Article Contents

Industry Insight: Low Voltage Led Strip Lights

The commercial and industrial lighting landscape is undergoing a profound transformation, driven by the relentless pursuit of energy efficiency, design flexibility, and operational reliability. Within this evolution, low voltage LED strip lighting has emerged not merely as a trend, but as a fundamental solution addressing critical demands across diverse professional environments. From illuminating high-end retail display coves and hospitality ambiance zones to providing task lighting in demanding factory settings and architectural feature highlighting in corporate lobbies, the need for precisely controllable, durable, and safe linear lighting is paramount. Crucially, in these professional applications where safety and performance are non-negotiable, adherence to stringent safety standards like ETL and CE is not optional; it is the absolute baseline for market acceptance and liability protection, ensuring products withstand rigorous operational conditions and electrical environments. Beauty STC, established in 1998, has been at the forefront of this LED revolution for over 25 years. We leverage deep engineering expertise and a commitment to rigorous quality control to deliver low voltage LED strip solutions specifically engineered for the harsh realities and exacting performance requirements of commercial and industrial projects, where reliability and certified safety are inseparable from successful implementation. Our focus remains on providing lighting professionals with the trusted, high-performance tools needed to build enduring installations.

Technical Specs & Certifications

Low voltage LED strip lights are a popular choice for both residential and commercial lighting due to their energy efficiency, flexibility in design, and ease of installation. Operating typically at 12V or 24V DC, these strips offer safe, dimmable, and reliable illumination. When evaluating high-performance low voltage LED strips, key technical specifications include lumens per watt (lm/W), Color Rendering Index (CRI), and Ingress Protection (IP) ratings—each playing a critical role in performance and suitability for various environments.

In terms of efficiency, high-quality low voltage LED strip lights achieve luminous efficacies ranging from 90 to 130 lumens per watt, depending on the LED chip type (such as 2835, 3528, or 5050) and binning quality. Strips using advanced SMD (Surface Mount Device) technology and optimized drivers can exceed 120 lm/W, delivering bright illumination while minimizing power consumption. This efficiency translates into lower energy costs and reduced heat output, contributing to longer service life.

Color fidelity is essential in applications where accurate color representation is critical—such as retail displays, art galleries, kitchens, and makeup areas. LED strips with a CRI greater than 90 ensure that colors appear natural and vibrant under the light. Beauty STC’s premium LED strips utilize high-CRI phosphor coatings and rigorously selected LED bins to consistently deliver CRI values of 90 to 95, meeting the demands of color-sensitive environments. These high-CRI strips often use Samsung, Epistar, or San’an Optronics chips, known for their color consistency and longevity.

Protection against environmental factors is addressed through IP (Ingress Protection) ratings. IP ratings define the level of protection against dust and moisture. For indoor dry locations, IP20 strips are sufficient. For bathrooms, kitchens, or outdoor-covered areas, IP65-rated strips—protected against low-pressure water jets and dust ingress—are recommended. Fully waterproof options such as IP67 (protected against temporary immersion) or IP68 (protected against continuous submersion) are ideal for outdoor landscaping, pool perimeters, or marine applications. Beauty STC manufactures LED strips with consistent silicone encapsulation and precision coating techniques, ensuring reliable performance across IP65 to IP68 ratings without compromising flexibility or light output.

Beauty STC is recognized for its commitment to quality and durability in LED lighting solutions. Their low voltage LED strips undergo stringent testing for thermal management, color consistency, and long-term lumen maintenance. With an average lifespan of 30,000 to 50,000 hours, Beauty STC strips maintain over 70% of initial lumens (L70) at end-of-life, thanks to high-quality drivers, copper PCBs for efficient heat dissipation, and rigorous quality control during manufacturing. The company adheres to international standards including CE, RoHS, and UL certifications, ensuring safe and reliable performance across global markets.

In summary, high-performance low voltage LED strip lights from Beauty STC deliver exceptional lumens per watt, CRI values exceeding 90, and robust IP protection up to IP68. These technical attributes, combined with stringent quality assurance, make Beauty STC a trusted choice for architects, designers, and contractors seeking reliable, efficient, and visually accurate lighting solutions.

Factory Tour: Manufacturing Excellence

Beauty STC’s primary manufacturing facility is located in Jiangmen City, Guangdong Province, China. This strategic location within the Pearl River Delta provides strong logistical advantages and access to a mature electronics supply chain. The Jiangmen factory serves as our core production hub for LED lighting products, with a significant focus on precision manufacturing for the global market, particularly for low-voltage LED strip lights.

The factory utilizes state-of-the-art SMT (Surface Mount Technology) production lines as the foundation for assembling high-quality LED strips. We operate multiple high-speed Yamaha YS series SMT machines capable of handling ultra-fine pitch components down to 0201 size with placement accuracy of ±0.025mm. These lines are configured for efficient production of flexible and rigid PCBs used in low-voltage strips, featuring automatic optical inspection (AOI) systems after placement to ensure component accuracy and solder joint integrity before proceeding to reflow soldering. The SMT capacity supports both high-volume production runs and flexible changeovers for custom OEM orders.

Rigorous aging and reliability testing are integral to our quality control process at the Jiangmen facility. All low-voltage LED strip light products undergo mandatory 72-hour continuous aging tests at full operational load under controlled thermal conditions. This extended burn-in process occurs in specialized environmental chambers that simulate real-world stress, including thermal cycling between +85°C and -40°C. Post-aging, strips undergo comprehensive electrical and photometric validation to verify consistent output, color stability, and absence of infant mortality failures before final packaging. This stringent protocol ensures the long-term reliability our OEM partners and end-users expect.

Beauty STC possesses extensive OEM capability specifically tailored for low-voltage LED strip lights, including both 12V and 24V DC products. Our Jiangmen factory supports full customization from initial design through to finished goods. We offer PCB layout modification, LED density and type selection (including high-CRI and RGB variants), bespoke coating formulations for IP ratings, custom cutting lengths, reel packaging configurations, and tailored labeling. Our engineering team collaborates closely with clients to adapt existing platforms or develop new strip solutions meeting specific performance, regulatory (including UL, CE, RoHS), and aesthetic requirements. With dedicated production cells and flexible scheduling, we efficiently handle OEM volumes ranging from medium batches to large-scale production, maintaining consistent quality through our ISO 9001 certified processes and delivering typical lead times of 25-30 days from order confirmation.

Application Scenarios

Low voltage LED strip lights are an excellent lighting solution for hotels, malls, and offices due to their energy efficiency, flexibility, and aesthetic appeal. These lights typically operate at 12V or 24V DC, making them safe and suitable for a wide range of indoor applications where safety and design are priorities.

In hotels, low voltage LED strip lights are ideal for accent lighting in guest rooms, behind headboards, under cabinets in minibars, and along cove ceilings in lobbies or corridors. They create a warm and inviting ambiance, enhancing the guest experience. In bathrooms, they can be installed under vanities or around mirrors to provide soft, glare-free illumination. Their low heat output ensures safety in confined or frequently used spaces.

Malls benefit from low voltage LED strips in display areas, signage backlighting, and architectural coves. They are commonly used to highlight retail displays, draw attention to promotions, and accentuate brand logos. The flexibility of the strips allows them to be bent around curved surfaces, making them perfect for dynamic and creative lighting designs in high-traffic commercial environments.

In office settings, these strips can be used under desks, within partition coves, or in suspended ceiling perimeters to provide indirect lighting that reduces eye strain and creates a modern workspace atmosphere. They are also effective for task lighting in meeting rooms or reception areas, where a professional yet welcoming environment is essential.

When installing low voltage LED strip lights, start by selecting the appropriate IP rating based on the environment. For dry indoor areas like offices and hotel rooms, IP20 or IP65 strips are sufficient. In areas exposed to moisture such as mall restrooms or office kitchens, opt for IP67-rated strips for added protection.

Always use a compatible low voltage LED driver or power supply matched to the strip’s voltage and total wattage. Calculate the total load carefully and avoid overloading the driver. For long runs, consider feeding power from both ends or using a power injection method to prevent voltage drop, which can cause dimming at the far end of the strip.

Ensure the surface is clean, dry, and smooth before applying the strip. Most low voltage strips come with an adhesive backing, but for more permanent installations, use additional mounting clips or aluminum channels to improve heat dissipation and longevity. Aluminum profiles also protect the strip and provide a more polished look.

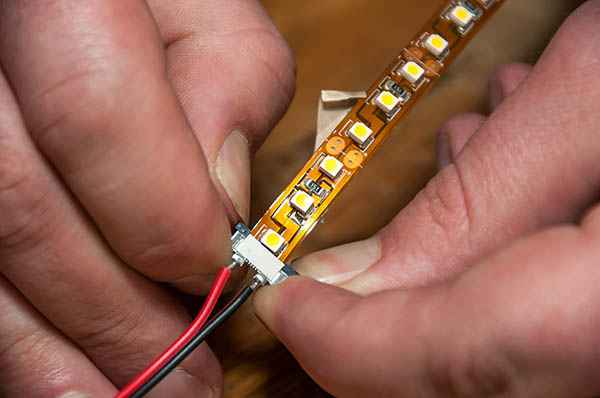

Use proper connectors if cutting or joining strips, and ensure all electrical connections are secure and insulated. For dimming functionality, pair the strips with a compatible low voltage dimmer and ensure the driver supports dimming.

Lastly, plan the layout in advance, considering the placement of the driver and control units. Keep drivers accessible for maintenance and ensure they are installed in well-ventilated areas to prevent overheating.

Why Choose Beauty STC Lighting

Elevate your lighting projects with Beauty STC’s precision-engineered low voltage LED strip lights designed for superior performance and seamless integration. Our strips deliver exceptional brightness uniformity color accuracy and energy efficiency while meeting stringent safety standards for versatile indoor and outdoor applications. As your manufacturing partner we provide fully customizable solutions including tailored lengths beam angles and IP ratings backed by rigorous quality control and dedicated engineering support. Partner with Beauty STC to access reliable high-volume production competitive pricing and technical expertise that ensures your projects exceed expectations. Contact our sales management team directly at [email protected] to discuss your specifications and receive a prompt quotation. Let us help you illuminate success through innovation and partnership.

⚡ LED Power Supply Calculator

Estimate the power supply needed for your LED strip project.