Article Contents

Industry Insight: Led Strip Lighting Plug In

The commercial and industrial lighting sector is undergoing a significant transformation, driven by the relentless pursuit of energy efficiency, operational flexibility, and reduced maintenance burdens. Within this dynamic environment, plug-in LED strip lighting solutions are rapidly emerging as a critical innovation, moving far beyond simple decorative applications. These systems offer facility managers, architects, and electrical contractors a compelling alternative to traditional hardwired linear lighting, addressing key pain points such as complex installation timelines, the need for specialized electrician labor for every modification, and the inflexibility of fixed layouts in evolving commercial and industrial spaces. Crucially, for any solution deployed in these high-stakes environments, robust safety and performance certifications are non-negotiable. Compliance with stringent standards like ETL for the North American market and CE marking for Europe is not merely a regulatory checkbox; it is a fundamental requirement ensuring electrical safety, reliable operation under demanding conditions, and peace of mind for specifiers and end-users alike. These certifications validate that the product meets rigorous international safety and electromagnetic compatibility benchmarks, a critical consideration when integrating lighting into complex building systems or hazardous industrial settings.

Beauty STC Manufacturing Co., Ltd., established in 1998, brings over 25 years of deep expertise in advanced LED lighting engineering and manufacturing to this evolving market. As a trusted partner for commercial and industrial lighting solutions globally, we understand the unique demands of professional environments. Our commitment goes beyond providing components; we deliver engineered systems where performance, reliability, and certified safety are intrinsically designed into every plug-in LED strip solution we create, enabling smarter, more adaptable, and code-compliant lighting infrastructures.

Technical Specs & Certifications

LED strip lighting plug-in solutions offered by Beauty (STC) Manufacturing Co., Ltd. are engineered for high performance, reliability, and consistent light quality, making them ideal for both residential and commercial applications. Our plug-in LED strip lighting systems are designed with precision to deliver optimal efficiency, color accuracy, and environmental protection.

In terms of efficiency, Beauty STC’s LED strip lighting achieves a luminous efficacy of 110 to 130 lumens per watt, depending on the specific model and color temperature. This high lumens-per-watt ratio ensures energy savings without compromising brightness, supporting sustainable lighting solutions across various installations. The strips utilize high-efficiency SMD 2835 or 5050 LED chips, which contribute to consistent light output and long-term performance.

Color Rendering Index (CRI) is a critical factor in lighting quality, particularly in environments where accurate color representation is essential, such as retail, art galleries, and kitchens. Beauty STC’s premium plug-in LED strips deliver a CRI greater than 90, with select high-CRI models reaching up to 95. This ensures that colors appear vibrant, natural, and true to life under the illuminated environment.

Regarding environmental protection, our LED strip lighting systems are available in multiple IP (Ingress Protection) ratings to suit different installation conditions. Common options include IP20 for indoor dry locations, IP65 for damp or outdoor environments offering protection against water jets and dust, and IP67 for full dust tightness and temporary water submersion. These ratings reflect Beauty STC’s commitment to durability and safety in diverse applications.

Beauty STC maintains rigorous quality control throughout the manufacturing process, using high-grade PCB materials, stable constant-current drivers, and robust silicone encapsulation where applicable. All products undergo extensive testing for thermal management, electrical safety, and long-term lumen maintenance. With an average lifespan of 30,000 to 50,000 hours, our plug-in LED strip lighting systems combine superior optical performance with exceptional reliability, reinforcing Beauty STC’s reputation as a trusted leader in innovative LED lighting solutions.

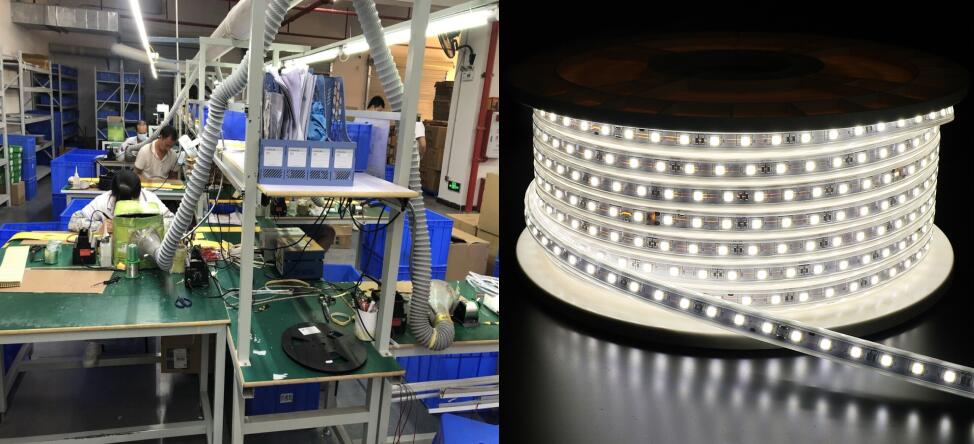

Factory Tour: Manufacturing Excellence

Beauty STC’s primary manufacturing facility is strategically located in the Jiangmen National High-Tech Industrial Development Zone within Guangdong Province, China. This modern factory spans over 30,000 square meters and is purpose-built for the efficient and high-quality production of LED lighting products, with a significant focus on flexible and rigid LED strip lighting solutions. The facility is designed to stringent international manufacturing standards, featuring controlled environmental zones, advanced cleanroom areas for critical processes, and comprehensive material handling systems to ensure product integrity throughout the production lifecycle.

The surface mount technology (SMT) production lines form the core of our manufacturing capability for LED strips. We operate multiple fully automated SMT lines equipped with state-of-the-art placement machines from leading manufacturers such as Yamaha and Fuji. These lines are configured for high-speed, high-precision assembly capable of handling components down to 0201 package size, essential for the dense LED arrays and miniature drivers used in modern plug-in strip systems. Each line integrates sophisticated solder paste inspection (SPI) systems to verify paste deposition accuracy and automated optical inspection (AOI) stations immediately after reflow soldering to detect any placement or soldering defects. The SMT process is meticulously controlled for humidity and temperature, utilizing nitrogen-assisted reflow ovens to minimize oxidation and ensure superior solder joint reliability, which is critical for the thermal management demands of high-power LED strips. Our SMT capacity supports both high-volume reel-to-reel production and flexible panelized runs for prototyping and lower-volume custom orders.

Rigorous aging and reliability testing are fundamental to our quality assurance protocol, particularly for plug-in LED strip lighting products where long-term performance and safety are paramount. We maintain a dedicated aging test laboratory housing numerous large-scale environmental chambers capable of simulating extended operational life under controlled stress conditions. Every production batch of LED strips undergoes mandatory aging tests, typically running for a minimum of 48 to 72 hours at elevated temperatures (often 60-70°C) and full operational load. During this burn-in period, strips are continuously monitored for functional failures, significant lumen depreciation, color shift (using integrated spectroradiometers), and thermal performance. We also conduct accelerated life testing (ALT) on sample batches according to IES LM-80 and TM-21 standards to project long-term lumen maintenance and predict product lifespan. This comprehensive aging regimen ensures that only strips meeting our strict performance and reliability criteria are released for shipment, minimizing field failures and supporting our product warranties.

Beauty STC possesses extensive OEM capability specifically tailored for plug-in LED strip lighting systems. We offer a complete turnkey solution where clients can leverage our engineering expertise and manufacturing infrastructure to bring their custom plug-in strip concepts to market. This encompasses full design support for custom PCB layouts optimized for specific connectors (such as GX53, GX50, G13, or proprietary plugs), driver integration, and thermal management. We source and qualify all critical components including LEDs, drivers, connectors, and flexible PCBs according to client specifications or our recommended high-reliability alternatives. Our production processes are fully adaptable to accommodate various plug types, voltage requirements (AC or DC), color temperatures, CCT tuning, dimming protocols, and IP ratings. We manage all aspects from prototyping and testing through to full-scale production, final assembly, and custom packaging, including labeling with the client’s brand. Our quality management system, certified to ISO 9001, ensures consistent adherence to client technical specifications and international safety standards like UL, CE, and RoHS throughout the OEM production process.

Application Scenarios

LED strip lighting plug-in systems are versatile and energy-efficient lighting solutions suitable for a wide range of commercial environments including hotels, malls, and offices. Their plug-and-play design makes them easy to install and ideal for both ambient and accent lighting applications.

In hotels, plug-in LED strip lighting is commonly used in guest rooms to highlight headboards, under cabinets, or along cove ceilings to create a welcoming and modern ambiance. They are also effective in lobbies, corridors, and lounge areas where soft, indirect lighting enhances the guest experience. Back-of-house areas such as staff rooms or storage areas can benefit from their low heat output and long lifespan, reducing maintenance needs.

In malls and retail environments, these LED strips are frequently installed in display windows, signage backlighting, shelving, and coves to draw attention to products and create dynamic visual displays. The flexibility of plug-in LED strips allows retailers to easily reconfigure lighting layouts during seasonal changes or promotional events without rewiring.

Offices utilize plug-in LED strips for under-cabinet lighting in workstations, along stair edges for safety, in meeting rooms for accent lighting, and in reception areas to project a professional and contemporary image. Task lighting under desks or shelves can also improve employee comfort and productivity without adding glare.

When installing plug-in LED strip lighting, start by measuring the area to determine the required length and ensure compatibility with the power supply. Always cut the strip only at designated cut points to avoid damaging the circuitry. Use aluminum channels for better heat dissipation and a cleaner, more professional finish—this also helps extend the lifespan of the LEDs. Secure the strips using the adhesive backing after thoroughly cleaning the surface with alcohol to ensure strong adhesion. Avoid sharp bends and do not exceed the maximum run length specified by the manufacturer to prevent voltage drop and inconsistent brightness.

Ensure the plug-in system is connected to a grounded outlet and avoid daisy-chaining multiple strips beyond the recommended load. For outdoor or high-moisture areas, use only IP65-rated or higher waterproof strips with appropriate connectors. Finally, test the lighting before finalizing the installation and consider using dimmable drivers and compatible wall controls to enhance user experience and energy efficiency.

Why Choose Beauty STC Lighting

Transform your lighting projects with Beauty STC’s premium plug-in LED strip solutions designed for seamless integration and superior performance. Our engineered systems eliminate complex installations, offering ready-to-use flexibility for residential, commercial, and creative applications without the need for hardwiring. Partner with Beauty STC to access rigorously tested, energy-efficient lighting that combines aesthetic precision with industrial-grade reliability.

Contact our dedicated partnership team today at [email protected] to discuss customized plug-in LED strip solutions, volume pricing, and technical support tailored to your specific requirements. Let Beauty STC’s engineering expertise elevate your next project with lighting that performs as brilliantly as your vision demands.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.