30 Rf values above 90, ensuring exceptional color fidelity for skin tones, fabrics, and merchandise. This is achieved through rigorous LED binning processes and proprietary phosphor formulations, not merely meeting but exceeding the CRI>90 requirement with consistent batch-to-batch reliability.

Regarding ingress protection, Beauty STC offers mini strip lights in multiple certified IP ratings to suit diverse installation environments. Our standard non-encapsulated strips carry an IP20 rating for dry indoor use. For damp locations or surface mounting in kitchens and bathrooms, we provide IP65-rated strips featuring a continuous silicone encapsulation that protects against low-pressure water jets and dust ingress. For fully recessed cove lighting or outdoor applications requiring submersion resistance, our IP67-rated mini strips utilize a dual-layer silicone overmolding process, validated to withstand temporary immersion up to 1 meter for 30 minutes. All encapsulated strips undergo 100% automated IP testing post-production, with accelerated aging tests simulating 50,000 hours of environmental exposure to ensure long-term seal integrity without yellowing or delamination.

Beauty STC’s quality commitment is evident in our manufacturing precision and stringent quality control. We utilize only Samsung LM301B or Nichia 219C mid-power LEDs on rigorously controlled 2-ounce copper PCBs for superior thermal dissipation, directly contributing to sustained lumen maintenance of L90/B10 at 50,000 hours. Every meter of strip undergoes 100% automated optical testing for chromaticity consistency (within a 3-step MacAdam ellipse) and flux verification, with CRI validation through第三方 certified spectroradiometer reports per ANSI C78.377. Our encapsulation processes occur in ISO Class 8 cleanrooms, eliminating particle contamination that could compromise IP performance. Additionally, Beauty STC implements a proprietary burn-in protocol where all strips operate at 120% rated current for 48 hours before shipment, ensuring early failure detection and field reliability far exceeding industry averages. This integrated approach to material selection, process control, and validation testing establishes Beauty STC mini strip lights as a benchmark for quality in the high-CRI, high-efficacy segment of the LED lighting market.

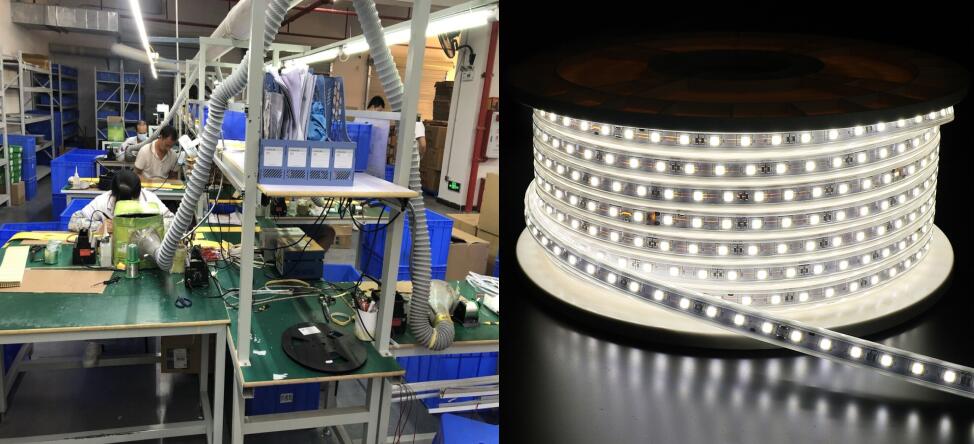

Factory Tour: Manufacturing Excellence

Beauty (STC) Manufacturing Co., Ltd. operates a modern and well-equipped manufacturing facility in Jiangmen, Guangdong Province, strategically located within one of China’s key industrial hubs for electronics and lighting production. The Jiangmen factory is designed to support high-volume manufacturing with a strong emphasis on quality control, efficiency, and flexibility to meet diverse customer demands, particularly in the LED lighting sector.

The facility is equipped with advanced SMT (Surface Mount Technology) production lines, featuring high-precision automated SMT machines from leading global manufacturers. These machines ensure accurate placement of small LED components and driver circuitry onto flexible and rigid PCBs used in LED mini strip lights. The SMT process is supported by automated optical inspection (AOI) systems that verify soldering quality and component alignment in real time, minimizing defects and ensuring consistent product performance.

To guarantee long-term reliability, Beauty STC implements rigorous aging and environmental testing procedures. Finished LED mini strip lights undergo extended aging tests—typically 24 to 72 hours—under elevated temperatures and full operational load. This process helps identify early failure points and ensures that only stable, durable products are shipped to customers. Additional testing includes waterproof verification (for applicable models), voltage tolerance checks, and light output consistency measurements.

The factory has robust OEM and ODM capabilities tailored specifically for LED mini strip lights. Beauty STC can customize product specifications such as length, color temperature (ranging from warm white to daylight), CRI (Color Rendering Index), IP rating, adhesive type, and connector configuration. Clients can also request private labeling, custom packaging, and integration of low-voltage DC or battery-powered drivers. With in-house engineering and design support, the company assists customers from prototyping through to mass production, ensuring fast turnaround times and strict adherence to international quality standards such as CE, RoHS, and UL.

Overall, the Jiangmen factory combines automated manufacturing, stringent quality assurance, and flexible customization to serve global lighting brands, distributors, and project partners with reliable, high-performance LED mini strip light solutions.

Application Scenarios

LED mini strip lights, characterized by their narrow profile typically around 10mm wide and flexible circuit boards, offer versatile solutions for enhancing ambiance, functionality, and aesthetics in commercial environments. Their compact size makes them ideal for applications where space is constrained or a discreet lighting effect is desired, while their energy efficiency and long lifespan suit the demanding operational hours of hotels, malls, and offices.

In hotel settings, LED mini strip lights excel in creating intimate and luxurious atmospheres. Install them under bed frames for a subtle floating effect that guides guests at night without harsh glare. They are perfect for illuminating vanity mirrors in bathrooms, providing even, shadow-free lighting for grooming. Within wardrobe closets, mini strips offer convenient task lighting when opening doors. Additionally, they enhance architectural details such as cove lighting in hallways, under stair treads for safety and drama, and along the edges of reception desks to highlight branding or create a welcoming glow. Their low heat output ensures safety in close proximity to fabrics and furniture.

For retail malls and shopping centers, these mini strips serve both functional and decorative purposes. Integrate them into product display shelving to spotlight merchandise, particularly in cosmetics, jewelry, or electronics sections where precise, cool illumination is critical. Use them within signage boxes for even backlighting of logos and information panels without visible hotspots. Mini strips effectively outline architectural features like column wraps or ceiling perimeters to define spaces and guide shopper flow. They also work well under handrails on escalators and staircases, improving safety with minimal visual intrusion, and can be embedded into display counters to create a premium, illuminated base for featured items.

Within office environments, LED mini strip lights improve both productivity and well-being. Install them under desks and workstations to reduce eye strain by softly illuminating the floor area, minimizing harsh contrasts between bright screens and dark surroundings. They provide excellent task lighting inside filing cabinets and storage units, activated by motion sensors or door switches. Use mini strips to illuminate the undersides of high partition walls in open-plan offices, creating defined zones without visual barriers. They are also effective for backlighting reception area logos, highlighting conference room nameplates discreetly, and adding subtle accent lighting along the edges of raised flooring access points for safety during maintenance.

Installation requires careful planning to ensure optimal performance and longevity. Always mount mini strips onto an aluminum channel or heatsink, especially for continuous runs exceeding 2 meters or in enclosed fixtures, as this is critical for thermal management and maintaining lumen output over time. Verify the power supply capacity matches the total wattage of the strip run plus a 20% safety margin to prevent voltage drop, which causes dimming at the far end of long installations. For runs longer than 5 meters, feed power from both ends or use amplified sections. Ensure all connections are secure and insulated using proper waterproof connectors if installed in potentially damp areas like near mall food courts or hotel pool decks. Adhere strictly to local electrical codes, utilizing only UL8750 or equivalent certified components for commercial use. Finally, clean the mounting surface thoroughly with isopropyl alcohol before applying the strip’s adhesive backing to guarantee a strong, lasting bond, particularly on vertical or overhead surfaces common in these applications.

Why Choose Beauty STC Lighting

Transform your lighting projects with high-quality LED mini strip lights from Beauty STC. As a trusted manufacturer, we deliver durable, energy-efficient, and versatile lighting solutions tailored to your needs. Partner with us to access competitive pricing, reliable supply, and expert support. Ready to elevate your product line or project? Contact our sales manager today at [email protected] and let’s build a brighter future together.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.